Professional Documents

Culture Documents

Heat Exchanger Design

Uploaded by

overlord5555Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Exchanger Design

Uploaded by

overlord5555Copyright:

Available Formats

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 1

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:27

Description

Heading

IZMJENJIVA TOPLINE DIMNI PLINOVI IZGARANJA - VODA

Remarks

Application Options

Calculation mode

Location of hot fluid

Select geometry based on this dimensional standard

Calculation Method

Rating / Checking

Tube side

SI

Advanced method

Application

Condenser type

Simulation calculation

Gas, no phase change

Set default

Set default

Application

Vaporizer type

Simulation calculation

Thermosiphon circuit calculation

Liquid, no phase change

Set default

Set default

Set default

Process Data

Hot Side

DIMNI PLINOVI

Fluid name

In

Mass flow rate (total)

Temperature

Vapor mass fraction

Operating pressure (absolute)

Pressure at liquid surface in column

Heat exchanged

kg/s

C

bar

bar

Fouling resistance

In

0,8203

950

1

0,993

Out

2,8133

115

1

0,793

15

0

2,5

90

0

2,2

kW

Heat Load Balance Options

Estimated pressure drop

Allowable pressure drop

Out

Cold Side

VODA

Heat load

bar

bar

m K/W

Heat load

0,2

0,2

0,3

0,5

0,0002

0,0004

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 2

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:29

Hot Side Databank

Physical property package

Hot side composition specification

COMThermo

Mole flowrate or %

Pressures

bar

0,993

0,793

Aspen property method

Aspen free-water method

Aspen water solubility

Aspen flash option

Aspen Plus or Aspen Properties run file

BL1(273)

BL1(313)

BL1(314)

Vapor-Liquid-Liquid

Hot Side - Component

ComThermo Components

Composition Component type

CO2

49,43

Program

SO2

0,07

Program

NO2

0,05

Program

Oxygen

13,52

Program

Water

36,93

Program

Hot Side - Stream Properties

Temperature

Specific

enthalpy

Vapor mass

fraction

C

950

kJ/kg

-7441,3

910

-7500,7

870

-7559,7

831

-7616,7

791

-7674,8

751

-7732,2

711

-7789,2

672

-7844,2

632

-7900

592

-7955,2

552

-8009,7

513

-8062,2

473

-8115,3

433

-8167,7

393

-8219,4

354

-8269

314

-8319

274

-8368,2

234

-8416,5

195

-8462,8

155

-8509,5

115

-8555,2

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 3

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Hot Side - Stream Properties

Temperature

Specific

enthalpy

Vapor mass

fraction

kJ/kg

950

-7441,3

910

-7500,7

870

-7559,7

831

-7616,7

791

-7674,7

751

-7732,2

711

-7789,2

672

-7844,2

632

-7900

592

-7955,1

552

-8009,6

513

-8062,1

473

-8115,3

433

-8167,7

393

-8219,3

354

-8268,9

314

-8318,9

274

-8368,1

234

-8416,4

195

-8462,7

155

-8509,3

115

-8555

Hot Side - Liquid Properties

TemperatureLiquid specific

Liquid thermal Liquid

heat

cond.

viscosity

C

950

910

870

831

791

751

711

672

632

592

552

513

473

433

393

354

314

274

234

195

155

115

kJ/(kg K)

W/(m K)

mPa s

Liquid

density

Liquid surface

tension

kg/m

N/m

Time: 12:44:29

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 4

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Hot Side - Liquid Properties

TemperatureLiquid specific

Liquid thermal Liquid

heat

cond.

viscosity

C

kJ/(kg K)

W/(m K)

mPa s

Liquid

density

Liquid surface

tension

kg/m

N/m

Vapor density

Vapor

weight

950

910

870

831

791

751

711

672

632

592

552

513

473

433

393

354

314

274

234

195

155

115

Hot Side - Vapor Properties

TemperatureVapor specificVapor thermal

Vapor

heat

cond.

viscosity

C

950

kJ/(kg K)

1,492

W/(m K)

0,0859

mPa s

0,0458

kg/m

0,32

32,8

910

1,48

0,0842

0,0448

0,33

32,8

870

1,469

0,0823

0,0437

0,34

32,8

831

1,457

0,0803

0,0426

0,35

32,8

791

1,444

0,0781

0,0415

0,37

32,8

751

1,431

0,0757

0,0404

0,38

32,8

711

1,417

0,0731

0,0393

0,4

32,8

672

1,403

0,0705

0,0382

0,41

32,8

632

1,387

0,0677

0,037

0,43

32,8

592

1,371

0,0648

0,0358

0,45

32,8

552

1,355

0,0617

0,0346

0,47

32,8

513

1,338

0,0587

0,0333

0,5

32,8

473

1,319

0,0555

0,0318

0,53

32,8

433

1,301

0,0523

0,03

0,55

32,8

393

1,281

0,0489

0,0282

0,59

32,8

354

1,261

0,0457

0,0264

0,63

32,8

314

1,241

0,0423

0,0246

0,67

32,8

274

1,219

0,0389

0,0227

0,72

32,8

234

1,198

0,0356

0,0208

0,77

32,8

195

1,177

0,0323

0,019

0,84

32,8

155

1,155

0,029

0,0172

0,92

32,8

115

1,133

0,0257

0,0153

1,01

32,8

Time: 12:44:30

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 5

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Hot Side - Vapor Properties

TemperatureVapor specificVapor thermal

Vapor

heat

cond.

viscosity

Vapor density

Vapor

weight

kJ/(kg K)

W/(m K)

mPa s

950

1,492

0,0859

0,0458

kg/m

0,26

32,8

910

1,48

0,0842

0,0448

0,26

32,8

870

1,468

0,0823

0,0437

0,27

32,8

831

1,457

0,0803

0,0426

0,28

32,8

791

1,444

0,0781

0,0415

0,29

32,8

751

1,431

0,0757

0,0404

0,31

32,8

711

1,417

0,0731

0,0393

0,32

32,8

672

1,403

0,0705

0,0382

0,33

32,8

632

1,387

0,0677

0,037

0,35

32,8

592

1,371

0,0648

0,0358

0,36

32,8

552

1,355

0,0617

0,0346

0,38

32,8

513

1,337

0,0587

0,0333

0,4

32,8

473

1,319

0,0555

0,0318

0,42

32,8

433

1,3

0,0522

0,03

0,44

32,8

393

1,281

0,0489

0,0282

0,47

32,8

354

1,261

0,0457

0,0264

0,5

32,8

314

1,24

0,0423

0,0246

0,53

32,8

274

1,219

0,0389

0,0227

0,57

32,8

234

1,197

0,0356

0,0208

0,62

32,8

195

1,176

0,0323

0,019

0,67

32,8

155

1,154

0,029

0,0172

0,73

32,8

115

1,132

0,0257

0,0153

0,81

32,8

Hot Side - 2-Phase liquid

Temperature

Liquid 2

heat

Liquid 2

cond.

Liquid 2

viscosity

Liquid

density

Liquid 2

tension

C

950

kJ/(kg K)

W/(m K)

mPa s

kg/m

N/m

910

870

831

791

751

711

672

632

592

552

513

473

433

393

354

314

274

234

195

155

115

Time: 12:44:31

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 6

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Hot Side - 2-Phase liquid

Temperature

Liquid 2

heat

Liquid 2

cond.

Liquid 2

viscosity

Liquid

density

Liquid 2

tension

kJ/(kg K)

W/(m K)

mPa s

kg/m

N/m

950

910

870

831

791

751

711

672

632

592

552

513

473

433

393

354

314

274

234

195

155

115

Time: 12:44:32

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 7

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:32

Cold Side Databank

Physical property package

Cold side composition specification

COMThermo

Mole flowrate or %

Pressures

bar

2,5

2,2

Aspen property method

Aspen free-water method

Aspen water solubility

Aspen flash option

Aspen Plus or Aspen Properties run file

BL1(316)

BL1(317)

BL1(318)

Vapor-Liquid-Liquid

Cold Side - Component

ComThermo Components

Water

Composition Component type

100

Cold Side - Stream Properties

Temperature

Specific

enthalpy

Vapor mass

fraction

C

15

kJ/kg

-15885,6

20

-15864,1

25

-15842,5

30

-15820,9

35

-15799,4

40

-15777,8

45

-15756,2

50

-15734,6

55

-15713

60

-15691,4

65

-15669,7

70

-15648

75

-15626,3

80

-15604,5

85

-15582,7

90

-15560,9

Program

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 8

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Cold Side - Stream Properties

Temperature

Specific

enthalpy

Vapor mass

fraction

kJ/kg

15

-15885,7

20

-15864,1

25

-15842,5

30

-15821

35

-15799,4

40

-15777,8

45

-15756,2

50

-15734,6

55

-15713

60

-15691,4

65

-15669,7

70

-15648

75

-15626,3

80

-15604,6

85

-15582,7

90

-15560,9

Cold Side - Liquid Properties

TemperatureLiquid specific

Liquid thermal Liquid

heat

cond.

viscosity

Liquid

density

Liquid surface

tension

N/m

0,0738

C

15

kJ/(kg K)

4,316

W/(m K)

0,5965

mPa s

1,136

kg/m

999,01

20

4,314

0,6041

1,0017

998,12

0,073

25

4,313

0,6114

0,8904

996,96

0,0721

30

4,313

0,6184

0,7972

995,55

0,0712

35

4,314

0,6251

0,7185

993,92

0,0704

40

4,316

0,6315

0,6514

992,09

0,0695

45

4,318

0,6375

0,5939

990,06

0,0686

50

4,321

0,6432

0,5442

987,87

0,0677

55

4,325

0,6486

0,5009

985,5

0,0668

60

4,33

0,6537

0,4631

982,98

0,066

65

4,335

0,6584

0,4298

980,31

0,0651

70

4,341

0,6629

0,4004

977,49

0,0642

75

4,348

0,667

0,3743

974,54

0,0633

80

4,357

0,6708

0,351

971,46

0,0623

85

4,365

0,6743

0,3301

968,26

0,0614

90

4,375

0,6774

0,3113

964,93

0,0605

Time: 12:44:32

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 9

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Cold Side - Liquid Properties

TemperatureLiquid specific

Liquid thermal Liquid

heat

cond.

viscosity

Liquid

density

Liquid surface

tension

kJ/(kg K)

W/(m K)

mPa s

kg/m

N/m

15

4,316

0,5965

1,136

999

0,0738

20

4,314

0,6041

1,0017

998,11

0,073

25

4,313

0,6114

0,8904

996,94

0,0721

30

4,313

0,6184

0,7972

995,53

0,0712

35

4,314

0,6251

0,7185

993,91

0,0704

40

4,316

0,6315

0,6514

992,07

0,0695

45

4,318

0,6375

0,5939

990,05

0,0686

50

4,321

0,6432

0,5442

987,85

0,0677

55

4,325

0,6486

0,5009

985,49

0,0668

60

4,33

0,6537

0,4631

982,97

0,066

65

4,335

0,6584

0,4298

980,29

0,0651

70

4,342

0,6629

0,4004

977,48

0,0642

75

4,349

0,667

0,3743

974,53

0,0633

80

4,357

0,6708

0,351

971,45

0,0623

85

4,366

0,6743

0,3301

968,25

0,0614

90

4,375

0,6774

0,3113

964,92

0,0605

Vapor density

Vapor

weight

Cold Side - Vapor Properties

TemperatureVapor specificVapor thermal

Vapor

heat

cond.

viscosity

C

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

kJ/(kg K)

W/(m K)

mPa s

kg/m

Diffusivity

m/s

Time: 12:44:33

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 10

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Cold Side - Vapor Properties

TemperatureVapor specificVapor thermal

Vapor

heat

cond.

viscosity

C

kJ/(kg K)

W/(m K)

Vapor density

mPa s

kg/m

Vapor

weight

m/s

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

Cold Side - 2-Phase liquid

Temperature

Liquid 2

heat

Liquid 2

cond.

Liquid 2

viscosity

Liquid

density

Liquid 2

tension

C

15

kJ/(kg K)

W/(m K)

mPa s

kg/m

N/m

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

Diffusivity

Time: 12:44:34

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 11

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Cold Side - 2-Phase liquid

Temperature

Liquid 2

heat

Liquid 2

cond.

Liquid 2

viscosity

Liquid

density

Liquid 2

tension

kJ/(kg K)

W/(m K)

mPa s

kg/m

N/m

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

Time: 12:44:34

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 12

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:34

Exchanger Type

Front head type

Shell type

Rear head type

Exchanger position

Location of front head for vertical units

"E" shell flow direction (inlet nozzle location)

Shell(s)

Front head

Rear head

Kettle

Front cover type

Rear cover type

Shell cover type

Front cover welded to a cylinder

Rear cover welded to a cylinder

A - channel & removable cover

F - two pass shell with long. baffle

L - removable channel with flat cover

Horizontal

Set default

Set default

ID

488

488

488

mm

mm

mm

mm

OD

508

Flat bolted

Flat bolted (L,N,P,W types)

Set default

Yes

No

Thickness

10

8

8

series

parallel

1

Front tubesheet thickness

Rear tubesheet thickness

Tube projection from front tubesheet

Tube projection from rear tubesheet

Distance from U-bend center to shell cover

Tubesheet type

Normal

Expanded only (no groove)(App.A 'k')

Include expansion joint

None

Flange type - hot side

Flange type - cold side

Hub

Hub

mm

mm

mm

mm

mm

55,52

55,52

3

3

mm

23,81

30-Triangular

Carbon Steel

Smooth

Tubes

Number of tubes (total)

Number of tubes plugged

Tube length

Tube type

Tube outside diameter

Tube wall thickness

Wall specification

Lowfin Tube type

Fin density

Tube wall thickness under fin

Tube root diameter

Fin height

Fin thickness

Outside/Inside surface area ratio

Distance unfinned at baffle

Tube insert type

Twisted tape 360 degree twist pitch

Twisted tape thickness

Tube internal enhancement

mm

mm

mm

312

0

1650

Plain

19,05

2

Average

As specified

#/m

mm

mm

mm

mm

mm

None

mm

mm

Unspecified

Tube pitch

Tube pattern

Tube material

Tube surface

Tube wall roughness

Tube cut angle (degrees)

Longitudinal fins per tube

Longitudinal fin height

Longitudinal fin thickness

Longitudinal root spacing

Longitudinal fin cut and twist length

Twisted tube twist pitch

Shell type: within shroud (convert to)

Shroud inlet location

Shroud inlet gap length

Shroud outlet gap length

Shroud thickness

Skid bar angle (deg)

mm

mm

mm

mm

mm

mm

Set default

None

mm

mm

mm

3,18

60

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 13

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:35

Baffles

Baffle type

Tubes are in baffle window

Baffle cut (% of diam.) outer

Align baffle cut with tubes

Multi-segmental baffle starting baffle

Baffle cut orientation

Baffle thickness

Baffle spacing center-center

Number of baffles

Baffle spacing at inlet

End length at front head (tube end to closest baffle)

End length at rear head (tube end to closest baffle)

Distance between baffles at central in/out for G,H,I,J shells

Distance between baffles at center of H shell

Special inlet nozzle support

Support or blanking baffle at rear end

Length of tube beyond support/blanking baffle

Number of extra supports for U-bends

Support/baffle to tangent of U-bend distance

Baffle OD to shell ID diametric clearance

Baffle tube hole to tube OD diametric clearance

Single segmental

Yes

41,55

Yes

Set default

Vertical

mm

9,52

mm

685

2

mm

423,98

mm

482,5

mm

mm

mm

no

no

mm

mm

mm

mm

4,76

0,4

Longitudinal Baffle

Window length at rear head for F, G, H shells

Window length at front head for G, H shells

Window length at center for H shells

Baffle thickness

Percent leakage across longitudinal baffle

mm

mm

mm

mm

Deresonating Baffles

Number of deresonating baffles

Largest deresonating baffle-baffle or baffle-shell distance

Baffles

Number of regions for variable baffle pitch

Number of baffle spaces

Baffle spacing

mm

Baffle cut percent, outer

Baffle cut percent, inner

Baffle cut percent,

intermediate

Variable baffle pitch: First to last pitch ratio

Number of supports at center of H shell

Number of supports at inlet/outlet for G, H, I, J shells

Number of supports between central baffles

Number of supports at front head end space

Number of supports at rear head end space

Number of supports for K, X shells

One region

9,52

0

0

mm

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 14

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:35

Bundle

Tube layout option

Use existing layout

Main input / Tube layout inconsistencies

Use Layout value (warning)

Normal bundle

Tube layout design

30-Triangular

Tube pattern

mm

23,81

Tube pitch

2

Tube passes

Vertical

Pass layout orientation

Quadrant (dbl.band)

Pass layout

Tube layout symmetry

Standard symmetry

Number of sealing strip pairs

1

Orientation of U-bends

Undefined

Minimum U-bend diameter

mm

Cleaning lane or tube alignment

Unaligned

Number of tie rods

Tie rod diameter

mm

9,55

Spacer diameter

mm

15,88

Open distance at top of layout

Open distance at bottom of layout

Open distance on left side of layout

Open distance on right side of layout

mm

mm

mm

mm

14,66

14,66

7,63

7,63

Shell ID to outer tube limit diametric clearance

Outer tube limit diameter

mm

mm

11,11

476,89

Horizontal pass partition width

Vertical pass partition width

Number of horizontal pass partition lanes

Number of vertical pass partition lanes

mm

mm

15,78

1

0

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 15

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Nozzles

Shell Side

Tube Side

Slip on

Slip on

Shell side nozzle flange rating

Shell side nozzle flange type

Use separate outlet nozzles for hot side liquid/vapor flows

Use separate outlet nozzles for cold side liquid/vapor flows

no

no

Shell Side

NozSizeSS

Nominal diameter

mm

Actual OD

mm

60,3

48,3

Actual ID

mm

52,3

41,1

Wall thickness

mm

3,6

Bottom

Top

No impingement

No impingement

Equate areas

Equate areas

Nozzle orientation

Distance to front tubesheet

mm

Number of nozzles

Multiple nozzle spacing

mm

Nozzle / Impingement type

Remove tubes below nozzle

Maximum nozzle RhoV2

Nozzle ignore options

kg/(m

s)

Shell side nozzle location options

Location of nozzle at U-bend

Nozzle diameter displayed on TEMA sheet

unspecified

Set default

ID

Tube Side

NozSizeTS

Nominal diameter

mm

Actual OD

mm

219,1

139,7

Actual ID

mm

203,1

125,5

Wall thickness

mm

7,1

Top

Bottom

Nozzle orientation

Distance to tubesheet

Centerline offset distance

Maximum nozzle RhoV2

Nozzle ignore options

mm

mm

kg/(m

s)

Dome OD

mm

Vapor belt diametric clearance

mm

Vapor belt slot area

Vapor belt axial length

m

mm

Impingement protection

Impingement protection device

Impingement plate diameter

Impingement plate length (parallel to tube axis)

Impingement plate width (normal to tube axis)

Impingement plate thickness

Impingement plate distance in from shell ID

Impingement plate clearance to tube edge

Impingement plate perforated area %

None

mm

mm

mm

mm

mm

mm

Time: 12:44:35

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 16

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Thermosiphon Piping

Pipework loss calculation

Percent head loss in inlet pipe

Percent head loss in outlet pipe

Set default

Height of column liquid level

Height of heat transfer region inlet

Height of return line to column

mm

mm

mm

Inlet circuit element

Internal diameter

mm

Length (pipe) or Radius (arc)

mm

Velocity heads (general element)

Elements in series

Elements in parallel

Outlet circuit element

Internal diameter

mm

Length (pipe) or Radius (arc)

mm

Velocity heads (general element)

Elements in series

Elements in parallel

Materials

Cylinder - hot side

Cylinder - cold side

Tubesheet

Double tubesheet (inner)

Baffles

Tube material

Tube material thermal conductivity

Tube material density

Tube material modulus of elasticity

Hastelloy C

Carbon Steel

Hastelloy C

Carbon Steel

Carbon Steel

W/(m K)

kg/m

N/mm

Tubesheet cladding - hot side

Tubesheet cladding - cold side

Gaskets - hot side

Gaskets - cold side

Flat metal jacketed fiber

Specifications

ASME Code Sec VIII Div 1

Normal

C - general service

DIN

ISO - International

Service class

TEMA class

Material standard

Dimensional standard

Design pressure (gauge)

Design temperature

Vacuum design pressure (gauge)

Test pressure (gauge)

Corrosion allowance

Radiography

bar

C

bar

bar

mm

Hot Side

3

985

1,59

Spot

Cold Side

3

125

1,59

Spot

Time: 12:44:35

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 17

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:35

Design Options

Use shell ID or OD as reference

Shell side nozzle location options

Location of nozzle at U-bend

Allow baffles under nozzles

Use proportional baffle cut

Number of tube rows between sealing strips

Percent of tubes to be plugged

Remove tubes for vapor disengagement space in flooded evaporator

Percent of shell diameter for disengagement

Number of regions for variable baffle pitch

Variable baffle pitch: First to last pitch ratio

Set default

unspecified

Set default

No

Set default

Set default

One region

Increment

Shell diameter

Tube length

Tube passes

Minimum

mm

mm

Set default

mm

Baffle cut (% of diameter)

Shells in series

Shells in parallel

Use pipe for shells below this diameter

mm

Minimum fluid velocity

Maximum fluid velocity

Target%AllowPresDropForNoz

m/s

m/s

Maximum exit entrainment ratio (mass liquid/vapor) (pool boilers only)

Allow local temperature cross

Design search thoroughness options

Basis for design optimization

Highest cost or area ratio considered

Minimum % excess surface area required

Show units that meet maximum actual/allowed hot side pressure drop ratio

Show units that meet maximum actual/allowed cold side pressure drop ratio

Optimisation item number to repeat

Hot Side

Cold Side

15

15

Set default

Previous

Set default

10

Maximum

2000

4500

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 18

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:35

Thermal Analysis Options

Hot Side

Cold Side

Liquid heat transfer coefficient multiplier

Two phase heat transfer coefficient multiplier

Vapor heat transfer coefficient multiplier

1

1

1

1

1

1

Pressure drop multiplier

Liquid heat transfer coefficient

Two phase heat transfer coefficient

Vapor heat transfer coefficient

W/(m K)

W/(m K)

W/(m K)

U-bend area will be considered effective for heat transfer

Fraction of tube area submerged for shell side condensers

Weir height above bundle for kettle reboiler

mm

Set default

Falling film evaporator distributor velocity heads for pressure loss calculation

Minimum allowable MTD Ft correction factor

Fouling calculation options

Adjust both sides based on fouling input

Hot Side

Fouling layer thickness

Fouling thermal conductivity

Cold Side

mm

W/(m K)

Correlations

Hot side pressure drop calculation options

Cold side pressure drop calculation options

Vibration analysis method

Tube axial stress

Effective cross flow fraction

Lowfin tube calculation method

Single phase tubeside heat transfer method

N/mm

friction+acceleration

friction+acceleration

Full HTFS analysis

1,01

HTFS / ESDU

HTFS recommended method

Condensation Options

Desuperheating heat transfer method

Condensation heat transfer model

Vapor shear heat transfer enhancement

Desuperheating heat transfer method

Priority for condenser outlet temperature (mixtures)

Wet wall

HTFS - Silver-Bell

Use vapor shear enhancement

Not Used

Vapor-Gas

Vaporization Options

Subcooled boiling accounted for in

Post dryout heat transfer determined

Heat transfer & pressure drop

yes

BoilingCurveCorrection

Heat flux reference point

Temperature difference (Delta T) reference point

Boiling curve exponent on Delta T

Correction to boiling curve

Falling film evaporation method

kW/m

C

Boiling curve not used

HTFS recommended method

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 19

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Enhancements

Shell side enhancements

Enhancement identification

BL1(305)

Reynolds number

Colburn J-factor

Friction factor

Tube side enhancements

Enhancement identification

BL1(307)

Reynolds number

Colburn J-factor

Friction factor

CalculationOptions

Maximum number of Iterations

100

Cold side pressure drop calculation options

Convergence tolerance - pressure

0

Full HTFS analysis

Relaxation parameter

Calculation grid resolution

0,5

Medium

Convergence criterion

Calculation step size

Stop when fully converged

0,2

Pressure drop calculation options - hot side

Pressure drop calculation options - cold side

Outlet, to max.pr.drop

Outlet, to max.pr.drop

Time: 12:44:35

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 20

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:35

Warnings and Messages

Description

1121

Input for Inlet temperature, 950 C is beyond the expected range, from -223,15 C to 726,85 C

1121

Input for Baffle pitch (spacing), 685 mm is beyond the expected range, from 50,8 mm to 488 mm

1121

Input for Str.1 Temperature Point, 950 C is beyond the expected range, from -253,15 C to 726,85

1121

Input for Str.1 Temperature Point, 910 C is beyond the expected range, from -253,15 C to 726,85

1121

Input for Str.1 Temperature Point, 870 C is beyond the expected range, from -253,15 C to 726,85

1121

Input for Str.1 Temperature Point, 831 C is beyond the expected range, from -253,15 C to 726,85

1121

Input for Str.1 Temperature Point, 791 C is beyond the expected range, from -253,15 C to 726,85

1121

Input for Str.1 Temperature Point, 751 C is beyond the expected range, from -253,15 C to 726,85

1121

Input for Str.1 Temp.for Vap.Props, 950 C is beyond the expected range, from -253,15 C to

726,85 C

1121

Input for Str.1 Temp.for Vap.Props, 910 C is beyond the expected range, from -253,15 C to

726,85 C

1121

Input for Str.1 Temp.for Vap.Props, 870 C is beyond the expected range, from -253,15 C to

726,85 C

1121

Input for Str.1 Temp.for Vap.Props, 831 C is beyond the expected range, from -253,15 C to

726,85 C

1121

Input for Str.1 Temp.for Vap.Props, 791 C is beyond the expected range, from -253,15 C to

726,85 C

1121

Input for Str.1 Temp.for Vap.Props, 751 C is beyond the expected range, from -253,15 C to

726,85 C

1121

Input for Str.1 Temperature Point, 950 C is beyond the expected range, from -253,15 C to 726,85

1121

Input for Str.1 Temperature Point, 910 C is beyond the expected range, from -253,15 C to 726,85

1121

Input for Str.1 Temperature Point, 870 C is beyond the expected range, from -253,15 C to 726,85

1121

Input for Str.1 Temperature Point, 831 C is beyond the expected range, from -253,15 C to 726,85

1121

Input for Str.1 Temperature Point, 791 C is beyond the expected range, from -253,15 C to 726,85

1121

Input for Str.1 Temperature Point, 751 C is beyond the expected range, from -253,15 C to 726,85

1121

Input for Str.1 Temp.for Vap.Props, 950 C is beyond the expected range, from -253,15 C to

726,85 C

1121

Input for Str.1 Temp.for Vap.Props, 910 C is beyond the expected range, from -253,15 C to

726,85 C

1121

Input for Str.1 Temp.for Vap.Props, 870 C is beyond the expected range, from -253,15 C to

726,85 C

1121

Input for Str.1 Temp.for Vap.Props, 831 C is beyond the expected range, from -253,15 C to

726,85 C

1121

Input for Str.1 Temp.for Vap.Props, 791 C is beyond the expected range, from -253,15 C to

726,85 C

1121

Input for Str.1 Temp.for Vap.Props, 751 C is beyond the expected range, from -253,15 C to

726,85 C

1860

The consolidated process conditions for Stream 1, prior to the main calculations, give a heat

load of -913,6 kW, for a flow of 0,8203 kg/s, with outlet temperature 115 C and quality (vapor

mass fraction) 1.

1860

The consolidated process conditions for Stream 2, prior to the main calculations, give a heat

load of 913,6 kW, for a flow of 2,8133 kg/s, with outlet temperature 90 C and quality (vapor mass

fraction) 0.

1228

An endspace length 423,98 mm is less than the baffle pitch 685 mm, and/or the TEMA minimum

(2 inches/ 50mm). The corresponding endlength and tubeplate thickness are 482,5 mm and

55,52 mm. Check your input carefully.

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 21

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:36

1446

The Advanced calculation has converged after 33 iterations

1641

The most fouling fluid is on the shell side. You may wish to put it on the tube side which is usually

easier to clean

1644

You have a fouling fluid on the shell side but no provision for mechanical cleaning lanes. You

may wish to go to a square (or rotated square) layout, or increase the tube pitch.

1645

You have a fixed rear head type and a large temperature difference between the streams. You

may wish to change to a floating head type (or U tubes) to allow for differences in thermal

expansion between the shell and the tubes. The pressure is low enough to use bellows as an

alternative.

1925

The outlet temperature of stream 1 has changed from the initially specified value 115 C, to

115,12 C. These temperatures relate respectively to the estimated outlet pressure 0,793 bar, and

the calculated outlet pressure 0,92461 bar. Design and Checking calculations are based on fixed

heat load: temperatures can change when pressures change. If you want to avoid this change in

temperature, set the estimated outlet pressure to 0,92461 bar and repeat the calculation.

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 22

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:36

Optimization Path

Shell

Pressure Drop

Tube Length

Item

Size

Actual

Reqd.

mm

488

mm

1650

mm

1498,9

488

1650

1498,9

Area

ratio

Baffle

Tube

Shell

Dp Ratio

Tube

Dp Ratio

Pitch

1,1

bar

0,03325

0,07

bar

0,06839

0,34

mm

685

1,1

0,03325

0,07

0,06839

0,34

685

Units

Total

Price

312

Dollar(US)

102887 OK

312

102887 OK

No. Tube No.

Pass

Design

Status

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 23

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:37

Recap of Designs

A

488

488

Shell size

mm

Tube length - actual

mm

1650

1650

Tube length - required

mm

1498,9

1498,9

Pressure drop, SS

bar 0,03325

0,03325

Pressure drop, TS

bar 0,06839

0,06839

Baffle spacing

mm

Number of baffles

685

685

Tube passes

Tube number

312

312

Number of units in series

Number of units in parallel

Total price

Program mode

Dollar(US) 102887

Design

102887

Rating /

Checking

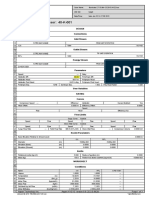

Heat Exchanger Specification Sheet

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

IZMJENJIVA TOPLINE DIMNI PLINOVI IZGARANJA - VODA

Size

Surf/unit(eff.)

488 -- 1650

28,6

mm

m

Fluid allocation

Fluid name

Fluid quantity, Total

Vapor (In/Out)

Liquid

Noncondensable

Temperature (In/Out)

Dew / Bubble point

Density

Vapor/Liquid

Viscosity

Molecular wt, Vap

Molecular wt, NC

Specific heat

Thermal conductivity

Latent heat

Pressure (abs)

Velocity

Pressure drop, allow./calc.

Type AFL

Connected in

Hor

1 parallel

1 series

Shells/unit 1

Surf/shell (eff.)

28,6

m

PERFORMANCE OF ONE UNIT

Shell Side

Tube Side

VODA

DIMNI PLINOVI

2,8133

0,8203

kg/s

0

0

0,8203

0,8203

kg/s

2,8133

2,8133

0

0

kg/s

0

0

0

0

kg/s

C

C

kg/m

mPa s

15

90

999,01

1,136

950

115,12

964,93 0,32

0,3113 0,0458

32,8

0,94

0,0154

32,8

4,316

4,375 1,492

1,132

kJ/(kg K)

0,5965

0,6774 0,0859

0,0257

W/(m K)

kJ/kg

2,5

2,46675

0,92461

0,993

bar

0,15

92,3

m/s

0,5

0,03325

0,2

0,06839

bar

Fouling resist. (min)

0,00025 Ao based

0,0004

0,0002

m K/W

Heat exchanged

MTD corrected

913,6

372,81

kW

C

Transfer rate, Service

Dirty

Clean 100,4

85,6

94,2

W/(m K)

CONSTRUCTION OF ONE SHELL

Sketch

Shell Side

Tube Side

Design/vac/test pressure:g

3

3

bar

Design temperature

125

985

C

Number passes per shell

2

2

Corrosion allowance

1,59

1,59

mm

Connections

In

52,3

1

203,1

mm 1

1

41,1

Out

Size/rating

1

125,5

ID

Intermediate

Tube No. 312

Tks-Avg 2

Length 1650

OD 19,05

mm

mm Pitch 23,81

mm

Tube type Plain

Tube pattern

30

#/m Material Carbon Steel

Shell Carbon Steel

ID 488

OD 508

mm Shell cover

Channel or bonnet

Channel cover

Hastelloy C

Hastelloy C

Tubesheet-stationary Hastelloy C

Tubesheet-floating

Floating head cover Impingement protection None

Baffle-crossing Carbon Steel

Type Single segmental

Cut(%d) 41,55

V Spacing: c/c 685

mm

mm

Baffle-long

Seal type

Inlet

Carbon Steel

423,98

Supports-tube

Bypass seal

Expansion joint

RhoV2-Inlet nozzle

Gaskets - Shell side

Floating head

Code requirements

Weight/Shell

Remarks

U-bend

T1

S2

T2

S1

Type

Tube-tubesheet joint

Type None

Bundle entrance 44

Tube Side

1717

ASME Code Sec VIII Div 1

Filled with water 1598,9

1230

Exp.

Bundle exit 45

Flat Metal Jacket Fibe

TEMA class

Bundle

kg/(m s)

C - general service

659,2

kg

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 25

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

488

x

1650

Size

Surf/Unit (gross/eff/finned)

Surf/Shell (gross/eff/finned)

mm

30,8

30,8

/

/

Type

AFL

28,6 /

28,6 /

Rating / Checking

Process Data

Total flow

Vapor

Liquid

Noncondensable

Cond./Evap.

Temperature

Dew / Bubble point

Quality

Pressure (abs)

Delta P allow/calc

Velocity

kg/s

kg/s

kg/s

kg/s

C

C

bar

bar

m/s

Liquid Properties

kg/m

Density

mPa s

Viscosity

kJ/(kg K)

Specific heat

W/(m K)

Therm. cond.

N/m

Surface tension

Molecular weight

Vapor Properties

kg/m

Density

mPa s

Viscosity

kJ/(kg K)

Specific heat

W/(m K)

Therm. cond.

Molecular weight

Two-Phase Properties

kJ/kg

Latent heat

Shell Side

In

Out

2,8133

0

0

2,8133

2,8133

0

0

15

90

0

2,5

0,5

0,08

0

2,46675

0,03325

0,08

999,01

1,136

4,316

0,5965

964,93

0,3113

4,375

0,6774

18,02

18,02

Heat Transfer Parameters

Reynolds No. vapor

1362,16 4970,17

Reynolds No. liquid

Prandtl No. vapor

8,22

2,01

Prandtl No. liquid

kW

Heat Load

Vapor only

0

2-Phase vapor

0

Latent heat

0

2-Phase liquid

0

Liquid only

913,6

Tubes

Type

ID/OD

mm

Length act/eff

mm

Tube passes

Tube No.

Tube pattern

Tube pitch

mm

Insert

Vibration problem

15,05 /

1650 /

Plain

19,05

1533

2

312

30

23,81

None

No / No

Hor

Connected in

Shells/unit

m

m

Time: 12:44:37

1 parallel

1

PERFORMANCE OF ONE UNIT

Heat Transfer Parameters

Tube Side

Total heat load

kW

In

Out

0,8203

Eff. MTD/ 1 pass MTD

C

Actual/Reqd area ratio - fouled/clean

0,8203

0,8203

0

0

W/(m K)

0

Coef./Resist.

0

Overall fouled

94,2

950

115,12

100,4

Overall clean

105,7

Tube side film

3950,1

1

1

Tube side fouling

0,993

0,92461

16578,8

Tube wall

0,06839

0,2

Outside fouling

2500

92,3

31,36

Outside film

2287,2

0,32

0,0458

1,492

0,0859

32,8

0,94

0,0154

1,132

0,0257

32,8

9705,68

28973

0,8

0,68

kW

-913,6

0

0

0

0

Shell Side Pressure Drop

Inlet nozzle

Inlet space Xflow

Baffle Xflow

Baffle window

Outlet space Xflow

Outlet nozzle

Intermediate nozzle

Tube Side Pressure Drop

Inlet nozzle

Entering tubes

Inside tubes

Exiting tubes

Outlet nozzle

Intermediate nozzle

Velocity / Rho*V2

Shell nozzle inlet

Shell bundle Xflow

Shell baffle window

Shell nozzle outlet

Shell nozzle interm

Tube nozzle inlet

Tubes

Tube nozzle outlet

Tube nozzle interm

Baffles

Type

Single segmental

Number

2

Cut(%d)

41,55

Cut orientation

V

Spacing: c/c

mm

685

Spacing at inlet

mm 423,98

Spacing at outlet

mm

423,98

1 series

913,6

372,81 / 372,5

1,1 / 1,17

m K/W

0,01061

0,00996

0,00946

0,00025

0,00006

0,0004

0,00044

89,16

2,39

0,57

3,77

4,12

bar

0,01067

0,00164

0,00037

0,00024

0,00149

0,01883

%

32,1

4,95

1,11

0,73

4,47

56,65

bar

0,00909

0,01034

0,04757

0,00871

0,01148

%

10,43

11,86

54,56

9,99

13,17

m/s

1,31

kg/(m s)

1717

0,08

0,15

0,08

0,14

2,2

4660

m/s

kg/(m s)

79,06

2002

31,36

92,3

70,36

4666

Nozzles: (No./OD)

Shell Side

mm

Inlet

1 / 60,3

1 / 48,3

Outlet

/

Other

Impingement protection

RhoV2 violation

Tube Side

1 / 219,1

1 / 139,7

/

None

No

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 26

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:38

Thermal Details - General

Rating / Checking

Shell Side

Tube Side

2,8133

0,8203

Total mass flow rate

kg/s

Vapor mass flow rate (In/Out)

kg/s

0,8203

0,8203

Liquid mass flow rate

kg/s

2,8133

2,8133

15

90

950

115,12

2,5

2,46675

0,993

0,92461

Vapor mass quality

Temperatures

Dew / Bubble point

Operating pressures

Film coefficient (mean)

Fouling resistance (OD based)

bar

W/(m K)

2287,2

105,7

m K/W

0,0004

0,00025

0,15

92,3

Velocity (highest)

m/s

Pressure drop (allow./calc.)

bar

Total heat exchanged

kW

0,5

913,6

0,03325

0,2

AFL

Unit

Overall clean coef (plain/finned)

W/(m K)

100,4

Overall dirty coef (plain/finned)

W/(m K)

94,2

Tubes

Plain

Effective area (plain/finned)

28,6

Insert

None

Effective MTD

Actual/required area ratio(dirty/clean)

1,1

488

Shell size

372,81

No.

312

1,17

Pattern

OD

pass

1 ser

1 par

1650

mm

Hor

mm

19,05 Tks

30

Pitch

Vibration problem

No

Baffles Single segmental

RhoV2 problem

No

Total cost

Shell side / Fouling / Wall / Fouling / Tube side

0,06839

23,81 mm

Cut(%d) 41,55

102887

Dollar(US)

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 27

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Overall Coefficient/Resistance Summary

Area required

Area ratio: actual/required

Time: 12:44:39

Clean

Dirty

Max Dirty

24,4

26

28,6

1,17

1,1

1.0

100,4

94,2

85,6

Overall coefficient

W/(m K)

Overall resistance

m K/W

0,00996

0,01061

0,01168

Shell side fouling

m K/W

0.0

0,0004

0,00105

0.0

0,00025

0,00067

Tube side fouling*

W/(m K)

m K/W

2287,2

0,00044

4,39

2500

0,0004

Tube wall

16578,8

0,00006

Tube side fouling*

3950,1

0,00025

Tube side film *

105,7

0,00946

Resistance Distribution

Shell side film

Shell side fouling

0,61

95

4,12

3,74

3,77

9,03

0,57

0,52

2,39

5,72

89,16

80,99

* Based on outside surface - Area ratio: Ao/Ai = 1,27

Thermal Details

Thermal Details - Hot Side

Total

1

Comp 1

0,66

Comp 2

0

Comp 3

0

Comp 4

0,13

Comp 5

0,2

Liquid mass fractions at inlet

0,66

0,13

0,2

Liquid mass fractions at outlet

0,66

0,13

0,2

Vapor mass fractions at inlet

Vapor mass fractions at outlet

Stream mass fractions

Liquid 2 mass fractions at inlet

Liquid 2 mass fractions at outlet

Stream mole fractions

0,49

0,14

0,37

Liquid mole fractions at inlet

0,49

0,14

0,37

Liquid mole fractions at outlet

0,49

0,14

0,37

Vapor mole fractions at inlet

Vapor mole fractions at outlet

0,544

0,0011

0,0006

0,1082

0,1664

Liquid-2 mole fractions at inlet

Liquid-2 mole fractions at outlet

Stream mass flow

kg/s 0,8203

0

Liquid mass flow at inlet

kg/s

Liquid mass flow at outlet

kg/s

Vapor mass flow at inlet

Vapor mass flow at outlet

kg/s 0,8203

kg/s 0,8203

Liquid 2 mass flow at inlet

kg/s

Liquid 2 mass flow at outlet

kg/s

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 28

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Thermal Details - Cold Side

Total

Comp 1

Stream mass fractions

Liquid mass fractions at inlet

Liquid mass fractions at outlet

Vapor mass fractions at inlet

Vapor mass fractions at outlet

Liquid 2 mass fractions at inlet

Liquid 2 mass fractions at outlet

Stream mole fractions

Liquid mole fractions at inlet

Liquid mole fractions at outlet

Vapor mole fractions at inlet

Vapor mole fractions at outlet

Liquid-2 mole fractions at inlet

Liquid-2 mole fractions at outlet

kg/s 2,8133

2,8133

Liquid mass flow at inlet

kg/s 2,8133

2,8133

Liquid mass flow at outlet

kg/s 2,8133

2,8133

Stream mass flow

Vapor mass flow at inlet

kg/s

Vapor mass flow at outlet

kg/s

Liquid 2 mass flow at inlet

kg/s

Liquid 2 mass flow at outlet

kg/s

Time: 12:44:39

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 29

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:39

Thermal Details - Coefficients

W/(m K)

Film Coefficients

Shell Side

Tube Side

Bare area (OD) / Finned area

Overall film coefficients

2287,2

Vapor sensible

Bare area (OD) / ID area

105,7

133,8

105,7

133,8

Two Phase

2287,2

Liquid sensible

In

Heat Transfer Parameters

Prandtl numbers

Vapor

Liquid

Reynolds numbers

Out

8,22

Temperature Difference

Overall Effective MTD

1362,16

C

372,81

One pass counterflow MTD

372,5

LMTD based on end points

353,34

Effective MTD correction factor

1,06

Wall Temperatures

Out

0,8

0,68

9705,68

28973

2,01

Vapor Nominal

Liquid Nominal

In

4970,17

Heat Flux (based on tube O.D.)

kW/m

Overall actual flux

35,1

Critical heat flux (at highest ratio)

Highest actual flux

101,5

Highest ratio, actual/critical flux

Shell mean metal temperature

37,82

66,86

Tube mean metal temperature

Tube wall temperatures (highest / lowest)

158,06

Shell Side

Heat Load Summary

21,86

Tube Side

kW

% total

kW

% total

Vapor only

-913,6

100

2-Phase vapor

Latent heat

2-Phase liquid

Liquid only

913,6

100

Total

913,6

100

-913,6

100

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 30

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:40

Thermal Details - Pressure Drop

Pressure Drop

bar

Maximum allowed

Total calculated

Gravitational

Frictional

Momentum change

Tube Side

0,5

0,2

0,03325

0,06839

0,03325

0,0872

-0,0188

bar

m/s

Pressure drop distribution

Shell Side

Inlet nozzle

1,31

Entering bundle

0,21

0,01067

%dp

0,00164

4,95

Bundle Xflow

0,08

0,08

0,00037

1,11

Baffle windows

0,14

0,15

0,00024

0,73

0,13

0,00149

4,47

Outlet space Xflow

0,14

Exiting bundle

0,22

Outlet nozzle

2,2

Intermediate nozzles

79,06

0,00909

10,43

92,3

0,01034

11,86

0,04757

54,56

31,36

0,00871

9,99

70,36

0,01148

13,17

92,3

Inlet space Xflow

Vapor outlet nozzle

%dp

32,1

Inside tubes

Liquid outlet nozzle

bar

m/s

0,01883

56,65

31,36

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 31

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:40

Thermal Details - Shell Side Stream Analysis

Shell Side Flow Fractions

Inlet

Middle

Outlet

Crossflow

0,73

0,68

0,73

Window

0,87

0,82

0,87

Baffle hole - tube OD

0,02

0,02

0,03

0,4

Baffle OD - shell ID

0,11

0,16

0,11

4,76

Shell ID - bundle OTL

0,14

0,14

0,14

11,11

Pass lanes

Rho*V2 analysis

Flow Area

mm

Shell inlet nozzle

2148

Shell entrance

Velocity

m/s

Diam. Clearance

mm

Density

kg/m

Rho*V2

kg/(m s)

1,31

999,01

1717

2232

4354

0,65

999,01

418

5953

Bundle entrance

13491

0,21

999,01

44

5953

Bundle exit

13491

0,22

964,93

45

5953

Shell exit

3373

0,86

964,93

721

5953

Shell outlet nozzle

1327

2,2

964,93

4660

mm

m/s

kg/m

kg/(m s)

Tube inlet nozzle

32397

79,06

0,32

2002

Tube inlet

27752

92,3

0,32

2728

Tube outlet

27752

31,36

0,94

927

Tube outlet nozzle

12370

70,36

0,94

4666

Thermosiphons

Thermosiphon stability

Vertical Tube Side Thermosiphons

Flow reversal criterion - top of tubes (should be > 0.5)

Flooding criterion - top of tubes (should be > 1.0)

Fraction of tube length flooded

Kutateladze Number in axial nozzle

Kettles

Recirculation ratio

Quality at top of bundle

Entrainment fraction

TEMA limit

kg/(m s)

kg/(m s)

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 32

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:40

Thermal Details - Vibration Analysis - Fluid Elastic Instability (HTFS)

1/1

Shell number:

1/2

Region number:

kg/m

7841,74

Tube axial stress

N/mm

1,01

Tube material Young's Modulus

N/mm

140649,7

Tube material density

U-bend longest unsupported length

Tube Location Tube natural

frequency

cycle/s

mm

Natural frequency Tube effective Dominant

method

mass

span

kg/m

108,29

Exact Solution

1,32

52,18

Exact Solution

1,32

108,29

Exact Solution

1,32

Fluid Elastic Instability Analysis

W/Wc

Tube Location Vibration

W/Wc

for heavy

for medium

(LDec=0.1) (LDec=0.03)

for light Estimated log for estimated

(LDec=0.01)

Dec

damping

No

0,02

0,04

0,06

0,04

0,03

No

0,05

0,09

0,15

0,05

0,07

No

0,02

0,04

0,06

0,04

0,03

Tube Locations:

1 - 1st row in bundle at inlet

2 - 1st row outside baffle overlap

3 - Top row inside baffle overlap

4 - 1st row inside baffle overlap

5 - Bottom row in bundle

Thermal Details - Vibration Analysis - Resonance Analysis (HTFS)

Location in Tube

Vibration

shell

Location

Span

length

Fv/Fn

Fv/Fa

Ft/Fn

Ft/Fa

Inlet

No

423,98

0,08

0,09

Inlet

No

1108,97

0,06

0,04

Inlet

No

423,98

0,03

0,02

Midspace 1

No

685

0,02

0,01

Midspace 2

No

0,04

0,02

Midspace 4

No

685

0,02

0,01

Outlet

No

423,98

0,03

0,02

Outlet

No

423,98

0,06

0,04

Outlet

No

423,98

0,03

0,02

mm

Vortex Turbulent

amplitude amplitude

mm

mm

TEMA

limit

mm

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 33

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Location in Natural

shell

Fn

cycle/s

Acoustic

Fa

Flow

velocity

cycle/s

m/s

X-flow

fraction

RhoV2

Strouhal No.

kg/(m s)

Inlet

108,29

3555,27

0,21

44

0,8

Inlet

52,18

3555,27

0,13

0,85

17

0,46

Inlet

108,29

3555,27

0,13

0,85

17

0,46

Midspace

108,29

3557,16

0,08

0,85

0,46

Midspace

52,18

3557,16

0,08

0,85

0,46

Midspace

108,29

3557,16

0,08

0,85

0,46

Outlet

108,29

3560,24

0,13

0,85

17

0,46

Outlet

52,18

3560,24

0,13

0,85

17

0,46

Outlet

108,29

3560,24

0,13

0,85

17

0,46

Time: 12:44:41

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 34

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:41

Thermal Details - Methods

Hot Side

Heat transfer coefficient multiplier

Heat transfer coefficient specified

Pressure drop multiplier

Pressure drop calculation option

Cold Side

No

No

No

friction+acceleration

No

No

No

friction+acceleration

Calculation method

Advanced method

Desuperheating heat transfer method

Multicomponent condensing heat transfer method

Vapor shear enhanced condensation

Liquid subcooling heat transfer (vertical shell)

Wet wall

HTFS - Silver-Bell

Yes

Not Used

Subcooled boiling accounted for in

Post dryout heat transfer accounted for

Correction to user-supplied boiling curve

Falling film evaporation method

Set default

No

Boiling curve not used

HTFS recommended method

Single phase tubeside heat transfer method

Lowfin Calculation Method

HTFS recommended method

HTFS / ESDU

Tube pass multiplier

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 35

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:41

Basic Geometry

Unit Configuration

Exchanger Type

AFL

Tube number (calcs.)

Position

Hor

Tube length actual

1 par

Arrangement

1 ser

Single segmental

Baffle type

Baffle number

mm

Tube passes

Plain

Tube type

Tube O.D.

mm

19,05

Tube pitch

mm

23,81

Spacing (center-center)

mm

685

Spacing at inlet

mm

423,98

Outside diameter

mm

mm

Inside Diameter

312

30

Tube pattern

Shell

508

Kettle

Front head

504

488

488

Shell Side

Inlet

Nozzle type

Number of nozzles

Actual outside diameter

mm

Outlet

1

48,3

219,1

139,7

203,1

125,5

mm

52,3

41,1

mm

14,66

14,66

mm

mm

Vapor belt inside width

Vapor belt slot area

Impingement protection

Distance to tubesheet

Outlet

Height under nozzle

Vapor belt inside diameter

Tube Side

Inlet

mm

mm

No

No

impingement impingement

140

140

mm

Rear head

504

488

60,3

Inside diameter

Dome inside diameter

1650

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 36

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:42

Tubes

Tubes

Type

Plain

Total number

Outside diameter

mm

19,05

Number of tubes plugged

Inside diameter

mm

15,05

Tube length actual

mm

1650

Wall thickness

mm

Tube length effective

mm

1533

1,27

Tubesheet thickness

mm

55,52

Area ratio Ao/Ai

Pitch

mm

Pattern

23,81

30

Thermal conductivity

Internal enhancement

Low circumferential fins

Low longitudinal fins

Fin height

Material

External enhancement

Fin density

312

Carbon Steel

W/(m K)

37,2185

#/m

Fin number

mm

mm

Fin thickness

Fin thickness

mm

Fin height

mm

Tube root diameter

mm

Fin spacing

mm

Tube wall thickness under fin

mm

Cut and twist length

mm

Tube inside diameter under fins

mm

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 37

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:42

Baffles

Baffles

Type

Single segmental

Baffle cut: inner / outer / interm

Yes

Tubes in window

Number

Actual (% diameter)

41,55

Nominal (% diameter)

41,55

Actual (% area)

39,29

Spacing (center-center)

mm

685

Spacing at inlet

mm

423,98

Cut orientation

Spacing at outlet

mm

423,98

Thickness

Spacing at central in/out for G,H,I,J shells

mm

Tube rows in baffle overlap

Spacing at center of H shell

mm

Tube rows in baffle window

9,5

End length at front head

mm

482,5

Baffle hole - tube od diam clearance

mm

0,4

End length at rear head

mm

482,5

Shell id - baffle od diam clearance

mm

4,76

V

mm

9,52

VariableBaffles

Baffle spacing

mm

Baffle cut percent, outer

Baffle cut percent, inner

Number of baffle spaces

Baffle region length

mm

Baffle cut area percent, outer

Baffle cut area percent, inner

Supports Misc. Baffles

Supports-tube

Longitudinal Baffle

Supports in endspace at front head

Thickness

mm

Supports in endspace at rear head

Window length at front head

mm

Supports between baffles

Window length at center

mm

Window length at rear head

mm

Support blanking baffle

No

Supports at U-bend

Supports at each G,H,J shell inlet and I shell outlet

Supports at center of H shell

Supports for K, X shells

Special support at inlet nozzle

No

9,52

423,98

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 38

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:42

Bundle

Bundle

Shell ID to center 1st tube row

Tube passes

mm

From top

14,66

Tube pass layout

From bottom

14,66

Tube pass orientation

Quadrant (dbl.band)

Vertical

From right

7,63

U-bend orientation

From Left

7,63

Horizontal pass lane width

mm

Vertical pass lane width

mm

None

Impingement protection

Undefined

15,78

No

Impingement distance

mm

Interpass tube alignment

Impingement plate diameter

mm

Deviation in tubes/pass

Impingement plate width

mm

Outer tube limit

mm

476,89

Impingement plate length

mm

Shell id - bundle otl diam clearance

mm

11,11

Impingement plate thickness

mm

Gross surface area per shell

30,8

Tie rod diameter

mm

9,55

Effective surface area per shell

28,6

Sealing strips (pairs)

Bare tube area per shell

28,6

Tube to tubesheet joint

Finned area per shell

Tube projection from front tsht

mm

U-bend area per shell

Tube projection from rear tsht

mm

-1

Tie rod number

1

Exp.

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 39

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:42

Mechanical Details

Internal enhancements

None

Tube insert type

Twisted tape 360 deg twist pitch

mm

Twisted tape thickness

mm

hiTRAN part number

Cost/Weight

Weights

kg

Cost data

Dollar(US)

Shell

258,7

Labor cost

24873

Front head

179,9

Tube material cost

Rear head

132,1

Material cost (except tubes)

1355

76660

Shell cover

Bundle

659,2

Total weight - empty

1230

Total weight - filled with water

1598,9

Total cost (1 shell)

102887

Total cost (all shells)

102887

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 40

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:42

Setting Plan

Views on arrow A

2622 Overall

T1

294

140

T1

S2

T2

S1

402

402

350

T2

441

404

404

S2

S1

294

330

990

1090

110

440

75

440

75

150

150

2 Bolts

Fixed

Ref

OD

Wall

S1 60 mm 4, mm

S2 48 mm 3,6 mm

T1 219 mm 8, mm

T2 140 mm 7,1 mm

Nozzle Data

Standard

150 ANSI Slip on

150 ANSI Slip on

150 ANSI Slip on

150 ANSI Slip on

Notes

Design Data

Design Pressure

Design Temperature

Full Vacuum

Corrosion Allowance

Test Pressure

Number of Passes

Radiography

PWHT

Internal Volume

2 Bolts

Sliding

Units

bar

C

Shell

3,

125,

Channel

3,

985,

mm

bar

1,5875

1,5875

0,286

0,1678

110

Pulling Length

IZMJENJIVA TOPLINE DIMNI PLINOVI IZGARANJA - VODA

Aspen Shell & Tube Exchanger

Setting Plan

AFL 488 - 1650

Design Codes

ASME Section VIII Div. 1

TEMA C

Drawing Number

Customer Specifications

Empty

1230 kg

Weight Summary

Flooded

1599 kg

Bundle

659 kg

Revision

Date

24.2.2015.

Dwg.

Chk.

App.

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 41

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:43

219,82 mm

Tube Layout

Shell inside diameter

mm

Front head inside diameter

mm

488,

Outer tube limit

mm

476,8875

Tube number (calcs.)

312

Tube number (layout)

219,82 mm

488,

312

Tube O.D.

mm

Tube pitch

mm

19,05

23,8125

Tube pattern

30

Tube passes

Tie rod number

-1

Tie rod diameter

mm

Sealing strips (pairs)

9,55

1

Baffle type

Single segmental

Impingement protection

None

Tube length

mm

1650,

Shell Side Inlet Nozzle Inside Diameter

mm

52,3

Shell Side Outlet Nozzle Inside Diameter

mm

41,1

IZMJENJIVA TOPLINE DIMNI PLINOVI IZGARA

Aspen Shell & Tube

Tube Layout

19,05

156

Design Codes

ASME Code Sec VIII Div 1

TEMA C - general service

Drawing Number

Customer Specifications

19,05

156

Revision

Date

24.2.2015.

Dwg.

App.

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 42

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

U-bend Details

Time: 12:44:43

Heat Exchanger Thermal Design

Shell&Tube V7.3.1 CP1Page 43

File: VELIKA MRCINA OD IZMJENJIVAA TOPLINE.EDRDate: 24.2.2015.

Time: 12:44:43

Calculation Details - Shell Side

Point Shell Shell Distance

No.

No.

No.

End

SS Bulk

Temp.

SS Fouling

Temp

Tube Metal

SS

SS Vapor

Temp

Pressure fraction

SS void

fraction

SS Heat

Load

SS Heat

flux

SS Film

Coef.

mm

bar

kW

kW/m

W/(m K)

60

15,01

18,69

22,12

2,48932

0,1

2170,5

144

15,49

19,38

23,03

2,48915

8,5

2183,5

228

16,01

20,12

24,01

2,48898

12,2

2197,4

313

16,56

20,91

25,05

2,48881

18,9

9,6

2211,5

397

17,14

21,75

26,16

2,48863

26

10,3

2226,6

481

17,76

22,64

27,34

2,48846

33,5

10,9

2242,9

484

17,79

24,48

29,12

2,48847

33,8

10,8

1615,3

581

18,55

25,68

30,68

2,48842

43,1

11,6

1630,4

679

19,37

26,97

32,36

2,48838

53

12,5

1646,5

10

776

20,25

28,36

34,16

2,48833

63,8

13,5

1663,9

11

874

21,21

29,85

36,11

2,48829

75,3

14,5

1682,7

12

971

22,24

31,45

38,2

2,48824

87,8

15,7

1702,3

13

1069

23,35

33,17

40,46

2,4882

101,3

16,9

1723,4

14

1166

24,55

35,02

42,89

2,48815

115,8

18,3

1746,4

15

1169

24,58

32,28

40,28

2,48814

116,3

18,6

2415,8

16

1253

25,72

33,86

42,43

2,48798

130,1

19,9

2443,7

17

1337

26,93

35,55

44,72

2,48781

144,8

21,3

2473,3

18

1422

28,23

37,36

47,19

2,48765

160,6

22,9

2504,2

19

1506

29,62

39,28

49,82

2,48749

177,5

24,5

2537,6

20

1590

31,12

41,34

52,65

2,48733

195,6

26,3

2572,4

21

1590

31,18

41,42

52,76

2,48733

196,3

26,4

2573,7

22