Professional Documents

Culture Documents

Turbomachinery Control System Design Objectives Article

Uploaded by

Chucho CarreroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turbomachinery Control System Design Objectives Article

Uploaded by

Chucho CarreroCopyright:

Available Formats

R I C K FA U S E L , B U S I N E S S D E V E L O P M E N T E N G I N E E R

TURBOMACHINERY CONTROL

SYSTEM DESIGN OBJECTIVES

The primary design objective for any turbomachinery control system should be to maintain

or maximize machine and associated process reliability. With this assurance firmly in

place, attention can then be turned to maximizing machine and process efficiency. This

article takes a broad brush to the general functional areas of concern and offers some

insight to proven techniques and solutions offered by Compressor Controls Corporation.

Machine And Process Reliability

A well-designed turbomachinery control

system should take into account typical, as

well as, rare types of process disturbances.

Analysis should be made of the size and

direction of these disturbances and how they

will be felt by the turbomachinery train in

both a static and dynamic sense. Process

disturbances are mostly associated with so

called pressure waves from the suction or

discharge network of the compressor.

However, disturbances in the process stream

or gas composition can be just at dramatic in

their effect on compressor control as

changes in pressure/flow rates.

Many process control professionals begin

with the notion that process reliability is

tantamount to machine reliability goals such

as compressor antisurge control, load

limiting, high and low pressure limiting,

overspeed prevention, etc. This notion is

quickly lost however when, for example, a

compressor surge incident causes a machine

to trip, bringing down the associated process.

In many processes, a surge incident can also

create enough process oscillation to initiate a

process trip prior to high temperatures and/

or train vibration initiating a machine trip. It

should be readily apparent that turbomachinery almost always operates as the heart of

the process and that it then becomes

impossible to separate machine and process

reliability.

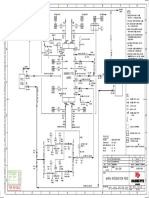

Picture 1: Simplified control system diagram for a steam turbine driven centrifugal compressor

The effectiveness of any control system is

influenced by all associated control elements,

including primary measuring elements,

transmitters, control valves, and actuators,

process vessel locations and process piping

configuration. The fastest and most accurate

control system cannot function optimally with

noisy input signals; slow or dysfunctional

control valves, or unnecessarily large process

lag times. It is particularly important when

dealing with the high speed of approaching surge

found in many applications, that the speed and

accuracy of the response of all antisurge control

loop elements is examined and addressed.

Speed control functions should be integrated

with coupled process control loops to enable

automatic tracking features and simplified

mode switching in order to minimize

requirements for operator involvement

particularly during critical times of start-up and

shutdown procedures.

Overspeed trip scenarios in turbine

applications are not only safety concerns, but

unnecessary trips are also quite obviously

machine and process reliability concerns. In

the case of turbo-compressor drives, surge

incidents (sometimes referred to as slipping

the load) can cause turbines to accelerate

rapidly to dangerously high speeds and

potentially overspeed trip situations. Some

algorithms have been developed for

integration between antisurge control

and speed control systems in order to head

off turbine overspeed and overspeed

trips when a compressor surge condition

is detected. Of course damage from

overspeed occurrences and trips can cause

extended process outages.

As we have touched on above, the prevention

of surge in centrifugal and axial compressors is

extremely important in maintaining process

reliability. While the flow reversal from a single

surge cycle will cause a shock wave through

the process, multiple surge cycle incidents left

unchecked will inevitably necessitate a unit

shutdown due to undesirable and possibly

dangerous process or machine conditions.

Multiple surge cycles can cause the gas stream

temperature to rise at an exponential pace

as the hot gas in the discharge is pulled back

through the machine and subsequently

recompressed over and over again.

Compressor damage caused by the thrust

reversals and high temperatures created by

surge cycles will reduce compressor efficiency

and in severe incidents can necessitate

unscheduled machine and process outages.

Turbomachinery control system design should

include special provisions for startup and shutdown operations. This includes

standardized and coordinated ramping

procedures both for normal and emergency

scenarios, continuous machine monitoring for

abnormal conditions and automatic starting

aborts, etc. Advanced automation techniques

have proven successful in making the

intelligence, and the experience, of the most

capable operations personnel available at

every unit startup and shutdown. With

automated startup and shutdown systems

in place available operators can be

concentrating on other potentially less

predictable areas of concern. Although

antisurge valve ramping is recommended for

startup and shutdown automation, it is also

important to maintain the integrity of the

proximity to surge and surge detection

algorithms for override purposes during any

valve ramping procedures.

Accurate and stable speed control is also

critical to the success of any turbomachinery

control system in a variable speed application.

As with compressor control, excellent turbine

speed control is also very much influenced by

the speed and precision in the movement of the

steam valve(s) on steam turbines and in the

actuation of the fuel valve in gas turbine

applications. Care should be given to

maximizing actuator speed of response with

stability and minimizing valve stick-on and

hysteresis.

3

Machine And Process Efficiency

an advantage to process efficiency.

Turbo-compressors are often arranged in

parallel or series configurations in order to add

system flexibility and or reliability. Some

installations have grown into multiple

compressor operations as process

requirements (capacities) have increased over

time. In all of these scenarios, an optimally

designed turbomachinery control system should

include some provisions for automatic

loadsharing between compressors and turbines.

When you consider that a 3,000 horsepower

mechanical drive unit costs the user an

excess of $1,000,000 worth of energy a year

(at less than an equivalent $.05/kWhr) it

becomes clear that energy efficiency should

be a key component in any good

turbomachinery control system design. More

importantly, process efficiency can be directly

related to precision of turbomachinery

control; i.e.: precise turbine speed control,

advanced antisurge control, integrated

process limiting variables, etc. As power

draw is proportional to speed, possibilities to

reduce turbines (when process conditions

allow), even in small amounts, should not be

overlooked. The goal is to meet all process

requirements while operating at the lowest

possible energy level.

GAS TURBINE

COMPRESSOR

TE

1

SE

1A

PT

1A

SE

1A

FT

1

PT

1B

TE

1A

TT

1A

PT

1C

TT

1B

TRAIN 1

In turbocompressor applications, much attention is given to minimizing antisurge recycle

(or blow-off in the case of air compressors) as

process gas that is being recycled or released

to atmosphere represents an overproduction

of compressed gas. This overproduction

can potentially be reduced through further

speed reductions and/or deeper compressor

inlet throttling; however, turbo-compressor

throttling is limited by the thermodynamic

capability of the compressor to produce the

head requirement necessary to maintain

process flow under low load conditions.

SIC

TIC

PIC

UIC

FY

PT

3

GAS TURBINE

COMPRESSOR

MPIC

TE

2

SE

2A

PT

2A

SE

2B

FT

2

PT

2B

TE

2B

TT

2A

PT

2C

TT

2B

TRAIN 2

A good antisurge control system design will

work to minimize overshoot from the

antisurge control line and maximize

compressor stability during process upsets,

thereby reducing the safe margin requirement in the antisurge setpoint. Minimum safe

margin in the antisurge control system

equates to a maximized operating envelope

without wasteful recycle or blow-off. By

moving the antisurge control line as close as

possible to the actual compressor surge limit,

it is also possible to move up the compressor

performance curve and produce higher

discharge or lower pressure when it is an

SIC

TIC

PIC

UIC

FY

Picture 2. Simplified control system diagram for two

gas turbine driven compressors

Optimized Compressor Loadsharing

check valves, and recycle take-off points (for

turbo-compressor applications). Care should

be taken to ensure adequate system cooling

capacity for all levels of operation. For

compressor applications, the cooling load

under conditions of 100% recycle needs to be

considered. Responsible parties should also

make decisions relation to:

The implementation of automatic fallback

strategies to provide continued operation in

the face of a lost input signal or the simultaneous loss of multiple input signals

A target system availability figure and the

appropriate level of redundancy to be implemented for field and control room instrumentation

UPS (uninterruptible power supply) system

strategy to be applied (if any)

In a turbo-compressor loadsharing system, the

primary process control variables and limiting

loops become the master control system

working through some type of loadsharing

system that is directly connected to the turbine

speed setpoints or compressor inlet throttling

devices. The question now becomes, on what

basis should the load between compressors be

divided. The system designer has to take into

account that none of the machines has an

unlimited efficient operating envelope as

dictated by the surge limit, process limits, and

the thermodynamic limitations of each

compressor. The designer also needs to be

aware that even identical compressors will very

rarely demonstrate identical characteristics in

the field. This is due to slight differences in

manufacturing differences in piping layout, etc.

Differences in sure limits mean that with

equalized flow division users can end up with

one machine in recycle or blowing off with

others working out on their compressors maps.

In parallel operations differences in head

producing capability means that running with

equal speed or throttling may leave users

running at less than optimal suction or

discharge pressure production. Clearly the

optimal loadsharing system would balance

compressor loading based on an online

calculation of distance from surge at low loads,

would work to minimize energy consumption

at mid-level loads, and work to maximize head

production under high demands for compressor

head.

The specifics of field instrumentation

specification as well as the selection of

control system initialization parameters should

be thought through from the point of view of

safe and reliable turbomachinery control and

protection.

Conclusion

Turbomachinery control system design

presents one of the most interesting and

demanding application in the process control

field. The successful turbomachinery control

system designer should work closely with user

representatives from other integral disciplines,

including process engineering, mechanical

engineering, as well as with operations

management in the design and specification of

an optimized control system for this application.

Due to the extremely critical nature of the

continuous operation of turbomachinery

(particularly in the process and oil and gas

production industries), proper system design is

critical in providing safe, reliable, and efficient

machine and process operation.

Control System Reliability

A preliminary level of hazards and operational

analysis and/or a process control system layer

of protection analysis should be done at the

onset of the design of a turbomachinery

control system. During this process, the system

designer should work to determine the

functionality and proper placement of system

flares; relief valves,

5

Global Experience. Global Support.

Australia / Brazil / China / India / Italy / Netherlands / Russia

Saudi Arabia / Singapore / U.A.E. / United Kingdom / United States

Contact your local sales representative.

Please visit our website:

WWW.CCCGLOBAL.COM

You might also like

- Understand Advanced Process Control: Back To BasicsDocument4 pagesUnderstand Advanced Process Control: Back To BasicsJohn AnthoniNo ratings yet

- MATLAB HardwareDocument1 pageMATLAB HardwareImran KhanNo ratings yet

- Control and Condition Monitoring of Reciprocating CompressorDocument2 pagesControl and Condition Monitoring of Reciprocating CompressorPedro DiazNo ratings yet

- GG 01 01 2017 26Document5 pagesGG 01 01 2017 26Shaban RabieNo ratings yet

- Anti-Surge White PaperDocument8 pagesAnti-Surge White Papervgogulakrishnan100% (1)

- SCHROEDER Automatic Recirculation Check ValveDocument14 pagesSCHROEDER Automatic Recirculation Check ValveAli Bari100% (1)

- Centrifugal Compressor: Fluid Machinery and DisplacementDocument22 pagesCentrifugal Compressor: Fluid Machinery and DisplacementLuqman KhaqimNo ratings yet

- Some Technical and Practical Recommendations About Pulsation Dampeners in Circuits With Dosing or Volumetric PumpsDocument10 pagesSome Technical and Practical Recommendations About Pulsation Dampeners in Circuits With Dosing or Volumetric PumpsRoberto Leon MendezNo ratings yet

- Understanding NPSH - NPSH Definitions - Page 2 of 2 - PumpsDocument3 pagesUnderstanding NPSH - NPSH Definitions - Page 2 of 2 - PumpsLam TranNo ratings yet

- Surge ProtectedDocument42 pagesSurge ProtectedRaul Roque Yujra100% (2)

- 1.dresser Rand Surge ControlDocument4 pages1.dresser Rand Surge ControlHimawan Sigit NugrohoNo ratings yet

- Noruegan StandardDocument152 pagesNoruegan StandarderikohNo ratings yet

- Centrifugal Compressor HorsepowerDocument9 pagesCentrifugal Compressor HorsepowerCurtis Dookie100% (1)

- Reciprocating Air Compressors: Compression RatioDocument25 pagesReciprocating Air Compressors: Compression RatioRichardt LootsNo ratings yet

- Compressor Choke: by TMI Staff & Contributors On August 27, 2019Document5 pagesCompressor Choke: by TMI Staff & Contributors On August 27, 2019Tusar KoleNo ratings yet

- Teikoku BrocrureDocument9 pagesTeikoku BrocrureAng WelliNo ratings yet

- Flow Profile For Reciprocating Pumps - Chemical Engineering ProcessingDocument3 pagesFlow Profile For Reciprocating Pumps - Chemical Engineering ProcessingVILLANUEVA_DANIEL2064No ratings yet

- Pumping TechnologyDocument25 pagesPumping TechnologyHanis Kamaruddin100% (1)

- Pulsation Supression DeviceDocument9 pagesPulsation Supression Devicesswoo3868No ratings yet

- DGS - 2. JCDocument15 pagesDGS - 2. JCfjafarvand100% (1)

- Pressure Pulsation in Reciprocating Pump - Part 1Document9 pagesPressure Pulsation in Reciprocating Pump - Part 1Jose PradoNo ratings yet

- Minimum Thermal FlowDocument4 pagesMinimum Thermal Flowdk4monjureNo ratings yet

- Blowers and Vacuum BoostersDocument6 pagesBlowers and Vacuum BoostersMara RusyadiNo ratings yet

- Hermetic Pumpen Canned Motor Pumps Catalogue For Model CN - CNF - CNKDocument16 pagesHermetic Pumpen Canned Motor Pumps Catalogue For Model CN - CNF - CNKADITYA_PATHAKNo ratings yet

- Best Practices in Compressor MountingDocument9 pagesBest Practices in Compressor MountingDaniel Puello RodeloNo ratings yet

- STI Reciprocating CompressorDocument29 pagesSTI Reciprocating CompressorfazzlieNo ratings yet

- Yarway Valve DesignDocument12 pagesYarway Valve DesignwaqashabibNo ratings yet

- Hermetic Canned PumpDocument16 pagesHermetic Canned PumpYlm PtanaNo ratings yet

- Case Study On Dresser Rand Ethylene CompressorDocument18 pagesCase Study On Dresser Rand Ethylene CompressorSDP02No ratings yet

- Turbine Off-Frequency Operation: GE Power SystemsDocument4 pagesTurbine Off-Frequency Operation: GE Power Systemskcirrenwod100% (1)

- Teikoku Rotary Guardian: Principle of OperationDocument2 pagesTeikoku Rotary Guardian: Principle of OperationMón Quà Vô Giá100% (1)

- KMBD BP(国外罗茨泵ROOTS)Document2 pagesKMBD BP(国外罗茨泵ROOTS)tutuli1990No ratings yet

- 6 Konitzer2Document32 pages6 Konitzer2mchramziNo ratings yet

- Section 03 - Compressor Basics PDFDocument17 pagesSection 03 - Compressor Basics PDFmohamedNo ratings yet

- AnsaldoThomassen Gas Turbine Engineering LRDocument4 pagesAnsaldoThomassen Gas Turbine Engineering LRAshik ChungathNo ratings yet

- Application Guide Line For Centrifugal Compressor Surge Control Systems PDFDocument75 pagesApplication Guide Line For Centrifugal Compressor Surge Control Systems PDFmoralesmjyNo ratings yet

- Is Rod Drop The Right Measurement For My Reciprocating Compressor?Document4 pagesIs Rod Drop The Right Measurement For My Reciprocating Compressor?Sagar MishraNo ratings yet

- Air CompressorsDocument59 pagesAir Compressorsommech2020No ratings yet

- Harris Pye Whru M/E EGB A/B: Whru Integration P&IdDocument1 pageHarris Pye Whru M/E EGB A/B: Whru Integration P&IdMarko Always-Online100% (1)

- 01 220043enc Routine Turbine MaintenanceDocument8 pages01 220043enc Routine Turbine Maintenanceajipramudio100% (1)

- Antisurge Factory Performance ODV Fgs4L11Document20 pagesAntisurge Factory Performance ODV Fgs4L11Ahmed Mohamed KhalilNo ratings yet

- Sok0929245 PDFDocument17 pagesSok0929245 PDFLeonardo Basante HerreraNo ratings yet

- Dupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsDocument12 pagesDupont Vespel Cr-6100: Application and Installation Guide For Centrifugal Pump Stationary Wear PartsFernando Tapia GibsonNo ratings yet

- Materials of Construction ConstructionDocument6 pagesMaterials of Construction ConstructionIlkuNo ratings yet

- Operating Pumps in ParallelDocument3 pagesOperating Pumps in Paralleldk4monjure100% (1)

- Compressor Power PointDocument28 pagesCompressor Power PointDiden Dz100% (1)

- Pump RotordynamicsDocument26 pagesPump RotordynamicsHalil İbrahim Küplü100% (1)

- Novel Method of Detection of Surge - Gas Machinery Journal Q2 - 13Document16 pagesNovel Method of Detection of Surge - Gas Machinery Journal Q2 - 13mantosh_bhattacharyaNo ratings yet

- ESD White Paper From NorgrenDocument24 pagesESD White Paper From NorgrenArun BalajiNo ratings yet

- Centrifugal and Axial Compressor ControlDocument13 pagesCentrifugal and Axial Compressor ControlMomentum Press0% (3)

- Kinney Piston Vacuum Pump BrochureDocument18 pagesKinney Piston Vacuum Pump BrochureVivek BelaNo ratings yet

- OHH OHHL E00697 (Pump Zulzer)Document6 pagesOHH OHHL E00697 (Pump Zulzer)Jose Sosa CojNo ratings yet

- Causes of Rotor Distortions and Applicable Common Straightening Methods For Turbine Rotors and ShaftsDocument6 pagesCauses of Rotor Distortions and Applicable Common Straightening Methods For Turbine Rotors and ShaftsIftekhar NizamNo ratings yet

- Classes and Comparisons Between CompressorsDocument48 pagesClasses and Comparisons Between CompressorsVijay MeenaNo ratings yet

- Materials System SpecificationDocument11 pagesMaterials System SpecificationEagle SpiritNo ratings yet

- Main Steam Turbine Controls Retrofit ISA FinalDocument13 pagesMain Steam Turbine Controls Retrofit ISA Finalvankayalasurya100% (1)

- Surge ControlDocument16 pagesSurge ControlSANTOSH KUMARNo ratings yet

- CCC AntisurgeDocument2 pagesCCC AntisurgeDamian Wahlig100% (1)

- Surge Control: Compressor Surge and MeasurementDocument4 pagesSurge Control: Compressor Surge and Measurementmtrj59100% (1)

- Automation of Palm Oil MillsDocument7 pagesAutomation of Palm Oil MillsKalana Jayatillake100% (2)

- Compressor Surge ControlDocument8 pagesCompressor Surge ControlSIVA100% (1)

- Introduction To Surge ControlDocument6 pagesIntroduction To Surge Controlnote222100% (1)

- 1 Building Maintenance Checklist HVACDocument17 pages1 Building Maintenance Checklist HVACamochieno100% (3)

- Automation Lang enDocument15 pagesAutomation Lang enkelly.raita1538No ratings yet

- Pe-3032 WK 1 Introduction To Control System March 04Document70 pagesPe-3032 WK 1 Introduction To Control System March 04Charlton S.Inao100% (2)

- Experiment E. Liquid Level Control Using Coupled TanksDocument29 pagesExperiment E. Liquid Level Control Using Coupled Tanks파랑No ratings yet

- Rheostasis: The Physiology of ChangeDocument188 pagesRheostasis: The Physiology of ChangemitchxpNo ratings yet

- Mark ViesDocument32 pagesMark ViesMauricio GuanellaNo ratings yet

- HC 900 Boiler Control ApplicationDocument7 pagesHC 900 Boiler Control ApplicationtriplbingaziNo ratings yet

- Technical Interview Questions For Instrumentation EngineeringDocument48 pagesTechnical Interview Questions For Instrumentation EngineeringtejasNo ratings yet

- On-Off Control System Characteristic: Oleh: Rizqiya W. Saputra, M.TDocument10 pagesOn-Off Control System Characteristic: Oleh: Rizqiya W. Saputra, M.TR.W. SaputraNo ratings yet

- Control System - Position Control SystemDocument4 pagesControl System - Position Control SystemAnas Elgaud100% (1)

- Комбинирани абрихт и щрайхмус машиниDocument69 pagesКомбинирани абрихт и щрайхмус машиниЈован МиочиновићNo ratings yet

- EXP Subsea A4Document12 pagesEXP Subsea A4Martinus LuckyantoNo ratings yet

- Reflex - Pressure VesselDocument48 pagesReflex - Pressure Vesselhabeebrah100% (1)

- A Boiler Combustion Control System With CombustionDocument4 pagesA Boiler Combustion Control System With Combustionlu linpyoNo ratings yet

- Gas Turbine PhilosophyDocument55 pagesGas Turbine PhilosophyFreddie Asiedu Larbi100% (1)

- EEIB413 Chapter 2Document123 pagesEEIB413 Chapter 2SanjanaLakshmi100% (1)

- Mathematical Model of Pneumatic Proportional ValveDocument6 pagesMathematical Model of Pneumatic Proportional Valvegladiolus86No ratings yet

- Feedback ControlDocument21 pagesFeedback ControlApril BalceNo ratings yet

- Class Notes - CONTROL SYSTEMSDocument3 pagesClass Notes - CONTROL SYSTEMSmeeravali_sn100% (1)

- PID Theory ExplainedDocument9 pagesPID Theory ExplainedMansen NsubugaNo ratings yet

- Wireless Proximity SensorsDocument4 pagesWireless Proximity SensorsMarey MorsyNo ratings yet

- Easy Auto Tuning GuideDocument8 pagesEasy Auto Tuning Guidepanderial100% (1)

- DK Engineering Brochure 2013 19-7-13 3007Document73 pagesDK Engineering Brochure 2013 19-7-13 3007viettiennguyenNo ratings yet

- Control System IntroductionDocument5 pagesControl System Introductionkapilkumar18No ratings yet

- QCS Section 22Document12 pagesQCS Section 22hvacsriniNo ratings yet

- Canal Operation TechniquesDocument32 pagesCanal Operation TechniquesIsmadiNo ratings yet

- Daikin ControlDocument175 pagesDaikin Controlchinitn100% (1)

- Wartsila O E RT Flex96C B MIM Part 2 of 2Document352 pagesWartsila O E RT Flex96C B MIM Part 2 of 2Uhrin Imre83% (6)