Professional Documents

Culture Documents

IEEE Education Society Papers-04448417

Uploaded by

Anoop MathewCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IEEE Education Society Papers-04448417

Uploaded by

Anoop MathewCopyright:

Available Formats

108

IEEE TRANSACTIONS ON EDUCATION, VOL. 51, NO. 1, FEBRUARY 2008

Project-Based Lab Teaching for

Power Electronics and Drives

Rui Hong Chu, Dylan Dah-Chuan Lu, Member, IEEE, and S. Sathiakumar, Senior Member, IEEE

AbstractProject-based learning motivates students to learn

actively, so it has been widely applied to many engineering subjects. However, the applications of this approach are limited in

electric power courses because of the hazards associated with

high voltage or mains voltage (240 V in Australia). This paper

presents a project designed for a Power Electronics and Drives

course. In this project, students use a programmable intelligent

computer (PIC) microcontroller and an H-bridge to design a

control system for a real practical application, such as a washing

machine, tram, or electric lift. Students gain hands-on experience,

and also improve their skill in product development, self-directed

learning, teamwork, and project management. Practical projects

increase the challenge for students and, hence, their interest level.

The project includes both hardware and software. Each part of

the project and the student assessment are described here.

Index TermsH-bridge, motor control, programmable intelligent computer (PIC) microcontroller, project-based lab teaching.

I. INTRODUCTION

ABORATORY and practical classes play an important role

in the education of scientists and engineers [1]. In the field

of engineering education, the latest research shows that laboratory work greatly increases students understanding. In addition, such practical work develops students towards the following learning goals [2]:

gaining practical skills and experience with equipment;

linking theory and practice;

gathering, manipulating, and interpreting data;

forming and testing hypotheses;

developing problem solving techniques;

becoming motivated and excited.

Lab classes are normally a necessary part of a curriculum for

electrical and electronic courses at the School of Electrical and

Information Engineering, University of Sydney, Australia. In a

lab class, students work in a group, follow a lab manual, set

up a circuit, test items required in the manual, and then analyze results. In this paper, this teaching procedure is referred to

as routine lab teaching, for comparison with project-based lab

teaching approach. Students can achieve the specified goals provided they are already keen to learn and to think for themselves.

Routine lab teaching, however, is felt to be ineffective in generating student enthusiasm and passion for learning. In this case,

Manuscript received December 7, 2006; revised June 24, 2007.

The authors are with the School of Electrical and Information Engineering,

Darlington Campus, The University of Sydney, NSW, 2006, Australia (e-mail:

ruihong@ee.usyd.edu.au).

Color versions of one or more of the figures in this paper are available online

at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/TE.2007.906607

students may not fully achieve the required goals, or may be

slow to reach their full creative talent and engineering potential.

Project-based learning is a student-centered strategy that fosters initiative and focuses the student on authentic real-world,

open-ended projects that can increase motivation for the majority of students, and enhance their learning [3], [4]. Students

not only maximize their practical learning experience to achieve

the listed above goals, but also develop other important abilities

in the following.

Cooperation and group work: students must learn to communicate in order to distribute the workload, discuss problems, and integrate the overall program.

Self-directed learning: as a project may involve multidisciplinary knowledge which is not standard lecture material,

students are driven to study and seek solutions which serve

to enhance their understanding of the theoretical material.

Project management: students organize a task based on the

talents of each group member, and each must define their

own task and manage their progress against a specified

timeline.

Product design: students have more scope to develop the

project so as to display their inventiveness.

All of these abilities are critical requirements in engineering

education.

Project-oriented learning for an electric machinery course

has been recently described [5], [6] which used embedded controller or computer-assisted methods to control machines. By

providing students with the opportunity to apply the knowledge

they have learned, the electric machinery course becomes more

appealing to them. However, in a course on Power Electronics

and Drives, high mains voltage, as well as the mechanical

hazards associated with motors, make it difficult to introduce

project-based lab teaching. To solve this problem, a project is

introduced which uses a programmable intelligent computer

(PIC) microcontroller and H-bridge to design a control system

for dc machines in order to simulate a practical application,

such as, a washing machine, an electric lift, or a tram or robot.

Senior students are perfectly safe working in the laboratory as

the power source and the control signals are all below 20 V.

Sections II and III of this paper present an overview of the

course and of the project, respectively. Sections IV, V, and VI

present details of this project, which include a PIC motor development (PIC_MCD) board, an H-bridge, and software development for the application of a washing machine and electric lift.

Section VII reports student feedback on the course.

II. COURSE OVERVIEW

Power Electronics and Drives is a third-year undergraduate

core subject in Electrical, Aerospace, and Mechatronic Engi-

0018-9359/$25.00 2008 IEEE

CHU et al.: PROJECT-BASED LAB TEACHING FOR POWER ELECTRONICS AND DRIVES

Fig. 1. Block diagram of the power electronics drive system.

neering at the University of Sydney. Conducted over the 13

weeks of one semester, the course consists of a weekly twohour lecture, supported by an alternating three-hour lab and a

one-hour tutorial. The topics covered in the course include fundamentals of magnetism and mechanics, dc machines, power

electronics devices, dcac, dcdc and acdc switching power

converters, 3-phase, 6-pulse rectifiers, and electronic control

of dc machines. The practical work includes four routine labs

and the project. The four routine labs (dc generator and motor,

three-phase rectifier, dc boost converter, and 4-quadrant dc machine control) are held in the first half of the semester, and familiarize students with real-world power electronics and machine

processes. The project started in the middle of the semester, immediately after the completion of the four routine labs, when

students had gained adequate theoretical knowledge (from lectures) and laboratory skills (from routine labs).

III. PROJECT SETUP AND ORGANIZATION

The project implements a power electronics drive system

shown in Fig. 1, using a PIC microcontroller and an H-bridge

to drive a dc motor for a particular application. Each part of the

setup in Fig. 1 is described briefly below.

Load: Students need to decide on an end application (load) to

implement the control process, for example, a washing machine,

an electric lift, a tram, a robotic system, etc.

Each different load application requires a particular type of

motor control.

DC motor: A 12-V, 1-A, 8100-rpm dc electric motor is provided. The motor can output 5.56 W of power and 40 g.cm of

torque, which is adequate to simulate a particular application

and safe for students to test in a laboratory.

Power electronics: Students need to develop the hands-on experience to build a H-bridge for a motor drive, is detailed in

Section V.

Microcontroller: The H-bridge needs the correct sequence of

pulses, known as pulse-width-modulation (PWM) control technique [7], at the gate-source terminals of the MOSFETs in order

to drive a motor. Students use a standard PIC_MCD board and

associated MPLAB package [8] and MCD bootloader for software development. Students program the PIC microcontroller

using Assembly or C programming language to output suitable

PWM pulses to the H-bridge. See Section IV for details.

109

Power sources: The PIC_MCD board operates at 5 V dc.

The power source for the student-made H-bridge can be operated from 10 V dc to 20 V dc. A Topward dc supply with

two outputs of 30 V, 2 A, and one output of 5 V, 3 A is sufficient

to power all the circuits in the laboratory.

Transducers/sensors: The transducers are used to sense a

signal of voltage, current, speed, torque or shaft position of the

load, which is sent back to the microcontroller to monitor and

regulate desired output variables. Students are required to design and build their own sensing circuits to provide a feedback

signal to the microcontroller. Details are given in Section VI.

To guide students in developing the project, they are given

the following basic required specifications as a baseline which

is not intended to be limiting.

Washing machine

Mimic the washing, rinsing and spin drying modes.

Spin in either direction and with different speeds in the

modes.

Use a graphical user interface (GUI) or push-button

and knob on the PIC_MCD board for washing program

selection.

Model train

Mimic the train going from one station to another by

showing the slow start to full steady state speed of the

motor, and vice versa.

Mimic the train going backwards slowly, in order to adjust its relative position to the platform.

Use a GUI or push-button and knob on the PIC_MCD

board to select different tracks.

Electric lift

Mimic a lift going up and down with frequent stops for

passengers going in and out of the lift.

Mimic different passenger weights on the lift with entry

and exit at different levels.

Use a GUI or push-button and knob on the PIC_MCD

board to choose different levels and stops.

During the last six weeks of the semester, the 82 students in

the class were placed in groups of 46 people for the project

work. Project support took several forms:

the scheduled lecture, tutorial, and laboratory sessions offered adequate support and discussion for students to develop a basic understanding of the drive system;

the laboratory was readily available during university

hours;

the necessary equipment (dc power supply, oscilloscope,

dc motor, soldering station, veroboard, wires, and computers loaded with the MPLAB software and bootloader)

were available in the laboratory;

components for making an H-bridge were provided;

a website which included all of the relevant information for

the project was provided;

students could choose an alternative application, in consultation with the laboratory supervisor, upon which to implement the drive system.

At the end of the project, each student was assessed on their

individual report of the project and their contributions to the

group work. In the individual report, students were required to

display their understanding of the overall project, and in par-

110

IEEE TRANSACTIONS ON EDUCATION, VOL. 51, NO. 1, FEBRUARY 2008

of complementary or four PWM signals to control the gates

of the four MOSFETs in the H-bridge. The ADC was used

to implement feedback control of the motor drive system by

connecting sensing circuits to 20-pin headers, or to existing

three finger-adjust pots on the board. A RS232 port provided

a GUI interface and also allowed input from product users.

Other functions, such as emergency stop, rotation control,

and start/stop can be implemented by using four pushbutton

switches on the board. The serial 8-bit LED indicators and their

different combinations gave the appropriate indications for a

motor operating in various stages and were also very helpful in

developing the software program. A MPLAB ICD2 debugger

[8] or a PRESTO that has a Microchip ICSP compatible programming port and that supports the PIC18F4431 chip was

used to program the microcontroller. Due to a limited supply

of MPLAB ICD2 and PRESTO programmers, some students

used the MCD bootloader and RS232 port to program the

microcontroller.

Fig. 2. The layout of PIC_MCD board.

ticular, describe their own contribution to the project in detail.

The assessment of the group work was conducted through group

presentations, where each student explained and demonstrated

the operation of the product they had designed. This assessment

scheme was fair and comprehensive for the students and prevented possible plagiarism.

IV. PIC18F4431 MOTOR CONTROL DEVELOPMENT

BOARDPIC_MCD

The PIC18F4431 MCD Board is designed to allow a

Microchip 18F4431 microcontroller to be easily interfaced to

the dc/ac motor control power electronics, as shown in Fig. 2.

This particular microcontroller has an inbuilt PWM module

with provision for up to four sets of complementary drive

waveforms and a nine channel 10-b A/D converter. Despite its

suitability for PWM applications, the PIC_MCD Board can

also be used as a general-purpose microcontroller development

board. The main features of the PIC_MCD board are

four complementary pairs of PWM output;

four pushbutton switches;

three finger-adjustable pots for analog inputs connecting to

analog-to- digital converter (ADC) modules;

RS232 port;

serial 8-bit LED indicator;

serial EEPROM;

2-mm and 4-mm sockets for the power supply connection;

two programming sockets: one general-purpose 5-pin

header for use with a PRESTO programmer or similar;

one Microchip ICSP programmer or compatible;

processor reset switch;

external access to processor pins via two banks of 20-pin

headers, that can easily be connected with an external PCB

or circuit.

A PIC_MCD board was provided to each group for this

project. Students used the board to output either two pairs

V. H-BRIDGEPOWER CONVERTER

The schematic circuit diagram of an isolated 4-quadrant

converter is shown in Fig. 3. Students were required to build

and test the converter based on the circuit. The MOSFETs

(FQPF65N06) Q1Q4 are the heart of the converter, which provides the average voltage (positive or negative) across the load

(motor) connected to the OUTPUT and current flows in either

is obtained, in

direction. The equation

which

is the output voltage,

is the DC supply voltage,

is the duty cycle of Q1 and Q4. The duty cycle of Q2

and

. From the above equation, it can be

and Q3 is simply

seen that the magnitude and polarity of the output voltage are

controlled by the duty cycle in this converter.

In order to switch the MOSFET Q1Q4 properly, two gate

drivers (IR2101) and four opto-couplers (HCPL2200) are

necessary. After programming suitable PWM signals to the

PIC_MCD board, the four PWM signals are sent to Q1, Q2,

Q3, and Q4 of the connector INPUT on the H-bridge by a 9-pin

D connector on the PIC_MCD board. The PWM signals are

fed to the LED anode of the opto-couplers. The phototransistor

amplifies the input signal and provides an isolated signal to the

inputs of the gate drivers. The two gate drivers provide gate

signals to the MOSFET Q1, Q2, Q3, and Q4, and Q1/Q2 or

Q3/Q4 are switched in a complementary manner.

A voltage of 15 V dc is supplied for the integrated circuits

opto-couplers and gate-drivers. Another 12 V is connected to

dc to provide dc bus voltage of the power converter.

VI. SOFTWARE DEVELOPMENT

A. Motor Control Strategy

The PWM control strategy is applied to a 4-quadrant converter for the motor drive system [7]. Fig. 4 shows the relationship between duty cycles of the PWM, and motor speed as well

as rotation. As shown by the equation in Section V, when the

duty cycle of the PWM is 50%, the average voltage across the

armature of a motor is zero, and, hence, the motor is stationary.

As the duty cycle increases, the speed of the motor increases

until it reaches the maximum speed in one direction at the duty

CHU et al.: PROJECT-BASED LAB TEACHING FOR POWER ELECTRONICS AND DRIVES

111

Fig. 3. The schematic circuit diagram of the isolated 4-quadrant converter.

Fig. 4. Relationship between duty cycles of PWM and motor movement.

cycle of 100%, and vice versa. Therefore, the speed and rotation of a dc motor can be adjusted by PWM signals from the

microcontroller.

B. MicrocontrollerPIC 18F4431

Microchips PIC 184431 microcontroller [9], which has the

PWM module designed particularly for power and motion control applications, was chosen for this project. The operation of

the PWM module is controlled by a total of 22 registers, which

are PWM control, PWM timer control, dead time control, PWM

period and duty cycle registers. In order for the motor to operate quietly, a switching frequency of between 520 kHz is programmed by PWM time base registers (PTMRH and PTMRL)

and PWM period registers (PTPERH and PTPERL). The dead

is set in the dead time control regtime of between 510

ister (DTCON) to protect MOSFETs. There are a total of 4 pairs

of PWM duty cycle registers defined by PDCx registers, which

generate four pairs of PWM channels that can be defined as independent or complementary mode through the PWM control

registers 0 and 1 (PWMCON0 and PWMCON1). In this project,

two pairs of complementary PWM outputs are required to control four MOSFETs in the H-bridge.

The PIC 18F4431 has a 10-b high-speed ADC module that

can be applied to motor control, sensor interfacing, and data

acquisition. The module has 9 registers, which consist of an

A/D result high/low register (ADRESH and ADRESL), A/D

control registers, an A/D channel select register (ADCHS),

and analog I/O select registers. In this project students used an

ADC that was connected to the finger-adjustable pots on the

PIC_MCD board in order to change the duty cycle either to

control the speed of a motor, or to interface with the feedback

control circuits.

C. Software Development for a Washing Machine

In this subsection, a washing machine is used as an example to

illustrate the details of software development. As stated above,

students can use either Assembly or C language to develop the

software. Since students enrolled in this subject had different

levels of knowledge of the microcontrollers, a sample code in

ASSEMBLY was provided, in which the basic configuration of

the PIC 18F4431 and PIC_MCD boards, the initializations of

the PWM module and the ADC module, and the concept of the

changing duty cycles of the PWM, were presented. Given this

information, and discussion with the lab supervisor, students

could quickly get on the right track.

The conceptual design of a washing machine from one group

of students is shown in Fig. 5. A user can select the options, auto,

heavy, regular, and light wash, from the liquid crystal display

(LCD). At any time, the exit/stop button can be pushed to stop

the machine and jump back to the beginning of the program [10].

Except for the programming of the LCD module, push button

and menu selection, the principal tasks were to program the

PWM and the ADC module, which are the main functions of

the PIC 18F4431 used in this project. If the selection made is

of heavy, regular, or light wash mode, the different duty cycle

values of D are set to the duty cycle register PDCx to start the

wash in one direction. Then a delay of 1.5 s and the turning off

of the PWM are executed. After this, a duty cycle of (1-D) is

loaded to the duty cycle register to start the wash in the opposite

direction, again followed by a delay of 1.5 s and the turning off

of the PWM. The whole process is repeated if necessary.

The ADC is used for speed feedback control to implement

the auto wash mode. Fig. 6 shows the schematic block diagram

of the closed loop system which uses a generator and a gearbox

to generate a voltage as a feedback signal, which is sent to the

ADC module on the PIC_MCD board. To ensure that the analog

required by

signal from the generator is within the

the microcontroller, a gearbox was used to change the angular

velocity.

To bring the washing machine closer to a mature product,

students developed several extra features. For example, push

buttons were affixed to the exterior of the system through the

external interrupt pins of the microcontroller to allow communication between users and the system; the HD44780U dot matrix LCD controller was used for the output interface, to yield a

112

IEEE TRANSACTIONS ON EDUCATION, VOL. 51, NO. 1, FEBRUARY 2008

Fig. 5. Conceptual design of a washing machine.

Fig. 6. Schematic block diagram of the close loop system of washing machine.

Fig. 7. Schematic block diagram of the closed loop system of the electric lift.

complete, user-friendly design; and pleasant music was played

at the end of each washing stage.

D. Software Development for an Electric Lift

To adjust the speed and direction for the electric lift, the programming for the PWM module is similar to that of the washing

machine. But here two feedback systems are required to indicate

the lift level and to control the speed, respectively. Fig. 7 shows

the feedback systems designed by one group of students. The G

in Fig. 7 was a generator coupled with the motor M to measure

the speed as it delivered a voltage proportional to the speed of

to

the driving motor [7]. The voltage range of

from the generator refers to the maximum speed of the lift in either direction. Since the ADC module in PIC 18F4431 requires

to make a valid conversion, a cira voltage between

cuit using Op-amp 741 was designed to convert the voltage from

, to

[11].

To detect the level of a lift, an optical sensing circuit, including a light-dependent resistor (LDR) and an LED, was designed to indicate every location on the shaft where the lift

stopped [11]. The LED shone directly into the LDR, causing

its resistance to drop to its lowest value. As the lift reached a

level, the light beam was cut, causing the LDRs resistance to increase dramatically. The voltage between the LDRs were measured and sent to the ADC module of the PIC_MCD board. By

detecting the status of the pins of the ADC module, the current

position of the lift was detected.

VII. STUDENT ASSESSMENT

A survey was conducted at the end of the semester. The majority of students (68%) agreed or strongly agreed that they were

satisfied with this subject. Also, 65% of the students thought that

this subject helped them to develop valuable generic attributes

(e.g., research inquiry skills, communication skills, personal intellectual autonomy, etc.). The feedback from students showed

CHU et al.: PROJECT-BASED LAB TEACHING FOR POWER ELECTRONICS AND DRIVES

that the project-based lab teaching was more appealing than routine lab work because it motivated students predominantly to

learn and understand. Most students acknowledged that they understood the PWM control strategy, and became familiar with

motor driving systems, including hardware and software. More

importantly they acquired project management abilities and improved group-working skills.

However, there were some comments on prerequisite subjects. Some (12%) of the students considered that prior learning

did not adequately prepare them for this subject. Half of the students enrolled in the subject were from Mechatronics, and had

been exposed to PIC microcontrollers; whereas the other half

were from Electrical Engineering, and had not. This situation

posed some difficulties, which will be addressed next year by

adding a lecture and tutorial on the PIC 18F4431. Moreover, to

balance the relative workload demands between hardware and

software involved in the project, the hardware work will be made

more demanding, and the software work will be simplified in

order to be fair for all the students enrolled in this subject.

VIII. CONCLUSION

This paper presents an example of applying project-based lab

teaching in a Power Electronic and Drives course, and demonstrates that this approach can be applied safely to this subject

area so as to make a power electronic lab more appealing to

students.

The paper describes the details of the project, including

the organization, hardware and software, and assessment. The

project meets the syllabus requirements for this subject and is

safe for students to implement in a laboratory environment.

Student understanding of motor drive systems was improved,

as were student skills in practical work, software development,

teamwork, and project management. The project defined basic

specifications for students to achieve, and also gave them

freedom to design additional features. Students gained the

abilities to deal with real-life practical problems, and to apply

their knowledge to solve realistic problems. Students found

developing a relatively complicated engineering product to be

a highly positive learning experience.

ACKNOWLEDGMENT

The authors would like to thank T. Wood for preparing the

PIC_MCD board and MCD bootloader for this project, and

R. Sutton and Prof. G. Lucas for reviewing the manuscript.

The authors also appreciate the constructive comments of the

reviewers.

113

REFERENCES

[1] D. Boud, J. Dunn, and E. Hegarty-Hazel, Teaching in Laboratories.

Guildford, U.K.: Society for Research into Higher Education, 1986.

[2] H. Fry, S. Ketteridge, and S. Marshall, A Handbook for Teaching &

Learning In Higher Education, Enhancing Academic Practice, 2nd

ed. London, U.K.: Kogan Page, 2003.

[3] H. Markkanen, G. Donzellini, and D. Ponta, NetPro: Methodologies

and tools for project based learning in Internet, in Proc. EDMEDIA

World Conf. Educational Multimedia, Hypermedia Telecommunications, Chesapeake, VA, 2001, pp. 12301235.

[4] D. Ponta, G. Donzellini, and H. Markkanen, NetPro: Network based

project learning in Internet, in Proc. Euro. Symp. Intelligent Technologies, Hybrid Systems and Their Implementation on Smart Adaptive Systems, Albufeira, Portugal, 2002, pp. 703708.

[5] S. Li and R. Challo, Restructuring an electric machinery course with

an integrative approach and computer-assisted teaching methodology,

IEEE Trans. Educ., vol. 49, no. 1, pp. 1628, Feb. 2006.

[6] E. Mese, Project-oriented adjustable speed motor drive course for undergraduate curricula, IEEE Trans. Educ., vol. 49, no. 2, pp. 236246,

May 2006.

[7] T. Wildi, Electrical Machines, Drives, and Power Systems, 6th ed.

Englewood Cliffs, NJ: Prentice-Hall, 2006.

[8] MPLAB Integrated Development Environment, Part Number:

SW007002, Microchip Technology Inc., Chandler, AZ [Online].

Available: http://www.microchip.com

[9] PIC18F2331/2431/4331/4431 Data Sheet, Microchip Technology Inc.,

Chandler, AZ [Online]. Available: http://www.microchip.com

[10] X. Yao, Elec3204 Term ProjectWashing Machine School of EIE,

Univ. Sydney, Australia, Tech. Rep. Group 7H, Oct. 2006.

[11] B. W. Zang, Elec3204 Term ProjectElectric Lift School of EIE,

Univ. Sydney, Australia, Tech. Rep. Group 4H, Oct. 2006.

Rui Hong Chu received the B.S. and M.S. degrees in electrical engineering

from Xian Jiao Tong University, China and the Ph.D. degree in electrical and information engineering from the University of Sydney, Australia, in 1989, 1992,

and 2004, respectively.

From 1992 to 1998, she was an Electrical Engineer at the Northwest Electric Power Research and Test Institute, Xian, China. She was with EnergyAustralia, Sydney, in 2003 until joining the School of Electrical and Information

Engineering, University of Sydney, in 2004.

Dylan Dah-Chuan Lu (S00M01) received the B.Eng.(Hons.) and Ph.D. degrees in electronic and information engineering from The Hong Kong Polytechnic University, Kowloon, Hong Kong, in 1999 and 2004, respectively.

In 2003, he joined PowerLab Limited, a spin-off company at The University

of Hong Kong, as a Senior Engineer. Currently, he is a Lecturer at the School

of Electrical and Information Engineering, The University of Sydney, Australia.

His research interests include modeling, synthesis and computer-aided design

of power converters, dc-dc converters for VRM applications, electronic ballast, controls, power-factor-correction circuits, soft-switching techniques, and

renewable electrical energy systems.

S. Sathiakumar (S82M85SM04) received the B.E., M.E., and Ph.D. degrees in electrical engineering from the Indian Institute of Science, Bangalore,

India.

His industrial experience includes working at the English Electric Company

of India Ltd., and the Indian Institute of Science before becoming Lecturer at the

University of Newcastle, Australia, until 1991. Currently, he is a Senior Lecturer

at the University of Sydney, Australia. His fields of interest are adaptive control

of electric machines, application of microprocessors and power converters for

real-time control, harmonic pollutionless PWM switching techniques for power

conversion, and renewable energy resources.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- VP Construction Real Estate Development in NY NJ Resume Edward CondolonDocument4 pagesVP Construction Real Estate Development in NY NJ Resume Edward CondolonEdwardCondolonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chapter Two Complexity AnalysisDocument40 pagesChapter Two Complexity AnalysisSoressa HassenNo ratings yet

- Preventing OOS DeficienciesDocument65 pagesPreventing OOS Deficienciesnsk79in@gmail.comNo ratings yet

- Amazon Case StudyDocument22 pagesAmazon Case StudySaad Memon50% (6)

- Steam Source Book PDFDocument108 pagesSteam Source Book PDFJose Levican A100% (1)

- Power Electronics Slides and Notes DC ConvertersDocument40 pagesPower Electronics Slides and Notes DC ConvertersAnoop MathewNo ratings yet

- Managerial Accounting-Fundamental Concepts and Costing Systems For Cost Analysis Module 1Document40 pagesManagerial Accounting-Fundamental Concepts and Costing Systems For Cost Analysis Module 1Uzma Khan100% (1)

- Artsenz Biz PlanDocument1 pageArtsenz Biz PlanAnoop MathewNo ratings yet

- Armature Reaction and CommutationDocument4 pagesArmature Reaction and CommutationAnoop MathewNo ratings yet

- Power Electronics Ned Mohan Slides Ch29Document12 pagesPower Electronics Ned Mohan Slides Ch29Anoop MathewNo ratings yet

- Power Electronics Ned Mohan Slides Ch30Document48 pagesPower Electronics Ned Mohan Slides Ch30Anoop MathewNo ratings yet

- Power Electronics Ned Mohan Slides Ch30Document48 pagesPower Electronics Ned Mohan Slides Ch30Anoop MathewNo ratings yet

- Power Electronics Ned Mohan Slides Ch26Document44 pagesPower Electronics Ned Mohan Slides Ch26Anoop MathewNo ratings yet

- Power Electronics Ned Mohan Slides Ch26Document44 pagesPower Electronics Ned Mohan Slides Ch26Anoop MathewNo ratings yet

- Power Electronics Ned Mohan Slides Ch28Document26 pagesPower Electronics Ned Mohan Slides Ch28Anoop MathewNo ratings yet

- Power Electronics Ned Mohan Slides Ch29Document12 pagesPower Electronics Ned Mohan Slides Ch29Anoop MathewNo ratings yet

- Power Electronics Ned Mohan Slides Ch22Document35 pagesPower Electronics Ned Mohan Slides Ch22Anoop MathewNo ratings yet

- Power Electronics Ned Mohan Slides Ch21Document27 pagesPower Electronics Ned Mohan Slides Ch21Anoop MathewNo ratings yet

- Power Electronics Ned Mohan Slides Ch19Document17 pagesPower Electronics Ned Mohan Slides Ch19Anoop MathewNo ratings yet

- Starkville Dispatch Eedition 12-9-18Document28 pagesStarkville Dispatch Eedition 12-9-18The DispatchNo ratings yet

- Numerical Transformer Differential RelayDocument2 pagesNumerical Transformer Differential RelayTariq Mohammed OmarNo ratings yet

- Leeka Kheifets PrincipleDocument6 pagesLeeka Kheifets PrincipleAlexandreau del FierroNo ratings yet

- C Sharp Logical TestDocument6 pagesC Sharp Logical TestBogor0251No ratings yet

- V Series: Three Wheel, Counterbalanced Lift TruckDocument126 pagesV Series: Three Wheel, Counterbalanced Lift TruckВиктор МушкинNo ratings yet

- Terms and Conditions 27 06 PDFDocument4 pagesTerms and Conditions 27 06 PDFShreyash NaikwadiNo ratings yet

- Matrix of Consumer Agencies and Areas of Concern: Specific Concern Agency ConcernedDocument4 pagesMatrix of Consumer Agencies and Areas of Concern: Specific Concern Agency ConcernedAJ SantosNo ratings yet

- Oxygen BarrierDocument20 pagesOxygen BarrierKarina ArdizziNo ratings yet

- Sangeetahealingtemples Com Tarot Card Reading Course in UsaDocument3 pagesSangeetahealingtemples Com Tarot Card Reading Course in UsaSangeetahealing templesNo ratings yet

- Document 3Document3 pagesDocument 3AdeleNo ratings yet

- PanasonicDocument35 pagesPanasonicAsif Shaikh0% (1)

- Unit 5 Andhra Pradesh.Document18 pagesUnit 5 Andhra Pradesh.Charu ModiNo ratings yet

- Reference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsDocument43 pagesReference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsNisha JosephNo ratings yet

- Bismillah SpeechDocument2 pagesBismillah SpeechanggiNo ratings yet

- Quantum Hopfield NetworksDocument83 pagesQuantum Hopfield NetworksSiddharth SharmaNo ratings yet

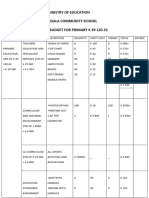

- Ministry of Education Musala SCHDocument5 pagesMinistry of Education Musala SCHlaonimosesNo ratings yet

- Pega AcademyDocument10 pagesPega AcademySasidharNo ratings yet

- Heat Exchanger Designing Using Aspen PlusDocument6 pagesHeat Exchanger Designing Using Aspen PlusMeethiPotterNo ratings yet

- Entrep Q4 - Module 7Document5 pagesEntrep Q4 - Module 7Paula DT PelitoNo ratings yet

- Beam Deflection by Double Integration MethodDocument21 pagesBeam Deflection by Double Integration MethodDanielle Ruthie GalitNo ratings yet

- Remuneration Is Defined As Payment or Compensation Received For Services or Employment andDocument3 pagesRemuneration Is Defined As Payment or Compensation Received For Services or Employment andWitty BlinkzNo ratings yet

- Minor Project Report Format MCADocument11 pagesMinor Project Report Format MCAAnurag AroraNo ratings yet

- Insurance Smart Sampoorna RakshaDocument10 pagesInsurance Smart Sampoorna RakshaRISHAB CHETRINo ratings yet

- Go Ask Alice EssayDocument6 pagesGo Ask Alice Essayafhbexrci100% (2)