Professional Documents

Culture Documents

Us 3690255

Uploaded by

wewewewCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 3690255

Uploaded by

wewewewCopyright:

Available Formats

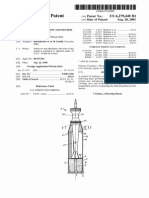

United States Patent

{15]

Vass et all.

[451 Sept. 12, 1972

[54]

LIQUID PROPELLANT CARTRIDGE

[72] Inventors: Edward J. Vass, Los Alamitos;

Richard H. Braun, Downey; Conrad

R. Platt, Huntington Beach, all of

Calif.

3,690,255

2,984,973

5/1961

Stegelman .......... ..60/39.48 X

2,872,870

3,195,407

2/1959

7/1965

Gey ....................... .. l02/39 X

Turner ........................... ..89/7

Primary Examiner-Samuel W. Engle

Attorney-Harry A. Herbert, Jr. and Ruth G. Codier

[73] Assignee: The United States of America as

represented by the Secretary of the

Ail Fore?

Oct 1, 1970

[22] Filed;

[57]

ABSTRACT

A system for controlled generation of high energy gas

from a liquid _propella_nt,_based upon a differential

area piston injecting liquld propellant mto a com

[21] APPl- N-1 77,160

bustion chamber in a regenerative cycle. One of its ap

plications is for cartridge bomb ejection. Pressure of

burning fuel ?red by a primer ruptures seals in a

[22] 98.3]. .......................... ..102/39, 89/7,_60/26.l . piston wall and causes extrusion of liquid fuel from a

[ 1 [3t- ...............................................

reservoir area into the piston Cavity

lies in the

[58] Fleld of Search ........ ..60/218, 26.1, 39.48; 89/7;

combustion area Combustion of the extruded liquid

7 81/1; 102/39

carries on a regenerative process until all fuel in the

[56]

reservoir has been consumed.

References Cited

UNITED STATES PATENTS

2,918,791

12/1959

1 Claim, 5 Drawing Figures

Greiner............... ..60/39.48 X

3% J7

7 \\\ \\\\ \ /

8/

4? dc

/ '

1% .57 7? 36

/

10

\\\\ _\\_\.\

5-1-12;

\ 3a

19

'

f3

#vl

2d

M

I I I I

2?? II

A 11-5.;

7 : 2 12%

25'

_._ r -

- _

_Z__

I - - -\

Z '"

7/

"__-\

" I _2_ T_\

-

[6 /

I 1' I. \

f1

\\\\' (3a

_ \\

"1 1 t. \

A]

(a

Z6

PATENTEnsar 12 1972

3.690.255

sum 2 or 2

76

.72

:Flrs 5

D

W37 7"

3,690,255

_ LIQUID PROPELLANT CARTRIDGE

DESCRIPTION OF THE DRAWINGS

BACKGROUND OF THE INVENTION _

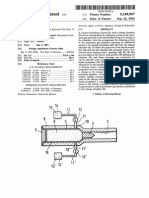

FIG. 1 is a longitudinal sectional view of the car

tridge assembly;

This invention relates to a system for controlled

generation of high energy gas from a liquid propellant,

and more particularly to a device which includes 'a dif

ferential area piston for a liquid propellant cartridge in

a bomb ejection system.

?ces;

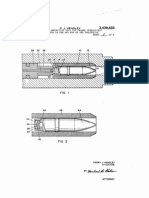

FIG. 3 is a-longitudinal sectional view of the piston

removed from the casing and taken on the line 3-3 of

Difficulty has been experienced in controlling com

FIG. 2; _

bustion rates. Systems were proposed based on a regu

lated ?owof liquid propellant from a two chamber car

tridge. This was expected to extend the burn time of the

developed; and

cartridge.

was expected to exert a pressure on a movable piston

second chamber and ejected it into a combustion area. 20

The rate at which the liquid burned'in'the- combustion

The problem .with this approach is typical of any con

propellant. The burning rate cannotbe controlled as it

is a function of the liquid s surface area. As ignition and

burning of the liquid take place, the surface area of the

liquid increases rapidly in a random manner to the ex

EMBODIMENT

The cartridge assembly is indicated generally by the

numeral 10. A'differential area piston 12 is assembled

into a casing 14 and sealed into place by a closure 16. A

chamber regulated the ?ow rate of the liquid-through

the ori?ce connecting the two chambers. The time of

ori?ce opening was expectedto be controlled by a dif-

cept dependent on the con?ned burning of bulk liquid

DESCRIPTION OF THE PREFERRED

which,_in turn, pressurized the liquid propellant in a

into'a pass channel from the?rst chamber.

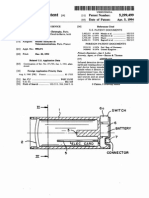

FIG. 5 is a breech assembly incorporating a modified

a primer in the ?rst of the two chambers. The com

bustion in the ?rst chamber located next to the primer

was expected to be accomplished byflame bleedoff

tion of the device. It is the original concept from which

the preferred embodiment of FIGS. -1, _2 and 3 was

liquid propellant to achieve relatively long, low-pres

ferential piston connected directly to the material to be

FIG. 4 is a longitudinal sectional view of a modi?ca

sure time curves. The liquid propellant was ignited with

_ ejected. Ignition of the liquid from the second chamber

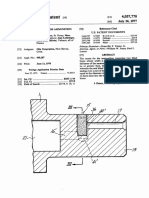

FIG.. 2 is a diagrammatic view of the piston face

showing the location of the ?ll hole and extrusion ori

primer assembly 18 is located. ina bore in. the closure

25

16. The bore extends completely through the closure

'16, accommodating also the ignition mix 19, when

function is to ignite the liquid propellant within a first

chamber 20. The piston 12,.the casing 14, and the clo

sure element 16 are fabricated of heat-treated steel for

strength and resistance to erosion. The piston 12 has a

free-volume internal cavity 21 to reduce the initial

combustion pressure. A pair of ori?ces, 22 and 24, pro

vide a metering entrance of the liquid burning material

from the second chamber 26 to the ?rst chamber 20.

tent that the burning process can occurv at the detona 35 The opening 28 functions as a ?ll hole. The piston 12 is

tion rate of the liquid.

'

Other dif?culties arose. Erosion became a problem. '

provided with grooves or recesses 30 and 32 to accom

Contamination occurred, particularly aluminum parti

also accommodate the retaining rings 37. The casing 14

modate the 0-rings 34 and 36. The recesses, 30 and 32,

cles' injected'from the cartridge case into the bomb 40 has two areas A and B with a differential internal

rack system.

diameter. The piston 12 has a corresponding dif

Furthermore, normal propyl nitrate (NPN), a liquid

propellant in general use, is incompatible with many

plastics and metals. Good sealing methods were dif

ficult to accomplish.

'

SUMMARY OF THE INVENTION

The objects of the invention are therefore, to provide

a regenerative system and a device which will:

a. reduce reactive forces by controlling the com

bustion rate of the liquid propellant;

b. increase the mean time between ejection-system

failures by using a liquid propellant having a low-com

bustion temperature, thus decreasing erosion;

c. reduce system contamination by decreasing

ferential in external diameters to ?t within areas A and

B of the casing 14, thus forming the chambers-20 and

26.

'

The ?rst or combustion chamber 20 is provided with

an exhaust port ori?ce 38. The closure 16 has an annu

lar shoulder which aligns thev assembly 10 when in

serted into a cartridge holder (not shown).

Since the liquid propellant normal propyl nitrate or

NPN which is used is incompatible with many plastics

and metals, the ori?ces 22 and 24 in the piston 12 are

sealed with epoxy adhesive and polyethylene plugs or

aluminum tape.

The 0-rings 34 and 36 are of ethylene propylene, or

comparable material and the retaining rings 37 are

residue through using liquid propellants and by

minimizing the quantity of aluminum particles injected

After the piston 12 has been inserted into the steel

from the cartridge case into the system; and

d. enable the system to withstand high temperatures.

casing 14 the liquid propellant is inserted through the

hole 28. The method used is to inject the liquid through

Epoxy adhesive and polythelane plugs are to be .used in

the piston ori?ces. Ethylene propylene and Teflon are

60 the hole 28 by means of a hypodermic needle and syr

inge so that any entrapped air will bleed back through

the hole. The quantity of fuel injected is measured and

one-piece steel case.

the hole sealed when the operation is completed.

These and other advantages, features and objects of 65 The closure plug 16 containing the primer assembly

18 is sealed onto the casing 14 with an epoxy seal.

the invention will become more apparent from the fol

lowing description taken in connection with the illus

The polyethylene plugs or aluminum tape used to

trative embodiments in the accompanying drawings.

cover the holes 22 and 24 rupture when the movement

used for 0-rings and piston seals. The piston casing is a

3,690,255

4

of the piston applies sufficient pressure against the

{team}: Si 322 iffdldbtiiilfdgfi?ngaesrsgge 5%; i?

NPN in the reservoir cavity 26. Until the proper pres

sure is applied, all of the NPN is contained in the car

tridge case 14 and held within the reservoir 27, since

54. The time of passage 54 opening is controlled by a

differential piston 64 connected directly to the stores

(not shown) to be ejected.

Ignition of the liquid from the second chamber 56 is

accomplished by a ?ame bleed off 66 into a by-pass

the cavity 26 is sealed by the piston O-ring 36. The cavi

ty 20 which is the combustion chamber is sealed by the

piston 0-ring 34, by the taped ori?ce 38 and the screw

46 closing the ori?ce 28.

When the pressure caused by the initial ?ring

channel 68.

Referring now to FIG. 5, a breech assembly 70 has a

primer recess 72, a transducer port 74 and an exhaust

reaches a predetermined level the sealing material of

port 76. A piston 78 provides a cavity 84 and separates

the ori?ces 22 and 24 rupture. The pressure of the

a ?rst chamber 82 from a combustion chamber 86.

piston 12 against the NPN causes extrusion of NPN

Recesses 88 and 90 house 0-rings 92 and 94 and a

into the chamber 20. The bores 22 and 24 are provided

back-up ring 96.

with counterbores 23 and 25 at the NPN piston surface

into which the sealing material can lodge without 15 Openings 98 provide a regulating ?ow from piston

clogging the ori?ce.

cavity area 84 to the combustion chamber 86.

In the operation of this device a regenerative process

MODE OF OPERATION

takes place as described above in the operation of the

The liquid propellant cartridge functions in the fol

lowing sequence:

Upon application of a ?ring pulse from a power

supply (not shown) the pyrotechnic mixture 19 within

the primer l8 ignites. Gas pressure and burning parti

cles accumulate in the cavity 20 at the large end of the

piston, and adjacent the primer 18. The cavity is

designed to provide free volume for gas expansion to

20

device of the preferred embodiment

Although the invention has been described with

reference to particular embodiments, it will be un

derstood to those skilled in the art that the invention is

capable of a variety of alternative embodiments within

the spirit and scope of the appended claims.

25

We claim:

1. A system for controlled generation of high energy

gas from a liquid propellant comprising: '

reduce the peak pressure. Some of the gas, escapes

a cylindrical casing having differential areas along its

through the exhaust port ori?ce 38. Simultaneous with

length,

this application of pressure, a reactive pressure greater

than that existing in the ?rst chamber 20 is created at 30 a close-?tting differential piston slidably disposed in

said cylindrical casing,

the small end of the piston 12 in the reservoir chamber

a reservoir chamber in said casing forward of said

26. This pressure differential is suf?cient to cause the

differential piston,

seals of the ori?ces 22, 24 and 28 to rupture, freeing

a combustion chamber in the central area of said dif

the liquid fuel in the reservoir chamber and allowing it

ferential piston,

to ?ow through these orifices. The ?ow rate is regu 35

a closure element ?xedly attached to the rearward

lated by the ori?ce size, the exhaust port size, and the

end of said casing for effectively sealing said com

differential pressure. As the liquid enters the cavity 20,

bustion chamber,

it is initiated and combusts.

a primer housed in a recess in said closure element,

The piston 12 is moved against the NPN by the initial

said primer being in operative communication

pressure of the primer and is sustained by the com 40

with said combustion chamber,

bustion of the liquid in the cavity 20. This causes the

a plurality of ori?ces in the closed forward end of

liquid to again be extruded through ori?ces 22, 24,

said differential piston in communication with said

passing from the reservoir chamber 26, through the

reservoir chamber, said ori?ces being dimensioned

piston ori?ces and into the combustion chamber 20.

to control the rate of flow of propellant into said

The residual combustion produced from the primer 18 45

combustion chamber,

again initiates the extruded liquid and it combusts at

rupturable seals covering each of said ori?ces, and

the large end of the piston in the cavity 20. This creates

a vent opening in said casing between said piston and

pressure in addition to that provided by the primer,

said closure element, said vent opening having a

regenerating the process until all the liquid in the reser

50

rupturable seal thereover for regulating the pres

voir 26 is extruded and consumed.

sure in said combustion chamber,

Referring now to FIG. 4, this Figure is a representa

whereby the ?ring of said primer causes pressure to

tion of the original form of the device from which the

build up in said combustion chamber and rupture

preferred embodiment was developed.

the vent opening seal while urging the piston for

In this embodiment, there is achieved a regulated

ward until the seals covering the ori?ces in said

?ow of liquid propellant from a cartridge 50 provided 55

differential piston are ruptured allowing liquid

with a pair of chambers 52 and 54 and a combustion

chamber 56. In this device the burn time of the propel

lant was extended and relatively long, low pressure

time curves were achieved. The liquid propellant is ig

nited with a primer 58 in the ?rst chamber 52. The 60

propellant in the reservoir chamber to pass into

the combustion chamber at a controllable rate and

be ignited by the residual combustion of the initial

?ring of said primer, thereby creating additional

pressure and regenerating the process until all of

the propellant in the reservoir chamber has flowed

into the combustion chamber and been consumed.

combustion in this chamber exerted pressure on the

movable piston 60. With the movement of the piston 60

the liquid propellant in the second chamber 54 ejects it

into the combustion area 56. The rate at which the

65

You might also like

- d20 Modern LVL 1-3 Le Chien de LonyxDocument6 pagesd20 Modern LVL 1-3 Le Chien de LonyxStéphane de DeckerNo ratings yet

- The Real Book Sixth Edition Volume 1 - TextDocument461 pagesThe Real Book Sixth Edition Volume 1 - Textnicholas.bowlerNo ratings yet

- SU Carbs TuningDocument13 pagesSU Carbs TuningXDBDNo ratings yet

- Intelectual Property Law (IPL) ReviewerDocument29 pagesIntelectual Property Law (IPL) ReviewerLove Lee Hallarsis Fabicon0% (1)

- Night of SilenceDocument2 pagesNight of SilenceMitchell Holland0% (6)

- Word Families Word Family PuzzlesDocument9 pagesWord Families Word Family PuzzlesflorenciabravoNo ratings yet

- Charles Nelson Pogue - US Patent - 1759354Document18 pagesCharles Nelson Pogue - US Patent - 1759354PM100% (1)

- GOOD MAN PRODUCTIONS, INC., V Corrie Covelli Civil Action Case No. 0:14-cv-62727-BBDocument13 pagesGOOD MAN PRODUCTIONS, INC., V Corrie Covelli Civil Action Case No. 0:14-cv-62727-BBCorrie CovelliNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Branding Five Steps Michael Johnson PDFDocument5 pagesBranding Five Steps Michael Johnson PDFZiad Bin Hashem0% (34)

- The Art of Conan ExilesDocument51 pagesThe Art of Conan Exileskamifede100% (1)

- TEPZZ - 4 885B - T: European Patent SpecificationDocument10 pagesTEPZZ - 4 885B - T: European Patent SpecificationshamsNo ratings yet

- Principles of Foundation Engineering Si Edition 8th Edition Das Solutions ManualDocument21 pagesPrinciples of Foundation Engineering Si Edition 8th Edition Das Solutions Manualallisontaylorfnrqzamgks100% (23)

- Umted States Patent (19) (11) Patent Number: 5,671,656: Cyphers Et A) - (45) Date of Patent: Sep. 30, 1997Document6 pagesUmted States Patent (19) (11) Patent Number: 5,671,656: Cyphers Et A) - (45) Date of Patent: Sep. 30, 1997zeichsteinNo ratings yet

- Siled Sept. 8, 1966: T, N. NccomeDocument5 pagesSiled Sept. 8, 1966: T, N. NccomeliNo ratings yet

- Depósito de Gases ResidualesDocument5 pagesDepósito de Gases ResidualesLuis BejaranoNo ratings yet

- Us 5149907Document7 pagesUs 5149907wewewewNo ratings yet

- Us2960824 PDFDocument5 pagesUs2960824 PDFgrigNo ratings yet

- United States Patent (191: Allum Et Al. (11) Patent NumberDocument12 pagesUnited States Patent (191: Allum Et Al. (11) Patent NumberdnddownloaderNo ratings yet

- H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Document4 pagesH. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Josh FullerNo ratings yet

- July 5, 1949. ' R. - Hasche - 2,475,282: Filed Jan. 21, 1946 ' 2 Sheets-Sheet 1Document5 pagesJuly 5, 1949. ' R. - Hasche - 2,475,282: Filed Jan. 21, 1946 ' 2 Sheets-Sheet 1Yanpiero BalladoresNo ratings yet

- United States Patent: (72) 3,195,589 7/1965 Houda, Jr..................... 141/82 XDocument6 pagesUnited States Patent: (72) 3,195,589 7/1965 Houda, Jr..................... 141/82 XMustafa ŞENNo ratings yet

- April 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965Document4 pagesApril 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965fgrt490No ratings yet

- United States PatentDocument5 pagesUnited States PatentPraveen SinghNo ratings yet

- United States Patent: Attorney-Pastoriza and KellyDocument4 pagesUnited States Patent: Attorney-Pastoriza and KellyEnrico FermiNo ratings yet

- United States PatentDocument5 pagesUnited States PatentAyu NurizzaNo ratings yet

- R.T MM MS: ' Filed July 28, 1965Document6 pagesR.T MM MS: ' Filed July 28, 1965Alexcel CorporalNo ratings yet

- Ullage CalculationDocument6 pagesUllage CalculationAamir Shahzad100% (2)

- US3094165 Wheeler Manfac-PatentDocument7 pagesUS3094165 Wheeler Manfac-Patentsoubhadra nagNo ratings yet

- Chapter 6 - Waste Heat Recovery DevicesDocument37 pagesChapter 6 - Waste Heat Recovery DevicesArshavin Watashi WaNo ratings yet

- Patent eDocument5 pagesPatent eDaniel OliveiraNo ratings yet

- Login Create Account (Free!) View Patents That Cite This Patent Click For Automatic Bibliography GenerationDocument8 pagesLogin Create Account (Free!) View Patents That Cite This Patent Click For Automatic Bibliography GenerationFilipNo ratings yet

- Filed Dec. 23, 1959: Aug. 15, 1961 L. A. Botkin 2,996,222Document4 pagesFiled Dec. 23, 1959: Aug. 15, 1961 L. A. Botkin 2,996,222sqmiNo ratings yet

- Dec. 6, 1966 R. M. Schrmer 3,289,409: (S Tij SDocument4 pagesDec. 6, 1966 R. M. Schrmer 3,289,409: (S Tij SAncaBotocNo ratings yet

- My Attorneys: Feb. 18, 1969 J. Britt EtalDocument4 pagesMy Attorneys: Feb. 18, 1969 J. Britt EtalBa1313yNo ratings yet

- Us 4037770Document3 pagesUs 4037770ererNo ratings yet

- United States Patent (19) : PerryDocument11 pagesUnited States Patent (19) : PerryDaniel MilanoNo ratings yet

- Aug. 15, 1967 H. Grigull Etal 3,335,462: 152088230340. B11346 Heinz 1'12? 83Document4 pagesAug. 15, 1967 H. Grigull Etal 3,335,462: 152088230340. B11346 Heinz 1'12? 83jaydevpatelNo ratings yet

- United States Patent (191: McguganDocument6 pagesUnited States Patent (191: McguganJamesStenhouseNo ratings yet

- Us 3407511Document5 pagesUs 3407511AhmadmartakNo ratings yet

- Hawkins US5011035Document5 pagesHawkins US5011035gobinath VPNo ratings yet

- United States Patent (19) : B JornstadDocument4 pagesUnited States Patent (19) : B JornstadlfilippiniNo ratings yet

- GT LL: NN W///, WM)Document5 pagesGT LL: NN W///, WM)lfilippiniNo ratings yet

- Us3850741 PDFDocument6 pagesUs3850741 PDFGandhi YellapuNo ratings yet

- US3782337Document7 pagesUS3782337Mustafa Umut SaracNo ratings yet

- Jan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LDocument6 pagesJan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LJesus ValleNo ratings yet

- 6665 3321 B558 6611 3346 SHHT 9999 0972 AAAA 8726 8378 10096 2676 2333Document8 pages6665 3321 B558 6611 3346 SHHT 9999 0972 AAAA 8726 8378 10096 2676 2333Brunno VasquesNo ratings yet

- Carbamate CondenserDocument23 pagesCarbamate Condensersaramartori.2002No ratings yet

- United States Patent: (45) June 27, 1972Document12 pagesUnited States Patent: (45) June 27, 1972Jaime Ocampo SalgadoNo ratings yet

- Us5361479 PDFDocument5 pagesUs5361479 PDFmohammadreza91No ratings yet

- Original: FiledDocument4 pagesOriginal: FiledwcaskeyNo ratings yet

- Olin BWP Primer Patent - US3062146Document5 pagesOlin BWP Primer Patent - US3062146orpheus1972No ratings yet

- Us 5236286Document8 pagesUs 5236286Herlan Setiawan SihombingNo ratings yet

- 'I Ini: March 28, l1961 .1. E. Dalgleish 2,976,679Document5 pages'I Ini: March 28, l1961 .1. E. Dalgleish 2,976,679ShameekaNo ratings yet

- 1,018,037 ... Patented Feb. 20, 1912.: .??? Coax/K Wyùkkevaoma ????Document3 pages1,018,037 ... Patented Feb. 20, 1912.: .??? Coax/K Wyùkkevaoma ????fernando Ancaya AncayaNo ratings yet

- Us5584264 PDFDocument4 pagesUs5584264 PDFMiguel Kühnert FrichenbruderNo ratings yet

- Sept. 20, 1966 - Alfllle 3,274,069: Filed June 17. 1965 5 Sheets $heet 1Document6 pagesSept. 20, 1966 - Alfllle 3,274,069: Filed June 17. 1965 5 Sheets $heet 1kikkuri13No ratings yet

- United States Patent: Primary Examiner-Verlin R. PendegrassDocument6 pagesUnited States Patent: Primary Examiner-Verlin R. PendegrassSmokeNo ratings yet

- Paten Sintesis MetanolDocument5 pagesPaten Sintesis MetanolFarras HaidaryNo ratings yet

- United States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980Document4 pagesUnited States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980KundanNo ratings yet

- Vacuum Systems: Reprinted With Permission From Ryans and Bays (2001)Document3 pagesVacuum Systems: Reprinted With Permission From Ryans and Bays (2001)ethanchiaaNo ratings yet

- Tài liệu5Document12 pagesTài liệu5Hoàng ĐứcNo ratings yet

- Refrigerant in Capillary Tube PDFDocument6 pagesRefrigerant in Capillary Tube PDFMayank Kumar100% (2)

- United States Patent (19) : Teyssier Et Al. 11) 4,299,809Document5 pagesUnited States Patent (19) : Teyssier Et Al. 11) 4,299,809apriyansyahNo ratings yet

- Bottom Blowdown: Download The (295 KB) Try Answering The For This Tutorial View The Complete Collection ofDocument8 pagesBottom Blowdown: Download The (295 KB) Try Answering The For This Tutorial View The Complete Collection ofsenaNo ratings yet

- United States Patent: Sultan Et Al. (45) Date of Patent: Apr. 29, 2008Document7 pagesUnited States Patent: Sultan Et Al. (45) Date of Patent: Apr. 29, 2008aqil_shamsiNo ratings yet

- Us 5831204Document5 pagesUs 5831204wewewewNo ratings yet

- United States Patent (191: WinerDocument5 pagesUnited States Patent (191: WinerwewewewNo ratings yet

- Us 5775636Document6 pagesUs 5775636wewewewNo ratings yet

- Us 8809689Document7 pagesUs 8809689wewewewNo ratings yet

- Us 3770563Document5 pagesUs 3770563wewewewNo ratings yet

- Us 5775636Document6 pagesUs 5775636wewewewNo ratings yet

- United States Patent: Ronn Et Al. (10) Patent N0.: (45) Date of PatentDocument7 pagesUnited States Patent: Ronn Et Al. (10) Patent N0.: (45) Date of PatentwewewewNo ratings yet

- Us 3439635Document5 pagesUs 3439635wewewewNo ratings yet

- United States Patent: Berej Noi Et AlDocument6 pagesUnited States Patent: Berej Noi Et AlwewewewNo ratings yet

- United States Patent (191: Hau (11) Patent Number: (45) Date of PatentDocument7 pagesUnited States Patent (191: Hau (11) Patent Number: (45) Date of PatentwewewewNo ratings yet

- Us 5237928Document4 pagesUs 5237928wewewewNo ratings yet

- Us 2802332Document3 pagesUs 2802332wewewewNo ratings yet

- Sept. 13, 1966: J. Marsh EtalDocument4 pagesSept. 13, 1966: J. Marsh EtalwewewewNo ratings yet

- Us 3823668Document4 pagesUs 3823668wewewewNo ratings yet

- (A Oe Émgoueogmo: +2 (ll/l4fl2Document6 pages(A Oe Émgoueogmo: +2 (ll/l4fl2wewewewNo ratings yet

- United States Patent (191Document7 pagesUnited States Patent (191wewewewNo ratings yet

- Us 5544587Document6 pagesUs 5544587wewewewNo ratings yet

- Us 5299499Document5 pagesUs 5299499wewewewNo ratings yet

- United States Patent (191: Ahlstriim Et A1. (11) Patent Number: (45) Date of PatentDocument5 pagesUnited States Patent (191: Ahlstriim Et A1. (11) Patent Number: (45) Date of PatentwewewewNo ratings yet

- LL L'L///"/"Z//: (12) United States PatentDocument4 pagesLL L'L///"/"Z//: (12) United States PatentwewewewNo ratings yet

- Us 6279448Document5 pagesUs 6279448wewewewNo ratings yet

- Us 20010047736Document6 pagesUs 20010047736wewewewNo ratings yet

- Ester: United States PatentDocument5 pagesEster: United States PatentwewewewNo ratings yet

- Us 5237927Document4 pagesUs 5237927wewewewNo ratings yet

- United States Patent (10) Patent N0.: US 7,540,240 B2Document4 pagesUnited States Patent (10) Patent N0.: US 7,540,240 B2wewewewNo ratings yet

- Us 20050230016Document4 pagesUs 20050230016wewewewNo ratings yet

- Us 4709636Document5 pagesUs 4709636wewewewNo ratings yet

- United States Patent: CarverDocument4 pagesUnited States Patent: CarverwewewewNo ratings yet

- Ieee 525 PDFDocument64 pagesIeee 525 PDFPham Trien100% (1)

- In Conflict and Order Understanding Society 14th Edition Eitzen Solutions ManualDocument11 pagesIn Conflict and Order Understanding Society 14th Edition Eitzen Solutions Manualgenevievetruong9ajpr100% (24)

- Wokingham Major Highways Winnersh Relief Road Phase 2Document28 pagesWokingham Major Highways Winnersh Relief Road Phase 2Wessex ArchaeologyNo ratings yet

- NovelPoint Tracking v. CLAAS North America Holdings Et. Al.Document4 pagesNovelPoint Tracking v. CLAAS North America Holdings Et. Al.PriorSmartNo ratings yet

- Creative Approaches To Problem Solving: A Framework For Innovation and Change, Third EditionDocument22 pagesCreative Approaches To Problem Solving: A Framework For Innovation and Change, Third EditionAlejandraPruittarqbp100% (49)

- 12 Diamond v. DiehrDocument49 pages12 Diamond v. DiehrAimee Grace GarciaNo ratings yet

- Full Download Voice and Voice Therapy 9th Edition Boone Test Bank PDF Full ChapterDocument21 pagesFull Download Voice and Voice Therapy 9th Edition Boone Test Bank PDF Full Chapterelvestoltec.8jee100% (21)

- Ae 036884 008Document1 pageAe 036884 008RanielNo ratings yet

- GDS133 - SepraSol™ Series Liquid Gas Coalescer HousingsDocument2 pagesGDS133 - SepraSol™ Series Liquid Gas Coalescer HousingshacenescribdNo ratings yet

- Airtel Brand ValuationDocument21 pagesAirtel Brand ValuationPratik Gupta100% (1)

- Engineering EthicsDocument39 pagesEngineering EthicsSaranya S100% (2)

- Toys Vocabulary Esl Crossword Puzzle Worksheets For KidsDocument4 pagesToys Vocabulary Esl Crossword Puzzle Worksheets For KidsMarita RamosNo ratings yet

- Livingston Chemicals, Incorporated v. Permviro Systems, Incorporated, 995 F.2d 1063, 4th Cir. (1993)Document4 pagesLivingston Chemicals, Incorporated v. Permviro Systems, Incorporated, 995 F.2d 1063, 4th Cir. (1993)Scribd Government DocsNo ratings yet

- Instant Download Psychology Frontiers and Applications Canadian 6th Edition Passer Solutions Manual PDF Full ChapterDocument12 pagesInstant Download Psychology Frontiers and Applications Canadian 6th Edition Passer Solutions Manual PDF Full ChapterRobertBlankenshipbrwez100% (7)

- MHE RDG Wonders LVRDR G3 ELL U6W1 26Document24 pagesMHE RDG Wonders LVRDR G3 ELL U6W1 26Kenneth N AngelineNo ratings yet

- ICTICT618 Project Portfolio Student v1 2022Document16 pagesICTICT618 Project Portfolio Student v1 2022Thanh NguyenNo ratings yet

- Brandon Curtiss Bankruptcy FilingDocument74 pagesBrandon Curtiss Bankruptcy FilingShelley PowersNo ratings yet

- Physics For Scientists and Engineers A Strategic Approach With Modern Physics 4th Edition Knight Test BankDocument21 pagesPhysics For Scientists and Engineers A Strategic Approach With Modern Physics 4th Edition Knight Test Banktopical.alemannic.o8onrh100% (30)

- TTSH SchematicsDocument14 pagesTTSH SchematicsPhilippeTavernierNo ratings yet

- A4 M4 Student GrammarDocument3 pagesA4 M4 Student GrammardopazomanNo ratings yet

- Shangri-La International Hotel Management Ltd. vs. Court of AppealsDocument3 pagesShangri-La International Hotel Management Ltd. vs. Court of AppealsGeenea VidalNo ratings yet