Professional Documents

Culture Documents

How To Select A Heat Shrink Sleeve

Uploaded by

Lava Sat0 ratings0% found this document useful (0 votes)

95 views2 pagesHeat

Original Title

How to Select a Heat Shrink Sleeve

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHeat

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

95 views2 pagesHow To Select A Heat Shrink Sleeve

Uploaded by

Lava SatHeat

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

How to select a heat-shrinkable product

Selecting the sleeve

Covalence heat-shrinkable sleeves lead the world in corrosion protection of pipeline girth welds. They are

specifically designed to combine ease of field installation with a level of performance that matches, or

exceeds, that of the main pipe coating. Project specifications and/or local standards must be observed,

when specifying a shrinkable sleeve for protection of a girth weld.

To ensure an optimal choice, the following parameters must be considered:

Pipe operating temperature

As temperature increases, the overall resistance of a coating generally decreases. Therefore, in order to

ensure adequate lifetime, it's important to select a coating that has been correctly performance tested at

maximum operating temperature. Covalence mastic coated sleeves are available for temperatures up to

80 C (176 F), and hot-melt sleeves up to 120 C (248 F).

Pipe coating type

Covalence heat-shrinkable sleeves are compatible with all commonly used pipe coatings, although

somewhat different installation procedures may be required, depending on the line coating employed.

The sleeves adhere well to coal tar (CT), coal tar enamel (CTE), asphalt-based coatings, fusion-bonded

epoxies (FBE), and all commonly applied polymer pipe coatings including polyethylene (PE) and

polypropylene (PP).

Some polypropylene coated pipes require special Covalence sleeves. When using polypropylene pipe

coating; please consult your Covalence representative for assistance in selecting the appropriate heatshrinkable joint protection sleeve.

The Covalence HTLP three-layer system is often used on three-layer polyethylene pipe coatings to

provide factory original quality to the field applied girth weld protection. The same system can also be

applied on two-layer polyethylene.

Cutback distance

Covalence offers heat-shrinkable sleeves in four standard widths:

285 mm (11.25 inches),300 mm (12 inches),450 mm (17.75 inches),

500 mm (19.75 inches),600 mm (23.50 inches)and 870 mm (34.25 inches)*.

(*)These standard widths may not be standard for all products.

Outside pipe diameter

When buried, larger diameter pipes incur higher soil stress due to the weight of the soil above them.

These stresses create tangential forces, which in low performance coatings tend to cause wrinkling at the

two, four, eight and ten o clock positions on the pipe. The best way to combat these forces is with highmodulus polymer shrink sleeves coated with high shear-strength adhesive. Covalence heat-shrinkable

sleeves possess the highest modulus in the industry, while the hot-melt adhesives are made of the finest

copolymers. Covalence hot-melt coated shrink sleeves provide the greatest resistance to soil stresses on

all diameters. Below 20 inches diameter, Covalences high performance mastic coated shrink sleeves

often provide a good balance of performance, economy and ease of installation.

Selecting the proper sleeve

Project specifications and local standards must be considered when specifying a shrinkable sleeve.

Next to these the following parameters must be considered for selecting the proper shrinkable sleeve:

Pipe Coating Type: Bitumen, Coal Tar Enamel (CTE), Cold Applied Tapes (CAT), Fusion Bonded Epoxy

(FBE), Polyethylene (PE), Polypropylene (PP)

Pipe Operating Temperature: 0 -120 C (0-248 F)

Pipe Operating Pressure: 100 mbar =1.42 psi,>4 bar =56.88 psi.

Pipe Medium: Gas, water, oil, etc.

Pipe Diameter: Outside diameter. For instance; 1" or DN25 for steel pipe, 160 mm jacket diameter for

insulated steel pipe.

Pipe Preparation: Surface cleaning: abrading, brushing, grit blasting.

Obtainable preheat temperature: very low (20-40 C)(68-104 F), low (60-70 C)(140-158 F), high

(80-100 C)(176-212 F), very high (230 C)(446 F)

Adverse Soil Conditions: stable: low soil stresses - unstable: shifting soil conditions, significant pipe

motion relative to soil

Mechanical Resistance Heat-shrinkable Coating: medium (B): moderate impact and penetration

resistance; high (C): high impact and penetration resistance

Pipe Laying Method: Open Trench, Directional Drilling, Off-Shore

Climate conditions (Ambient Temperature during Sleeve Application):

Sea climate: not very cold -not very warm

Land climate: very cold -warm

Desert climate: very cold -hot

All of the above parameters affect the type of coating which will provide the best performance, ease of

installation and value.

You might also like

- Flange Insulation PresentationDocument10 pagesFlange Insulation PresentationNadeemNo ratings yet

- Geosynthetic Clay LinerDocument1 pageGeosynthetic Clay LinerRonald MacazanaNo ratings yet

- Hydro Static Universal Field Test ProcedureDocument16 pagesHydro Static Universal Field Test ProcedureHarvey Svetlik100% (1)

- Flange Insulation Kits: DescriptionDocument6 pagesFlange Insulation Kits: DescriptionLis RincónNo ratings yet

- TFP and TFT Back in Town (Tight Fit CRA Lined Pipe and Tubing)Document12 pagesTFP and TFT Back in Town (Tight Fit CRA Lined Pipe and Tubing)Deadnightvikernes100% (1)

- T&A Flange Insulation Kits PDFDocument4 pagesT&A Flange Insulation Kits PDFJuan CarlosNo ratings yet

- Wrapping RaychemDocument60 pagesWrapping Raychema_c_eNo ratings yet

- Heat Shrink ProcedureDocument7 pagesHeat Shrink ProcedureBabar Manzoor GhauriNo ratings yet

- HSS80 Heat Shrink Sleeve: Features & BenefitsDocument2 pagesHSS80 Heat Shrink Sleeve: Features & BenefitsAnonymous eEJDOR2100% (1)

- Pressure VesselsDocument14 pagesPressure VesselsChevronelleNo ratings yet

- Gabion Wall Installation GuideDocument5 pagesGabion Wall Installation GuideJoel KomaNo ratings yet

- HDPE Pipe and Fitting Materials Fusion Joining and Installation 1Document8 pagesHDPE Pipe and Fitting Materials Fusion Joining and Installation 1Mohamed ElsayedNo ratings yet

- ASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFDocument7 pagesASTM A674 - Polyethylene Encasement For Ductile Iron Pipe For Water or Other Liquids PDFApolos CastNo ratings yet

- Holiday TestDocument2 pagesHoliday TestnationalfoxNo ratings yet

- GRP Installation GuideDocument13 pagesGRP Installation GuidepparreraNo ratings yet

- C1729 Is A New ASTM Standard For Aluminum JacketingDocument2 pagesC1729 Is A New ASTM Standard For Aluminum JacketingTushar Arekar100% (2)

- Method Statement For GRP Pipe InstallationDocument8 pagesMethod Statement For GRP Pipe Installationdj_holo100% (1)

- Pipeline Acronyms and Classifications GuidelineDocument12 pagesPipeline Acronyms and Classifications GuidelinelsaishankarNo ratings yet

- Method of Statement For HDPE - Zone 6 (01.08.2019) - (Rev.04)Document13 pagesMethod of Statement For HDPE - Zone 6 (01.08.2019) - (Rev.04)pjss_sepadu1632No ratings yet

- Method Statements of Surface Treatment and Painting For Valves Nh3 ProjectDocument5 pagesMethod Statements of Surface Treatment and Painting For Valves Nh3 ProjectDuongthithuydung0% (1)

- FRP Installation GuideDocument8 pagesFRP Installation GuideDouglas HillNo ratings yet

- Road Crossing Method of StatementDocument4 pagesRoad Crossing Method of StatementKo Zay100% (1)

- BS 5480-2 (1982) Design and Performance RequirementsDocument24 pagesBS 5480-2 (1982) Design and Performance RequirementsGregory Simmon100% (1)

- Answers - Questionnaire-Bonder06-TT+LaminationDocument6 pagesAnswers - Questionnaire-Bonder06-TT+Laminationchandana kumarNo ratings yet

- Method Statement - GRP Pipe InstallationDocument3 pagesMethod Statement - GRP Pipe InstallationKharisma JayatraNo ratings yet

- Flange InsulDocument8 pagesFlange InsulAneesh JoseNo ratings yet

- Nitoproof 10Document2 pagesNitoproof 10Balasubramanian Ananth67% (3)

- Wavistrong Installation ManualDocument63 pagesWavistrong Installation ManualRenganathan Prabunath0% (1)

- Field Lamination Method StatementDocument13 pagesField Lamination Method Statementkais rguigui0% (1)

- The Repair OptionDocument4 pagesThe Repair OptionMAGUNAMNo ratings yet

- FRP Above Ground Installation ManualDocument32 pagesFRP Above Ground Installation ManualCarlos GutierrezNo ratings yet

- 2010 11-05-14 STOPAQ Training PresentationDocument21 pages2010 11-05-14 STOPAQ Training Presentationalfreddieick1No ratings yet

- Recommended storage procedures for packaged production equipmentDocument3 pagesRecommended storage procedures for packaged production equipmentJuan Pablo Chavez IxtepanNo ratings yet

- Welding Procedure For PVCDocument4 pagesWelding Procedure For PVCVince Tuyulab0% (1)

- L4-QAT-087C Method Statement For Patch Repair WorkDocument10 pagesL4-QAT-087C Method Statement For Patch Repair WorkrajaNo ratings yet

- Stationary Equipment Procedure (Pack 1)Document5 pagesStationary Equipment Procedure (Pack 1)Farhan SheikhNo ratings yet

- Technical Brochure Gre Site Activities: 44 Years ExperienceDocument30 pagesTechnical Brochure Gre Site Activities: 44 Years ExperienceSebastian RajeshNo ratings yet

- Renderoc TGDocument2 pagesRenderoc TGMansoor Ali50% (2)

- Camx 2015 Vaidya UabDocument11 pagesCamx 2015 Vaidya UabJuNeng NigLtdNo ratings yet

- APGA Code of Practice For Upstream PE Gathering Lines in The CSG IndustryDocument174 pagesAPGA Code of Practice For Upstream PE Gathering Lines in The CSG Industrydamian o'connorNo ratings yet

- GRI-GM13 Specification High Density Polyethylene GeomembranesDocument24 pagesGRI-GM13 Specification High Density Polyethylene GeomembranesFauzia Rizky0% (1)

- Application ProcedureDocument18 pagesApplication ProcedureTeguh SilaNo ratings yet

- UPVC High Pressure Water Supply Piping System Installation ProcedureDocument3 pagesUPVC High Pressure Water Supply Piping System Installation ProcedureAl Mumeen Construction ServicesNo ratings yet

- 3LPP Three Layer Polypropylene CoatingDocument3 pages3LPP Three Layer Polypropylene CoatingCarlos Maldonado SalazarNo ratings yet

- Brega-Sidra 34Document11 pagesBrega-Sidra 34ahmed08839494No ratings yet

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocument19 pagesHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNo ratings yet

- Concrete Work 1. Standard and Codes of PracticeDocument28 pagesConcrete Work 1. Standard and Codes of PracticeArka ShahRilNo ratings yet

- Hdpe Pressure Pipe ManualDocument62 pagesHdpe Pressure Pipe Manualmai huy tânNo ratings yet

- 13 14 Technical Literature and StandardsDocument8 pages13 14 Technical Literature and StandardsMohammad Rashad BarakatNo ratings yet

- Sa-7918-1, Rev A, (850146), 12.16.2018Document2 pagesSa-7918-1, Rev A, (850146), 12.16.2018Rami ELLOUMINo ratings yet

- Technical Data Sheet for Unsaturated Vinyl Ester CoatingDocument5 pagesTechnical Data Sheet for Unsaturated Vinyl Ester CoatingBiju_PottayilNo ratings yet

- Louver Installation InstructionsDocument2 pagesLouver Installation Instructionssubbiah1986No ratings yet

- Installation Manual OXYFLEX® MF1100 October 2014 PDFDocument8 pagesInstallation Manual OXYFLEX® MF1100 October 2014 PDFRomuel PioquintoNo ratings yet

- Normas de Referencia - Fibra de VidroDocument12 pagesNormas de Referencia - Fibra de Vidroricardobor100% (1)

- GRP Lamination Processing - Instructions PDFDocument34 pagesGRP Lamination Processing - Instructions PDFmuhammadkashikNo ratings yet

- How To Select A Heat-Shrinkable Product: Selecting The SleeveDocument2 pagesHow To Select A Heat-Shrinkable Product: Selecting The SleeveMekhmanNo ratings yet

- 2A?Djkhkcu: Insulation & LiningsDocument4 pages2A?Djkhkcu: Insulation & LiningsbenssjNo ratings yet

- Prime Surface Plate CoilDocument12 pagesPrime Surface Plate CoilGrimmo1979No ratings yet

- HDPE Drainage ManualDocument48 pagesHDPE Drainage ManualTransgulf2013No ratings yet

- Construction Contract BaselineDocument1 pageConstruction Contract BaselineLava SatNo ratings yet

- Abaqus/CFD – Sample Problems for Simulating Fluid FlowDocument42 pagesAbaqus/CFD – Sample Problems for Simulating Fluid FlowLava SatNo ratings yet

- Oil and Gas FAQsDocument6 pagesOil and Gas FAQsLava SatNo ratings yet

- 1 PDFDocument2 pages1 PDFSam ShahNo ratings yet

- Non Linear Waves - Michael BrorsenDocument40 pagesNon Linear Waves - Michael BrorsenLava SatNo ratings yet

- Introduction To Beam Theory Theory: Area Moments of Inertia, Deflection, and Volumes of BeamsDocument41 pagesIntroduction To Beam Theory Theory: Area Moments of Inertia, Deflection, and Volumes of BeamsDrAmit DuttaNo ratings yet

- 3.2 Programming The Work: Created by Guy Henley, Last Modified by Mustafa Abusalah On Nov 20, 2014Document2 pages3.2 Programming The Work: Created by Guy Henley, Last Modified by Mustafa Abusalah On Nov 20, 2014Lava SatNo ratings yet

- Developing Fair Pipeline Contract ConditionsDocument4 pagesDeveloping Fair Pipeline Contract ConditionsLava SatNo ratings yet

- 3.3 Contract Price Information To Facilitate Evaluation of ChangesDocument1 page3.3 Contract Price Information To Facilitate Evaluation of ChangesLava SatNo ratings yet

- Numerical Simulation of F Rost Heave in Soils Around The Buried Oil Pipeline in Island Talik Permafrost RegionDocument12 pagesNumerical Simulation of F Rost Heave in Soils Around The Buried Oil Pipeline in Island Talik Permafrost RegionLava SatNo ratings yet

- 3 1Document3 pages3 1Lava SatNo ratings yet

- Interpolating Tabular Data With MathcadDocument2 pagesInterpolating Tabular Data With MathcadLava SatNo ratings yet

- 3 1Document3 pages3 1Lava SatNo ratings yet

- Fabrication Sequence of JacketDocument37 pagesFabrication Sequence of JacketLava SatNo ratings yet

- Icc Cricket World Cup 2015 Schedule With TimeDocument3 pagesIcc Cricket World Cup 2015 Schedule With TimeMuhammad NaeemNo ratings yet

- Advanced 100% Solids Rigid Polyurethane Coatings Technology For Pipeline Field Joints and RehabilitationDocument14 pagesAdvanced 100% Solids Rigid Polyurethane Coatings Technology For Pipeline Field Joints and RehabilitationLava SatNo ratings yet

- Chainman Catalogue EditDocument57 pagesChainman Catalogue EditRem LaraziNo ratings yet

- 7day PrimerDocument15 pages7day PrimerGospodin Covek100% (5)

- Short Term Pleasure vs. Long Term GainDocument31 pagesShort Term Pleasure vs. Long Term Gainunreal2No ratings yet

- Annex D - Stw-Comflow3Document45 pagesAnnex D - Stw-Comflow3Lava SatNo ratings yet

- Meaningful Hindu tenets explained by Tamil poet KannadhasanDocument599 pagesMeaningful Hindu tenets explained by Tamil poet KannadhasanLava Sat100% (1)

- Properties of British Universal Steel Columns and BeamsDocument4 pagesProperties of British Universal Steel Columns and BeamsLava SatNo ratings yet

- Exercise Chart: PN 303731 © 2010 ICON Health & Fitness, Inc. All Rights Reserved. Specifications Subject To ChangeDocument1 pageExercise Chart: PN 303731 © 2010 ICON Health & Fitness, Inc. All Rights Reserved. Specifications Subject To ChangeLava SatNo ratings yet

- AP Bearings For Industrial ApplicationsDocument79 pagesAP Bearings For Industrial Applicationsmikab25No ratings yet

- 1977 OTC 2827 The Design of Single Point MooringsDocument8 pages1977 OTC 2827 The Design of Single Point MooringsLava SatNo ratings yet

- 107 Insert Control ButtonsDocument3 pages107 Insert Control ButtonsLava SatNo ratings yet

- DRAFT Calculation Supposed To Be in Line With DNV-RP-F105 (Feb 2006) Sec. 3.5 and 3.6Document4 pagesDRAFT Calculation Supposed To Be in Line With DNV-RP-F105 (Feb 2006) Sec. 3.5 and 3.6Lava SatNo ratings yet

- 107 Insert Control ButtonsDocument3 pages107 Insert Control ButtonsLava SatNo ratings yet

- Anchor ManualDocument187 pagesAnchor ManualAde Aris Satria100% (5)

- LEP1403 - 00 Viscosity of Newtonian and Non-Newtonian Liquids (Rotary Viscometer) PDFDocument5 pagesLEP1403 - 00 Viscosity of Newtonian and Non-Newtonian Liquids (Rotary Viscometer) PDFJose GalvanNo ratings yet

- Report On New Demineralized Water PlantDocument17 pagesReport On New Demineralized Water PlantGulfam ShahzadNo ratings yet

- CH 6701 Cre IiDocument230 pagesCH 6701 Cre IiVaibhav Gupta100% (1)

- ME 423: Machine Design: Design of Scalp Cooling Systems For Preventing Alopecia During Chemotherapy Prof. Ramesh SinghDocument15 pagesME 423: Machine Design: Design of Scalp Cooling Systems For Preventing Alopecia During Chemotherapy Prof. Ramesh SinghTejas LadheNo ratings yet

- Gas Absorption: Based On Mccabe, Smith, Harriott 7 EdDocument22 pagesGas Absorption: Based On Mccabe, Smith, Harriott 7 EdnazrinNo ratings yet

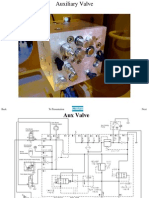

- Aux Valve Brakes ST710Document16 pagesAux Valve Brakes ST710Jose VegaNo ratings yet

- Technical Brief InsolublesDocument4 pagesTechnical Brief InsolublesLord KrsnikNo ratings yet

- GAS SHEET 1uDocument7 pagesGAS SHEET 1uKarim MagdyNo ratings yet

- Basic Principles and DefectsDocument18 pagesBasic Principles and DefectsAkshaj NevgiNo ratings yet

- Vogt Valves Catalog and Application ManualDocument53 pagesVogt Valves Catalog and Application ManualRomner CordovaNo ratings yet

- Chemicals for Flocculation and Dewatering TreatmentDocument1 pageChemicals for Flocculation and Dewatering TreatmentROCKN'UNLMTD StudioNo ratings yet

- List of Indian Standards For Fire Fighting: Revision)Document2 pagesList of Indian Standards For Fire Fighting: Revision)Nanu PatelNo ratings yet

- Lecture 1 SeriesDocument43 pagesLecture 1 SerieschetsNo ratings yet

- U of I Facilities Standards - Control ValvesDocument25 pagesU of I Facilities Standards - Control Valvesforevertay2000No ratings yet

- FERTIGATIONDocument96 pagesFERTIGATIONNohaAbdulWarthNo ratings yet

- Vabal /SF 12: Overcenter ValvesDocument2 pagesVabal /SF 12: Overcenter ValvesSachin RamadasanNo ratings yet

- Siphon EffectDocument12 pagesSiphon EffectKhalid AnwarNo ratings yet

- Certificate Aboveground PipingDocument5 pagesCertificate Aboveground Pipingsajeed76740No ratings yet

- Wet Scrubber Design & Operation TipsDocument4 pagesWet Scrubber Design & Operation TipsZee KayNo ratings yet

- Energypack Thermic Fluid HeaterDocument4 pagesEnergypack Thermic Fluid HeaterutechprojectsNo ratings yet

- Simulation and Experiments On An Isolated Racecar Wheel Rotating in Ground ContactDocument15 pagesSimulation and Experiments On An Isolated Racecar Wheel Rotating in Ground ContactVyssionNo ratings yet

- Bosch Industrijski Kotlovi - Proizvodni ProgramDocument26 pagesBosch Industrijski Kotlovi - Proizvodni ProgramAnonymous ub0Yzv1PCNo ratings yet

- Well Control Training Services BDocument2 pagesWell Control Training Services BAndre Luiz Santos0% (1)

- PS0121-DWG-B-003 Sheet 5 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Isometric Sect. 4 R.5Document1 pagePS0121-DWG-B-003 Sheet 5 Jalur Pemipaan Dari WDO Fase 1 & 2 Menuju Drain Tank CCDS - Isometric Sect. 4 R.5yusak adi setiawanNo ratings yet

- Progression Toward Sustainable Refrigeration Products: Pressure (Psig) Temperature ChartDocument1 pageProgression Toward Sustainable Refrigeration Products: Pressure (Psig) Temperature Chartgeoryi castroNo ratings yet

- Melting Point Determination TechniquesDocument4 pagesMelting Point Determination TechniquesSobi SitjarNo ratings yet

- Failure Mode and Effect Analysis of Centrifugal PumpDocument2 pagesFailure Mode and Effect Analysis of Centrifugal PumpHAFIZMUHAMMAD SAJID100% (2)

- - =-3.6 log ф ^ - J J (: 182 Chapter 6 Interphase Transport in Isothermal SystemsDocument3 pages- =-3.6 log ф ^ - J J (: 182 Chapter 6 Interphase Transport in Isothermal SystemsAndrianPratamaNo ratings yet

- Reaction Areas in AodDocument4 pagesReaction Areas in AodPrakash MishraNo ratings yet

- Problem Set 3Document3 pagesProblem Set 3sweet mondayNo ratings yet

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsFrom EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsRating: 5 out of 5 stars5/5 (1)

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationFrom EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationRating: 4.5 out of 5 stars4.5/5 (2)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilFrom EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilNo ratings yet

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesFrom EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNo ratings yet

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsFrom EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsNo ratings yet

- Subsea Valves and Actuators for the Oil and Gas IndustryFrom EverandSubsea Valves and Actuators for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (1)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Corrosion Control in the Oil and Gas IndustryFrom EverandCorrosion Control in the Oil and Gas IndustryRating: 4 out of 5 stars4/5 (12)

- Petroleum Rock Mechanics: Drilling Operations and Well DesignFrom EverandPetroleum Rock Mechanics: Drilling Operations and Well DesignRating: 5 out of 5 stars5/5 (1)