Professional Documents

Culture Documents

The Recycling of Table Olive Brine Using Ultrafiltration and Activated Carbon Adsorption PDF

Uploaded by

Seyit AvcuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Recycling of Table Olive Brine Using Ultrafiltration and Activated Carbon Adsorption PDF

Uploaded by

Seyit AvcuCopyright:

Available Formats

Journal of Food Engineering 17 (1992) 291-305

The Recycling of Table Olive Brine using Ultrafiltration

and Activated Carbon Adsorption

A. Garrido, P. Garcia & M. Brenes

Unidad Estructural de Investigaci6n de Biotecnologia de Alimentos. lnstituto de la

Grasa y sus Derivados, Apartado 1078.41012-Sevilla,

Spain

(Received 23 September

199 1; revised version received 28 November

accepted 1 December 1991)

199 1;

ABSTRACT

Brines from green table olive processing are a highly polluted waste water

which, at present, are discarded with the other liquid residues of the

packing factories. They are thus dificult to treat at both plant and municipal treatment facilities. Their recycling could eliminate about 80% of the

total pollution and facilitate treatment of the remaining liquid wastes.

Field tests showed that recycling of such brines after treatment with both

06% (w/v) of activated carbon and ultrafiltration through a polysulphone

membrane of IO00 daltons pore size can produce quantities of brine that,

with minor composition adjustments, can be added to the solution

employed for packing the final product. This can then be used in other

operations where brine is required. A possible design of the regeneration

process is also proposed.

INTRODUCTION

World table olive production is about 800000 t/year. Of this olive

production green table olives in brine (Sevillian or Spanish style) are the

most popular product, with production yields of 350 000 t/year, a large

proportion of which is produced in Spain (150 000 t/year).

The procedure for preparing green table olives consists of treating the

fruits with dilute NaOH solution (lye) to increase skin permeability and

partially eliminate bitterness, followed by two water washings to remove

the excess of alkali from the previous treatment. Thena 1 l-l 3% (w/v)

NaCl solution is added to the fruits, in which they undergo a lactic

291

Journal of Food Engineering 0260-8774/92/$05.00

Publishers Ltd, England. printed in Great Britain

- 0

1992

Elsevier

Science

A. Garrido, P. Garcia, A4.Brenes

292

fermentative process. They remain in this solution until they are ready

for packing or sale. Residual solutions from this process cause high

pollution levels in public watercourses and interfere in the normal work

of municipal waste water treatment plants.

Recently, the traditional method of processing has been modified and

industrial practice has incorporated technology that re-uses lye (Garrido

et al., 1979) and partially or totally eliminates wash waters (Gonzalez et

al., 1984), without any negative influence on the quality of the final

product. The reduced volume of alkaline solutions generated by this new

procedure are discarded in shallow ponds, where they undergo solar

evaporation. However, brines are still discarded when olives are packed

and, at the moment, industry has not yet adopted any measures to prevent pollution.

In Spain, 65% of the green table olive production is packed in small

containers (jars, cans, plastic bags, etc.). Thus, the packing industry

handles around 100 000 t/year, which generates about 50 000 m3 of

heavily polluted waste brines. Their principal characteristics are shown

in Table 1 (Garrido, 1990). In general, they have a high biological

oxygen demand (BOD,), lactic acid and salt content. Until now, they

have been discarded with the rest of the waste waters produced in the

factory, 6-12 litres/kg of fruit, making the whole liquid wastes untreatable at both plant and municipal treatment facilities.

A suitable solution might be the segregation of these brines, which

account for 80-85% of the final pollution but represent only 20% of the

total liquid residues. In addition, their re-use could benefit from the

value of their constituents: lactic acid and salt. Recycling possibilities are

diverse: new fermentation processes; addition to the original brines when

Main

Physico-chemical

TABLE 1

Characteristics

Brines

Characteristic

PH

NaCl (g/litre)

Free acidity, as lactic acid (g/litre)

Combined acidity (meq/litre)

Colour (&,-A

7oo)

Polyphenols, as tannic acid (g/litre)

Suspended solids (g/litre)

BOD, (g O,/litre)

COD (g O,/litre)

of Fermentation

Range

3.60-4.30

60-90

s-15

80-120

0.20~0.60

0.18-0.30

0.20-2.00

14-18

16-26

The recycling of table olive brine

293

olives are passed, for conditioning, from the fermenters to plastic drums;

for packing the final product; etc.

The recycling of spent brines has been widely investigated. Durkee et

al. (1973) described field tests on a submerged combustion system,

which, after evaporating most of the water, removed the organic matter

and recovered the salt by incineration of the concentrated slurry. Normal

fermentation was achieved using this recycled salt (Durkee et al., 1974).

Nevertheless, further research was directed to treatment of these solutions by other physico-chemical methods with the aim of reducing the

costs involved in the recycling process. Thus, Palnitkar and McFeeters

( 1975) reported that treating spent brines from cucumber fermentations

with NaOH solutions, followed by neutralization with HCl, gave a regenerated brine that when re-used for new fermentations resulted in a

quality similar to that produced by fermentation in fresh brine. Glaros

and Geisman (1980) studied a method to speed up flocculation. A

similar process was also proposed for olives (Leoni et al., 198 1).

Field tests for reconditioning brines from the conservation step of ripe

olive processing using activated carbon adsorption demonstrated

the

effectiveness of their re-use in the following season (Ginnette, 1968).

However, experiments re-using green table olive brines at different dilutions or degrees of reconditioning for new fermentation processes have

failed until now, probably due to the presence of metabolic compounds

from the first fermentation which inhibit lactic bacteria. There are also

problems with transport of such solutions to the processing factories

which are often far away from the canning facilities. Thus, the best

solution is either their recycling for packing or their addition to the

original brines during the olive conditioning operations. Garrido (1979)

showed that this option was possible, although the high prices of the

adsorbent and the retention of a high proportion of lactic acid by the

adsorbent had prevented its industrial use. However, more recently,

Brenes and Garrido ( 1988) have discovered a special activated carbon

that adsorbs colour very selectively with the elimination of only a small

percentage of lactic acid.

Membrane technology is also applicable to the regeneration of these

solutions, in spite of the fact that early tests failed because of the substances dissolved in olive brines and the chemical composition of the

available membranes (Rose, 1982). However, ultrafiltration (UF) is

finding increasing application in the food industry, sometimes in conjunction with activated carbon - as in the system proposed by Welsh

and Zall (1984) for regenerating and re-using fishery refrigeration

brines. Regeneration of brines from cucumbers had been reported by

Buescher (1984) and Fleming et al. ( 1988). Moreover, Brenes et al.

294

A. Garrido, P. Garcia, M. Brenes

(1988) reported the successful application of ultrafiltration through

polysulphone membranes to recover green table olive brines. Later, the

influence of some operating variables on the process and the effect of the

brines on polyphenol membranes was also investigated (Brenes et al.,

1990).

As a normal continuation of the most recent developments in the

regeneration of fermentation brines by activated carbon adsorption and

ultrafiltration, the aim of this study was to carry out comparative field

tests on an industrial scale. Their performance, the influence of brine

recycling on the main quality attributes of the final products, and the

adaptability of the commercial eqdipment to the working requirements

of the packing factories were investigated. The design of the two possible

processes derived from the research is also proposed.

MATERIALS

AND METHODS

Olives and brines

Experiments were carried out on fruit of the Hojiblanca cultivar (Olea

europaea arolensis) and their fermentation brines. The characteristics of

these solutions ranged between the limits presented in Table 1. The total

previous storage period was 8 months.

Analyses

Free acidity, combined acidity, salt content and pH of the brines, as well

as the texture of the fruits, were determined as described by FernGndez et

al. (1985). The brine colour was measured, after filtration through a

0*45-pm membrane (HAWP, Millipore Corp.), as the difference in

absorbance at 440 and 700 mn (A,,,-A,,,)

(Montaiio, 1987). Olive

colour was determined as proposed by Sgnchez et al. (1985).

Treatment with activated carbon and microfiltration

A sample of 6 g/litre (0*6%, w/v) of GA type activated carbon (Industrias

Kern, Barcelona, Spain) was added to 300 litres of brine and stirred for 1

h to complete the adsorption process. The brine was then filtered

through a ceramic filter of O-2-pm pore size in a Chaconsa apparatus

(Chaconsa, S.A., Murcia, Spain).

The equipment had two modules of 19 tubular filters (4 mm diameter)

with a total filtration surface of O-2 m* each. It also had a heat exchanger

The recycling of table olive brine

295

to control the working temperature. Every 15 min the automatic electronic control reversed the pressure on the filters, by injection of compressed air, to partially clean the membranes. Cleaning at the end of the

operation period consisted of steam injection followed by successive

rinsing with dilute NaOH and HNO, solutions, with a final water rinse to

eliminate any remaining chemicals. In general, the operation was carried

out in accordance with the manufacturers specifications (Anon., 1988).

Ultrafiltration equipment

Ultrafiltration trials were made with a Paterson Candy International

apparatus (Paterson Candy Int., Whitchurch, Hants, UK) fitted with a

module of 18 tubular polysulphone membranes of 12.5 mm internal

diameter giving a total filtration surface of 2.6 m2, and a heat exchange

module to facilitate temperature control during operation. The molecular weight cut-off of these membranes was 1000 daltons. The equipment

was used in accordance with the manufacturers specifications (Anon.,

1986). Operating pressure was 18 bars. Recycling flux was 30 litres/min,

corresponding

to a velocity of 3.9 m/s along the membranes. Postoperation cleaning consisted of water rinsing, use of a detergent solution

(Henkel P-3 141) at a temperature of 40-45C followed by further

rinsing. During the shut-down period, a 0.25% (w/v) solution of

potassium metabisulphite was introduced into the module to preserve

the membranes.

Experimental design

Active carbon adsorption and crossflowmicrofiltration

A factorial experiment was conducted with two types of regenerated

brines (one only filtered and one previously treated with 0.6% of activated carbon), two commercial olive products (plain and pitted), two can

sizes (2700 and 250 g per can) and two percentages (70 and 30%, v/v) of

recycled brine in the packing solutions. At the same time, olives were

also packed in fresh brine. The maximum proportion of re-use was

imposed by the concentrations of lactic acid and salt in the regenerated

brine which are usually higher than those required in the final product.

UltrajZtration

Three working modes were used to confirm the apparatus performance:

(i) total recycling, i.e. recycling to the feed tank both permeate and

concentrate; (ii) partial recycling, recycling concentrate to the feed tank

with removal of the permeate; (iii) partial recycling with replacement, i.e.

296

A. Garrido, P. Garcia, M. Brenes

the initial volume of brine in the feed tank was maintained by recycling

the concentrate and adding continuously to this tank the same volume of

brine as was removed as permeate. A 300-litre tank was used as a brine

reservoir.

For packing, only plain fruit and 250-g cans were used, as these gave

the highest brine colours in the carbon adsorption experiments. The

proportion of re-used brine in the final product was only 45% due to the

constraints imposed by the physico-chemical

characteristics of the

original brine and the final product. Comparisons with fruit packed in

fresh brine were also made.

Cans from all treatments were pasteurized using the normal industrial

process. Ten cans per treatment were collected and duplicates or triplicates were analysed after 3 months (to permit equilibrium). Studies were

also made at longer periods of time, although no differences between

their results and those obtained at the first sampling were noticed. Thus,

in this paper, physico-chemical analyses of brines and fruit studies correspond only to the 3-months data. Olives were also compared by the rank

method (Kramer & Twigg, 1962) to study the influence of the different

variables on the flavour.

All experiments were carried out in the factory of Agrosevilla, S.A.

Coop. (La Roda de Andalucia, Seville, Spain).

RESULTS AND DISCUSSION

Regeneration

filtration

by adsorption

with activated carbon and crossflow

No differences were found between these field tests and the data

reported previously (Brenes et al., 1988). So the main interest was to

study the equipment performance when the activated carbon slurry was

concentrated by crossflow microfiltration.

The flux changes in three different runs are shown in Fig. 1. There was

a diminution through the working day from 150-135 litres/m* per hour

at the beginning, to 110-l 15 litres/m* per hour at the end of the day.

Differences between the initial values are due to different flux recovery

rates after each cycle and indicate the remarkable influence of cleaning

on membrane permeability recovery. Maximum recovery was about

90-95% - a fairly good proportion.

The concentrated waste slurry had a high organic content, in addition

to the activated carbon. Although no treatment was attempted for its

elimination, the technical staff of the factory thought it might be burned

The recycling oftable olive brine

100

Fig. 1.

123456

297

TIME fhr)

Flux change in the crossflow filtration equipment, The solution was a slurry of

green table olive brines treated with 5 g/litre of GA-type activated carbon.

in the boiler after being sun dried, as was usually done with other solid

olive residues.

Cleaning the membranes after each working day took about 2.5 h.

During this time one worker was assigned to the operation, which must

be carried out carefully to achieve a satisfactory flux recovery for further

use.

Similar behaviour was observed when brine was only filtered,

although the decline was a little slower and the final volume of solids in

the concentrate was very small.

The main physico-chemical characte~stics of some of the brines from

the factorial packing experiment with recycled brine are shown in Table

2. This shows values for 250-g cans only, as they were the containers

where the negative effects were most evident, as they had highest fruit/

brine ratio. Combined acidity and pH are higher when percentages of

recycled brine increase and the propo~ons

of activated carbon diminish. Values for packing solutions containing 70% of recycled brines are

excessively high, indicating that such conditions require a previous

partial combined acidity correction to reduce both combined acidity and

pH to the usual levels in fresh brine. However, using 35% of both types

of regenerated brines, their values were lower and could sometimes be

acceptable, although a slight correction is advisable. In any case, the

product must be preserved by pasteurization.

Brine colour was also affected. Variance analysis of the results and

Duncan multiple comparison tests (Ruiz Maya, 1977) showed no significant differences for pitted olives, between fresh brines and those containing 70% and 3St6 of recycled solution regenerated with 0.6% of

activated carbon, Brine colour of plain olives packed with fresh brine

was slightly (although significantly) worse. Using 70% and 35% of activa-

24

22

23

93

0.24

105

0.36

22

0.56

450

5.60

057

4.53

5.80

Pitted

22

22

87

0.33

0.56

4.37

5.30

Plain

24

21

22

21

110

0.45

0.58

459

5.60

Plain

Filtered

combined

24

22

101

0.48

0.52

457

5.10

Pitted

70% (v/v)

free acidity, 1 X lo-?;

66

0.22

0.53

4.27

5.40

Pitted

35% (v/v)

Percentage of recycled brine used in the packing brine (v/v).

Note:Combined standard errors: pH, 3 x lo-; NaCl, 3 X lo-;

texture, 1; fruit colour, 1.

Fruit

Texture (kgf/cm

of pitted olives)

Colour (A44,,-A700)

(% w/v)

Free acidity, as lactic

acid (%, w/v)

Combined acidity

(meqjlitre)

Cofour (A440-A70,J

Brine

L&I

Plain

70% (v/v)

Treated with 0.6% activated carbon

Recycled

Type of brine

24

22

77

0.33

052

4.32

5.50

Pitted

24

23

70

0.28

0.56

4.21

5.30

Plain

22

22

59

0.23

0.53

4.08

5.30

Pitted

acidity, 3; brine colour 1 X 10m2; fruit

22

22

93

0.46

0.56

4.42

5.30

Plain

35% (v/v)

Fresh

TABLE 2

Average Values of the Physico-chemical

Characteristics of Brines as well as Texture (kgf/cm? 100 g of Pitted Olives) and Colour

(A,,,-A ,) of Fruits of Two Replicates. Olives were Packed with Solutions Containing Different Proportions of Brines Regenerated by

Adsorption with Different Percentages of Activated Carbon in 250-g Drained Weight Cans. Analysis was Performed Three Months After

Canning

s

p

8

3

9

?J

Q

.Ii

5

299

The recycling of table olive brine

ted carbon treated brines with plain olives as well as 35% of only filtered

brine with pitted fruits, the colour was also acceptable. However, filtered

brines gave unacceptable brine colour in the rest of the cases. Figure 2

summarizes these results.

The effect on the fruit attributes is presented in Table 2 for the same

cans in which brines were studied. Variance analysis of data showed no

statistically significant difference.

Considering that fruit packed with fresh brine and fruit packed with

brine regenerated by activated carbon are the most commercially

suitable, sensory analysis was confined to such samples. Preference ranking tests carried out on both plain and pitted olives showed no significant

differences (Kramer & Twigg, 1962).

Thus, it may be concluded that brine regeneration by activated carbon

adsorption, followed by crossflow filtration could be applied successfully

for recycling brines. It gives a good concentration ratio and great flexibility in relation to the percentage of active carbon used. However, for

packing with the maximum percentage of 70% of regenerated brine in

the final volume, a proportion of about 0.6 g/litre of activated carbon is

recommended. A correction of excessive original high combined acidity

is always advisable. Lower levels of regenerated liquids in the packing

PITTRD

Flesh

brine

up to 70% of

recycled brine

treated with

recycled brine

0.6% of activated carbon

same

<

35% of recycled

filtered brine

colour

colour

acceptable

brine

<

Fig. 2.

acceptable

colour

70% of recycled

filtered brine

-m

increase

FRUITS

up to 70% of recycled

brine treated with

0.6 % of activated

carbon

colour

*

<

unacceptable

colour

colour

PLAIN

Fresh

PRUITR

<

up to 70% of recycled

filtered brine

increase

unacceptable

colour

Summary of the influence of recycling proportion of different regenerated

brines on the colour of packing brines (250-g drained weight cans).

A. Garrido, I? Garcia, M. Brenes

300

solutions would need a lower proportionof adsorbent and combined

acidity reduction.

The only equipment problems noticed were related to the filters. The

length of the cleaning process was excessive and their small internal

diameter may lead to blockages if the velocity of the circulating slurry

decreases unexpectedly. So, a greater diameter of filter would be desirable. However, no problem was detected during this test.

Ultrafiltration

Permeate flux changes in the threedifferent operation modes are shown

in Fig. 3. In general, they declined throughout the working time. There

was a flux diminution of about 8 lure/m2 per hour from the beginning of

the work to the end of the 7-8 h of daily operation, except in the total

recycling mode in which it was around half of this amount. Partial recycling mode with replacement of the permeate had the lowest flux.

However, differences were small between the two possible working

modes, recycling of permeate with and without replacement. If the

operating period is less than 7-8 h, simple recycling is better. With

longer periods, performance was very similar. Thus, the working mode

does not have a significant influence on the equipment effectiveness; as

Fig. 4 shows for an experiment in which both modes were used

successively.

Usually, experiments

were carried out at room temperature

(1518C) but higher temperatures and previous flocculation of brines

TOTAL

PARTIAL

123456

Fig. 3.

RECYCLING

MODE

RECYCLING

MODE

PAriTIAL

RECYCLING

REPLACEMENT

MODE

WITH

TIME (hr)

Flux change of permeate during ultrafiltration of brines in different operation

modes (temperature = 1SOC).

The recycling of table olive brine

301

30

28

,

.

.

\.

26

=

x

3

24

lL

t;

. Partial

recy - I*

cling

mode

with replace

- I

22 - ment of per - I

_ meate

-

\

%

20

I Partial

t

recycling

Fig. 4.

1.

TIME (hrl

Flux change of permeate during ultrafiltration of brines in partial recycling and

partial recycling with replacement modes (temperature = 1ST)

with 2 g/litre of bentonite (from a 2%, w/v solution) increased the flux

and maintained it better than treating brines directly. The joint effect can

achieve an increase of about 30% in the flux. The industrial use of these

favourable influences will depend on the balance between the treatment

costs and the investment reduction (less filtering surface) that may be

achieved.

In all cases, the cleaning operation took about 1.5 h. An operator was

required only at the beginning and end of the process. After this operation, flux recovery was measured by using water as the ultrafiltration

liquid. Considerable fluctuations were observed between the initial flux

on the different working days, showing that the correct application of

cleaning had a determining influence on this parameter and, consequently, must be carried out carefully. No flux diminution

with

membrane utilization time was noticed during the period of the experiments (about 90 h).

The physico-chemical

characteristics of brines from olives packed

with solutions containing 45% of regenerated brine, together with those

of brine from olives packed with fresh brine are shown in Table 3. Data

are for plain fruit and 250-g cans, which was the treatment that showed

the most unfavourable effects of recycling. There were clear differences

in pH and combined acidity values in the equilibrium between both

forms of packing. This was similar to regeneration by adsorption,

although the pH values reached in the case of recycled brine by ultrafiltration were lower than those obtained in the adsorption experiment and

were appropriate for packing when pasteurization was used to assure the

product preservation. With respect to brine colour there were no statistical differences and in all cases it was the normal colour that might be

A. Garrido, P. Garcia, M. Brenes

302

TABLE 3

Average Values of the Physico-chemical Characteristics of the Brines of Green Table

Olives Packed with 45% of Recycled and Fresh Brines. Plain Fruit and 250-g Drained

Weight Cans were used U

Type of brine

Recycledb

4.05

4.60

0.70

104.0

0.109

PH

NaCl (%, w/v)

Free acidity, as lactic acid (%, w/v)

Combined acidity (meq/litre)

Colour (A,,,,-A 7oo)

Fresh

3.66

4.80

0.76

65.0

0.100

The values are the averages of three replicates. Analysis was performed 3 months after

canning.

Combined standard errors: pH, 1 X lo- l; NaCl, 9X lo-*; free acidity, 2x lo-*;

combined acidity, 2.3; colour, 6 x 10 - j.

hOf the packing brine, 45% had been recycled.

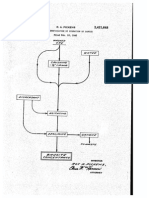

BRINE

INLE.1

TANK

FILTER

02

PUMP

HEAT

Fig. 5.

GROUP

EXCHANGER

Possible scheme for an industrial process.

expected in these green table olive solutions from jars or cans. No effect

on texture, colour or sensorial preferences was detected.

Thus, the experiment showed that using the correct initial combined

acidity and proportion of recycled brine, good physico-chemical conditions could be achieved in the final packing solution.

Possible schematic

design of the regeneration

processes

The whole process for the two treatments can be designed as shown in

Fig. 5. In both cases, a tank with a capacity depending on the daily

The recyclingof rubleoZivebrine

303

production would be required. It might be used for the activated carbon

treatment, the ~occulation with bentonite or just as a brine reservoir if

brine is ultrafiltered directly. This container must be provided with a

stirrer and a device in the bottom to remove the decanted solids as well

as with accessories to add the carbon or any other additive. The

decanted treated solution would pass from the container to the crossflow

or ultrafiltration equipment, as appropriate.

CONCLUSIONS

From the above results it can be deduced that the two treatments used to

regenerate green table olive fermentation brines could be used to recycle

such solutions. Their re-use can be diverse: addition to the solutions

used for packing; making up of brine requirements when olives are put in

plastic drums for conditioning; and employment for new fermentative

processes, although in this case proportions should be low and it is the

least recommended mode of reutilization at present.

In any case, re-use in adequate proportions to prepare packing solutions might be a reasonable alte~ative. The main influence on the final

product depends on the physico-chemical characteristics of the solutions. An increase in pH and combined acidity is always observed. This

increase in buffer capacity might be a serious drawback if fruit is to be

preserved only by its pH and salt concentrations. In this case, a correction in the combined acidity by addition of a strong acid is required.

Otherwise, final pH will not reach a value low enough for product stability. However, if the product is pasteurized, as is becoming standard

practice in the industry, there is always the possibility of selecting the

appropriate

proportion

of regenerated brine for the required final

characteristics. This percentage will vary from case to case and will

depend on the constraints imposed by the product conditions - in

particular, combined acidity, acid and salt contents in the fermentation

brine as well as type of packing containers (jars, cans, plastic bags, etc.).

With the Hojibl~ca cultivar it has been shown that 45% of ultraf~tered

and up to 70% of carbon regenerated brines treated with 06% of activated carbon (with a slight acidity correction) can be added to the packing

solutions.

No serious economic conclusions can be deduced from these experiments. However, an approximate study was made by the technical staff

of the firm where the experiment was carried out. They considered the

prices of the lactic acid and salt, and the reduction in pollution taxes. The

results showed that returns would more than pay for the investment and

running costs of any of the regeneration systems studied.

304

A. Garrido, P. Garcia, M. Brenes

ACKNOWLEDGEMENTS

The authors wish to thank Agrosevilla, S.A. Coop. (La Roda de

Andalucia, Sevilla, Spain) where field tests were carried out, TFB

(Madrid, Spain) and Chaconsa, S.A. (Murcia, Spain) for the use of the

ultrafiltration and crossflow microfiltration equipment, respectively, and

Drs Rejano and Sanchez for advising on the sensory analysis.

The authors also express their sincere gratitude to Consejo Superior

de Investigaciones Cientificas (Madrid, Spain) for providing special

support for this research and CICYT under whose project ALI88-0151CO2-0 1 this work was done.

REFERENCES

Anon., (1986). Manual of Instructions. Paterson Candy International,

Leverstoke Mill, Whitchurch, Hampshire, UK.

Anon., ( 1988). Manual de operacibn. Chaconsa, S.A., Murcia, Spain.

Brenes, M. & Garrido, A. (1988). Regeneracibn de salmueras de aceitunas

verdes estilo sevillano con carbon active y tierras decolorantes. Grasas y

Aceites., 9,96-101.

Brenes, M., Garcia, P. 22 Garrido, A. (1988). Regeneration of Spanish style

green table olive brines by ultrafiltration. J. Food Sci., 53, 1733-6.

Brenes, M., Montaiio, A. & Garrido, A. (1990). Ultrafiltration of green table

olive brines: Influence of some operating parameters and effect on polyphenol composition. 1. Food Sci., 55,2 14- 17.

Buescher, R. W. (1984). Hollow fiber ultrafiltration of spent pickle brines.

Arkansas Farm. Research., 33(l),

4.

Durkee, E. L., Lowe, E., Baker, K. A. & Benges, J. W. (1973). Field tests of salt

recovery system for spent brine. 1. Food Sci., 38,507-l

1.

Durkee, E. L., Lowe, E. & Toockeck, E. A. ( 1974). Use of recycled salt in

fermentation of cucumber salt stock. J. Food Sci., 39, 1032-3.

Fernandez, M. J. et al. (1985 ). Biotecnologia de la aceituna de mesa, Instituto de

la Grasa, Sevilla, Spain.

Fleming, H. P., McFeeter, R. F., Daeschel, M. A., Humphries, E. G. &

Thompson, R. L. (1988). Fermentation of cucumbers in anaerobic tanks. J.

Food Sci., 153,127-33.

Garrido, A. (1979). Regeneration

sevillano o espafiol mediante

Aceites., 30,5-10.

de salmueras de aceitunas verdes al estilo

la adsorcion con carbon active. Grasas y

Garrido, A. (1990). Environmental Impact: Fermented Food and Vegetables. I

Congreso Interncional de Tecnologia y Desarrollo Alimentario, Murcia,

Spain, Promociones y Publicaciones Universitarias Barcelona. pp. 363-74.

Garrido, A., Cordon, J., Rejano, L., Gonzalez, F. & Sanchez, F. (1979). Elaboracion de aceitunas verdes estilo espaiiol con reutilization de lejias y supresion

de lavados. Grasas y Aceites., 30,227-34.

The recycling of table olive brine

305

Ginnette, L. F. ( 1968). Reconditioning and reusing brines by carbon column

adsorption. 47th Annual Technical Report of the California Olive Association, USA.

Glaros, T. & Geisman, J. R. (1980). Organic flocculants spent pickle curing

brine recycling. J. Food Sci., 45,402-3.

Gonzalez, F., Rejano, L., Duran, M. C., Sanchez, F., Castro, A., Garcia. P. &

Garrido, A. ( 1984). Elaboration

de aceitunas verdes estilo espanol sin

lavado. Solution a 10s problemas de adicion de HCl y efecto de1 tratamiento

con lejias bajas. Grusasy Aceitus., 35, 155-9.

Kramer, A. & Twigg, B. A. ( 1962). Fundamentals of Quality Controlfor the Food

Industry. AVI Publishing Company, Inc., Westport, CT, USA.

Leoni, C., Grischott, F. & Fortini, G. ( 1981). Trattamento di efluenti specifici

dellindustria alimentare particolarmente ricchi di substance organiche. Znd.

Conserve., 56, 173-7.

Montaiio, A. (1987). Proceso ripido para la elaboration de aceitunas verdes

aderezadas. PhD thesis, University of Seville, Spain.

Palnitkar, M. P. & McFeeters, R. F. (1975). Recycling spent brines in cucumber

fermentations. J. Food Sci., 40, 13 1 l- 15.

Rose, W. W. (1982). Innovation treatment technology. 59th Annual Technical

Report of the California Olive Association, USA.

Ruiz Maya, L. (1977). Metodos estadisticos de investigation. Presidencia de

Gobierno, Instituto National de Estadistica, Madrid, Spain.

Sanchez, A., Rejano, L. & Montaiio, A. (1985). Determination de1 color en las

aceitunas verdes aderezadas de la variedad Manzanilla. Grasas y Aceites., 36,

258-6

1.

Welsh, F. & Zall, R. (1984). An ultrafiltration activated treatment system for

renovating fishery refrigeration brines. Can. Inst. Food Sci. Technof. J.. 17,

92-6.

You might also like

- Algorithmic Approach To Process Design of Direct Rotary Dryers CoolersDocument19 pagesAlgorithmic Approach To Process Design of Direct Rotary Dryers CoolersSeyit AvcuNo ratings yet

- Performance Fire Retardant Additives For Wire and CableDocument6 pagesPerformance Fire Retardant Additives For Wire and CableSeyit AvcuNo ratings yet

- Mixed Aluminum Hydroxide Powder-1Document10 pagesMixed Aluminum Hydroxide Powder-1Seyit AvcuNo ratings yet

- Carbon Dioxide Gas Absorbent Containing Lithium SilicateDocument18 pagesCarbon Dioxide Gas Absorbent Containing Lithium SilicateSeyit AvcuNo ratings yet

- Pretreatment System For Goethitic BauxitesDocument7 pagesPretreatment System For Goethitic BauxitesSeyit AvcuNo ratings yet

- The Comparison of The Bayer Process Wastes On The Base of Chemical and Physical PropertiesDocument6 pagesThe Comparison of The Bayer Process Wastes On The Base of Chemical and Physical PropertiesSeyit AvcuNo ratings yet

- An Investigation On Characterization and Thermal Analysis of The Aughinish Red Mud PDFDocument5 pagesAn Investigation On Characterization and Thermal Analysis of The Aughinish Red Mud PDFSeyit AvcuNo ratings yet

- Method of Producing Lithium FluortdeDocument2 pagesMethod of Producing Lithium FluortdeSeyit AvcuNo ratings yet

- Carbon Dioxide Gas Absorbent Containing Lithium SilicateDocument18 pagesCarbon Dioxide Gas Absorbent Containing Lithium SilicateSeyit AvcuNo ratings yet

- Process For Preparing Lithium CarbonateDocument205 pagesProcess For Preparing Lithium CarbonateSeyit AvcuNo ratings yet

- Thermodynamic Process Modeling and Simulation of A Diaspore Bauxite Digestion ProcessDocument64 pagesThermodynamic Process Modeling and Simulation of A Diaspore Bauxite Digestion ProcessSeyit AvcuNo ratings yet

- Role of Mineralogy and Geochemistry in The Beneficiation of Jajarm Bauxite From North East Iran Comparison With Some Other Bauxite Deposits of The WorldDocument15 pagesRole of Mineralogy and Geochemistry in The Beneficiation of Jajarm Bauxite From North East Iran Comparison With Some Other Bauxite Deposits of The WorldSeyit AvcuNo ratings yet

- Purification of Bayer Process LiquorsDocument11 pagesPurification of Bayer Process LiquorsSeyit AvcuNo ratings yet

- Submicron Alpha Alumina High Temperature Bonded AbrasivesDocument7 pagesSubmicron Alpha Alumina High Temperature Bonded AbrasivesSeyit AvcuNo ratings yet

- Evaporation Process ControlDocument3 pagesEvaporation Process ControlNedjeljko VranicNo ratings yet

- Materials and Energy Balance in Metallurgical ProcessesDocument20 pagesMaterials and Energy Balance in Metallurgical ProcessesSeyit Avcu100% (1)

- Production of High Purity AluminaDocument18 pagesProduction of High Purity AluminaSeyit AvcuNo ratings yet

- SpecifyingStainlessSteelSurfaceTreatments 10068 PDFDocument5 pagesSpecifyingStainlessSteelSurfaceTreatments 10068 PDFSeyit AvcuNo ratings yet

- Bauxite Beneficiation by Hydration of GangueDocument6 pagesBauxite Beneficiation by Hydration of GangueSeyit AvcuNo ratings yet

- Upgrading of Bauxites, BDocument17 pagesUpgrading of Bauxites, BSeyit AvcuNo ratings yet

- Bayer CausticisationDocument18 pagesBayer CausticisationSeyit AvcuNo ratings yet

- Method of Digesting Bauxite Via The Bayer Process With The Addition of Reducing AgentsDocument4 pagesMethod of Digesting Bauxite Via The Bayer Process With The Addition of Reducing AgentsSeyit AvcuNo ratings yet

- SpecifyingStainlessSteelSurfaceTreatments 10068 PDFDocument5 pagesSpecifyingStainlessSteelSurfaceTreatments 10068 PDFSeyit AvcuNo ratings yet

- Aluminum Oxide From Bayer Process, Metallurgical GradeDocument28 pagesAluminum Oxide From Bayer Process, Metallurgical GradeSeyit AvcuNo ratings yet

- Determining heat transfer coefficients in a falling film evaporatorDocument7 pagesDetermining heat transfer coefficients in a falling film evaporatorSeyit AvcuNo ratings yet

- Pretreatment System For Goethitic BauxitesDocument7 pagesPretreatment System For Goethitic BauxitesSeyit AvcuNo ratings yet

- GEA P03e Evaporation Technology 1Document24 pagesGEA P03e Evaporation Technology 1Seyit Avcu100% (2)

- An Investigation On Characterization and Thermal Analysis of The Aughinish Red Mud PDFDocument5 pagesAn Investigation On Characterization and Thermal Analysis of The Aughinish Red Mud PDFSeyit AvcuNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- PilotPlantEquipment ListDocument2 pagesPilotPlantEquipment ListAhmed Khalid RasheedNo ratings yet

- Ultrafiltration Process SkidDocument3 pagesUltrafiltration Process SkidDenis AkingbasoNo ratings yet

- Aspen Plus v8.0 - Getting Started Customizing ModelsDocument70 pagesAspen Plus v8.0 - Getting Started Customizing ModelsLucas WalkerNo ratings yet

- Pradeep Rathy - VAPCO Zero Liquid DischargeDocument63 pagesPradeep Rathy - VAPCO Zero Liquid DischargePradeep Rathy67% (3)

- TSE Treatment BOQDocument1 pageTSE Treatment BOQurssulthan44160% (1)

- Wastewater Treatment Using Membrane TechnologyDocument13 pagesWastewater Treatment Using Membrane TechnologyPoojitha H SNo ratings yet

- Extended Abstract Novel In-Situ Photocatalytic Membrane Filtration For Laundry Wastewater Treatment Into Clean WaterDocument7 pagesExtended Abstract Novel In-Situ Photocatalytic Membrane Filtration For Laundry Wastewater Treatment Into Clean WaterDani Puji UtomoNo ratings yet

- Dairy ProteinsDocument15 pagesDairy Proteinssushant deyNo ratings yet

- Treatment GuideDocument13 pagesTreatment GuideLTE002No ratings yet

- 2017 Tubular Ultrafiltration Ceramic Membrane Based On Titania NanoparticlesDocument8 pages2017 Tubular Ultrafiltration Ceramic Membrane Based On Titania NanoparticlesMuhammad Arqam ZaheerNo ratings yet

- Cold WFI in Best Quality: Generate, Store and Distribute WfiDocument11 pagesCold WFI in Best Quality: Generate, Store and Distribute WfiBulent InanNo ratings yet

- 〈1228.3〉 Depyrogenation by FiltrationDocument4 pages〈1228.3〉 Depyrogenation by Filtrationmehrdarou.qaNo ratings yet

- Lenntech Water Treatment Solutions GuideDocument11 pagesLenntech Water Treatment Solutions GuideMegamax1985No ratings yet

- Products and Solutions For The Biopharmaceutical Industry PDFDocument764 pagesProducts and Solutions For The Biopharmaceutical Industry PDFBiopharmaNo ratings yet

- 00 MBR - Aml - enDocument2 pages00 MBR - Aml - enBiagio SeniseNo ratings yet

- Biotech CIP Cycle Development-Case Study Examples Utilizing QRMDocument73 pagesBiotech CIP Cycle Development-Case Study Examples Utilizing QRMsasirkumar1No ratings yet

- Scope of Traditional Indian Dairy ProductsDocument10 pagesScope of Traditional Indian Dairy ProductsHitesh KaushikNo ratings yet

- Argentina Membrane Filtration JCD PDFDocument42 pagesArgentina Membrane Filtration JCD PDFjpsingh75No ratings yet

- PET Recycle Case StudyDocument5 pagesPET Recycle Case StudyIndustria ProyectosNo ratings yet

- Aria Water Treatment SystemDocument12 pagesAria Water Treatment SystemcysautsNo ratings yet

- DEGREMONT GUIDE2012 EN REV02 BDDocument30 pagesDEGREMONT GUIDE2012 EN REV02 BDnermeen ahmedNo ratings yet

- Hyflux Kristal MembraneDocument6 pagesHyflux Kristal Membranefatrasky50% (2)

- Datasheet HFS60Document3 pagesDatasheet HFS60RajeswaranNo ratings yet

- Waste Treatment and Disposal TechnologyDocument90 pagesWaste Treatment and Disposal TechnologybillNo ratings yet

- Food and Bio Process EngineeringDocument24 pagesFood and Bio Process EngineeringRosane Cavalcante100% (1)

- Kristal Eng PDFDocument32 pagesKristal Eng PDFDũng Phạm AnhNo ratings yet

- Wave - Three Technolgies - One ToolDocument2 pagesWave - Three Technolgies - One ToolexergicNo ratings yet

- Operating Handbook - Howllow Fiber Cartidges For Membrane SeparationsDocument28 pagesOperating Handbook - Howllow Fiber Cartidges For Membrane SeparationsRafael MagalhãesNo ratings yet

- Advances in Polymeric Nanofiltration Membrane - A ReviewDocument56 pagesAdvances in Polymeric Nanofiltration Membrane - A ReviewPolanqNo ratings yet

- POFP I - Lesson Plan July 2019 PDFDocument9 pagesPOFP I - Lesson Plan July 2019 PDFPoorani KalyanakumarNo ratings yet