Professional Documents

Culture Documents

1.1 Torispherical Ends Calculation - PZN - DJ03 - DN500: Title Calculation LP Header - 0LBA10BR100

Uploaded by

pakitingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.1 Torispherical Ends Calculation - PZN - DJ03 - DN500: Title Calculation LP Header - 0LBA10BR100

Uploaded by

pakitingCopyright:

Available Formats

Project Name:

ITPOK Poznan

Title: Calculation LP Header - 0LBA10BR100

AIC:

ON HOLD

Document Nr-Rev:

ON HOLD - 0.0

1.1 Torispherical Ends Calculation - PZN_DJ03 - DN500

DESIGN OF ENDS UNDER INTERNAL PRESSURE ACCORDING EN 13480-3

PIPE CLASS: PZN_DJ03

Cap dimensions:

Nominal Diameter

DN500

Outer Diameter

Do = 508,0 mm

Ordered wall thickness

e = 25,0 mm

Pipe Inner Diameter

Di = Do - 2e = 458,0 mm

Inside spherical radius for torispherical end Ri = 0,8 Do = 406,40 mm

Inside knuckle radius ri = 0,15 Do = 76,20 mm

Temperature and Internal Pressure

Calculation Temperature

Tc = 300 C

Calculation Pressure Pc = 79,0 bar (g)

Material

DIN num. 1.5415

No Austentico Steel

Wall thickness Allowances

Corrosion and/or erosion allowance c0 = 1,00 mm

Absolute value of the negative tolerance taken from the material standard or given

by piping manufacturer. Tolerances according to EN 10216-5:

c 1 e ord ; c 1

c 1=max

c 1=15,0

=0,00

c1

mm

c1 =3,75 mm

Thinning allowance for possible thinning during manufacturing process.

c2 = 0,00 mm

Joint coefficient

Joint coefficient

z = 1,00 for circumferential joints

Analysis Thickness

e a=ec0 c 1 bc 2=20,25 mm

Print date 10.03.15 12:21

Last saved 00.00.00

Page 1 of 4

Project Name:

ITPOK Poznan

Title: Calculation LP Header - 0LBA10BR100

AIC:

ON HOLD

Document Nr-Rev:

ON HOLD - 0.0

Dai =Do 2 eas =mm

Design Stress

According to EN 13480-3, Design stress is calculated as follows:

Design Stress f

Austenitic Steel

Non-austenitic Steel

Elongation A

f=

A 35%

30% A < 35%

f =min

A < 30%

f =min

{

{

R p 1,0t

1,5

R p 1,0t R m

;

1,5 2,4

R p 0,2t R m

;

1,5 2,4

}

}

f =min

R p 0,2 t R m

;

1,5 2,4

Material 1.5415 No Austentico Steel

Minimum Elongation A = 20%

Minimum Tensile Strength

Rm = 450,00 MPa

Minimum proof strength at 300C

Rp0,2t = 173,00 MPa

Design stress f = 115,33 MPa

Mechanical properties values have been taken from EN 10216-5.

Design stress to prevent buckling

fb = 115,33 MPa

For all materials except cold formed austenitic stainlees steel fb = f

For cold formed austenitic stainlees steel fb = 1,6 f

Design conditions

r i 0,2 Di=91,60

r i 0,06 Di=27,48

COMPLY

r i 2 e=50,00

e 0,08 D i=91,60 mm

e 0,001 D i=27,48 mm

for carbon steelaustenitic steel ends

COMPLY

if e <0,003 D i=50,00 mm then

t c 100 C

Print date 10.03.15 12:21

Last saved 00.00.00

Page 2 of 4

Project Name:

ITPOK Poznan

Title: Calculation LP Header - 0LBA10BR100

AIC:

ON HOLD

Document Nr-Rev:

Ri D o

ON HOLD - 0.0

COMPLY

Calculation of

Y =min

Z =log

X=

e

; 0,04 =0,04

Ri

( Y1 )=1,40

ri

=0,17

Ri

N= 1,006

1

=1,00

4

6,2+ ( 90 Y )

For X =0,06 = 0,06=N (0,3635 Z 3+ 2,2124 Z 23,2937 Z+ 1,8873 )

For 0,06 X =0,1 =25 [ ( 0,1X ) 0,06+(X 0,06) 0,1 ]

=0,52

For X =0,1 = 0,1=N (0,1833 Z 3 +1,0383 Z 21,2943 Z+0,8370 )

For 0,1 X=0,2 =10 [ ( 0,2 X ) 0,1 +(X0,1) 0,2 ]

For X =0,2 = 0,2 =max [ 0,5321,843 Y 78,375 Y 2 ;(0,5) ]

Validation of Cap Wall Thickness

Minimum required thickness

e max( e s ; ekn y ; e kn b )

p c Ri

e s=

=14,16 mm

2 fz0,5 p c

p c (0,75 Ri +0,2 Di )

e kn y =

=14,09mm

f

1

1,5

{( ) }

p D

e kn b=(0,75 Ri +0,2 Di ) c i

f b ri

0,825

=7,70 mm

COMPLY

Maximum pressure

Print date 10.03.15 12:21

Last saved 00.00.00

Page 3 of 4

Project Name:

ITPOK Poznan

Title: Calculation LP Header - 0LBA10BR100

AIC:

ON HOLD

Document Nr-Rev:

ON HOLD - 0.0

p c min( p s ; pkn y ; pknb )

2 f ea z

p s=

=11,21 MPa

Ri +0,5 e a

f ea

COMPLY

pkn y =

=11,36 MPa

(0,75 Ri +0,2 Di)

1,5

ea

r i 0,825

e kn b=111 f b

=33,66 MPa

0,75 Ri +0,2 Di

Di

)( )

Usage rate

pc

= 70,4%

min( ps ; p kn y ; p kn b )

Print date 10.03.15 12:21

Last saved 00.00.00

Page 4 of 4

You might also like

- GAS PIPELINE CALCULATIONDocument37 pagesGAS PIPELINE CALCULATIONrasnowmah2012No ratings yet

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDocument72 pagesAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuNo ratings yet

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- Cone Design Tool: Pressure Vessel Engineering LTDDocument1 pageCone Design Tool: Pressure Vessel Engineering LTDkedubhajjiNo ratings yet

- Mathcad - Bolt Loading VDI M39 01Document10 pagesMathcad - Bolt Loading VDI M39 01Pete SwiftNo ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Bab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselDocument36 pagesBab Iii: Re-Design Dan Hasil Perhitungan Horizontal Pressure VesselTri AgungNo ratings yet

- ASME VIII-1 Calculations for Sample Pressure VesselDocument21 pagesASME VIII-1 Calculations for Sample Pressure VesselTrishul Nath Pallay100% (1)

- Pressure Vessel Engineering LTD.: Design ConditionsDocument30 pagesPressure Vessel Engineering LTD.: Design ConditionsTrishul Nath PallayNo ratings yet

- Design of BeamDocument17 pagesDesign of Beamravikiran226100% (1)

- Element ThicknessDocument10 pagesElement ThicknesskhairulakbarNo ratings yet

- Asme Viii CalcsDocument20 pagesAsme Viii CalcsSriram VjNo ratings yet

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- Calculation As Per Asme b31.3Document8 pagesCalculation As Per Asme b31.3Rajkumar ANo ratings yet

- Super CalculationsDocument9 pagesSuper CalculationsNoé MarínNo ratings yet

- Design Calculation Sheet: H2So4 Neutralization TankDocument43 pagesDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNo ratings yet

- L 8 IhjnmklgfDocument27 pagesL 8 IhjnmklgfbrintopvNo ratings yet

- Es Emp Iocal Colo en 13480Document25 pagesEs Emp Iocal Colo en 13480castibraNo ratings yet

- Storage Tank Design Calculations for Hydrogen PeroxideDocument12 pagesStorage Tank Design Calculations for Hydrogen Peroxidechompink6900No ratings yet

- K-4b Perhitungan PipaDocument51 pagesK-4b Perhitungan PipaIndra MaulanaNo ratings yet

- Nozzle CalculationsDocument2 pagesNozzle CalculationsBaher Elsheikh100% (3)

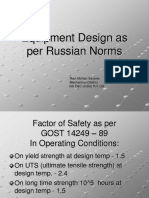

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikasNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Reinforcement calculations for multiple nozzlesDocument15 pagesReinforcement calculations for multiple nozzlesMuhammad Hassan MaqsoodNo ratings yet

- Engineering Example CalculationDocument78 pagesEngineering Example Calculationkae kaeNo ratings yet

- Horizontal Retention Tank Design and CalculationsDocument40 pagesHorizontal Retention Tank Design and Calculationslaleye_olumideNo ratings yet

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Nozzle F Factor CalculationsDocument5 pagesNozzle F Factor CalculationsSivateja NallamothuNo ratings yet

- Displacement Control STN 10iDocument2 pagesDisplacement Control STN 10itungNo ratings yet

- Company Name: Input DataDocument4 pagesCompany Name: Input Dataagb71c2478No ratings yet

- Section 18 PDFDocument25 pagesSection 18 PDFJap IbeNo ratings yet

- PV 1390 Cal R1Document44 pagesPV 1390 Cal R1namasralNo ratings yet

- Mathcad - ASME I I VIII I Thickness Cylindrical ShellDocument3 pagesMathcad - ASME I I VIII I Thickness Cylindrical ShellkurcekNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument30 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersmishtinilNo ratings yet

- Calculo Plug Hex HeadDocument18 pagesCalculo Plug Hex HeadDalberto RamirezNo ratings yet

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- Miter B1 ADocument55 pagesMiter B1 AFarid TataNo ratings yet

- Cleat Connection For PlatformsDocument29 pagesCleat Connection For PlatformsRajveer SinghNo ratings yet

- PV Elite 2012 R1 Licensee: Pressure Filename: 102 Horz Tank - Internal Pressure Calculations: Step: 3 7:29P Oct 5,2012Document7 pagesPV Elite 2012 R1 Licensee: Pressure Filename: 102 Horz Tank - Internal Pressure Calculations: Step: 3 7:29P Oct 5,2012isaacalvareztejanoNo ratings yet

- 31barg CalculationDocument10 pages31barg Calculationshani5573No ratings yet

- Design of T Beam Using SP16 Economic Depth and CheckDocument10 pagesDesign of T Beam Using SP16 Economic Depth and CheckRiazahemad B JagadalNo ratings yet

- Moment Connection - Flush End Plate-19.01.06Document48 pagesMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- RCC11 Element DesignDocument6 pagesRCC11 Element DesignAli IssamNo ratings yet

- Mathcad - 539900-050-130 Padeye Pulling Skid 9.5 TDocument7 pagesMathcad - 539900-050-130 Padeye Pulling Skid 9.5 TPablo Diego Didoné100% (1)

- Pipeline Design-InstallationDocument19 pagesPipeline Design-InstallationFaridah ZahraNo ratings yet

- Design Calculations For Pressure VesselsDocument32 pagesDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- Irjet V4i11110Document6 pagesIrjet V4i11110AboalmaaliNo ratings yet

- Bracket - 4 DesignDocument1 pageBracket - 4 Designbjreddy100% (2)

- C4.tension Member Compatibility ModeDocument45 pagesC4.tension Member Compatibility ModejojomarbunNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Iisc Csa Call LetterDocument3 pagesIisc Csa Call Lettervkk intensiveNo ratings yet

- FACTORS Affecting The Entrepreneurial DynamicsDocument4 pagesFACTORS Affecting The Entrepreneurial DynamicsAzraNo ratings yet

- Muru Crane CV WordDocument6 pagesMuru Crane CV WordMURUGESAN PONNIAHNo ratings yet

- Gear Box ReportDocument39 pagesGear Box ReportNisar HussainNo ratings yet

- XCMG ZL50GN 手册Document6 pagesXCMG ZL50GN 手册Lisa XiaoNo ratings yet

- The Find Out The Present Status of Thumps Up, Coca-ColaDocument158 pagesThe Find Out The Present Status of Thumps Up, Coca-Colagazala_shaikh0% (1)

- NBFC Playbook: Understanding Non-Banking Financial CompaniesDocument13 pagesNBFC Playbook: Understanding Non-Banking Financial CompaniesAkshay TyagiNo ratings yet

- Right Call - Issue 9Document4 pagesRight Call - Issue 9api-241999402No ratings yet

- Probationary DigestsDocument22 pagesProbationary DigestsMatt ManlapidNo ratings yet

- LAB 3 - Rockwell Hardness TestingDocument10 pagesLAB 3 - Rockwell Hardness TestingLEKA THOBEJANENo ratings yet

- Question and Answer - 50Document31 pagesQuestion and Answer - 50acc-expertNo ratings yet

- CS 132 Mathematics For Computer Science: Applications of DerivativesDocument23 pagesCS 132 Mathematics For Computer Science: Applications of DerivativesDhuanne EstradaNo ratings yet

- Afl Fact SheetDocument1 pageAfl Fact Sheetapi-257609033No ratings yet

- Difference Between Baseband and Broadband TransmissionDocument3 pagesDifference Between Baseband and Broadband Transmissionfellix smithNo ratings yet

- Configuracion y O&M BTS NokiaDocument43 pagesConfiguracion y O&M BTS Nokiajcardenas55No ratings yet

- Rackham - Confrontation - OphidiansDocument14 pagesRackham - Confrontation - Ophidiansjasc0_hotmail_itNo ratings yet

- EUA 105 Pfizer Paxlovid FS For HCPs 05242023 - 0Document41 pagesEUA 105 Pfizer Paxlovid FS For HCPs 05242023 - 0bachillerataNo ratings yet

- Capacity Building Programme Methods Template Signed1Document14 pagesCapacity Building Programme Methods Template Signed1REXNo ratings yet

- Quadcopter Project Presentation Using KK 2.1.5 ControllerDocument13 pagesQuadcopter Project Presentation Using KK 2.1.5 ControllerAkshay SinghalNo ratings yet

- (Labour Law-1) - 1Document4 pages(Labour Law-1) - 1Arghyadeep NagNo ratings yet

- Gupta Et Al. (1989)Document23 pagesGupta Et Al. (1989)Prabath PzNo ratings yet

- Items in The Classroom: Words)Document2 pagesItems in The Classroom: Words)Alan MartínezNo ratings yet

- OpenStack Installation Guide For (RHEL, CentOS, Fedora)Document140 pagesOpenStack Installation Guide For (RHEL, CentOS, Fedora)kinamedebo100% (1)

- Audio System and Pairing: Supplementary Rider's ManualDocument106 pagesAudio System and Pairing: Supplementary Rider's ManualSylvainsfcNo ratings yet

- Commercial Dispatch Eedition 7-10-19Document16 pagesCommercial Dispatch Eedition 7-10-19The DispatchNo ratings yet

- Narrative Report - Food Safety and SanitationDocument4 pagesNarrative Report - Food Safety and SanitationMarjorie Dela CruzNo ratings yet

- Statement Showing The List of Lps Applications of Isnapur (V) Patancheru (M)Document14 pagesStatement Showing The List of Lps Applications of Isnapur (V) Patancheru (M)dpkrajaNo ratings yet

- US V RuizDocument2 pagesUS V RuizCristelle Elaine ColleraNo ratings yet

- Magnetic Separator GuideDocument31 pagesMagnetic Separator GuideMNButt100% (1)

- Ima612s - Intermediate Macroeconomics - 2nd Opp - Jan 2020Document7 pagesIma612s - Intermediate Macroeconomics - 2nd Opp - Jan 2020Martha EeluNo ratings yet