Professional Documents

Culture Documents

HRC STD 6100 004 M 01 PDF

Uploaded by

Emir MujićOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HRC STD 6100 004 M 01 PDF

Uploaded by

Emir MujićCopyright:

Available Formats

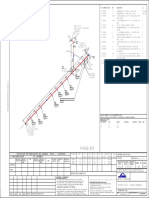

H

M 1:5

820

170

160

M 1:5

160

160

170

150

160

3

2

844

820

160

16.3

160

160

170

50

12

12

170

12

108

120

Hub 19

02

12

24

796

01

01

Novapress 3x24x1016

1016

1040

1016

5x160=801.2

1004

1104

5x160=800

1040

50

784

884

02 Novapress 3x24x844

50

A-A

24

12

12

50

120

108

Acces door:

Drw.No: HRC-STD-6100-001

M 1:5

01

5

160

130

Schraube M8x25 ISO 4017

03 Skt.

Hex. bolt

8 ISO 7089

04 Scheibe

Washer

Mu M8 ISO 4034

05 Skt.

Hex. nut

General tolerances:

Welded constructions: DIN EN ISO 13920 - class B / E

Prefabricated steel components: DIN 18203-2

Mechanically worked parts: DIN ISO 2768 - class m / K

402

3

Welding quality levels according to QI-Plan related to order

WELDING DETAILS:

367

778

2

884

Stiffener:

tmin

a

3

2

4

3

5

3

t1

b

3

4

4

5

5

6

6

4

7

4

8 GENERAL: Welding coordination acc. to DIN EN ISO 14731.

5

Quality requirements for weldings : DIN EN ISO 3834

Welding joint preparation acc. to DIN EN ISO 9692-1.

6

7

8

Welding joint preparation for site welds must be implemented in the workshop!

8

9

10

All screw and weld connections in contact with flue gas must be welded gas-tight.

All fillet welds a = 3mm, if not otherwise indicated.

Welding Information: Symbolic representation

Stiffener:

t2

Shop weld

Sheet metal connections:

Stiffener:

HAMON

t2

Site weld

t1

t1

ASM-001

Flange connection:

H

0

10

20

30

H

40

50

60

70

80

90

H

100

t1

t2

t1

t2

~t

dicht / tight

To put sheets together cross joint

are inadmissible!

Sheets have to be arranged in an offset pattern

ASM-001

M 1:5

Door complete

170

160

160

160

170

150

160

connecting flange

Hub 19

120

125

120

3

2

789

5x160=800

120

95

100

Door leaf I

Door leaf II

160

Werkstatt

3

Alle Gelenkteile mit Molykote-Paste behandeln.

Workshop

Finish mounting the locking bar (Item22). It have to be free-movable.

Cover all hinges with Molykote paste.

402

6

778

3

2

370

3

2

General tolerances:

884

Welded constructions: DIN EN ISO 13920 - class B / E

Prefabricated steel components: DIN 18203-2

Mechanically worked parts: DIN ISO 2768 - class m / K

Welding quality levels according to QI-Plan related to order

WELDING DETAILS:

3

2

4

3

5

3

t1

b

3

4

4

5

5

6

6

4

7

4

8 GENERAL: Welding coordination acc. to DIN EN ISO 14731.

5

Quality requirements for weldings : DIN EN ISO 3834

Welding joint preparation acc. to DIN EN ISO 9692-1.

6

7

8

Welding joint preparation for site welds must be implemented in the workshop!

8

9

10

All screw and weld connections in contact with flue gas must be welded gas-tight.

All fillet welds a = 3mm, if not otherwise indicated.

Welding Information: Symbolic representation

Stiffener:

Stiffener:

t2

tmin

a

Sheet metal connections:

Stiffener:

HAMON

Shop weld

t1

t1

t2

Site weld

Flange connection:

t1

10

20

30

H

40

50

60

70

80

90

H

100

t1

~t

t2

H

0

t2

dicht / tight

To put sheets together cross joint

are inadmissible!

Sheets have to be arranged in an offset pattern

50

32

04

15

05

01

01 04

06

15-16

03

152

120

06

15-16

60 40

18

09-13 08

80

09-13

a2

a2

06

08

350

a2

15-16

ISO2341-B-4x28

11 Bolzen

Clevis pin with head

03

1x10 ISO1234

13 Splint

split pin

4 ISO7089

09 12 Scheibe

washer

09

10,2x2,6-17

10 Rohr

pipe

789

1004

789

07

06

06

14

a2

a2

a2

a2

03

06

40

30

50

18

a2

a2

160

18

17

18

317

14

X

5x160=800

14

102

152

25

884

784

250

220

07 05

350

M 1:1

15

50

M 1:5

317

1004

50

connecting flange

3

120

60 40

450

450

60 40

95

01

4

32

18

18

15-16

30 52

60 40

95

102

15-16

06

A-A

M 1:1

06

50

50

15-16

A

09-13

18

52

A

06

32

170

160

160

02

02

160

408

442

170

06

32

9

06

476

442

a2

a2

884

442

442

50

3

784

34.5

50

30

01 03

05 08

a2

06

80

82

85

160

a2

a2

a2

General tolerances:

40

25

14

15-16

815

30

03

06

15-16

a2

07

09-13

34.5

815

04

Welded constructions: DIN EN ISO 13920 - class B / E

Prefabricated steel components: DIN 18203-2

Mechanically worked parts: DIN ISO 2768 - class m / K

14

15-16

Welding quality levels according to QI-Plan related to order

WELDING DETAILS:

34.5

3

2

4

3

5

3

t1

b

3

4

4

5

5

6

6

4

7

4

8 GENERAL: Welding coordination acc. to DIN EN ISO 14731.

5

Quality requirements for weldings : DIN EN ISO 3834

Welding joint preparation acc. to DIN EN ISO 9692-1.

6

7

8

Welding joint preparation for site welds must be implemented in the workshop!

8

9

10

All screw and weld connections in contact with flue gas must be welded gas-tight.

All fillet welds a = 3mm, if not otherwise indicated.

Welding Information: Symbolic representation

Stiffener:

Stiffener:

t2

tmin

a

Sheet metal connections:

Stiffener:

HAMON

Shop weld

t1

t1

t2

Site weld

Flange connection:

H

0

10

20

30

H

40

50

60

70

80

90

H

100

t1

t2

t1

t2

~t

dicht / tight

To put sheets together cross joint

are inadmissible!

Sheets have to be arranged in an offset pattern

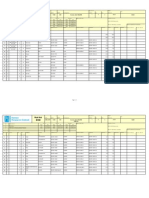

Item 01

M 1:5

884

30

12

18

50

102

6

26.5

27

15

R30

Item 06

M 1:2

154

Rd.20-665

round

27

R3

1004

160

20

12

30

15

20

115

Bl.3x50x5

plate

50

102

50

115

185

130.5

220

230 10.5

884

20

21

15

16

100

M 1:5

Pl.3x884x185

plate

50

Biegelinie

bending line

30

Rd.18-100

round

40

154

228

47

-0.2

-0.5

15

Biegelinie

bending line

M 1:1

0

R3

1004

5x160=800

R3

18

Pl.3x1004x228

plate

27

50

47

220

160

32

Item 04

Biegelinie

bending line

Pl.3x154x47

plate

170

884

12

32

32

160

Pl.3x884x228

plate

Biegelinie

bending line

154

47

R3

154

228

47

18

15

Biegelinie

bending line

27

90

160

15

15

160

228

154

50

12

170

140

47

32

M 1:5

884

160

30

R3

Pl.3x884x228

plate

Item 02

110

Pl.3x154x53,5

plate

64

30

70

32

10.5

85

160

18

170

27

Biegelinie

bending line

Biegelinie

bending line

50

30

12

50

160

12

160

R3

30

884

160

84

0

R3

170

M 1:2

M 1:5

R3

Item 05

M 1:2

3

32

Item 07

Item 03

48.5

47.5

53.5

60

30

30

a2

Item 09

Item 14

M 1:2

M 1:1

M 1:1

15

16

20

23

+0.1

-0.1

15

85

85

5

Pl.3x37x23

plate

Pl.3x32,5x15

plate

Pl.5x250x85

plate

Item 08

General tolerances:

25

32.5

7.5

Welded constructions: DIN EN ISO 13920 - class B / E

Prefabricated steel components: DIN 18203-2

Mechanically worked parts: DIN ISO 2768 - class m / K

37

250

Welding quality levels according to QI-Plan related to order

WELDING DETAILS:

3

2

4

3

5

3

t1

b

3

4

4

5

5

6

6

4

7

4

8 GENERAL: Welding coordination acc. to DIN EN ISO 14731.

5

Quality requirements for weldings : DIN EN ISO 3834

Welding joint preparation acc. to DIN EN ISO 9692-1.

6

7

8

Welding joint preparation for site welds must be implemented in the workshop!

8

9

10

All screw and weld connections in contact with flue gas must be welded gas-tight.

All fillet welds a = 3mm, if not otherwise indicated.

Welding Information: Symbolic representation

Stiffener:

Stiffener:

t2

tmin

a

Sheet metal connections:

Stiffener:

HAMON

Shop weld

t1

t1

t2

Site weld

Flange connection:

t1

10

20

30

H

40

50

60

70

80

90

H

100

t1

~t

t2

H

0

t2

dicht / tight

To put sheets together cross joint

are inadmissible!

Sheets have to be arranged in an offset pattern

Item 23

Item 24

M 1:5

Item 20

Item 22

M 1:5

M 1:5

M 1:5

A4,8x10 DIN7337

28 Blindniet

blind rivet

25

47

55

58

23

452

530

16,31

24

23

22

Pl.3x1014x407

plate

29 Blindniet A5x10 DIN7337

1014

1060

1060

992

53 46 53

Pl.3x992x172

plate

1014

998

992

982

1060

992

Locking bar shortened as shown

at individual part

1014

789

25

13

452

23

25

407

360

Pl.3x992x181,5

plate

25

181.5

156.5

a2

55

16,31

172

147

992

22

plate

20

125

20 25

plate

23

5

3

150

147

Stangenhub 19

lift height

Door leaf I

1

M 1:5

3

27Pl.1x982x333

3 21 Pl.4x1014x25

407

402

396

8

3

5

28

20

26

25

25

20

R3

147

147

53.5

5

20

27

30

24

Item 25

23

M 1:5

396

a2

+0.2

0

Item 26

M 1:5

a2

Bl.3x50x5

plate

45

16

a2

396

360

407

R3

47

26

290.5

26

53.5

147

147

147

21

25

25

53.5

26

290.5

25

13.5

15

25

16

31

26

25

10

R3

16,31

147

20 22

150

150

Rd.18-60

round

1

3

a0,7

31

a2

47

396

342.5

333

15

25

60

50

360

407

23

10

156.5

26

8

3

5

R3

a2

M 1:1

13

55

100

55

16,31

23

58

Stangenhub 19

lift height

452

B

16,31

Biegelinie

bending line

20

Biegelinie

bending line

530

452

blind rivet

General tolerances:

26

53.5

53.5

26

290.5

396

26

5

3

t1

b

3

4

4

5

5

6

6

4

7

4

8 GENERAL: Welding coordination acc. to DIN EN ISO 14731.

5

Quality requirements for weldings : DIN EN ISO 3834

Welding joint preparation acc. to DIN EN ISO 9692-1.

6

7

8

Welding joint preparation for site welds must be implemented in the workshop!

8

9

10

All screw and weld connections in contact with flue gas must be welded gas-tight.

All fillet welds a = 3mm, if not otherwise indicated.

Welding Information: Symbolic representation

Stiffener:

290.5

396

4

3

Site weld

Shop weld

Sheet metal connections:

t1

26

3

2

t1

16,31

Stiffener:

t2

tmin

a

20

Stiffener:

HAMON

Biegelinie

bending line

t2

Biegelinie

bending line

Welding quality levels according to QI-Plan related to order

WELDING DETAILS:

147

172

Pl.3x396x172

plate

25

Pl.3x396x172

plate

25

13.5 5

172

147

B-B

M 1:1

3

23 30

Welded constructions: DIN EN ISO 13920 - class B / E

Prefabricated steel components: DIN 18203-2

Mechanically worked parts: DIN ISO 2768 - class m / K

Flange connection:

H

0

10

20

30

H

40

50

60

70

80

90

H

100

t1

t2

t1

t2

~t

dicht / tight

To put sheets together cross joint

are inadmissible!

Sheets have to be arranged in an offset pattern

Door leaf II

Item 36

Item 37

Item 38

M 1:5

M 1:5

M 1:5

417

363.5

417

363.5

a2

16,31

R3

20

125

53.5

25

37

26

365

53.5

R3

37 35Pl.3x1014x372

plate

25

26

147

40 Pl.1x982x408

plate

150

147

147

372

1

3

181

156

147

5

3

8

3

5

52

M 1:5

427

422

416

147

25

26

365

26

16,31

53.5

363.5

363.5

992

1014

998

992

982

39

35

C

16,31

100

20

507

25

26

26

365

417

26

25

Item 39

R3

8

3

5

38

16,31

38

365

417

R3

Biegelinie

bending line

156

a2

26

Pl.3x417x172

plate

Biegelinie

bending line

789

1014

39

Biegelinie

bending line

a2

M 1:2

147

a2

275

Pl.3x992x181

plate

100

147

172

Pl.3x417x172

plate

53.5

25

36

172

147

23

507

36

55

R15

Rd.10-257

round

418

408

20

5

20

C-C

a0,7

M 1:1

3

1

40

30

36

a2

39 35

5

30

16,31

16,31

275

372

425

General tolerances:

Welded constructions: DIN EN ISO 13920 - class B / E

Prefabricated steel components: DIN 18203-2

Mechanically worked parts: DIN ISO 2768 - class m / K

54

5 13.5

97

23

23

147

150

160

13.5

35

Welding quality levels according to QI-Plan related to order

WELDING DETAILS:

3

2

4

3

5

3

t1

b

3

4

4

5

5

6

6

4

7

4

8 GENERAL: Welding coordination acc. to DIN EN ISO 14731.

5

Quality requirements for weldings : DIN EN ISO 3834

Welding joint preparation acc. to DIN EN ISO 9692-1.

6

7

8

Welding joint preparation for site welds must be implemented in the workshop!

8

9

10

All screw and weld connections in contact with flue gas must be welded gas-tight.

All fillet welds a = 3mm, if not otherwise indicated.

Welding Information: Symbolic representation

Stiffener:

Stiffener:

t2

tmin

a

Sheet metal connections:

Stiffener:

HAMON

Shop weld

t1

t1

t2

Site weld

Flange connection:

H

0

10

20

30

H

40

50

60

70

80

90

H

100

t1

t2

t1

t2

~t

dicht / tight

To put sheets together cross joint

are inadmissible!

Sheets have to be arranged in an offset pattern

You might also like

- LS 545-15 Anchor supports for horizontal pipingDocument7 pagesLS 545-15 Anchor supports for horizontal pipingtejasp8388No ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- XOMOXLinedPlugValvesEMEA TechnicalDataDocument20 pagesXOMOXLinedPlugValvesEMEA TechnicalDataperoooNo ratings yet

- Jite PCB Connectors and Cinch Terminal Strips SEO-Optimized TitleDocument24 pagesJite PCB Connectors and Cinch Terminal Strips SEO-Optimized TitleKenon FlemingsNo ratings yet

- 200: Shell Cassettes Corner Node - Type 230-60Document8 pages200: Shell Cassettes Corner Node - Type 230-60sasikumarNo ratings yet

- Weld ToleranceDocument1 pageWeld ToleranceNirav DesaiNo ratings yet

- 8202 2Document10 pages8202 2Yang WuNo ratings yet

- Ejercicios Modelado y Ensamblaje BasicoDocument14 pagesEjercicios Modelado y Ensamblaje BasicoNanii Vasquez PerekeNo ratings yet

- Notes: Apply Two Layer of Anti Corrosion Paint Then Apply Third Layer of Semi Glossy Paint. Check Height of Base Assembly For AdjustmentDocument1 pageNotes: Apply Two Layer of Anti Corrosion Paint Then Apply Third Layer of Semi Glossy Paint. Check Height of Base Assembly For AdjustmentkhalidcosmosNo ratings yet

- Bs en 14399 Parts 1 To 8Document7 pagesBs en 14399 Parts 1 To 8ramonyk_003558100% (1)

- 8525 Seris ConnectorDocument11 pages8525 Seris ConnectorJosé Alexandre GomesNo ratings yet

- Din 1480 2005Document6 pagesDin 1480 2005PacoNo ratings yet

- Serie HP eDocument10 pagesSerie HP eMarceloPolicastroNo ratings yet

- Bulks PDFDocument44 pagesBulks PDFmihai085No ratings yet

- Fittings Din11852 Din11850Document14 pagesFittings Din11852 Din11850dingobk1No ratings yet

- 11422Document10 pages11422balajivangaruNo ratings yet

- SAE Flanges PDFDocument55 pagesSAE Flanges PDFG.SWAMI100% (2)

- Butterfly Valve Technical Data SheetDocument6 pagesButterfly Valve Technical Data SheetMr. ANo ratings yet

- Swagelok Flange AdaptersDocument6 pagesSwagelok Flange AdapterstotcsabNo ratings yet

- Diaphragm Valve, Metal: ConstructionDocument6 pagesDiaphragm Valve, Metal: ConstructionDenial BasanovicNo ratings yet

- GRIPPER CLAMP SUB-ASSEMBLY HOUSING GRIPPERDocument1 pageGRIPPER CLAMP SUB-ASSEMBLY HOUSING GRIPPERDudeboy Nautic100% (1)

- Magnetic Shunt Panel: PauwelsDocument1 pageMagnetic Shunt Panel: PauwelstskmechNo ratings yet

- Threading Tools (SST Series)Document8 pagesThreading Tools (SST Series)Gilberto ManhattanNo ratings yet

- Assembly Details: HMG / Ministry of Local DevelopmentDocument1 pageAssembly Details: HMG / Ministry of Local DevelopmentkoklenderNo ratings yet

- Bolt Length TableDocument16 pagesBolt Length TablePrasanta Kumar BeheraNo ratings yet

- IsometricsDocument4 pagesIsometricsMuhammedHafisNo ratings yet

- En10028 2Document12 pagesEn10028 2Patilea Daniela100% (1)

- Toyo Valve PN TypeDocument12 pagesToyo Valve PN Typent_long76No ratings yet

- VCA03 FH2 CE Fire HydrantDocument2 pagesVCA03 FH2 CE Fire HydrantSenghy MaoNo ratings yet

- Piping Material Specification-Rev0Document25 pagesPiping Material Specification-Rev0Mohsen Ardestani100% (4)

- EmtDocument9 pagesEmtWaleed Mohammed FekryNo ratings yet

- Detail of Beam Cp-38: Grid LocationDocument1 pageDetail of Beam Cp-38: Grid Locationflat222No ratings yet

- RCC 43 Wide Beam SadDocument25 pagesRCC 43 Wide Beam Sadttlong230487No ratings yet

- PB TW10 GBDocument6 pagesPB TW10 GBfebri_bontangNo ratings yet

- Hook Fastening: AdvantagesDocument1 pageHook Fastening: AdvantagesRus AlinNo ratings yet

- Lifting Eye Nuts: Steel / Stainless SteelDocument1 pageLifting Eye Nuts: Steel / Stainless SteelMalik Uzair ZafarNo ratings yet

- Catalog Valve KSBDocument58 pagesCatalog Valve KSByoboo100% (1)

- Hanging Pipe Support with Sideways Sliding for Insulated PipesDocument7 pagesHanging Pipe Support with Sideways Sliding for Insulated PipesYang WuNo ratings yet

- Legrand Cable GlandsDocument12 pagesLegrand Cable GlandsSreekanth RaveendranNo ratings yet

- SymbolDocument48 pagesSymbolmomoitachiNo ratings yet

- Tubos Huecos Seccion Cuadrada - PROTUBSADocument56 pagesTubos Huecos Seccion Cuadrada - PROTUBSACarlos Di Perna AriniNo ratings yet

- Next Generation: Ultragrip Reducing CouplingsDocument1 pageNext Generation: Ultragrip Reducing CouplingsblindjaxxNo ratings yet

- DB 698 GBDocument8 pagesDB 698 GBDenial BasanovicNo ratings yet

- Steel Supply Sub-Grades To EC3Document22 pagesSteel Supply Sub-Grades To EC3Anonymous iS33V5No ratings yet

- Vxf2aidrDocument132 pagesVxf2aidrSamira Adnan HalilovićNo ratings yet

- Cold Drawn Seamless Steel Tubes For Mechanical ApplicationsDocument8 pagesCold Drawn Seamless Steel Tubes For Mechanical ApplicationsDiego TrinidadNo ratings yet

- Volume3A MechDocument321 pagesVolume3A MechAdeel JamilNo ratings yet

- Z45T125M 125S Flange End Non-Rising Stem Gate Valve: Scope of ApplicationDocument1 pageZ45T125M 125S Flange End Non-Rising Stem Gate Valve: Scope of ApplicationthewallstreetNo ratings yet

- En 10222-5Document23 pagesEn 10222-5Sakshi Agrawal100% (1)

- Ladder and Self Closing Gate For Storage TankDocument15 pagesLadder and Self Closing Gate For Storage TankAkshat JainNo ratings yet

- Reductor Modelo r47 - Mesa Superior de SeleccionDocument3 pagesReductor Modelo r47 - Mesa Superior de SeleccionjuguenriNo ratings yet

- Metric Section BDocument26 pagesMetric Section BniladriprasadrNo ratings yet

- Lifting Eye Bolts Steel Stainless Steel Din 580 PDFDocument1 pageLifting Eye Bolts Steel Stainless Steel Din 580 PDFheitormartNo ratings yet

- ValvulaDocument8 pagesValvulaJosé Gasset Del ValleNo ratings yet

- REV Date Description ECR Release 180 1-18-13 A: TitleDocument1 pageREV Date Description ECR Release 180 1-18-13 A: TitleXTL_MXNo ratings yet

- Van An Toan 300b0d01Document1 pageVan An Toan 300b0d01tmh_hacid07No ratings yet

- rc18011 f09Document7 pagesrc18011 f09Trayo AyangbayiNo ratings yet

- En 15085-1 2007Document10 pagesEn 15085-1 2007rizzo8No ratings yet

- ISO - 15614-1 - 2004 - DAmd - 1 (E) - ODŠTAMPANO Character - PDF - Document PDFDocument7 pagesISO - 15614-1 - 2004 - DAmd - 1 (E) - ODŠTAMPANO Character - PDF - Document PDFEmir MujićNo ratings yet

- SWR Bracket Boss: Sovex ORDER NO.: 170850 Project: AmhDocument21 pagesSWR Bracket Boss: Sovex ORDER NO.: 170850 Project: AmhEmir MujićNo ratings yet

- Hot Dip Galvanizing corrosion categoriesDocument2 pagesHot Dip Galvanizing corrosion categoriesJpolyPolyNo ratings yet

- En 15906Document11 pagesEn 15906Emir MujićNo ratings yet

- Din 933 PDFDocument3 pagesDin 933 PDFVinicius Monteiro AmaralNo ratings yet

- Din 934Document0 pagesDin 934mjinspectorNo ratings yet

- The New Declaration of Performance (Description)Document39 pagesThe New Declaration of Performance (Description)Bogdan MuresanNo ratings yet

- SWR Bracket Boss: Sovex ORDER NO.: 170850 Project: AmhDocument21 pagesSWR Bracket Boss: Sovex ORDER NO.: 170850 Project: AmhEmir MujićNo ratings yet

- Unfire Pressure VesselDocument146 pagesUnfire Pressure Vesselsungkang83% (6)

- S690QL - Hemiska Analiza PDFDocument7 pagesS690QL - Hemiska Analiza PDFEmir MujićNo ratings yet

- Es Emp Iocal Colo en 13480Document25 pagesEs Emp Iocal Colo en 13480castibraNo ratings yet

- Access Door Parts ListDocument3 pagesAccess Door Parts ListEmir MujićNo ratings yet

- Es Emp Iocal Colo en 13480Document25 pagesEs Emp Iocal Colo en 13480castibraNo ratings yet

- PV Elite WebinarDocument24 pagesPV Elite WebinarAndrea Hank LattanzioNo ratings yet

- Transfl Spoj KRDocument32 pagesTransfl Spoj KREmir MujićNo ratings yet

- Zupcanik 1 ModelDocument1 pageZupcanik 1 ModelEmir MujićNo ratings yet

- 10019Document12 pages10019Emir MujićNo ratings yet

- MA1201 Calculus and Basic Linear Algebra II Solution of Problem Set 4Document10 pagesMA1201 Calculus and Basic Linear Algebra II Solution of Problem Set 4Sit LucasNo ratings yet

- Felizardo C. Lipana National High SchoolDocument3 pagesFelizardo C. Lipana National High SchoolMelody LanuzaNo ratings yet

- Pulse Width ModulationDocument13 pagesPulse Width Modulationhimanshu jainNo ratings yet

- 2021 JHS INSET Template For Modular/Online Learning: Curriculum MapDocument15 pages2021 JHS INSET Template For Modular/Online Learning: Curriculum MapDremie WorksNo ratings yet

- Extrajudicial Settlement of Estate Rule 74, Section 1 ChecklistDocument8 pagesExtrajudicial Settlement of Estate Rule 74, Section 1 ChecklistMsyang Ann Corbo DiazNo ratings yet

- HVAC Master Validation PlanDocument51 pagesHVAC Master Validation Plannavas197293% (30)

- How To Text A Girl - A Girls Chase Guide (Girls Chase Guides) (PDFDrive) - 31-61Document31 pagesHow To Text A Girl - A Girls Chase Guide (Girls Chase Guides) (PDFDrive) - 31-61Myster HighNo ratings yet

- Guia de Usuario GPS Spectra SP80 PDFDocument118 pagesGuia de Usuario GPS Spectra SP80 PDFAlbrichs BennettNo ratings yet

- 100 Training Games - Kroehnert, GaryDocument180 pages100 Training Games - Kroehnert, GarywindsorccNo ratings yet

- Wheeled Loader L953F Specifications and DimensionsDocument1 pageWheeled Loader L953F Specifications and Dimensionssds khanhNo ratings yet

- Shouldice Hospital Ltd.Document5 pagesShouldice Hospital Ltd.Martín Gómez CortésNo ratings yet

- Cover Letter PDFDocument1 pageCover Letter PDFAli EjazNo ratings yet

- Allan S. Cu v. Small Business Guarantee and FinanceDocument2 pagesAllan S. Cu v. Small Business Guarantee and FinanceFrancis Coronel Jr.No ratings yet

- Excel Solver Optimization ReportDocument9 pagesExcel Solver Optimization ReportMy Duyen NguyenNo ratings yet

- Paper SizeDocument22 pagesPaper SizeAlfred Jimmy UchaNo ratings yet

- CENG 5503 Intro to Steel & Timber StructuresDocument37 pagesCENG 5503 Intro to Steel & Timber StructuresBern Moses DuachNo ratings yet

- Process Financial Transactions and Extract Interim Reports - 025735Document37 pagesProcess Financial Transactions and Extract Interim Reports - 025735l2557206No ratings yet

- Applied Statics and Strength of Materials 6th Edition Ebook PDFDocument61 pagesApplied Statics and Strength of Materials 6th Edition Ebook PDFteri.sanborn87695% (44)

- TJUSAMO 2013-2014 Modular ArithmeticDocument4 pagesTJUSAMO 2013-2014 Modular ArithmeticChanthana ChongchareonNo ratings yet

- Command List-6Document3 pagesCommand List-6Carlos ArbelaezNo ratings yet

- Chapter 4 DeterminantsDocument3 pagesChapter 4 Determinantssraj68No ratings yet

- British Universal Steel Columns and Beams PropertiesDocument6 pagesBritish Universal Steel Columns and Beams PropertiesjagvishaNo ratings yet

- Inventory ControlDocument26 pagesInventory ControlhajarawNo ratings yet

- Bad DayDocument3 pagesBad DayLink YouNo ratings yet

- Aries Computer Repair SolutionsDocument9 pagesAries Computer Repair SolutionsedalzurcNo ratings yet

- Product Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966Document1 pageProduct Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966shama093No ratings yet

- Endangered EcosystemDocument11 pagesEndangered EcosystemNur SyahirahNo ratings yet

- Pemaknaan School Well-Being Pada Siswa SMP: Indigenous ResearchDocument16 pagesPemaknaan School Well-Being Pada Siswa SMP: Indigenous ResearchAri HendriawanNo ratings yet

- 2020 Global Finance Business Management Analyst Program - IIMDocument4 pages2020 Global Finance Business Management Analyst Program - IIMrishabhaaaNo ratings yet

- Grading System The Inconvenient Use of The Computing Grades in PortalDocument5 pagesGrading System The Inconvenient Use of The Computing Grades in PortalJm WhoooNo ratings yet