Professional Documents

Culture Documents

Simulation of Mono Layer Solar Cell Using COMSOL and Fabrication in Particle Controlled BAEC Clean Room

Uploaded by

Sardar Masud RanaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simulation of Mono Layer Solar Cell Using COMSOL and Fabrication in Particle Controlled BAEC Clean Room

Uploaded by

Sardar Masud RanaCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 6, June - 2014

Simulation of Mono Layer Solar Cell Using

COMSOL and Fabrication in Particle Controlled

BAEC Clean Room

Md. Rajibul Hoque Rajib1, Sardar Masud Rana2,*, Md. Rakibul Hasan2, Rashed Al Amin1,**, Md. Shahid Iqbal1, Md.

Ruhul Kabir Anik1, Md. Nasrul Hoque Mia2, Mahbubul Hoq2, Mahmudul Hasan2

1

Department of EEE, Mymensingh Engineering College ( University of Dhaka ), Bangladesh

2

Institute of Electronics, Atomic Energy Research Establishment, Dhaka

KeywordsCOMSOL Multiphysics, solar cell, J-V

characteristics, lux meter, fabrication.

I.

INTRODUCTION

controlled clean room. After fabrication it can be said that, the

fabrication efficiency of mono layer silicon solar cell is

exceeding 12% which is much better fabrication in the present

world.

II.

DESIGN AND SIMULATION RESULT

The model has been built in 2D space dimension,

electromagnetic wave frequency domain in COMSOL

Multiphysics. The p-region is 15nm, intrinsic region is 200

nm and n-region is 27 nm decomposed in silicon wafer. The

designed mono layer solar cell model shown in Fig.1.

IJE

RT

AbstractThe performance of solar photovoltaic cells

depends on its design, material properties, and fabrication

technology. This paper presented a comparative study of mono

layer silicon solar cell simulation result designed by COMSOL

Multiphysics and the fabrication result of this solar cell. With

the absorption variation of light intensity; this paper compares

the simulation result of J-V characteristics and the efficiency of

the cell with fabricated efficiency. In software we get the

efficiency of the solar cell is 27% - 28% and after fabrication of

that cell the efficiency is 11% - 12% using sun simulator.

With the inexorable rise of world energy consumption and

the limited, and rather quickly diminishing supply of fossil

fuels[1,2], it is high time that the world begin to look for

photovoltaic (PV) technology, more commonly known as

solar energy. Ever since its discovery in 1839 by Edmund

Becquerel[3], PV technology had been experiencing a steady

development of solar cell efficiency. At present more than

85% of the industrial solar cells are fabricated based on p type

silicon material. The major objectives of simulation in solar

cell research are testing the validity of proposed physical

structures, geometry on cell performance, and fitting of

modeling output to experimental results.

The conversion efficiency of hydrogenated amorphous

silicon single-junction thin-film solar cells has gradually been

improved from 2.4% [4] to 10.1% [5]. The hydrogenated

amorphous silicon (a-Si:H) solar cell progress has been started

from the invention of first Schottky device with an efficiency

of 2.4% by Kabir et al. [6]. The main factors determining the

conversion efficiency are the following: the kind of semi

conductive material, the incompatibility of solar radiation with

the cell absorption, spectrum sensitivity of photo element and

the construction of a cell [7-9].

The aim of this study is to analysis the performance of the

p-type mono layer solar cell simulation efficiency and

investigates a comparison with fabrication efficiency. After

design and simulation of the silicon solar cell; the designed

model is fabricate on the energy laboratory of BAEC,

Bangladesh. For proper fabrication we use BAEC particle

IJERTV3IS061043

Fig. 1.

Mono layer solar cell model in COMSOL

Electromagnetic wave is defined in the top of air region

as light intensity. Light incident on the surface of PIN solar

cell, some part is reflected and some part is refracted into the

solar cell. As a result electron hole pair is generated. This

contributes for creating the voltage and current in the solar

cell. For different light intensity J-V characteristics curves are

plotted. It is seen that short circuit current density and open

circuit voltage increases with light intensity.

The intensity of sun light varies in different hours of the

day. The short circuit current density J sc, open circuit voltage

Voc and efficiency of solar cell also vary with the light

www.ijert.org

1934

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 6, June - 2014

intensity. Light intensity from the time 10.00 to 17.00 is

measured by lux meter in Bangladesh Atomic Energy

Research Establishment, Institute of

Electronics. We

measured highest light intensity which is 774W/m^2 at 13.00

and lowest is 284W/m^2 at 17.00. The measurement of the

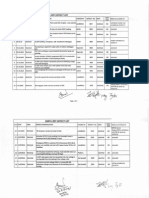

light intensity and change of efficiency is shown on Table. 1.

Time

10.00

11.00

12.00

13.00

14.00

15.00

16.00

17.00

Light

intensity

(W/m^2)

616

648

687

774

569

442

333

284

Jsc

(A/m^2)

Voc

(V)

Efficiency

(%)

453.6

480.9

431.2

541.8

398.3

309.4

233.1

198.88

0.5722

0.5737

0.5708

0.5768

0.5688

0.5623

0.5550

0.5509

28.04

28.11

27.97

28.26

27.88

27.55

27.19

26.99

Light intensity, current density

efficiency of the solar cell at various times.

TABLE I.

Fig. 2.

Variation of efficiency at different times

The values of light intensity are putting in the model. For

different light intensity different J-V curves are simulated.

From the J-V curves Jsc and Voc are measured. With a Fill

Factor 0.7 efficiency are calculated. We observed that

efficiency increases with light intensity. Highest efficiency is

28.26% at the highest light intensity 774W/m^2.

and

The J-V characteristics graph at different day time of the

solar cell is shown on Fig. 3.

IJE

RT

The efficiency graph of the solar cell at different time is

shown on Fig. 2.

Fig. 3.

IJERTV3IS061043

J-V characteristics graph at, (a) 10:00 AM (b) 11:00 AM (c) 12:00 PM (d) 01:00 PM

www.ijert.org

1935

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 6, June - 2014

IJE

RT

Another J-V characteristics graph at different day time of

the solar cell is shown on Fig. 4.

Fig. 4.

J-V characteristics graph at, (a) 02:00 PM (b) 03:00 PM (c) 04:00 PM (d) 05:00 PM

Electron density of the solar cell is shown on Fig. 5.

Fig. 5.

IJERTV3IS061043

(a) Electron density and (b) Electron density surface of the solar cell.

www.ijert.org

1936

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 6, June - 2014

Hole density of the solar cell is shown on Fig. 6.

Fig. 6.

(a) Hole density and (b) Hole density surface of the solar cell.

Generation rate of the solar cell is shown on Fig. 7.

III.

FABRICATION PROCESS AND RESULT

IJE

RT

We have used the recipes of RCA for the fabrication of

solar cell. For cleaning, saw damage removal process ( 10%

NaOH with DI water ) and hydrophobic process with the

ratio of ( 1ml Hydrofluoric acid with 50ml DI water )

process has been done. For texturing solution is made with

potassium hydroxide, Iso-2-propanol and DI water with

corresponding ratio 1gram, 5ml and 125ml. Surface

reflectance measurement is done once after the saw removal

process and then after the texturing process and finally the

result of these two are compared to the reflectance of a

standard mirror.

Fig. 7.

Generation rate of the solar cell.

Space charge density is shown on Fig. 7

Fig. 8.

IJERTV3IS061043

Next, the edge isolation process is done using a screen

printing machine and a diffusion barrier paste is used to

isolate the edge. The mask screen both top and bottom,

squeezer, spatula and the work holder carriage is cleaned

very well using the IPA solution. After the screen printing is

done the wafers are dried for 10 minutes in a preheated oven

at 200C.

For diffusion or doping process the wafers are kept on a

tray made of a glass for diffusion process. When the

diffusion machine reached 600C then the tray containing

the wafers are transferred to the diffusion chamber.

Nitrogen gas is turned on for 10 minutes and then

temperature is increased to 875C keeping the Nitrogen gas

on. After 875C is reached nitrogen gas is turned off and

Oxygen and POCl3 ( Phosphorus oxy-try-chloride ) are

turned on simultaneously. After 10 minutes nitrogen gas is

turned on for 10 minutes and then nitrogen gas is turned off

and only oxygen gas is turned on for next 10 minutes. The

temperature of the chamber is reduced to 600C from 875C

and this stage nitrogen gas is turned on again. When the

temperature is falling down at 600C nitrogen gas is turned

off and wafers are ready to take out. After doping process

the sheet resistance is measured. Sheet resistance of

different wafer is shown on TABLE 2.

Space charge density of the solar cell.

www.ijert.org

1937

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 6, June - 2014

Sheet resistance of different wafer on the

solar cell fabrication process.

TABLE II.

Experimental

wafer

Wafer 1

Wafer 2

Wafer 3

Sheet

resistance

before

cleaning

4.6 K

5 K

4.7 K

Sheet

resistance

after

texturing

4.3 K

4.4 K

4.3 K

Sheet

resistance

after

diffusion

2.16 K

2.19 K

2.1 K

simulation, ideal values are taken but in fabrication we

cannot get the ideal material and wafer defect, doping error

and contact error may occurred in fabrication process. It

gives us only 12% efficiency which is the better fabrication

efficiency in the world of mono layer solar cell.

REFERENCES

The front contact is made by Silver paste and back

contact is made by Aluminium paste. After printing, rapid

thermal annealing process is done with the temperature

500C, 600C and 800C respectively. The wafers are

passed through a moving belt which goes inside the RTA

machine. Rapid thermal annealing is important because it

provides proper contact between the conductor and

semiconductor. After transmission line measurement

process the desire cell making process is completed.

The efficiency of the solar cell is measured by sun

simulator and got 10% - 12% efficiency.

IV.

CONCLUSION

IJE

RT

The mono layer solar cell has been simulated in COSOL

and finally fabricated to investigate the compares between

designed and fabricated efficiency. It is seen that, the

fabricated and simulated efficiency is different. Because in

[ 1] US Department of Energy web site, accessed 1/8/2011,

http://www.eia.doe.gov/.

[ 2] US Department of Energy, Annual Energy Review July 2006,

Accessed 1/8/2011, http://www.eia.doe.gov/.

[ 3] J. Nelson. The Physics of Solar Cells. Imperial College Press,

London, 2003.

[ 4] D. E. Carlson and C. R. Wronski, Amorphous silicon solar

cell, Applied Physics Letters, vol. 28, no. 11, pp. 671673,

1976.

[ 5] U. Kroll, C. Bucher, S. Benagli et al., High-efficiency p-i-n aSi:H solar cells with low boron cross-contamination prepared

in a large-area single-chamber PECVD reactor, Thin Solid

Films, vol. 451-452, pp. 525530, 2004.

[ 6] M. I. Kabir, Z. Ibarahim, K. Sopian, and N. Amin, A review

on progress of amorphous and microcrystalline silicon thin

film solar cells, Recent Patents on Electrical Engineering, vol.

4, no. 1, pp. 5062, 2011.

[ 7] K. Nakajima, K. Ohdaira, K. Fujiwar, W. Pan, Solar cell

system using a polished concave Si-crystal mirror, Solar

Energy Materials and Solar Cells 72 (2005) 323-329.

[ 8] A. Blakers, K. Weber, V. Everett, S. Deenapanray, E. Franklin,

Sliver solar cells and moduls; Centre for Sustainable Energy,

Systems Australian National University,(2004).

[ 9] A. Goetzberger, C. Hebling, Photovoltaic materials, past,

present, future, Solar Energy Matererials Solar Cells 62,

(2000)

IJERTV3IS061043

www.ijert.org

1938

You might also like

- Printable Solar CellsFrom EverandPrintable Solar CellsNurdan Demirci SankirNo ratings yet

- Simulating Using Com SolDocument5 pagesSimulating Using Com SolRavin KumarNo ratings yet

- V3i6 Ijertv3is061043Document6 pagesV3i6 Ijertv3is061043SankarSabapathiNo ratings yet

- Solar CellDocument38 pagesSolar CellPrudhvinadh KopparapuNo ratings yet

- PHSV01I04P0240Document12 pagesPHSV01I04P0240physicsjournalNo ratings yet

- Sb2S3 Thickness-Related Photocurrent and OptoelectDocument10 pagesSb2S3 Thickness-Related Photocurrent and OptoelectShrabaniPaulNo ratings yet

- You and Your Family, Oct 2011Document5 pagesYou and Your Family, Oct 2011emediageNo ratings yet

- Impact of Two Types Flat Reflector Materials On Solar Panel CharacteristicsDocument12 pagesImpact of Two Types Flat Reflector Materials On Solar Panel CharacteristicsedumacerenNo ratings yet

- Properties of High-Efficiency CIGS Thin-Film Solar Cells: February 2005 - NREL/CP-520-37404Document7 pagesProperties of High-Efficiency CIGS Thin-Film Solar Cells: February 2005 - NREL/CP-520-37404handerson_chrisNo ratings yet

- Impact of Defects On Quality Contact Systems For Photoelectric ConvertersDocument5 pagesImpact of Defects On Quality Contact Systems For Photoelectric ConvertersСергей ХрипкоNo ratings yet

- High Efficiency Multi-Junction Solar Cell Design: Amit Kumar Senapati, Manjit Bahadur SinghDocument5 pagesHigh Efficiency Multi-Junction Solar Cell Design: Amit Kumar Senapati, Manjit Bahadur SingherpublicationNo ratings yet

- Improving The Efficiency of Polycrystalline Solar Panel Via Water Immersion MethodDocument7 pagesImproving The Efficiency of Polycrystalline Solar Panel Via Water Immersion Methodaniket bobadeNo ratings yet

- The PassivatedEmitterandRearCell (PERC) :fromconceptiontomass ProductionDocument8 pagesThe PassivatedEmitterandRearCell (PERC) :fromconceptiontomass ProductionShovon PalNo ratings yet

- Properties of High-Efficiency Cuingase Thin Film Solar CellsDocument4 pagesProperties of High-Efficiency Cuingase Thin Film Solar CellsSnowdenn BreddNo ratings yet

- It's Everything But AnythingDocument17 pagesIt's Everything But Anythingjaideep2020bece021No ratings yet

- Plastic Solar Cells Report Part 2Document32 pagesPlastic Solar Cells Report Part 2IRSHAD PNo ratings yet

- Performance Comparison Between Silicon Solar Panel and Dye-Sensitized Solar Panel in MalaysiaDocument8 pagesPerformance Comparison Between Silicon Solar Panel and Dye-Sensitized Solar Panel in MalaysiaMADHIYAH YAHAYA BERMAKAINo ratings yet

- JETIR1904C52Document4 pagesJETIR1904C52em1teamdNo ratings yet

- Andika 2019 IOP Conf. Ser. Earth Environ. Sci. 343 012224Document8 pagesAndika 2019 IOP Conf. Ser. Earth Environ. Sci. 343 012224JIJIN KNo ratings yet

- 7 - 2008 - Cas - The Laboratory Technology of Crystalline Silicon Solar CellsDocument4 pages7 - 2008 - Cas - The Laboratory Technology of Crystalline Silicon Solar CellsserhanNo ratings yet

- 10 5923 J Msse 20120102 04Document6 pages10 5923 J Msse 20120102 04mohanadNo ratings yet

- Multi Scale Modeling of Nano Enable Solar Cell With Implementation On An HPC SetupDocument6 pagesMulti Scale Modeling of Nano Enable Solar Cell With Implementation On An HPC Setupmalan12No ratings yet

- Comparative Analysis of Photovoltaic Technologies For HighDocument11 pagesComparative Analysis of Photovoltaic Technologies For HighalexNo ratings yet

- Conical Solar StillDocument27 pagesConical Solar StillAbhijeet EkhandeNo ratings yet

- EME4353: Advanced Engineering Materials Assignment 1Document7 pagesEME4353: Advanced Engineering Materials Assignment 1Shakil MalikNo ratings yet

- Project - Silicon Solar Cell-CoDocument55 pagesProject - Silicon Solar Cell-CoSudheer SebastianNo ratings yet

- Akgul 2017Document5 pagesAkgul 2017Eman NasirNo ratings yet

- Nio Used As Window Layer FOR Si Solar Cells: V.Bhargavi 315207238011 1/2 M.TECH Nano TechnologyDocument26 pagesNio Used As Window Layer FOR Si Solar Cells: V.Bhargavi 315207238011 1/2 M.TECH Nano Technologyanand sureshNo ratings yet

- Performance of A Solar Panel With Water Immersion Cooling TechniqueDocument12 pagesPerformance of A Solar Panel With Water Immersion Cooling Techniqueaniket bobadeNo ratings yet

- Solar PhotovoltaicsDocument45 pagesSolar PhotovoltaicsDarshan KhuntNo ratings yet

- 7article Azojete Vol 9 69-81Document13 pages7article Azojete Vol 9 69-81Oyeniyi Samuel KehindeNo ratings yet

- Production Technology For Amorphous Silicon-Based #Exible Solar CellsDocument9 pagesProduction Technology For Amorphous Silicon-Based #Exible Solar CellsLong HoàngNo ratings yet

- Solar TrackingDocument3 pagesSolar TrackingJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Solar CoatingDocument5 pagesSolar CoatingBineesh BrunoNo ratings yet

- Overview of Solar DesalinationDocument17 pagesOverview of Solar Desalinationalagar krishna kumarNo ratings yet

- Mathematical Model Derivation of Solar Cell by Using Onediode Equivalent Circuit Via SimulinkDocument12 pagesMathematical Model Derivation of Solar Cell by Using Onediode Equivalent Circuit Via SimulinkShorav SuriyalNo ratings yet

- Water Stagnant of Solar ModulesDocument6 pagesWater Stagnant of Solar ModulesNITIN MISHRANo ratings yet

- Dark and Illuminated Characteristics of Photovoltaic Solar Modules. Part I: Influence of Dark Electrical StressDocument11 pagesDark and Illuminated Characteristics of Photovoltaic Solar Modules. Part I: Influence of Dark Electrical StressSarkarNo ratings yet

- Report Infrared Solar CellDocument22 pagesReport Infrared Solar Cellabhishek5singh5surajNo ratings yet

- 75 Tist V5N2.Document4 pages75 Tist V5N2.ROOSSVELT PRABHU TEACHINGNo ratings yet

- Lab Manual - Experiment 2Document6 pagesLab Manual - Experiment 2YuuKohNo ratings yet

- Improving The Efficiency of Polycrystall PDFDocument6 pagesImproving The Efficiency of Polycrystall PDFSheila Mae CulpableNo ratings yet

- Passive Cooling On The Performance of Photovoltaic Solar Panels Operating in Extremely Hot WeatherDocument14 pagesPassive Cooling On The Performance of Photovoltaic Solar Panels Operating in Extremely Hot WeatherAnonymous pKuPK3zUNo ratings yet

- CuO Based Solar Cell With V2O5 BSF Layer - Theoretical Validation of Experimental DataDocument12 pagesCuO Based Solar Cell With V2O5 BSF Layer - Theoretical Validation of Experimental DataNur Aisyah ShariNo ratings yet

- Solar Cell 2Document8 pagesSolar Cell 2ManishNo ratings yet

- AjayDocument109 pagesAjayVigneshwaran Murugan100% (1)

- Development and Testing of An Energy Harvesting TileDocument6 pagesDevelopment and Testing of An Energy Harvesting TileJames MorenoNo ratings yet

- Ref 4Document4 pagesRef 4Saad AlFraidyNo ratings yet

- Project1 DoneDocument15 pagesProject1 DoneDr-naser MahmoudNo ratings yet

- Synthesis and Deposition of Ag Nanoparticles by CoDocument9 pagesSynthesis and Deposition of Ag Nanoparticles by Comonikasharma1604No ratings yet

- PaperfinalDocument11 pagesPaperfinalhind elNo ratings yet

- Effect of Heat Treatments and Reduced Absorber Layer Thickness OnDocument89 pagesEffect of Heat Treatments and Reduced Absorber Layer Thickness Onhanderson_chrisNo ratings yet

- Numerical Analysis of CdS-CIGS Interface Configuration On The Performances of Cu (In, Ga) Se2 Solar CellsDocument7 pagesNumerical Analysis of CdS-CIGS Interface Configuration On The Performances of Cu (In, Ga) Se2 Solar CellsArsh MalikNo ratings yet

- EUPVSEC 2010 Light TransmissionDocument6 pagesEUPVSEC 2010 Light TransmissionDeepak RoutNo ratings yet

- Analysis The Effect of Reflector Flat Mirror ConveDocument10 pagesAnalysis The Effect of Reflector Flat Mirror ConveSumant MalganNo ratings yet

- Visible-Light-Induced Self-Cleaning Property of Bi Ti O Tio Composite Nanowire ArraysDocument8 pagesVisible-Light-Induced Self-Cleaning Property of Bi Ti O Tio Composite Nanowire ArraysLulueleNo ratings yet

- Automatic Cleaning System For Solar PanelDocument8 pagesAutomatic Cleaning System For Solar PanelSHIELDNo ratings yet

- Irjet V9i2681Document12 pagesIrjet V9i2681Faisal Hossain Reevu ,160021026No ratings yet

- Full DocumentDocument39 pagesFull Documentsaikrishna645No ratings yet

- Photoluminescence and Electroluminescence Imaging of Perovskite Solar CellsDocument9 pagesPhotoluminescence and Electroluminescence Imaging of Perovskite Solar CellseniNo ratings yet

- Class 5 EVS Chapter 13 Amazing EnergyDocument5 pagesClass 5 EVS Chapter 13 Amazing EnergyragharikaNo ratings yet

- RTDocument9 pagesRTAkash AgarwalNo ratings yet

- Corp PresDocument20 pagesCorp PresvanjadamjanovicNo ratings yet

- HPI Market Data 2011 - ContentsDocument6 pagesHPI Market Data 2011 - ContentsYang Gul LeeNo ratings yet

- EM EM Product Line: R-134a R-600a R-290Document12 pagesEM EM Product Line: R-134a R-600a R-290Nicoleta PotoracNo ratings yet

- Eagle 1500V 60: 280-300 WattDocument2 pagesEagle 1500V 60: 280-300 Wattmiguel h pintosNo ratings yet

- Types of Air CompressorsDocument2 pagesTypes of Air CompressorsSrinivas GoudNo ratings yet

- Hydraulic Pump ContDocument15 pagesHydraulic Pump ContbmdbmdbmdNo ratings yet

- Sample Computation For Boiler EfficiencyDocument6 pagesSample Computation For Boiler Efficiencyra_tagolimotNo ratings yet

- Steam CondenserDocument53 pagesSteam CondenserGeorge Markas100% (1)

- KP-00+++-CQ712-B7360-Electrical Works (Switchyard Lightning Arrester Installation)Document3 pagesKP-00+++-CQ712-B7360-Electrical Works (Switchyard Lightning Arrester Installation)Utku Can KılıçNo ratings yet

- Centrifugal - Pump DOE USADocument4 pagesCentrifugal - Pump DOE USAGopal KrishnaNo ratings yet

- Seminar On Solar RoadwaysDocument17 pagesSeminar On Solar Roadwaysk rajendra100% (4)

- 8 Science Exemplar Problems Chapter 6Document7 pages8 Science Exemplar Problems Chapter 6Kambaska Kumar BeheraNo ratings yet

- Creditnote 265109 3841524Document2 pagesCreditnote 265109 3841524ali hassanNo ratings yet

- Zambia Chapter 4 CDocument22 pagesZambia Chapter 4 Cdoud98No ratings yet

- Lect 1 19EEE111 Introduction PartBDocument34 pagesLect 1 19EEE111 Introduction PartBDenifer DeepNo ratings yet

- The Hill Chart of A Francis Turbine Is Indicated in The Figure. The Turbine Is Operating With A HeadDocument4 pagesThe Hill Chart of A Francis Turbine Is Indicated in The Figure. The Turbine Is Operating With A HeadBorja PumaresNo ratings yet

- Guideline For Solar PV System Installation For ServiceProvidersDocument66 pagesGuideline For Solar PV System Installation For ServiceProvidersdharmapriyaussNo ratings yet

- Dr. K.S.dhathathreyan CFCTChennaiDocument37 pagesDr. K.S.dhathathreyan CFCTChennaiSuman RachaNo ratings yet

- 3 PH Transformer and Generator ModelsDocument11 pages3 PH Transformer and Generator ModelsMansa ManuNo ratings yet

- Asian Development Bank - Bangladesh Power System Enhancement and Efficiency Improvement Project - 2017-04-03Document4 pagesAsian Development Bank - Bangladesh Power System Enhancement and Efficiency Improvement Project - 2017-04-03Pee KayNo ratings yet

- Electric ActuatorsDocument2 pagesElectric ActuatorsCair Euromatic Automation Pvt. Ltd.No ratings yet

- AXA PCA 130&210 Fault Finding Formula 7Document2 pagesAXA PCA 130&210 Fault Finding Formula 7ambuenaflorNo ratings yet

- Danish Wind Turbine Industry Report - Sara GrobbelaarDocument23 pagesDanish Wind Turbine Industry Report - Sara GrobbelaarSara S Grobbelaar100% (1)

- Defects Captured During RRTDocument37 pagesDefects Captured During RRTdreamboy87No ratings yet

- NEMA Premium CatalogDocument38 pagesNEMA Premium CatalogPedro SanchezNo ratings yet

- Crude Oil Storage Tank Heating CoilDocument3 pagesCrude Oil Storage Tank Heating CoilbadelitamariusNo ratings yet

- Kilpilahti Combined Heat and Power ProjectDocument3 pagesKilpilahti Combined Heat and Power ProjectAnonymous KduLd7No ratings yet

- Impact of Energy Consumption On The EnvironmentDocument9 pagesImpact of Energy Consumption On The Environmentadawiyah sofiNo ratings yet

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldFrom EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldRating: 4 out of 5 stars4/5 (597)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- Fire Season: Field Notes from a Wilderness LookoutFrom EverandFire Season: Field Notes from a Wilderness LookoutRating: 4 out of 5 stars4/5 (142)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorFrom EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorRating: 4.5 out of 5 stars4.5/5 (137)

- The Soul of an Octopus: A Surprising Exploration into the Wonder of ConsciousnessFrom EverandThe Soul of an Octopus: A Surprising Exploration into the Wonder of ConsciousnessRating: 4.5 out of 5 stars4.5/5 (254)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (812)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildFrom EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildRating: 4.5 out of 5 stars4.5/5 (44)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsFrom EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsRating: 3.5 out of 5 stars3.5/5 (13)

- The Other End of the Leash: Why We Do What We Do Around DogsFrom EverandThe Other End of the Leash: Why We Do What We Do Around DogsRating: 5 out of 5 stars5/5 (65)

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsFrom EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsRating: 4 out of 5 stars4/5 (223)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingFrom EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingRating: 3.5 out of 5 stars3.5/5 (35)

- Come Back, Como: Winning the Heart of a Reluctant DogFrom EverandCome Back, Como: Winning the Heart of a Reluctant DogRating: 3.5 out of 5 stars3.5/5 (10)

- The Hidden Life of Trees: What They Feel, How They CommunicateFrom EverandThe Hidden Life of Trees: What They Feel, How They CommunicateRating: 4 out of 5 stars4/5 (1003)

- Braiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsFrom EverandBraiding Sweetgrass: Indigenous Wisdom, Scientific Knowledge and the Teachings of PlantsRating: 4.5 out of 5 stars4.5/5 (1424)

- Darwin's Doubt: The Explosive Origin of Animal Life and the Case for Intelligent DesignFrom EverandDarwin's Doubt: The Explosive Origin of Animal Life and the Case for Intelligent DesignRating: 4 out of 5 stars4/5 (19)

- The Mind of Plants: Narratives of Vegetal IntelligenceFrom EverandThe Mind of Plants: Narratives of Vegetal IntelligenceRating: 4.5 out of 5 stars4.5/5 (12)

- Microscopy of Numerology: Numerology SimplifiedFrom EverandMicroscopy of Numerology: Numerology SimplifiedRating: 5 out of 5 stars5/5 (2)

- The Pleistocene Era: The History of the Ice Age and the Dawn of Modern HumansFrom EverandThe Pleistocene Era: The History of the Ice Age and the Dawn of Modern HumansRating: 4 out of 5 stars4/5 (5)

- Remnants of Ancient Life: The New Science of Old FossilsFrom EverandRemnants of Ancient Life: The New Science of Old FossilsRating: 3 out of 5 stars3/5 (3)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldFrom EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldRating: 4.5 out of 5 stars4.5/5 (18)