Professional Documents

Culture Documents

tmp33B9 TMP

Uploaded by

FrontiersOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

tmp33B9 TMP

Uploaded by

FrontiersCopyright:

Available Formats

Open Chem.

, 2015; 13: 743747

Research Article

Open Access

Raluca Voda, Adina Negrea, Lavinia Lupa, Mihaela Ciopec, Petru Negrea, Corneliu Mircea

Davidescu, Monica Butnariu*

Nanocrystalline ferrites used as adsorbent in the

treatment process of waste waters resulted from

ink jet cartridges manufacturing

Abstract: Dye pollution in waste waters causes serious

environmental and health risk, legislation problems

and is a serious challenge to environmental scientists.

In this work the treatment of waste waters resulted

from ink jet cartridges manufacturing, using different

nanocrystalline ferrites MIIFe2O4 (MII = Mg, Cu) as

adsorbent materials, has been investigated. The ferrites

were obtained by thermal decomposition at 500C of

the magnesium and copper ferrioxalate coordination

compounds. The nanocrystalline ferrites powder was

investigated by various methods such as XRD, IR,

SEM and EDX. The discoloration of the waste waters

has been spectrophotometrically studied. The ferrites

could be removed easily after adsorption by using

a magnetic filtration process. The results indicated that

the maximum adsorption efficiency was obtained after

60 min of treatment, magnesium ferrite showing a higher

efficiency than the copper ferrite in the treatment process

of waters resulted from ink jet cartridges manufacturing.

Keywords: nanocrystalline ferrites, oxalate, oxides, ink

jet, adsorption

DOI: 10.1515/chem-2015-0092

received November 13, 2014; accepted December 8, 2014.

*Corresponding author: Monica Butnariu: Banats University of

Agricultural Sciences and Veterinary Medicine Regele Mihai I

al Romaniei from Timisoara, 300645, Calea Aradului, no. 119,

Romania, E-mail: monicabutnariu@yahoo.com,

Raluca Voda, Adina Negrea, Lavinia Lupa, Mihaela Ciopec,

Petru Negrea, Corneliu Mircea Davidescu: University Politehnica

Timisoara, Faculty for Industrial Chemistry and Environmental

Engineering, Bv. Parvan no. 6, Timisoara, RO300223, Romania

1 Introduction

In order to minimize the waste discharge, the reuse

and the recycling terms are also commonly used in the

inkjet cartridges manufacturing. The first step in the

remanufacturing of the inkjet cartridges before refilling is

the washing of the remained ink. Consequently at this step

results waste waters containing large variety of pollutants

such as dyes and surfactants, which are characterized by

high toxicity and low degradability [15]. The release of

these waters in some effluents can reduce light penetration

and photosynthesis, causing suffocation of aquatic flora

and fauna [6]. Therefore these waste waters must be treated

before discharge. In this aim there is a real need to develop

an effective and cost viable waste water treatment [79].

Numerous methods have been studied for the removal of

dyes from waste waters such as: flocculation/coagulation

[3,5,1012], oxidation [1], photocatalysis [13], ultrafiltration

[2,8,14], adsorption [6,7,9] and biological processes [4]. Due

to the easy of operation most of the researchers focused

on the adsorption processes [6,7,9,15]. Anyway, this method

presents some drawbacks such as: high cost, difficult

disposal and regeneration [1,9]. In order to overcome

these drawbacks in this study, adsorbent materials

ferrite nanoparticles MIIFe2O4 (MII = Mg, Cu) were used in

the removal process of dye from waste waters resulting

from inkjet cartridges manufacturing. It was reported

that these nanoparticles presented good efficiency as

reusable adsorbents due to their reduced obtaining cost,

high surface area and easy recovery using their magnetic

properties [9,1620]. The ferrites nanoparticles studied

in this paper were obtained by thermal decomposition of

coordination compounds at lower temperatures and, its

superiority in comparison with other oxalate precursor

methods of the mixed oxides [21].

2015 Raluca Voda et al., licensee De Gruyter Open.

This work is licensed under the Creative Commons Attribution-NonCommercial-NoDerivs

3.0 License.

Unauthenticated

Download Date | 2/24/15 1:38 PM

744

Raluca Voda et al.

2 Experimental Procedure

All the reagents used for the synthesis of ferrites

were analytical grade, including ferric(III) nitrate

(Fe(NO3)39H2O, Mw = 403,95 g mol1, Merck), magnesium

nitrate (Mg(NO3)26H2O, Mw = 256,41 g mol1, Merck), copper

nitrate (Cu(NO3)23H2O, Mw = 241,60 g mol1, Merck), 1,2

ethanediol (C2H4(OH)2, Mw = 62,07 g mol1, Merck) and 2M

nitric acid solution (Merck).

The new elaborate method for synthesis of oxalate

species is based on the redox reaction:

removal process of dye from waste waters the influence

of the solid: liquid (S:L) ratio and contact time, upon the

removal efficiency, was studied. In order to determine the

optimum S:L ratio, 25 mL of residual waters was treated

with various quantity of adsorbent materials (0.02, 0.03,

0.04, 0.05, 0.06 and 0.07 g). The samples were shaken

for 1 hour using a Julabo SW23 shaker, and after were

filtered and the resulting solutions were again analyzed

through UVVIS spectrophotometry. After establishing the

optimum S:L ratio the influence of the shaking time (15,

30, 45, 60, 90 and 120 min) upon the adsorption capacity

was determined. The degree of adsorption was determined

based on the following equation:

3C2H4(OH)2 + 8NO3 + 2H+ 3C2O42 + 8NO + 10H2O

h=

An aqueous solution of xEG (ethyleneglycol) +

2Fe(NO3)39H2O + M(NO3)26H2O + yHNO3 (2M) with x 3

and y2 was prepared and heated in a water bath. The

reaction was considered completed when no more gas

evolution was observed. The solid reaction products were

purified by refluxing from an acetonewater mixture.

After filtration, the precipitates were finally washed

with acetone and maintained in air until constant mass.

The oxides MIIFe2O4 (MII = Mg, Cu) are obtained after the

calcinations of the coordination compounds for one hour

at 500C using a heating rate of a 5C min1.

The residual solution containing dyes was obtained

from a local manufacturer where the empty inkjet

cartridges are refilled.

where:

represent the removal degree of dye, %;

adsinit represent the initial absorbance of the dye present in

the waste water at 625 nm;

adsfin represent the absorbance of the dye present in the waste

water at 625 nm, after treatment with the studied ferrites.

2.1 Materials

2.2 Apparatus and procedure

The FTIR spectra (KBr pellets) of the ferrites were recorded

on a Vertex 70 BRUKERFTIR spectrophotometer in the

range 4004000 cm1. The oxides were characterized

by XRay diffraction (XRD) analysis. The powder XRay

diffraction patterns of the obtained oxides were recorded

at room temperature with a XRD using a Rigaku Ultima IV

diffractometer, using Cu K radiation ( = 1.5418 ). SEM

images were recorded using a Quanta FEG 250 microscope,

equipped with an EDAX/ZAF quantifier.

The obtained ferrites powders were used as adsorbent

material in the removal process of dye from waste water

from the inkjet cartridges remanufacturing. The waste

waters before and after treatments with the ferrites

were analyzed through UVVIS spectrophotometry

using a Varian Cary 50 spectrophotometer. The spectra

were recorded in the range of 300800 nm. In order to

determine the efficiency of the studied adsorbent in the

( Adsinit - Ads fin )

Adsinit

100 (1)

3 Results and discussion

3.1 Characterization of nanocrystalline

ferrites

The synthesis method of the coordination compound

[Fe2MII(C2O4)4(OH2)6] (MII = Mg, Cu) is based on the redox

reaction between 1,2-ethanediol and nitrate ion, in the

presence of nitric acid (2M) [21].

The oxides MIIFe2O4 (MII = Mg, Cu) are obtained after

the calcinations of the coordination compounds at 500C.

The ferrites were identified by IR and XRD.

The IR spectra (Fig. 1) show two intense absorption

bands 1 and 2, corresponding to the vibration of

tetrahedral and octahedral complexes, which are indicative

of formation of spinel structure being in agreement with

the literature data [22,23,24]. The higher frequency band

1 is in the range 530640 cm1 and the lower frequency

band 2 is in the range 400480 cm1.

In Fig. 2 are presented the XRD patterns of the products

obtained after independent calcinations in the furnace at

500C in static air atmosphere. For both products the XRD

patterns show the presence of the characteristic peaks of

pure MIIFe2O4 (MII = Mg, Cu) ferrites which were identified

using JCPDS 040120916 and JCPDS 040137127,

respectively.

Unauthenticated

Download Date | 2/24/15 1:38 PM

Nanocrystalline ferrites-adsorbent of waste waters

745

Figure 1: FTIR spectra of MIIFe2O4 (MII = Mg, Cu) ferrites obtained after

the calcinations at 500C for 1h of the coordination compounds.

Figure 2: XRD patterns of MIIFe2O4 (MII = Mg, Cu) ferrites.

The average crystallites size was evaluated using

Scherrers formula [25]:

dXRD = [0.91/(cos)] 57.32

(2)

where: dXRD is the crystallite size;

the wave length (Cu K);

the corrected halfwidth obtained using quartz as

reference and the Waren formula, and

is the diffraction angle of the most intense diffraction

peak.

The lattice parameter a was calculated using

formula:

a = d hkl h 2 + k 2 + l 2 (3)

where: h, k, l are the Miller indices of the crystal planes;

dhkl is the inter planer spacing.

As mentioned before, a heating treatment of the two

coordination compounds performed at 500C determines

Figure 3: SEM images of MIIFe2O4 (MII = Mg, Cu) ferrites: (a) MgFe2O4

and (b) CuFe2O4.

the formation MIIFe2O4 (MII = Mg, Cu) ferrites characterized

by a lattice parameter at 8.41/8.40 (MgFe2O4/CuFe2O4)

and an average crystallites size of 79/90 (MgFe2O4/

CuFe2O4).

Note that lattice parameter values are close to those

reported by literature, while the average crystallites sizes

are lower than the ones reported by literature for ferrites

obtained by other methods [2628], the adsorption

maximum capacity is strongly influenced by ferrites

particles size [16,29].

The SEM images (Fig. 3) show that the ferrites consist

of agglomerated spherical particles with 1030 nm average

particle size.

Qualitative and quantitative EDX analyzes showed

a high purity and corresponding stoichiometry of the

products analyzed.

Unauthenticated

Download Date | 2/24/15 1:38 PM

746

Raluca Voda et al.

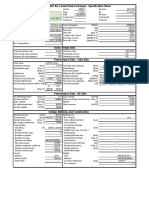

Table 1: The influence of the S:L ration upon the adsorption process

efficiency.

S:L ratio,

g of adsorbent:

mL of waste waters

Adsorption process efficiency, %

MgFe2O4

CuFe2O4

0.02:25

0.03:25

0.04:25

0.05:25

0.06:25

0.07:25

47.1

67.8

76.1

96.9

97.3

97.9

60.8

60.6

61.1

60.7

59.5

68.2

Figure 4: UVVIS spectrum of the used waste water.

Table 2: The influence of the stirring time upon the adsorption

process efficiency.

3.2 Use of obtained ferrites as adsorbent

materials

Stirring time, min

The obtained ferrites were used in the removal process

of dyes from waste waters resulting during the inkjet

cartridges manufacturing. The used waste water was

analyzed through the UVVIS spectrophotometry and the

obtained spectrum between 300800 nm is presented in

Fig. 4. The studied water is a colored one which contains

three colors at three specific wavelengths: 625, 564 and

333 nm. Because the color which absorbs at 625 nm

presents the higher peak, which means is in the higher

proportion, therefore in subsequent studies this

wavelength was used to obtain absorption values. The

influence of the S:L ratio upon the efficiency of the

adsorption process of dye onto the studied ferrites is

presented in Table 1.

From the experimental data it can be observed that

the use of a higher quantity of copper ferrite didnt lead

to a higher degree of separation of dye from aqueous

solution. In the case of magnesium ferrite the increasing

of the S:L ratio leads to the increasing of the adsorption

process efficiency. This influence is not significant for a

S:L ratio higher than 0.05 g of ferrite in 25 mL of waste

waters. Therefore further studies are conducted at this S:L

ratio for both studied ferrites.

The influence of the stirring time upon the efficiency

of the adsorption process of dye onto the studied ferrites

is presented in Table 2. It can be observed that for both

studied ferrites the highest removal efficiency of the

dye from waste waters is obtained in the first 60 min of

stirring. At higher stirring time the increasing of the

adsorption process efficiency is not significant, therefore

is not recommended to work use a higher stirring time

from the economic point of view. Also it can be noticed

that the magnesium ferrite present a higher efficiency

15

30

45

60

90

120

Adsorption process efficiency, %

MgFe2O4

CuFe2O4

49.93

68.71

82.09

96.9

98.3

98.9

22.07

47.06

52.35

60.7

71.86

73.66

compared with the copper ferrite in the removal process

of dye from the real waste water. This could be explained

by the fact that the particles sizes of the magnesium ferrite

are smaller than those of the copper ferrite; therefore the

surface contact between the adsorbent and adsorbate is

higher. The fact that the particle size of the nanoferrites

influences the adsorption performance was also should

by other researchers [17].

4 Conclusions

Nanocrystalline MIIFe2O4 (MII = Mg, Cu) ferrites with

spinel structure were obtained after the calcinations

of magnesium and copper ferrioxalate coordination

compounds at 500C. The FTIR spectra showed two

characteristic metal oxygen vibrational bands responsible

for the spinel oxides. The XRay diffraction patterns prove

that at 500C the spinel phase was obtained. The average

particle size of oxides was in the range of 1030 nm, as

revealed by XRD and SEM techniques.

The nanoferrites obtained by thermal decomposition

at 500C of the magnesium and copper ferrioxalate

coordination compounds show good adsorptive properties

based on particles size. The obtained ferrites presented

good efficiency in the removal process of dye from a real

Unauthenticated

Download Date | 2/24/15 1:38 PM

Nanocrystalline ferrites-adsorbent of waste waters

waste water. The highest degree of separation of the dye

from the waste water resulted from the inkjet cartridges

remanufacturing is obtained when is used a S:L ratio of

0.05 adsorbent in 25 mL of waters for 1 h of shaking. In

case of use of magnesium ferrite is achieved the total

removal of dyes from the waste waters.

Acknowledgments: This work was partially supported

by the strategic grant POSDRU/159/1.5/S/137070 (2014) of

the Ministry of National Education, Romania, cofinanced

by the European Social FundInvesting in People, within

the Sectoral Operational Programme Human Resources

Development 20072013.

References

[1] Louhichi B., Bensalah N., Comparative study of the treatment of

printing ink wastewater by conductivediamond electrochemical

oxidation, Fenton process, and ozonation, Sustain. Environ.

Res, 2014, 24, 4958

[2] Zhang G.J., Liu Z.Z., Song L.F., Hu J.Y., Ong S.L, Ng W.J, Post

treatment of banknote printing works wastewater ultrafiltration

concentrate, Water Res., 2004, 38, 35873595

[3] Saint Amand F.J., Hydrodynamics of deinking flotation, Int.

J. Min. Proc., 1999, 56, 277316

[4] Viesturs U., Leite M., Eisimonte M., Eremeeva T., Treimanis A.,

Biological deinking technology for the recycling of office waste

papers, Bioresource Technol., 1999, 67, 255265

[5] Ma X.J., Xia H.L., Treatment of waterbased printing ink

wastewater by Fenton process combined with coagulation,

J. Hazard. Mater., 2009, 162, 386390

[6] Wang L., Li J., Wang Y., Zhao L., Jiang Q., Adsorption capability

for Congo red on nanocrystalline MFe2O4 (M = Mn, Fe, Co, Ni)

spinel ferrites, Chem. Eng. J., 2012, 181182, 7279

[7] Iram M., Guo C., Guan Y., Ishfaq A., Liu H., Adsorption and

magnetic removal of neutral red dye from aqueous solution

using Fe3O4 hollow nanospheres, J. Hazard. Mater., 2010, 181,

10391050

[8] Wu J.S., Liu C.H., Chu K.H., Suen S.Y., Removal of cationic dye

methyl violet 2B from water by cation exchange membranes,

J. Membrane Sci., 2008, 309, 239245

[9] Vrlan C., Ciocrlan R. G., Roman T., Gherca D., Cornei N., Pui

A., Studies on adsorption capacity of cationic dyes on several

magnetic nanoparticles, Acta Chemica Iasi, 2013, 21, 1930

[10] Metes A., Koprivanac N., Glasnovic A., Flocculation as a treatment

method for printing ink wastewater, Water Environ. Res., 2000,

72, 680688

[11] Nandy T., Shastry S., Pathe P.P., Kaul S.N., Pretreatment

of currency printing ink wastewater through coagulation

flocculation process, Water Air and Soil Pollution, 2003, 148,

1530

[12] Roussy J., Chastellan P., Vooren M. van, Guibal E., Treatment of

inkcontaining wastewater by coagulation/flocculation using

biopolymers, Water SA, 2005, 31, 369376

747

[13] Fernandez J., Kiwi J., Lizama C., Freer J., Baeza J., Mansilla

H.D., Factorial experimental design of orange II photocatalytic

discoloration process, J. Photochem. Photobiol. A, 2002, 151,

213219

[14] Ersu C.B., Braida W., Chao K.P., Ong S.K., Ultrafiltration of ink and

latex wastewaters using cellulose membranes, Desalination,

2004, 164, 6370

[15] Purkait M.K., Maiti A., DasGupta S., De S., Removal of Congo red

using activated carbon and its regeneration, J. Hazard. Mater.,

2007, 145, 287295

[16] Xiangyu H., Jing F., Xiaohan L., Milin Z., Comparable Studies

of Adsorption and Magnetic Properties of Ferrite MnFe2O4

Nanoparticles, Porous Bulks and Nanowires, Chem. Res. in

Chinese Universities, 2011, 27, 543546

[17] Mayo J.T., Yavuz C., Yean S., Cong L., Shipley H., Yu W., Falkner

J., Kan A., Tomson M., Colvin V.L., The effect of nanocrystalline

magnetite size on arsenic removal, Sci. Technol. Adv. Mater.,

2007, 8, 7175

[18] Casbeer E., Virender K.S., Li X.Z., Synthesis and photocatalytic

activity of ferrites under visible light: A review, Sep. Purif.

Technol., 2012, 87, 114

[19] Liu Q., Wang L., Xiao A., Gao J., Ding W., Yu H., Huo J., Ericson M.,

Templated preparation of porous magnetic microspheres and

their application in removal of cationic dyes from wastewater,

J. Hazard. Mater., 2010, 181, 586592

[20] Tai Y., Wang L., Fan G., Gao J.M., Yu H., Zhang L., Recent research

progress on the preparation and application of magnetic

nanospheres, Poly. Int., 2011, 60, 976994

[21] Dumitru R., Papa F., Balint I., Culita D., Munteanu C., Stanica N.,

Ianculescu, A., Diamandescu, L., Carp O., Mesoporous cobalt

ferrite: A rival of platinum catalyst in methane combustion

reaction, Appl. Catal. A: Gen., 2013, 467, 178186

[22] Modi K.B., Chhantbar M.C., Joshi H.H., Study of elastic behaviour

of magnesium ferrialuminates, Ceram. Int., 2006, 32, 111114

[23] Gingasu D., Mindru I., Patron L., Cizmas C.B., Tetragonal copper

ferrite obtained by selfpropagating combustion, J. Alloy.

Compd, 2008, 460, 627631

[24] Balavijayalakshmi J., Saranya M., Synthesis and Characterization

of Copper doped Magnesium ferrite nanoparticles, J. NanoSci.

NanoTechno. 2014, 2, 397399

[25] Suryanarayana C., Norton M.G., XRay Diffraction A Practical

Approach, Plenum Press, New York, 2008

[26] Nejati K., Zabihi R., Preparation and magnetic of nano size

nickel ferrite particles using hydrothermal method, Chem. Cent.

J., 2012, 6, 16

[27] Naidek K.P., Bianconi F., da Rocha T.C., Zanchet D., Bonacin J.A.,

Novak M.A., Vaz Md, Winnischofer H., Structure and morphology

of spinel MFe2O4 (M=Fe, Co, Ni) nanoparticles chemically

synthesized from heterometallic complexes, J. Colloid Inter.

Sci., 2011, 358, 3946

[28] Chauhan S.S., Ojha C., Srivastava A.K., Synthesis and

characterization of CuFe2O4 nanoparticles, Int. J. Theor. & App.

Sci., 2009, 1, 911

[29] Gao Z., Cui F., Zeng S., Guo L., Shi J., A high surface area

superparamagnetic mesoporous spinel ferrite synthesized by

a templatefree approach and its adsorbative property,

Micropor. Mesopor. Mat., 2010, 132, 188195

Unauthenticated

Download Date | 2/24/15 1:38 PM

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Design of Offshore StructuresDocument29 pagesDesign of Offshore StructuresJOSE PRASOBH..JNo ratings yet

- Belt Road Capital Management: Method Statement For Installation Pipe Sleeve BRCM-CFU-ET&S-GENERAL-MS-1003Document8 pagesBelt Road Capital Management: Method Statement For Installation Pipe Sleeve BRCM-CFU-ET&S-GENERAL-MS-1003Dong Vanra100% (1)

- 10 Handbook Standard For Portable Fire ExtinguishersDocument205 pages10 Handbook Standard For Portable Fire ExtinguishersJosesin SinsinNo ratings yet

- Merichem Process Technologies Brochure (English)Document31 pagesMerichem Process Technologies Brochure (English)Walid Fattah100% (3)

- Powder Metallurgy Stainless Steels - Processing Microstructures, and PropertiesDocument227 pagesPowder Metallurgy Stainless Steels - Processing Microstructures, and PropertiesSamuel TesfayeNo ratings yet

- IB MYP Chemistry Term End AssessmentDocument2 pagesIB MYP Chemistry Term End AssessmentKrishna Teja67% (3)

- Pile Jacking FullTextDocument223 pagesPile Jacking FullTextGeorge Ardianda CrNo ratings yet

- Municipal Solid Waste Management in India With Special Reference To Tirupati Town in Andhra PradeshDocument4 pagesMunicipal Solid Waste Management in India With Special Reference To Tirupati Town in Andhra PradeshInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- tmp80F6 TMPDocument24 pagestmp80F6 TMPFrontiersNo ratings yet

- tmpCE8C TMPDocument19 pagestmpCE8C TMPFrontiersNo ratings yet

- tmpEFCC TMPDocument6 pagestmpEFCC TMPFrontiersNo ratings yet

- tmp3CAB TMPDocument16 pagestmp3CAB TMPFrontiersNo ratings yet

- tmpF178 TMPDocument15 pagestmpF178 TMPFrontiersNo ratings yet

- tmpE7E9 TMPDocument14 pagestmpE7E9 TMPFrontiersNo ratings yet

- tmpFFE0 TMPDocument6 pagestmpFFE0 TMPFrontiersNo ratings yet

- Tmp1a96 TMPDocument80 pagesTmp1a96 TMPFrontiersNo ratings yet

- tmpF407 TMPDocument17 pagestmpF407 TMPFrontiersNo ratings yet

- tmp6F0E TMPDocument12 pagestmp6F0E TMPFrontiersNo ratings yet

- tmpF3B5 TMPDocument15 pagestmpF3B5 TMPFrontiersNo ratings yet

- Tmpa077 TMPDocument15 pagesTmpa077 TMPFrontiersNo ratings yet

- tmpE3C0 TMPDocument17 pagestmpE3C0 TMPFrontiersNo ratings yet

- tmpC0A TMPDocument9 pagestmpC0A TMPFrontiersNo ratings yet

- tmp6382 TMPDocument8 pagestmp6382 TMPFrontiersNo ratings yet

- tmp60EF TMPDocument20 pagestmp60EF TMPFrontiersNo ratings yet

- Tmp75a7 TMPDocument8 pagesTmp75a7 TMPFrontiersNo ratings yet

- tmp72FE TMPDocument8 pagestmp72FE TMPFrontiersNo ratings yet

- tmp37B8 TMPDocument9 pagestmp37B8 TMPFrontiersNo ratings yet

- tmp998 TMPDocument9 pagestmp998 TMPFrontiersNo ratings yet

- tmp8B94 TMPDocument9 pagestmp8B94 TMPFrontiersNo ratings yet

- tmpB1BE TMPDocument9 pagestmpB1BE TMPFrontiersNo ratings yet

- tmpC30A TMPDocument10 pagestmpC30A TMPFrontiersNo ratings yet

- tmp4B57 TMPDocument9 pagestmp4B57 TMPFrontiersNo ratings yet

- tmpD1FE TMPDocument6 pagestmpD1FE TMPFrontiersNo ratings yet

- tmp9D75 TMPDocument9 pagestmp9D75 TMPFrontiersNo ratings yet

- tmpA0D TMPDocument9 pagestmpA0D TMPFrontiersNo ratings yet

- tmp27C1 TMPDocument5 pagestmp27C1 TMPFrontiersNo ratings yet

- tmp3656 TMPDocument14 pagestmp3656 TMPFrontiersNo ratings yet

- tmp2F3F TMPDocument10 pagestmp2F3F TMPFrontiersNo ratings yet

- Abstracts Book EWWM2014Document276 pagesAbstracts Book EWWM2014azilleNo ratings yet

- Loctite 577™: Technical Data SheetDocument5 pagesLoctite 577™: Technical Data SheetAditya DarmawanNo ratings yet

- Asphalt Rejuvenators Fact or FableDocument17 pagesAsphalt Rejuvenators Fact or FableAramisFariasNo ratings yet

- Operaciones Unitarias en Ingenieria Quimica Mccabe 6 Ed SolucionarioDocument404 pagesOperaciones Unitarias en Ingenieria Quimica Mccabe 6 Ed SolucionarioRafael Lara VerduzcoNo ratings yet

- FinancialBid2 9487080392Document86 pagesFinancialBid2 9487080392renjith p sNo ratings yet

- Rigid Pavement: Postgraduate Studies Highways EngineeringDocument15 pagesRigid Pavement: Postgraduate Studies Highways EngineeringHANAN HUSSNo ratings yet

- MyTiCon Screws Design Guide VU 1.2Document52 pagesMyTiCon Screws Design Guide VU 1.2TomNo ratings yet

- Clean Surfaces and Floors Lesson Explains TechniquesDocument47 pagesClean Surfaces and Floors Lesson Explains TechniquesEmerson Cruz0% (1)

- By Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetDocument12 pagesBy Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetPackage RotaryNo ratings yet

- Rawlplug en R Kex II Pure Epoxy Resin Threaded RodsDocument9 pagesRawlplug en R Kex II Pure Epoxy Resin Threaded RodsgumuskapiNo ratings yet

- Bending Load Cell Type 54: ApplicationsDocument3 pagesBending Load Cell Type 54: ApplicationsFaizeus CorpNo ratings yet

- CgtophDocument2 pagesCgtophcristian orihuelaNo ratings yet

- Advanced Manufacturing Question SampleDocument2 pagesAdvanced Manufacturing Question SampleBakul RoyNo ratings yet

- High-solids zinc epoxy primer data sheetDocument4 pagesHigh-solids zinc epoxy primer data sheetMina RemonNo ratings yet

- Science Answer Key Class IxDocument7 pagesScience Answer Key Class IxLakshay BansalNo ratings yet

- Champion Lubricants Storage HandlingDocument6 pagesChampion Lubricants Storage HandlingIonut SomneaNo ratings yet

- Material Turbine - 2 PDFDocument6 pagesMaterial Turbine - 2 PDFMonikaNo ratings yet

- Practice Exam 1Document5 pagesPractice Exam 1ManuelPauloAcogidoNo ratings yet

- Paul Meijering: Focusing On Quality and Relationships Ensures SuccessDocument68 pagesPaul Meijering: Focusing On Quality and Relationships Ensures SuccesssagarNo ratings yet

- Inconel 112-DatasheetDocument1 pageInconel 112-DatasheetrobertNo ratings yet

- Thermon Sa - Heat Trace Technologies - Energy SavingsDocument9 pagesThermon Sa - Heat Trace Technologies - Energy Savingsjose manuel alvarez rodriguezNo ratings yet

- IMI CCI Product DRAG-Control-Valves AW LRESDocument4 pagesIMI CCI Product DRAG-Control-Valves AW LRESOscarGomezMecanicoNo ratings yet