Professional Documents

Culture Documents

OIL GAS Plug Valves

Uploaded by

Mabeli MartinezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OIL GAS Plug Valves

Uploaded by

Mabeli MartinezCopyright:

Available Formats

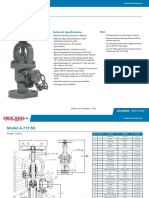

Manual Bleed with

Thermal Relief

Thermal Relief with Gauge

A check valve, set at 25 psi, releases to upstream body side the overpressure due to thermal

expansion of the fluid trapped in the body cavity.

The manual bleed system verifies the seat sealing

integrity.

Relief system, set at 25 psi, to release overpressure, due to body fluid thermal expansion, to

upstream body side. It is combined with a gauge

to check the seat sealing integrity.

Thermal Relief

Manual Bleed with Gauge

A check valve, set at 25 psi, releases to upstream

side any overpressure due to thermal expansion

of the body cavity fluid.

Manual bleed, combined with a gauge to verify

the seat seal integrity.

Picture by Port of Bilbao Authority

Available Bleed Systems

0035

All the MTS DBB Plug valves are fitted with a drain valve in the bottom bonnet. It can be used as

manual bleed to verify the seat integrity as well as to drain completely the shell cavity.

MTS Valves And Technology, S.L.

Pol. Ind. Bakiola, Pab,17

48498 Arrankudiaga (Spain)

Tel:. (+34) 946 481 215

Fax :(+34) 946 481 791

e-mail: comercial@mtsvalves.com

www.mtsvalves.com

Oil & Gas

ISO 9001:2008

MTS Valves Colombia

Calle 26A No. 13-97 Oficina 1601

Bogota D.C (Colombia)

Tel: (57-1) 655 23 10

Cel (Mob) (57) 312 377 32 94

www.mtsvalves.com

Valvospain, S.L.

Pol. Ind. Kazadako Saratxo

01468 Amurrio (Spain)

DBB Dual Expanding Plug Valves

MTS valves are installed in Liquid

Bulk Terminals, Aviation Fuel Tank

Farms, Pipelines and Refineries

Introduction

Main Features

Design Data

MTS Valves & Technology is a reputed and well

known plug valve manufacturer. It was founded

in 1973, and belongs to Valvospain Group since

2006. MTS provides to its Customers not only the

best High Quality, Reliable and Low Maintenance

Valve, but the best service, and advice in the

selection of the most accurate valve for each

service.

API599 and ASME B16.34

END DIMENSIONS

13

12

MTS has become a world Leader Company on

manufacturing self-lubricated Plug valves, mainly

for high pressure in Desalination Plants.

10

2

11

14

Our company has been focusing all its Research and Development efforts during the

last years on developing the DBB Dual Expanding

Plug Valve.

MTS has designed a complete range of Dual

Expanding Plug Valves and is manufacturing

DBB Plug Valves for Tank Terminals, such as Fujairah

Aegean Terminal in 2013.

5

4

1

What Double Block and Bleed means

It is the valve capability to seal both seating

surfaces at the same time, upstream and

downstream, allowing the shell cavity bleeding

without any risk of losing the pipeline fluid. The

valve ensures the tight shut-off at both ends,

providing a double closing valve.

This characteristic is usually demanded in critical services and fulfilled in the past by mean

of two valves. The DBB plug valve design saves

costs and reduces the required space in line as

result of being a single valve.

Standard Materials of Construction

VALVE PART

MATERIAL

1

2

3

4

5

6

7

8

9

10

11

12

13

Body

Top Bonnet

Bottom Bonnet

Plug

Slip

Slip Seal

Stem

Gland Bushing

Guiding Bushing

Packing

Guiding Shaft

Cam

Yoke

ASTM A-216 WCC + ENP (25/30 m)

ASTM A-216 WCC

ASTM A-216 WCC

ASTM A-216 WCC + ENP (25/30 m)

EN-GJS-500-7 Ductile Iron

Viton

ASTM A-182 F6

ASTM A-182 F6

17-4 PH

Graphite

ASTM A-182 F6

F-174 + Nitriding (QPQ)

ASTM A-216 WCC

14

Spiral wound Gasket

AISI 316 + Graphite

ITEM

DESIGN

Viton seals guarantee positive tight shut-off in

both its seating faces, upstream and downstream, at the same time. It is achieved by the

plug wedge effect and it is independent of the

pipeline pressure.

BODY PRESSURE RELIEF

It is an optional feature and provides possibility

to bleed the body cavity, either manually or/and

automatically. It avoids plug-lock or even possible shell damage due to thermal over-pressure.

FIRE SAFE DESIGN

Slip metal face matches body seat face, assuring

metal-to-metal sealing, in case of resilient seal

results fired.

BACK SEAT

Top guiding shaft matches the top bonnet seat

area when the valve is fully open, increasing

the packing life and allowing its replacement

while the line is under pressure.

FACE-TO-FACE DIMENSIONS

ASME B16.10 Short Pattern

HYDROSTATIC TEST

API-598 and API-6D

Manufacturing

Range

FULL BORE DESIGN

150# - from 2 to 24

300# - from 2 to 20

600# - from 2 to 20

REGULAR BORE DESIGN

14

BUBBLE TIGHT SHUT-OFF

Flanged to ASME B16.5

BW ends to ASME B16.25

3

EASY MAINTENANCE

Slips and packing rings can be easily replaced without needing to remove the valve from the pipeline.

CHARACTERISED PORT

Plug and body ports are diamond shaped,

allowing flow regulation and avoiding sudden

increases of flow.

DOUBLE TRUNNION DESIGN

The plug is perfectly guided by mean of top and

bottom shafts. It ensures clearance between slips

and body when turning the plug, avoiding seal

wearing.

NO WEARING IN SEALING ELEMENTS

Both slips are retracted from the body seat area,

previously to turn the plug, avoiding any friction

between the slip resilient insert and the body. This

characteristic increases the life of the sealing

elements and decreases the operating torque,

being an advantage when comparing to other

types of isolation service valves, such as gate or

ball valves.

150# - from 2 to 36

300# - from 2 to 24

600# - from 2 to 20

OPERATING

Hand drive (handwheel /gearbox),

pneumatic drive, hydraulic drive

and electrical drive

.

Applications

Multi-Product Manifolds, separating different

kind of products and avoiding their mixing.

Ships and Trucks fuel loading systems.

Fuel Tanks discharging, avoiding loss of fuel in

closed position when frequent operations.

Oil & Gas transport pipelines.

Airport Fuel Tank Terminals.

Fluids

Gasoline, Gasoil, MDO, Crude, Naphtha, MTBE,

Kerosene, Gas condensate, Water

Picture by Port of Bilbao Authority

Introduction

Main Features

Design Data

MTS Valves & Technology is a reputed and well

known plug valve manufacturer. It was founded

in 1973, and belongs to Valvospain Group since

2006. MTS provides to its Customers not only the

best High Quality, Reliable and Low Maintenance

Valve, but the best service, and advice in the

selection of the most accurate valve for each

service.

API599 and ASME B16.34

END DIMENSIONS

13

12

MTS has become a world Leader Company on

manufacturing self-lubricated Plug valves, mainly

for high pressure in Desalination Plants.

10

2

11

14

Our company has been focusing all its Research and Development efforts during the

last years on developing the DBB Dual Expanding

Plug Valve.

MTS has designed a complete range of Dual

Expanding Plug Valves and is manufacturing

DBB Plug Valves for Tank Terminals, such as Fujairah

Aegean Terminal in 2013.

5

4

1

What Double Block and Bleed means

It is the valve capability to seal both seating

surfaces at the same time, upstream and

downstream, allowing the shell cavity bleeding

without any risk of losing the pipeline fluid. The

valve ensures the tight shut-off at both ends,

providing a double closing valve.

This characteristic is usually demanded in critical services and fulfilled in the past by mean

of two valves. The DBB plug valve design saves

costs and reduces the required space in line as

result of being a single valve.

Standard Materials of Construction

VALVE PART

MATERIAL

1

2

3

4

5

6

7

8

9

10

11

12

13

Body

Top Bonnet

Bottom Bonnet

Plug

Slip

Slip Seal

Stem

Gland Bushing

Guiding Bushing

Packing

Guiding Shaft

Cam

Yoke

ASTM A-216 WCC + ENP (25/30 m)

ASTM A-216 WCC

ASTM A-216 WCC

ASTM A-216 WCC + ENP (25/30 m)

EN-GJS-500-7 Ductile Iron

Viton

ASTM A-182 F6

ASTM A-182 F6

17-4 PH

Graphite

ASTM A-182 F6

F-174 + Nitriding (QPQ)

ASTM A-216 WCC

14

Spiral wound Gasket

AISI 316 + Graphite

ITEM

DESIGN

Viton seals guarantee positive tight shut-off in

both its seating faces, upstream and downstream, at the same time. It is achieved by the

plug wedge effect and it is independent of the

pipeline pressure.

BODY PRESSURE RELIEF

It is an optional feature and provides possibility

to bleed the body cavity, either manually or/and

automatically. It avoids plug-lock or even possible shell damage due to thermal over-pressure.

FIRE SAFE DESIGN

Slip metal face matches body seat face, assuring

metal-to-metal sealing, in case of resilient seal

results fired.

BACK SEAT

Top guiding shaft matches the top bonnet seat

area when the valve is fully open, increasing

the packing life and allowing its replacement

while the line is under pressure.

FACE-TO-FACE DIMENSIONS

ASME B16.10 Short Pattern

HYDROSTATIC TEST

API-598 and API-6D

Manufacturing

Range

FULL BORE DESIGN

150# - from 2 to 24

300# - from 2 to 20

600# - from 2 to 20

REGULAR BORE DESIGN

14

BUBBLE TIGHT SHUT-OFF

Flanged to ASME B16.5

BW ends to ASME B16.25

3

EASY MAINTENANCE

Slips and packing rings can be easily replaced without needing to remove the valve from the pipeline.

CHARACTERISED PORT

Plug and body ports are diamond shaped,

allowing flow regulation and avoiding sudden

increases of flow.

DOUBLE TRUNNION DESIGN

The plug is perfectly guided by mean of top and

bottom shafts. It ensures clearance between slips

and body when turning the plug, avoiding seal

wearing.

NO WEARING IN SEALING ELEMENTS

Both slips are retracted from the body seat area,

previously to turn the plug, avoiding any friction

between the slip resilient insert and the body. This

characteristic increases the life of the sealing

elements and decreases the operating torque,

being an advantage when comparing to other

types of isolation service valves, such as gate or

ball valves.

150# - from 2 to 36

300# - from 2 to 24

600# - from 2 to 20

OPERATING

Hand drive (handwheel /gearbox),

pneumatic drive, hydraulic drive

and electrical drive

.

Applications

Multi-Product Manifolds, separating different

kind of products and avoiding their mixing.

Ships and Trucks fuel loading systems.

Fuel Tanks discharging, avoiding loss of fuel in

closed position when frequent operations.

Oil & Gas transport pipelines.

Airport Fuel Tank Terminals.

Fluids

Gasoline, Gasoil, MDO, Crude, Naphtha, MTBE,

Kerosene, Gas condensate, Water

Picture by Port of Bilbao Authority

Introduction

Main Features

Design Data

MTS Valves & Technology is a reputed and well

known plug valve manufacturer. It was founded

in 1973, and belongs to Valvospain Group since

2006. MTS provides to its Customers not only the

best High Quality, Reliable and Low Maintenance

Valve, but the best service, and advice in the

selection of the most accurate valve for each

service.

API599 and ASME B16.34

END DIMENSIONS

13

12

MTS has become a world Leader Company on

manufacturing self-lubricated Plug valves, mainly

for high pressure in Desalination Plants.

10

2

11

14

Our company has been focusing all its Research and Development efforts during the

last years on developing the DBB Dual Expanding

Plug Valve.

MTS has designed a complete range of Dual

Expanding Plug Valves and is manufacturing

DBB Plug Valves for Tank Terminals, such as Fujairah

Aegean Terminal in 2013.

5

4

1

What Double Block and Bleed means

It is the valve capability to seal both seating

surfaces at the same time, upstream and

downstream, allowing the shell cavity bleeding

without any risk of losing the pipeline fluid. The

valve ensures the tight shut-off at both ends,

providing a double closing valve.

This characteristic is usually demanded in critical services and fulfilled in the past by mean

of two valves. The DBB plug valve design saves

costs and reduces the required space in line as

result of being a single valve.

Standard Materials of Construction

VALVE PART

MATERIAL

1

2

3

4

5

6

7

8

9

10

11

12

13

Body

Top Bonnet

Bottom Bonnet

Plug

Slip

Slip Seal

Stem

Gland Bushing

Guiding Bushing

Packing

Guiding Shaft

Cam

Yoke

ASTM A-216 WCC + ENP (25/30 m)

ASTM A-216 WCC

ASTM A-216 WCC

ASTM A-216 WCC + ENP (25/30 m)

EN-GJS-500-7 Ductile Iron

Viton

ASTM A-182 F6

ASTM A-182 F6

17-4 PH

Graphite

ASTM A-182 F6

F-174 + Nitriding (QPQ)

ASTM A-216 WCC

14

Spiral wound Gasket

AISI 316 + Graphite

ITEM

DESIGN

Viton seals guarantee positive tight shut-off in

both its seating faces, upstream and downstream, at the same time. It is achieved by the

plug wedge effect and it is independent of the

pipeline pressure.

BODY PRESSURE RELIEF

It is an optional feature and provides possibility

to bleed the body cavity, either manually or/and

automatically. It avoids plug-lock or even possible shell damage due to thermal over-pressure.

FIRE SAFE DESIGN

Slip metal face matches body seat face, assuring

metal-to-metal sealing, in case of resilient seal

results fired.

BACK SEAT

Top guiding shaft matches the top bonnet seat

area when the valve is fully open, increasing

the packing life and allowing its replacement

while the line is under pressure.

FACE-TO-FACE DIMENSIONS

ASME B16.10 Short Pattern

HYDROSTATIC TEST

API-598 and API-6D

Manufacturing

Range

FULL BORE DESIGN

150# - from 2 to 24

300# - from 2 to 20

600# - from 2 to 20

REGULAR BORE DESIGN

14

BUBBLE TIGHT SHUT-OFF

Flanged to ASME B16.5

BW ends to ASME B16.25

3

EASY MAINTENANCE

Slips and packing rings can be easily replaced without needing to remove the valve from the pipeline.

CHARACTERISED PORT

Plug and body ports are diamond shaped,

allowing flow regulation and avoiding sudden

increases of flow.

DOUBLE TRUNNION DESIGN

The plug is perfectly guided by mean of top and

bottom shafts. It ensures clearance between slips

and body when turning the plug, avoiding seal

wearing.

NO WEARING IN SEALING ELEMENTS

Both slips are retracted from the body seat area,

previously to turn the plug, avoiding any friction

between the slip resilient insert and the body. This

characteristic increases the life of the sealing

elements and decreases the operating torque,

being an advantage when comparing to other

types of isolation service valves, such as gate or

ball valves.

150# - from 2 to 36

300# - from 2 to 24

600# - from 2 to 20

OPERATING

Hand drive (handwheel /gearbox),

pneumatic drive, hydraulic drive

and electrical drive

.

Applications

Multi-Product Manifolds, separating different

kind of products and avoiding their mixing.

Ships and Trucks fuel loading systems.

Fuel Tanks discharging, avoiding loss of fuel in

closed position when frequent operations.

Oil & Gas transport pipelines.

Airport Fuel Tank Terminals.

Fluids

Gasoline, Gasoil, MDO, Crude, Naphtha, MTBE,

Kerosene, Gas condensate, Water

Picture by Port of Bilbao Authority

Manual Bleed with

Thermal Relief

Thermal Relief with Gauge

A check valve, set at 25 psi, releases to upstream body side the overpressure due to thermal

expansion of the fluid trapped in the body cavity.

The manual bleed system verifies the seat sealing

integrity.

Relief system, set at 25 psi, to release overpressure, due to body fluid thermal expansion, to

upstream body side. It is combined with a gauge

to check the seat sealing integrity.

Thermal Relief

Manual Bleed with Gauge

A check valve, set at 25 psi, releases to upstream

side any overpressure due to thermal expansion

of the body cavity fluid.

Manual bleed, combined with a gauge to verify

the seat seal integrity.

Picture by Port of Bilbao Authority

Available Bleed Systems

0035

All the MTS DBB Plug valves are fitted with a drain valve in the bottom bonnet. It can be used as

manual bleed to verify the seat integrity as well as to drain completely the shell cavity.

MTS Valves And Technology, S.L.

Pol. Ind. Bakiola, Pab,17

48498 Arrankudiaga (Spain)

Tel:. (+34) 946 481 215

Fax :(+34) 946 481 791

e-mail: comercial@mtsvalves.com

www.mtsvalves.com

Oil & Gas

ISO 9001:2008

MTS Valves Colombia

Calle 26A No. 13-97 Oficina 1601

Bogota D.C (Colombia)

Tel: (57-1) 655 23 10

Cel (Mob) (57) 312 377 32 94

www.mtsvalves.com

Valvospain, S.L.

Pol. Ind. Kazadako Saratxo

01468 Amurrio (Spain)

DBB Dual Expanding Plug Valves

MTS valves are installed in Liquid

Bulk Terminals, Aviation Fuel Tank

Farms, Pipelines and Refineries

Manual Bleed with

Thermal Relief

Thermal Relief with Gauge

A check valve, set at 25 psi, releases to upstream body side the overpressure due to thermal

expansion of the fluid trapped in the body cavity.

The manual bleed system verifies the seat sealing

integrity.

Relief system, set at 25 psi, to release overpressure, due to body fluid thermal expansion, to

upstream body side. It is combined with a gauge

to check the seat sealing integrity.

Thermal Relief

Manual Bleed with Gauge

A check valve, set at 25 psi, releases to upstream

side any overpressure due to thermal expansion

of the body cavity fluid.

Manual bleed, combined with a gauge to verify

the seat seal integrity.

Picture by Port of Bilbao Authority

Available Bleed Systems

0035

All the MTS DBB Plug valves are fitted with a drain valve in the bottom bonnet. It can be used as

manual bleed to verify the seat integrity as well as to drain completely the shell cavity.

MTS Valves And Technology, S.L.

Pol. Ind. Bakiola, Pab,17

48498 Arrankudiaga (Spain)

Tel:. (+34) 946 481 215

Fax :(+34) 946 481 791

e-mail: comercial@mtsvalves.com

www.mtsvalves.com

Oil & Gas

ISO 9001:2008

MTS Valves Colombia

Calle 26A No. 13-97 Oficina 1601

Bogota D.C (Colombia)

Tel: (57-1) 655 23 10

Cel (Mob) (57) 312 377 32 94

www.mtsvalves.com

Valvospain, S.L.

Pol. Ind. Kazadako Saratxo

01468 Amurrio (Spain)

DBB Dual Expanding Plug Valves

MTS valves are installed in Liquid

Bulk Terminals, Aviation Fuel Tank

Farms, Pipelines and Refineries

You might also like

- Gate ValveDocument27 pagesGate ValveYogesh Kumar Bhatnagar0% (1)

- Gate, Globe & Check Valves GuideDocument52 pagesGate, Globe & Check Valves GuideBabar Manzoor GhauriNo ratings yet

- Crane Engineering Data 1Document56 pagesCrane Engineering Data 1jerry666aNo ratings yet

- Grove G9 Wafer Gate ValveDocument9 pagesGrove G9 Wafer Gate Valvetxlucky80No ratings yet

- Ball Valve Seat Seal Injection SystemDocument28 pagesBall Valve Seat Seal Injection SystemmudrijasmNo ratings yet

- SWI Products MetalDocument21 pagesSWI Products MetalPrasanth PrasadNo ratings yet

- Through Conduit Gate Valves Slab & ExpandingDocument7 pagesThrough Conduit Gate Valves Slab & ExpandingRockny310No ratings yet

- Blakeborough Choke ValveDocument12 pagesBlakeborough Choke ValveWalid Ben HuseinNo ratings yet

- Api 600 Cast Steel Valves 1: Service FeaturesDocument5 pagesApi 600 Cast Steel Valves 1: Service FeaturesRevanNo ratings yet

- Valvula CLKMC 0112 USDocument8 pagesValvula CLKMC 0112 USAndrew ZeaNo ratings yet

- PRODUCT RANGE GATE VALVEDocument6 pagesPRODUCT RANGE GATE VALVETanmoy DuttaNo ratings yet

- Cokebuster: A Proven SolutionDocument11 pagesCokebuster: A Proven Solutionengg_mech77No ratings yet

- Clarkson KGFDocument8 pagesClarkson KGFJorge Castro CucurellaNo ratings yet

- Broady 3500 BrochureDocument12 pagesBroady 3500 Brochureahmedm2020No ratings yet

- Ad00912v Wkmsaf T SealDocument36 pagesAd00912v Wkmsaf T SealJulia WadeNo ratings yet

- Vanessa Butterfly ValvesDocument12 pagesVanessa Butterfly Valvesdragon2065No ratings yet

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- CT WKM Gate Saf T Seal 01 PDFDocument36 pagesCT WKM Gate Saf T Seal 01 PDFchonubobbyNo ratings yet

- Perar Trunnion Ball ValvesDocument54 pagesPerar Trunnion Ball ValvesUday GokhaleNo ratings yet

- PDF - Gate Valve OS and YDocument10 pagesPDF - Gate Valve OS and YLENINROMEROH4168No ratings yet

- Pump Sales WebDocument7 pagesPump Sales WebGermán Soledad MolinaNo ratings yet

- Guided Valves Technical BulletinDocument15 pagesGuided Valves Technical BulletinVladimir VuletinNo ratings yet

- Three Way Valve Technical OverviewDocument8 pagesThree Way Valve Technical OverviewWalter JosephNo ratings yet

- Velan Forged Steel CatalogueDocument26 pagesVelan Forged Steel CatalogueJuan Carlos Ojeda RamirezNo ratings yet

- GWC Valve International Cast Steel ValvesDocument32 pagesGWC Valve International Cast Steel ValvesGWC Valve International100% (1)

- API 6A and 6D Ball ValvesDocument27 pagesAPI 6A and 6D Ball ValveszayerirezaNo ratings yet

- Velan Forged Steel Gate, Globe & ChecksDocument25 pagesVelan Forged Steel Gate, Globe & Checksmhorst1No ratings yet

- VX Check Rite GeneralDocument8 pagesVX Check Rite Generalhijitus_80No ratings yet

- High Performance Butterfly ValvesDocument8 pagesHigh Performance Butterfly ValvesTejas JasaniNo ratings yet

- L&T Aquaseal Butterfly Check ValvesDocument24 pagesL&T Aquaseal Butterfly Check ValvesSohail PathanNo ratings yet

- Accuseal Plug ValveDocument20 pagesAccuseal Plug ValveTendai Felex Maduke100% (2)

- PIPING - VALVES - American Flow Control (Gate Valves) (8 PAGES)Document8 pagesPIPING - VALVES - American Flow Control (Gate Valves) (8 PAGES)fkhajehNo ratings yet

- API 6A Valves Design, Construction and FeaturesDocument12 pagesAPI 6A Valves Design, Construction and Featuresedo_tapia_ur100% (1)

- Solutions-Mining-Industry-Bray ControlsDocument12 pagesSolutions-Mining-Industry-Bray ControlsEleo Gabriel Egusquiza RamosNo ratings yet

- CT valve handles high speeds in gas compressorsDocument5 pagesCT valve handles high speeds in gas compressorsTu PhamNo ratings yet

- Iso 9001 CertifiedDocument4 pagesIso 9001 CertifiedLuis R. Salas SotoNo ratings yet

- WOM Magnum Gate Valve BrochureDocument8 pagesWOM Magnum Gate Valve BrochuresjongejongeNo ratings yet

- 2010 KMT Waterjet PSC Catalog - LDocument39 pages2010 KMT Waterjet PSC Catalog - LaeradriNo ratings yet

- Control Valves and Regulators for Industrial ApplicationsDocument12 pagesControl Valves and Regulators for Industrial Applicationsleandroperao5374No ratings yet

- Demco DM DTDocument30 pagesDemco DM DTGregory StewartNo ratings yet

- L&T ButterflyValves Triple OffsetDocument16 pagesL&T ButterflyValves Triple OffsetvarathapandianNo ratings yet

- H CatalogDocument16 pagesH CatalogFrancis NelsonNo ratings yet

- Severe Service ValveDocument16 pagesSevere Service ValvesekharsamyNo ratings yet

- BS 5351 Ball Valves CatalogDocument10 pagesBS 5351 Ball Valves CatalogcatalineulaNo ratings yet

- Vessel Bottom Disc Valves for Full Flow and Dead Space Free DesignDocument8 pagesVessel Bottom Disc Valves for Full Flow and Dead Space Free DesignMahesh KumarNo ratings yet

- Atomac BrochureDocument28 pagesAtomac BrochureManish TulaskarNo ratings yet

- Basic Seal TrainingDocument42 pagesBasic Seal TrainingSherif Adel100% (1)

- 2011 07 Mar00080 en Katalog Typs WebDocument28 pages2011 07 Mar00080 en Katalog Typs WebzayerirezaNo ratings yet

- Bonetti WBY CatalogueDocument16 pagesBonetti WBY CatalogueisluqueNo ratings yet

- Kirloskar Valves Technical Specification CatalogueDocument24 pagesKirloskar Valves Technical Specification CatalogueAbhinay SuratkarNo ratings yet

- Apollo ValvesDocument44 pagesApollo ValvesDevdatt WaghuleNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- 65-17 Municipal AguaDocument6 pages65-17 Municipal AguaMabeli MartinezNo ratings yet

- Astm A 276 1 PDFDocument7 pagesAstm A 276 1 PDFNitinNo ratings yet

- Serie 760Document4 pagesSerie 760Mabeli MartinezNo ratings yet

- 381 enDocument4 pages381 enMabeli MartinezNo ratings yet

- Serie 740Document4 pagesSerie 740Mabeli MartinezNo ratings yet

- Astm A 276 1 PDFDocument7 pagesAstm A 276 1 PDFNitinNo ratings yet

- Astm A 276 1 PDFDocument7 pagesAstm A 276 1 PDFNitinNo ratings yet

- Milton Roy Seri HDocument16 pagesMilton Roy Seri HDanielle HarveyNo ratings yet

- Astm A36 PDFDocument5 pagesAstm A36 PDFAnindya Aulia Pratiwi67% (3)

- Engineering Piping Design Guide Fibra de VidrioDocument36 pagesEngineering Piping Design Guide Fibra de VidrioMabeli MartinezNo ratings yet

- IFC Basket Strainers GuideDocument24 pagesIFC Basket Strainers GuideMabeli MartinezNo ratings yet

- Astm A36 PDFDocument5 pagesAstm A36 PDFAnindya Aulia Pratiwi67% (3)

- Vortex™ Gasket-Nm: TOMBO™ No. 1838R-NMDocument1 pageVortex™ Gasket-Nm: TOMBO™ No. 1838R-NMNal FivefivetwooneNo ratings yet

- Angle Valve Technical Specs and Parts ListDocument2 pagesAngle Valve Technical Specs and Parts ListARMANDONo ratings yet

- Manual Alemite 7785 - SeriesDocument14 pagesManual Alemite 7785 - SeriesGezzy Boys 28No ratings yet

- MSS SP-6 SimplificadaDocument1 pageMSS SP-6 Simplificadasidneyg12No ratings yet

- Product CatalogueDocument8 pagesProduct CatalogueRavi PachegaonkarNo ratings yet

- Service Air Comp MAS G250 - Spare PartsDocument87 pagesService Air Comp MAS G250 - Spare PartsecrNo ratings yet

- Pj8 Service ManualDocument15 pagesPj8 Service ManualHugo TejadaNo ratings yet

- Peco Katalog PDFDocument178 pagesPeco Katalog PDFandi nainggolanNo ratings yet

- Motor 3066Document130 pagesMotor 3066mateo apolinar100% (22)

- Quad Sym 600 Manuel ServiceDocument96 pagesQuad Sym 600 Manuel ServiceAndriamaro RajaonarifetraNo ratings yet

- Dana Spicer 8000 Series Transmission PartsDocument8 pagesDana Spicer 8000 Series Transmission PartsRachid SmailiNo ratings yet

- Dean RA Pump ManualsDocument23 pagesDean RA Pump ManualscoltonNo ratings yet

- Schlegel Conductive Elastomers r1Document31 pagesSchlegel Conductive Elastomers r1yobet_navaNo ratings yet

- LT3355v5 FullCatalogDocument152 pagesLT3355v5 FullCatalogAhmed Emad AhmedNo ratings yet

- FIVALCO KatalogDocument47 pagesFIVALCO KatalogdavidNo ratings yet

- Kiln Shell Specification SummaryDocument20 pagesKiln Shell Specification SummaryAnonymous p4GdtQpNo ratings yet

- Engineering Manual: Concrete Pressure PipeDocument176 pagesEngineering Manual: Concrete Pressure Pipeahmad elnggarNo ratings yet

- Montacargas DP 100 - LL2SPEEDDocument57 pagesMontacargas DP 100 - LL2SPEEDJonny Zambrano MeraNo ratings yet

- ENGINE LUBRICATION SYSTEM OVERVIEWDocument18 pagesENGINE LUBRICATION SYSTEM OVERVIEWIstvanNo ratings yet

- GAB Neumann Brochure 2018Document24 pagesGAB Neumann Brochure 2018Alberto AporNo ratings yet

- API Flange Bolting Data ChartDocument6 pagesAPI Flange Bolting Data ChartkswaghmareNo ratings yet

- SCI GroovedDocument56 pagesSCI GroovedVeer GangjiNo ratings yet

- Pat List-Timas-Desalter PDFDocument14 pagesPat List-Timas-Desalter PDFrizky efrinaldoNo ratings yet

- Installation and Maintenance Instructions: Crosby Style Jos-E, Jbs-E, JLT - Jbs-E, JLT - Jos-E ValvesDocument22 pagesInstallation and Maintenance Instructions: Crosby Style Jos-E, Jbs-E, JLT - Jbs-E, JLT - Jos-E ValvesMoe MozhganNo ratings yet

- Pilot Operated Pressure Regulator SpecificationsDocument2 pagesPilot Operated Pressure Regulator SpecificationsRendy MulyadiNo ratings yet

- A SIMPLE & PORTABLE EQUIPMENT FOR WATER PERMEABILITY TESTDocument12 pagesA SIMPLE & PORTABLE EQUIPMENT FOR WATER PERMEABILITY TESTgundulpNo ratings yet

- Sekisui Catalog PlantPipeMaterialsDocument78 pagesSekisui Catalog PlantPipeMaterialsLam ThanhNo ratings yet

- Wolf 250 PDFDocument76 pagesWolf 250 PDFryan hernandesNo ratings yet

- ELECTDocument10 pagesELECTThirunavukkarasuThiruNo ratings yet

- Gasket DesignDocument10 pagesGasket Designnikita saleNo ratings yet