Professional Documents

Culture Documents

FL - Hydronic Piping Specialties

Uploaded by

Abdul RaheemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FL - Hydronic Piping Specialties

Uploaded by

Abdul RaheemCopyright:

Available Formats

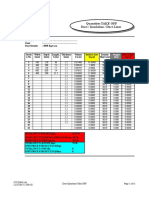

232116 HYDRONIC PIPING SPECIALTIES

232116 - HYDRONIC PIPING SPECIALTIES

ABM Military College Pack # 5

Technical Specification - Rev. 0

232116 - 1

232116 HYDRONIC PIPING SPECIALTIES

SECTION 232116 - HYDRONIC PIPING SPECIALTIES

PART 1 - GENERAL

SCHEDULE 0 - RELATED DOCUMENTS

PRODUCT DATA SHEET 0 - Drawings and general provisions of the Contract, including General and

Supplementary Conditions and Division 01 Specification Sections, apply to this Section.

SCHEDULE 1 - SUMMARY

PRODUCT DATA SHEET 0 - Section includes special-duty valves and specialties for the following:

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0.10

Hot-water heating piping.

Chilled-water piping.

Dual-temperature heating and cooling water piping.

Condenser-water piping.

Glycol cooling-water piping.

Makeup-water piping.

Condensate-drain piping.

Blowdown-drain piping.

Air-vent piping.

Safety-valve-inlet and -outlet piping.

SCHEDULE 2 - ACTION SUBMITTALS

PRODUCT DATA SHEET 0 - Product Data: For each type of the following:

0.1

0.2

0.3

Valves: Include flow and pressure drop curves based on manufacturer's testing for calibratedorifice balancing valves and automatic flow-control valves.

Air-control devices.

Hydronic specialties.

SCHEDULE 3 - CLOSEOUT SUBMITTALS

PRODUCT DATA SHEET 0 - Operation and Maintenance Data: For air-control devices, hydronic

specialties, and special-duty valves to include in emergency, operation, and maintenance manuals.

SCHEDULE 4 - MAINTENANCE MATERIAL SUBMITTALS

ABM Military College Pack # 5

Technical Specification - Rev. 0

232116 - 2

232116 HYDRONIC PIPING SPECIALTIES

PRODUCT DATA SHEET 0 - Differential Pressure Meter: For each type of balancing valve and

automatic flow control valve, include flowmeter, probes, hoses, flow charts, and carrying case.

SCHEDULE 5 - QUALITY ASSURANCE

PRODUCT DATA SHEET 0 - Pipe Welding:

Boiler and Pressure Vessel Code: Section IX.

0.1

Qualify procedures and operators according to ASME

Safety valves and pressure vessels shall bear the appropriate ASME label. Fabricate and stamp

air separators and expansion tanks to comply with ASME Boiler and Pressure Vessel Code:

Section VIII, Division 1.

PART 2 - PRODUCTS

SCHEDULE 0 - PERFORMANCE REQUIREMENTS

PRODUCT DATA SHEET 0 - Hydronic piping components and installation shall be capable of

withstanding the following minimum working pressure and temperature unless otherwise indicated:

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

0.10

Hot-Water Heating Piping: at 200 deg F (93 deg C) .

Chilled-Water Piping: at 200 deg F (93 deg C).

Dual-Temperature Heating and Cooling Water Piping: at 200 deg F (93 deg C).

Condenser-Water Piping: at 150 deg F (66 deg C).

Glycol Cooling-Water Piping: at 150 deg F (66 deg C).

Makeup-Water Piping: 80 psig (552 kPa) at 150 deg F (66 deg C) .

Condensate-Drain Piping: 150 deg F (66 deg C).

Blowdown-Drain Piping: 200 deg F (93 deg C).

Air-Vent Piping: 200 deg F (93 deg C).

Safety-Valve-Inlet and -Outlet Piping: Equal to the pressure of the piping system to which it is

attached.

SCHEDULE 1 - VALVES

PRODUCT DATA SHEET 0 - Gate, Globe, Check, Ball, and Butterfly Valves:

Comply with

requirements specified in Section 230523 "General-Duty Valves for HVAC Piping."Section 15112

"General-Duty Valves for HVAC Piping."

PRODUCT DATA SHEET 1 - Automatic Temperature-Control Valves, Actuators, and Sensors: Comply

with requirements specified in Section 230900 "Instrumentation and Control for HVAC."Section 15900

"HVAC Instrumentation and Controls."

PRODUCT DATA SHEET 2 - Plastic Ball Valves:

ABM Military College Pack # 5

Technical Specification - Rev. 0

232116 - 3

232116 HYDRONIC PIPING SPECIALTIES

2.1

2.2

2.3

2.4

2.5

2.6

1. Body: One-, two-, or three-piece CPVC or PVC to match piping.

Ball: Full-port CPVC or PVC to match piping.

Seats: PTFE.

Seals: EPDM.

6. End Connections: Socket, union, or flanged.

Handle Style: Tee shape.

CWP Rating: Equal to piping service.

Maximum Operating Temperature: Equal to piping service.

PART 3 - Not all manufacturers comply with the standard in subparagraph below.

0.1

Comply with MSS SP-122.

PRODUCT DATA SHEET 1 - Plastic Butterfly Valves:

1.1

1.2

1.3

1. Body: PVC or CPVC to match piping wafer type for installation between flanges.

2. Disc: EPDM-coated steel.

Seats: PTFE.

Handle Style: Locking lever.

CWP Rating: Equal to piping service.

Maximum Operating Temperature: Equal to piping service.

PRODUCT DATA SHEET 2 - Plastic Check Valves:

2.2

2.3

2.4

2.5

2.6

1. Body: One-, two-, or three-piece PVC or CPVC to match piping.

Ends: Socket or flanged.

Seats: PTFE.

Check Style: Swing or ball type.

CWP Rating: Equal to piping service.

Maximum Operating Temperature: Equal to piping service.

PRODUCT DATA SHEET 3 - Bronze, Calibrated-Orifice, Balancing Valves:

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

1. Body: Bronze, ball or plug type with calibrated orifice or venturi.

Ball: Brass or stainless steel.

Plug: Resin.

Seat: PTFE.

End Connections: Threaded or socket.

Pressure Gage Connections: Integral seals for portable differential pressure meter.

Handle Style: Lever, with memory stop to retain set position.

CWP Rating: Minimum 125 psig (860 kPa).

Maximum Operating Temperature: 250 deg F (121 deg C).

PRODUCT DATA SHEET 4 - Cast-Iron or Steel, Calibrated-Orifice, Balancing Valves:

ABM Military College Pack # 5

Technical Specification - Rev. 0

232116 - 4

232116 HYDRONIC PIPING SPECIALTIES

1.

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

Body: Cast-iron or steel body, ball, plug, or globe pattern with calibrated orifice or

venturi.

Ball: Brass or stainless steel.

Stem Seals: EPDM O-rings.

Disc: Glass and carbon-filled PTFE.

Seat: PTFE.

End Connections: Flanged or grooved.

Pressure Gage Connections: Integral seals for portable differential pressure meter.

Handle Style: Lever, with memory stop to retain set position.

CWP Rating: Minimum 125 psig (860 kPa).

Maximum Operating Temperature: 250 deg F (121 deg C).

PRODUCT DATA SHEET 5 - Diaphragm-Operated, Pressure-Reducing Valves: ASME labeled.

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

1. Body: Bronze or brass.

Disc: Glass and carbon-filled PTFE.

Seat: Brass.

Stem Seals: EPDM O-rings.

Diaphragm: EPT.

Low inlet-pressure check valve.

Inlet Strainer: removable without system shutdown.

Valve Seat and Stem: Noncorrosive.

Valve Size, Capacity, and Operating Pressure: Selected to suit system in which installed, with

operating pressure and capacity factory set and field adjustable.

PRODUCT DATA SHEET 6 - Diaphragm-Operated Safety Valves: ASME labeled.

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

1. Body: Bronze or brass.

Disc: Glass and carbon-filled PTFE.

Seat: Brass.

Stem Seals: EPDM O-rings.

Diaphragm: EPT.

Wetted, Internal Work Parts: Brass and rubber.

Inlet Strainer: removable without system shutdown.

Valve Seat and Stem: Noncorrosive.

Valve Size, Capacity, and Operating Pressure: Comply with ASME Boiler and Pressure Vessel

Code: Section IV, and selected to suit system in which installed, with operating pressure and

capacity factory set and field adjustable.

PRODUCT DATA SHEET 7 - Automatic Flow-Control Valves:

7.2

7.3

1. Body: Brass or ferrous metal.

Piston and Spring Assembly: Stainless steel, Corrosion resistant, tamper proof, self-cleaning,

and removable.

Combination Assemblies: Include bronze or brass-alloy ball valve.

ABM Military College Pack # 5

Technical Specification - Rev. 0

232116 - 5

232116 HYDRONIC PIPING SPECIALTIES

7.4

7.5

7.6

7.7

7.8

Identification Tag: Marked with zone identification, valve number, and flow rate.

Size: Same as pipe in which installed.

Performance: Maintain constant flow, plus or minus 5 percent over system pressure

fluctuations.

Minimum CWP Rating: 175 psig (1207 kPa), 300 psig (2070 kPa).

Maximum Operating Temperature: 200 deg F (93 deg C), 250 deg F (121 deg C).

SCHEDULE 1 - AIR-CONTROL DEVICES

PRODUCT DATA SHEET 0 - Manual Air Vents:

0.1

Body: Bronze.

0.2

Internal Parts: Nonferrous.

0.3

Operator: Screwdriver or thumbscrew.

0.4

Inlet Connection: NPS 1/2 (DN 15).

0.5

Discharge Connection: NPS 1/8 (DN 6).

0.6

CWP Rating: 150 psig (1035 kPa).

0.7

Maximum Operating Temperature: 225 deg F (107 deg C).

PRODUCT DATA SHEET 1 - Automatic Air Vents:

1.1

Body: Bronze or cast iron.

1.2

Internal Parts: Nonferrous.

1.3

Operator: Noncorrosive metal float.

1.4

Inlet Connection: NPS 1/2 (DN 15).

1.5

Discharge Connection: NPS 1/4 (DN 8).

1.6

CWP Rating: 150 psig (1035 kPa).

1.7

Maximum Operating Temperature: 240 deg F (116 deg C).

PRODUCT DATA SHEET 2 - Expansion Tanks:

2.1

2.2

2.3

2.4

Tank: Welded steel, rated for 125-psig (860-kPa) working pressure and 375 deg F (191 deg C)

maximum operating temperature, with taps in bottom of tank for tank fitting and taps in end of

tank for gage glass. Tanks shall be factory tested after taps are fabricated and shall be labeled

according to ASME Boiler and Pressure Vessel Code: Section VIII, Division 1.

Air-Control Tank Fitting: Cast-iron body, copper-plated tube, brass vent tube plug, and

stainless-steel ball check, 100-gal. (379-L) unit only; sized for compression-tank diameter.

Provide tank fittings for 125-psig (860-kPa) working pressure and 250 deg F (121 deg C)

maximum operating temperature.

Tank Drain Fitting: Brass body, nonferrous internal parts; 125-psig (860-kPa) working pressure

and 240 deg F (116 deg C) maximum operating temperature; constructed to admit air to

compression tank, drain water, and close off system.

Gage Glass: Full height with dual manual shutoff valves, 3/4-inch- (20-mm-) diameter gage

glass, and slotted-metal glass guard.

PRODUCT DATA SHEET 3 - Diaphragm, Bladder-Type Expansion Tanks:

ABM Military College Pack # 5

Technical Specification - Rev. 0

232116 - 6

232116 HYDRONIC PIPING SPECIALTIES

3.1

3.2

3.3

Tank: Welded steel, rated for 125-psig (860-kPa) working pressure and 375 deg F (191 deg C)

maximum operating temperature. Factory test after taps are fabricated and supports installed

and are labeled according to ASME Boiler and Pressure Vessel Code: Section VIII, Division 1.

Diaphragm, Bladder: Securely sealed into tank to separate air charge from system water to

maintain required expansion capacity.

Air-Charge Fittings: Schrader valve, stainless steel with EPDM seats.

PRODUCT DATA SHEET 4 - Tangential-Type Air Separators:

4.1

4.2

4.3

4.4

4.5

Tank: Welded steel; ASME constructed and labeled for 125-psig (860-kPa) minimum working

pressure and 375 deg F (191 deg C) maximum operating temperature.

Air Collector Tube: Perforated stainless steel, constructed to direct released air into expansion

tank.

Tangential Inlet and Outlet Connections: Threaded for NPS 2 (DN 50) and smaller; flanged

connections for NPS 2-1/2 (DN 65) and larger.

Blowdown Connection: Threaded.

Size: Match system flow capacity.

PRODUCT DATA SHEET 5 - In-Line Air Separators:

5.1

5.2

5.3

Tank: One-piece cast iron with an integral weir constructed to decelerate system flow to

maximize air separation.

Maximum Working Pressure: Up to 175 psig (1207 kPa).

Maximum Operating Temperature: Up to 300 deg F (149 deg C).

PRODUCT DATA SHEET 6 - Air Purgers:

6.1

6.2

6.3

Body: Cast iron with internal baffles that slow the water velocity to separate the air from

solution and divert it to the vent for quick removal.

Maximum Working Pressure: 150 psig (1035 kPa).

Maximum Operating Temperature: 250 deg F (121 deg C).

SCHEDULE 2 - HYDRONIC PIPING SPECIALTIES

PRODUCT DATA SHEET 0 - Y-Pattern Strainers:

0.1

0.2

0.3

0.4

Body: ASTM A 126, Class B, cast iron with bolted cover and bottom drain connection.

End Connections: Threaded ends for NPS 2 (DN 50) and smaller; flanged ends for NPS 2-1/2

(DN 65) and larger.

Strainer Screen: Stainless-steel, 20-40-60-mesh strainer, or perforated stainless-steel basket.

CWP Rating: 125 psig (860 kPa).

PRODUCT DATA SHEET 1 - Basket Strainers:

ABM Military College Pack # 5

Technical Specification - Rev. 0

232116 - 7

232116 HYDRONIC PIPING SPECIALTIES

1.1

1.2

1.3

1.4

Body: ASTM A 126, Class B, high-tensile cast iron with bolted cover and bottom drain

connection.

End Connections: Threaded ends for NPS 2 (DN 50) and smaller; flanged ends for NPS 2-1/2

(DN 65) and larger.

Strainer Screen: 40-60-mesh startup strainer, and perforated stainless-steel basket with 50

percent free area.

CWP Rating: 125 psig (860 kPa).

PRODUCT DATA SHEET 2 - T-Pattern Strainers:

2.1

2.2

2.3

2.4

Body: Ductile or malleable iron with removable access coupling and end cap for strainer

maintenance.

End Connections: Grooved ends.

Strainer Screen: 40-60-mesh startup strainer, and perforated stainless-steel basket with 57

percent free area.

CWP Rating: 750 psig (5170 kPa).

PRODUCT DATA SHEET 3 - Stainless-Steel Bellow, Flexible Connectors:

3.1

3.2

3.3

3.4

3.5

Body: Stainless-steel bellows with woven, flexible, bronze, wire-reinforcing protective jacket.

End Connections: Threaded or flanged to match equipment connected.

Performance: Capable of 3/4-inch (20-mm) misalignment.

CWP Rating: 150 psig (1035 kPa).

Maximum Operating Temperature: 250 deg F (121 deg C).

PRODUCT DATA SHEET 4 - Spherical, Rubber, Flexible Connectors:

4.1

4.2

4.3

4.4

4.5

Body: Fiber-reinforced rubber body.

End Connections: Steel flanges drilled to align with Classes 150 and 300 steel flanges.

Performance: Capable of misalignment.

CWP Rating: 150 psig (1035 kPa).

Maximum Operating Temperature: 250 deg F (121 deg C).

PRODUCT DATA SHEET 5 - Expansion Fittings:

Comply with requirements in Section 230516

"Expansion Fittings and Loops for HVAC Piping."Section 15124 "Expansion Fittings and Loops for

HVAC Piping."

ABM Military College Pack # 5

Technical Specification - Rev. 0

232116 - 8

You might also like

- 094135-PE-SPC-001 Piping Material Specification-REV 4Document76 pages094135-PE-SPC-001 Piping Material Specification-REV 4thongpvgas100% (1)

- HVAC Design CheckListDocument16 pagesHVAC Design CheckListmohamednavaviNo ratings yet

- GCP 9-5 PlumbingDocument0 pagesGCP 9-5 PlumbingHanniel MadramootooNo ratings yet

- NFPA 13 Sprinkler System Layout and Design RequirementsDocument24 pagesNFPA 13 Sprinkler System Layout and Design RequirementsAnonymous qrSsYuxyoYNo ratings yet

- Controlling liquid pipeline surgesDocument6 pagesControlling liquid pipeline surgesalyshahNo ratings yet

- Cryogenic Service Ball ValveDocument2 pagesCryogenic Service Ball ValvesaminasritnNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Duct Take Off-ModelDocument11 pagesDuct Take Off-ModelAbdul RaheemNo ratings yet

- SEO-Optimized Steam Piping TitleDocument7 pagesSEO-Optimized Steam Piping Title황철No ratings yet

- Kitchen Hood DesignDocument24 pagesKitchen Hood DesignSameera LakmalNo ratings yet

- Steam and Condensate Design StandardsDocument6 pagesSteam and Condensate Design StandardsDiana SoareNo ratings yet

- Knife Gate ValveDocument7 pagesKnife Gate ValveAbdul RaheemNo ratings yet

- Process Flow and P&IDs Workbook 2 (Inc Drawings)Document55 pagesProcess Flow and P&IDs Workbook 2 (Inc Drawings)Mahathir Che Ap100% (10)

- Refrigerant PipingDocument8 pagesRefrigerant PipingfaltuNo ratings yet

- CHEVRON Shell and Tube Exchanger Component Design ConsiderationsDocument42 pagesCHEVRON Shell and Tube Exchanger Component Design Considerationsbabak mir80% (5)

- Flushing Cistern AssingnmentDocument7 pagesFlushing Cistern AssingnmentLenson Mhango100% (1)

- Valve Procurement SpecsDocument39 pagesValve Procurement Specsjoseph.maquez24100% (2)

- GreenStep LEED GA Sample Exam 1Document9 pagesGreenStep LEED GA Sample Exam 1amrezzat0% (1)

- CraneDocument32 pagesCranesabes26100% (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- PG Diploma in Piping Design and Autocad Training CourseDocument4 pagesPG Diploma in Piping Design and Autocad Training CourseWin LinnNo ratings yet

- Vacuum Insulated CO2Document13 pagesVacuum Insulated CO2dragosm78No ratings yet

- Trane Submittal Centrifugal Water ChillersDocument10 pagesTrane Submittal Centrifugal Water Chillersjun005No ratings yet

- Floating Ball ValvesDocument16 pagesFloating Ball ValvesGovundan Guru0% (1)

- Project Standard Specification: Refrigerant Piping 15530 - Page 1/9Document9 pagesProject Standard Specification: Refrigerant Piping 15530 - Page 1/9adel rihanaNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Amman Strategic Reserve Terminal For Petroleum Products: B Issued For Review ABD ABD AMS MADocument11 pagesAmman Strategic Reserve Terminal For Petroleum Products: B Issued For Review ABD ABD AMS MAAbd Al Rahman OmaryNo ratings yet

- Cryogenic Standard Tank DesignsDocument12 pagesCryogenic Standard Tank DesignsGautam Gupta100% (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Water Installations Code 2016Document49 pagesWater Installations Code 2016Ahmad AbbasNo ratings yet

- Valve Basic Concepts at HTTPDocument8 pagesValve Basic Concepts at HTTPalone160162No ratings yet

- Hydronic PipingDocument11 pagesHydronic PipingLjubomir DjurinNo ratings yet

- This Product Masterspec Section Modifies The Original Masterspec Text, and Does Not Include The Full Content of The Original Masterspec SectionDocument17 pagesThis Product Masterspec Section Modifies The Original Masterspec Text, and Does Not Include The Full Content of The Original Masterspec Sectionabdullah sahibNo ratings yet

- 220523-General-Duty Valves For Plumbing PipingDocument9 pages220523-General-Duty Valves For Plumbing PipingAttef BedaweNo ratings yet

- Steam, Domestic Storage Water HeaterDocument7 pagesSteam, Domestic Storage Water Heaterbandithaguru6338No ratings yet

- 08 - SpeckDocument5 pages08 - SpeckSezer CetinNo ratings yet

- Project Standard Specification: Valves Page 1/8Document8 pagesProject Standard Specification: Valves Page 1/8adel rihanaNo ratings yet

- SECTION 15110 Valves Part 1 - General 1.01 Related DocumentsDocument9 pagesSECTION 15110 Valves Part 1 - General 1.01 Related DocumentsMunir RasheedNo ratings yet

- Project Standard Specification: Valves 15100 - Page 1/7Document7 pagesProject Standard Specification: Valves 15100 - Page 1/7adel rihanaNo ratings yet

- As 0201 en Gauge Valves and Pressure Gauge AccessoriesDocument36 pagesAs 0201 en Gauge Valves and Pressure Gauge AccessoriesTache MihaiNo ratings yet

- AquaFuse PolyBaSS CatalogueDocument11 pagesAquaFuse PolyBaSS Catalogueani_datNo ratings yet

- Statement of Work: April 15, 2013Document6 pagesStatement of Work: April 15, 2013Devendra SinghNo ratings yet

- Pfeiffer Br26d EngDocument4 pagesPfeiffer Br26d EngAleksandr KrigerNo ratings yet

- Fainger Leser Catalogue' 11Document68 pagesFainger Leser Catalogue' 11rudrakrNo ratings yet

- 22 11 17 - Gas Pipe and AppurtenancesDocument7 pages22 11 17 - Gas Pipe and AppurtenancesTeguh SetionoNo ratings yet

- Cryogenic Ball Valve: Lishui Oak Valve Parts Co,.LtdDocument7 pagesCryogenic Ball Valve: Lishui Oak Valve Parts Co,.LtdShams TabrezNo ratings yet

- 14 400E 6DC Final Valvula BermadDocument4 pages14 400E 6DC Final Valvula Bermadmax_powerNo ratings yet

- ValvesDocument11 pagesValvesAdamNo ratings yet

- Cryogenic Pressure Regulator GuideDocument4 pagesCryogenic Pressure Regulator GuidedhaktodesatyajitNo ratings yet

- Valves & Controls: Kunkle Safety and Relief ProductsDocument2 pagesValves & Controls: Kunkle Safety and Relief ProductsgbogboiweNo ratings yet

- Project Standard Specification: Compressed-Air Piping 15481-Page 1/9Document9 pagesProject Standard Specification: Compressed-Air Piping 15481-Page 1/9adel rihanaNo ratings yet

- Ashcroft PI 1259 Duragauge Pressure GaugeDocument2 pagesAshcroft PI 1259 Duragauge Pressure GaugejplutodNo ratings yet

- Section 15183 - Refrigerant PipingDocument11 pagesSection 15183 - Refrigerant PipingJavier BarbosaNo ratings yet

- SECTION 15100 ValvesDocument10 pagesSECTION 15100 ValvesintequabNo ratings yet

- PLUMBING SPECIALTIES TITLEDocument19 pagesPLUMBING SPECIALTIES TITLEadel rihanaNo ratings yet

- 23 11 23 Facility Natural-Gas PipingDocument19 pages23 11 23 Facility Natural-Gas PipingKak SofiNo ratings yet

- SRC Alpha Version1 PDFDocument26 pagesSRC Alpha Version1 PDFRajat JainNo ratings yet

- M322-Final 2014-4-3Document13 pagesM322-Final 2014-4-3Luis Fernando Flores FigueirasNo ratings yet

- Plan Api 23Document20 pagesPlan Api 23JAIMENo ratings yet

- Globe ValveDocument1 pageGlobe ValveBruno LimaNo ratings yet

- InlineSamplingValves SIVDocument6 pagesInlineSamplingValves SIVmorizoneNo ratings yet

- CBE - Active Chilled Beam OverviewDocument14 pagesCBE - Active Chilled Beam OverviewStefanNo ratings yet

- Temperature .: Psig 200 Deg FDocument28 pagesTemperature .: Psig 200 Deg Fabdelazeem ElhajNo ratings yet

- Model 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentDocument4 pagesModel 210 Digital Electro-Hydraulic Set Stop - PDF-, AttachmentMohd HassanudinNo ratings yet

- Rowan University Design Guide 2013Document2 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Cryogenic CatalogDocument12 pagesCryogenic CatalogjbaptistaaNo ratings yet

- D 101635 X 012Document28 pagesD 101635 X 012manmohansingh1999No ratings yet

- High Pressure Forged Gate Valves Pressure Temperature RatingsDocument16 pagesHigh Pressure Forged Gate Valves Pressure Temperature Ratingsg9g9No ratings yet

- Cash Cryogenic ControlsDocument16 pagesCash Cryogenic ControlsWormInchNo ratings yet

- BE - EngGuide - YCWL WaterCooled Scroll Liquid Chiller Style A 60 Hz-2 PDFDocument78 pagesBE - EngGuide - YCWL WaterCooled Scroll Liquid Chiller Style A 60 Hz-2 PDFDiegol ErnestoNo ratings yet

- Round DiffuserDocument5 pagesRound DiffuserAbdul RaheemNo ratings yet

- Airmaster DiffuserDocument9 pagesAirmaster DiffuserAbdul RaheemNo ratings yet

- ECOTHERM Heat Pumps for Hot Water and Pool HeatingDocument20 pagesECOTHERM Heat Pumps for Hot Water and Pool HeatingAbdul RaheemNo ratings yet

- Round DiffuserDocument5 pagesRound DiffuserAbdul RaheemNo ratings yet

- Terminal Units Engineering Guide PDFDocument26 pagesTerminal Units Engineering Guide PDFAbdul RaheemNo ratings yet

- Ceramic Products Tonic II, Connect Air, Tesi, San RemoDocument4 pagesCeramic Products Tonic II, Connect Air, Tesi, San RemoAbdul RaheemNo ratings yet

- Hot Dip Galvanized Steel SheetDocument1 pageHot Dip Galvanized Steel SheetAbdul RaheemNo ratings yet

- Eaton - 40 KvaDocument2 pagesEaton - 40 KvaAbdul RaheemNo ratings yet

- Chilled Water Flow Ranges in PipeDocument1 pageChilled Water Flow Ranges in PipeAbdul RaheemNo ratings yet

- Amca IndexDocument1 pageAmca IndexAbdul RaheemNo ratings yet

- Kitchen Exhaust Fan - Centrifugal (Model)Document5 pagesKitchen Exhaust Fan - Centrifugal (Model)Abdul RaheemNo ratings yet

- Install External Condensate Trap and Make Electrical ConnectionsDocument1 pageInstall External Condensate Trap and Make Electrical ConnectionsAbdul RaheemNo ratings yet

- Air Changes Per HoursDocument1 pageAir Changes Per Hoursmpwasa100% (3)

- QCD FSS 7.2Document4 pagesQCD FSS 7.2Abdul RaheemNo ratings yet

- G 196 ContentDocument22 pagesG 196 ContentAbdul RaheemNo ratings yet

- Kharama December English FinalDocument44 pagesKharama December English FinalKarren SVNo ratings yet

- ULselect V1.2publicDocument3 pagesULselect V1.2publicAbdul RaheemNo ratings yet

- Buildings & Facilities Inspection FormDocument1 pageBuildings & Facilities Inspection FormAbdul RaheemNo ratings yet

- Hose BibDocument1 pageHose BibAbdul RaheemNo ratings yet

- Excel Short CutsDocument1 pageExcel Short CutsAbdul RaheemNo ratings yet

- FS G.annex Rev2015.UnlockedDocument122 pagesFS G.annex Rev2015.UnlockedMedhat ElhagrasyNo ratings yet

- FS G.annex Rev2015.UnlockedDocument122 pagesFS G.annex Rev2015.UnlockedMedhat ElhagrasyNo ratings yet

- FS G.annex Rev2015.UnlockedDocument122 pagesFS G.annex Rev2015.UnlockedMedhat ElhagrasyNo ratings yet

- Pages From EMEC - BP2 - MS - HDPE Pressure Pipes For Water SupplyDocument1 pagePages From EMEC - BP2 - MS - HDPE Pressure Pipes For Water SupplyAbdul RaheemNo ratings yet

- Gate Valve DrawingDocument2 pagesGate Valve Drawingpriyanka GNo ratings yet

- Butterfly Valve Datasheet - Class 150 Centric Disc 2"-12Document1 pageButterfly Valve Datasheet - Class 150 Centric Disc 2"-12DjohnMaNo ratings yet

- Flange Adaptors Brochure PDFDocument2 pagesFlange Adaptors Brochure PDFnidhinNo ratings yet

- Directional Solenoid and Pneumatic ValvesDocument176 pagesDirectional Solenoid and Pneumatic ValvesKelvin Viza SoraideNo ratings yet

- Tronex One ItemDocument27 pagesTronex One ItemkasvikrajNo ratings yet

- SW ASME 16.5 - 150-300 LBDocument1 pageSW ASME 16.5 - 150-300 LBanderson añezNo ratings yet

- Fittings Catalog 2010Document97 pagesFittings Catalog 2010aredkaNo ratings yet

- Hydraulic Circuitry (Valves To Oil Cooler To Filter) - (S - N 512911001 - 512911999) - 331Document4 pagesHydraulic Circuitry (Valves To Oil Cooler To Filter) - (S - N 512911001 - 512911999) - 331Ronaldo Javier Vergara AnayaNo ratings yet

- Harga Pipa PVC, Conduit, Fitting dan Lem PVC TerbaruDocument3 pagesHarga Pipa PVC, Conduit, Fitting dan Lem PVC TerbaruAngga SenjayaNo ratings yet

- Piping & Mechanical BOQ - R1Document100 pagesPiping & Mechanical BOQ - R1yassh RaoNo ratings yet

- TP-WELLS-09073-DAS-A4-D1-L - Valve DSDocument21 pagesTP-WELLS-09073-DAS-A4-D1-L - Valve DSJessica RahmaNo ratings yet

- Technical Data Sheet: High Pressure Dry System: 1. DescriptionDocument7 pagesTechnical Data Sheet: High Pressure Dry System: 1. DescriptionDjapaNo ratings yet

- Flow Through PipesDocument8 pagesFlow Through PipesVijaykumar SurlaNo ratings yet

- Non Circular Pipe FrictionDocument3 pagesNon Circular Pipe Frictionravi_radanNo ratings yet

- Advanced Water Distribution Modeling and ManagementDocument54 pagesAdvanced Water Distribution Modeling and Managementscorpio1878No ratings yet

- Proportional Pressure Control Valve EPDRD3-04Document9 pagesProportional Pressure Control Valve EPDRD3-04josemiguel1992No ratings yet

- Price List (Viking) 2077 PDFDocument3 pagesPrice List (Viking) 2077 PDFNaresh PokharelNo ratings yet

- Fusiotherm CatalogueDocument193 pagesFusiotherm CataloguePeter FowlesNo ratings yet

- Carel Electronic Expansion Valve Catalogue 2023 06 15Document4 pagesCarel Electronic Expansion Valve Catalogue 2023 06 15Jose Ignacio Figueroa CortesNo ratings yet

- Grease Traps Installation RequirementsDocument2 pagesGrease Traps Installation RequirementsYuzar StuffNo ratings yet

- Service ManualDocument48 pagesService ManualhectorNo ratings yet

- Design Flow Control ValveDocument22 pagesDesign Flow Control ValveMohini RajputNo ratings yet

- Pages From Design of Fluid Systems-Hook-Ups, Spirax Sarco 4Document1 pagePages From Design of Fluid Systems-Hook-Ups, Spirax Sarco 4Ujwal KhandokarNo ratings yet