Professional Documents

Culture Documents

Single Zone Fusible Loop Charge Panel

Uploaded by

Sanjeev Kumar T MOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Single Zone Fusible Loop Charge Panel

Uploaded by

Sanjeev Kumar T MCopyright:

Available Formats

EML MANUFACTURING, LLC.

Engineered Heaters and Controls.

Home

FUSIBLE LOOP CHARGE PANEL

About Us

Products

Electric Heaters

Process Heater

Immersion Heater

Circulation Heater

Specialty Heater

Heater Repair

Fusible Loop Charge Panel

What is a fusible loop charge panel? A fusible loop charge panel is a pneumatic panel that monitors a

fusible loop system for the detection of fire. The fusible loop panel also complements a fire and gas

detection system. Fusible loop system are installed on offshore platforms to detect fire. The installation of

the fusible loop are in accordance with API RP 14C recommendation.

The charge panel will regulate and meter a fix amount of instrument air to the fusible loop. During a fire,

the heat generated by the fire will melt one or more of the fusible plug located in or near the fire. The

'melting' of the plug will cause a release of air from fusible loop through the plug. Since the release of this

Fuel Gas Conditioning regulated air exceeds the amount of regulated/metered air supply, the pressure in the loop will

decrease significantly. This decrease in pressure is monitored by a pressure switch on the charge panel.

Filters & Separators

The signal from the switch is then utilized to signal an alarm to the Fire and Gas System. In addition, an

additional pneumatic output is tied to the deluge valve pilot valve where it is use to open the deluge

Process Equipment

valve.

Pressure Vessel

Control Panel

Charge Panel

We offer 3 standard panels with the following data sheet.

Customer:

Tag#

EML Manufacturing

P.O. Box 41935, Houston, TX 77241

Aftermarket

Description:

Rev

Date

By

3/27/2010

BW

Technical Guide

Project:

Doc#:

Ph 281-272-2066

CHARGE PANEL DATA SHEET

Contact

Sitemap

www.emlmanufacturing.com

CHARGE PANEL DATA SHEET

Model

FLCP-10

FLCP-20

FLCP-30

Media

N2 / Inst. Air

N2 / Inst. Air

N2 / Inst. Air

Max Pressure, psig

180@150F

180@150F

180@150F

Pneumatic Supply

1/4" FNPT

1/4" FNPT

1/4" FNPT

Outlet to plugs

1/4" Tube

1/4" Tube

3/8" Tube

Pressure Sensor

1/4" Tube

1/4" Tube

Connected To Sensor

Size

N/A

0.5 gal (2L)

0.5 gal (2L)

Material

N/A

316/L

316/L

Design, psig

N/A

200@200F

200@200F

Qty

None

Isolation Valve

No

No

Yes

Drain Connection

N/A

1/4" NPT

1/4" NPT

Supply, 0-200psig/(kg/cm^2)

No

No

Yes - Panel Mount

Regulated, 0-60psig/(kg/cm^2)

Yes

Yes

Yes - Panel Mount

Loop, 0-60psig/(kg/cm^2)

No

Yes - Panel Mount

Yes - Panel Mount

Gauge Size & Material

2", 316SS

2" & 2.5", 316SS

2.5", 316SS

Gauge Vibration Resistance

Gauge Isolation Valve, 316SS

Yes

Yes

Yes

No

No

Type

Plate

Panel - 4 sides enclosed Panel - 4 sides enclosed

Sunshade

No

Optional

Optional

Material

316/L SS

316/L SS

316/L SS

Pneumatic Supply

Connection

Volume Bottle, Note 1

Pressure Gauge

Yes - Panel Mount

Construction

Mounting

Angle Stand

Angle Stand

Angle Stand

Size, in (approx)

24"h x 20"w x 8"d

24"h x 20"w x 8"d

24"h x 20"w x 8"d

Tubing Size

1/4" x 0.035"

1/4" x 0.035"

3/8' x 0.035"

Tubing Material

316SS Seamless

316SS Seamless

316SS Seamless

Tubing Fittings

316SS, Double Ferule

316SS, Double Ferule

316SS, Double Ferule

Supply Isolation Valve

Yes

Yes

Yes

Material

316SS

316SS

316SS

Drain

Manual

Automatic

Automatic

Inlet Check Valve, 316SS. Note 2.

Single

Single

Double (Two)

Manual Loading Valve, 316SS. Momentary. Note 3.

No

Yes

Yes

Auto lockout valve, 316SS. Note 4.

No

No

Yes

Metering Orifice, 316SS.

Yes

Yes

Yes

Yes - Field Installed

Yes - Field Installed

Yes - Integral

Filter Regulator

Controls

Pressure Sensor

Sealed Pressure Switch

Note 1 - Volume bottle provides an air reservoir in the event of pneumatic supply interruption.

Note 2 - Check valve prevents the loss of loop/reservoir pressure in the event of pneumatic supply interruption.

Note 3 - Loading valve speeds up the start-up of the fusible loop.

Note 4 - Valve isolates pneumatic supply from loop when a plug is activated.

Note 5 - Explosion proof hermetically sealed pressure switch to indicate the activation of a fusible plug.

Switch approved for Division 1 and 2; Class I, Groups A, B, C and D; Class II, Groups E, F and G Hazardous Locations.

ATEX approved switch is available on request.

Specification for our high quality FLCP-30 charge panel includes

a

Single zone charge panel. Panel constructed out of 316/L with full depth enclosure on top and sides.

Equipped with 2 liter (0.52 gallon) capacity volume bottle with double check as a back-up to interruption of

air/nitrogen supply. Volume bottle constructed out of 316/L stainless steel and design for 200 psig with

hydro testing. Equipped with 316SS isolation valve and drain.

All 316SS filter regulator with automatic liquid drain feature.

Panel equipped with 316SS quick charge button to provide quickly and efficient start-up.

A 316SS low pressure cutoff switch is provided to remove air/nitrogen from the loop in the event of a

fusible plug activation to ensure a failsafe system.

Panel is equipped with an explosion proof hermetically sealed pressure switch to indicate the activation of

a fusible plug. Switch approved for Division 1 and 2; Class I, Groups A, B, C and D; Class II, Groups E, F

and G Hazardous Locations. ATEX approved switch is available on request.

Copper free aluminum pull box provided to facilitate wiring of pressure switch.

2.5" Vibration resistant stainless steel pressure gauge for the indication of supply pressure. Dual scale 0

to 200 psi/(kg/cm^2) range. Equipped with 316SS isolation valve mounted on front of panel with locking

provision.

2.5" Vibration resistant stainless steel pressure gauge for the indication of regulated pressure. Dual scale

0 to 60 psi/(kg/cm^2) range. Equipped with 316SS isolation valve mounted on front of panel with locking

provision.

2.5" Vibration resistant stainless steel pressure gauge for the indication of loop pressure. Dual scale 0 to

60 psi/(kg/cm^2) range. Equipped with 316SS isolation valve mounted on front of panel with locking

provision.

3/8" tube connection provide with 316SS inlet isolation valve with locking provision for customer's

incoming pneumatic supply.

3/8" tube connection provide for connection to fusible loop. 1/2" tube connection available on request.

Tubing are 3/8"OD x 0.049" seamless 316/L stainless steel. Tube fittings are high quality double ferrule

316SS tube fittings.

All wetted parts are constructed out of 316 Stainless Steel to prevent corrosion and contamination of

fusible loop.

Air or Nitrogen supply to range from 60 to 180 psig.

Size is approximately 20W x 24H x 8.5D.

We also offer fusible plug and fusible tubing to complement our fusible loop panel.

Do contact us for your instrumentation needs.

You might also like

- Fusible Plug Loop Panel1Document5 pagesFusible Plug Loop Panel1caigithe85245650% (2)

- Fusible Plug Procedure SWP-E - Rev 3Document8 pagesFusible Plug Procedure SWP-E - Rev 3IsaalexNo ratings yet

- Technical Recommendations For Choke Valve SpecificationsDocument7 pagesTechnical Recommendations For Choke Valve SpecificationsajaysapruNo ratings yet

- Block 5 Al Shaheen Field Development: GLF-WHP02-EPCI4Document30 pagesBlock 5 Al Shaheen Field Development: GLF-WHP02-EPCI4Hibri HalimNo ratings yet

- PETRONAS Floating Liquefied Natural GasDocument9 pagesPETRONAS Floating Liquefied Natural GasDaniel Ismail100% (1)

- Fusible Loop Charge Panel SpecificationDocument1 pageFusible Loop Charge Panel SpecificationJosh SabimanNo ratings yet

- PVRVDocument4 pagesPVRVbkkbrazil100% (1)

- Pamplate Fusible LoopDocument2 pagesPamplate Fusible Loopbastian99No ratings yet

- Table of Contents for Valve Actuator SpecificationDocument10 pagesTable of Contents for Valve Actuator SpecificationzazaNo ratings yet

- ZZ - 1207652196 - Fast Loop Sampling System Specification-R2 PDFDocument4 pagesZZ - 1207652196 - Fast Loop Sampling System Specification-R2 PDFJohn PaulNo ratings yet

- CCTV PDFDocument29 pagesCCTV PDFIovi DanielNo ratings yet

- CORIOLIS FLOWMETER DATASHEETDocument1 pageCORIOLIS FLOWMETER DATASHEETscribd_thakurNo ratings yet

- MSA Controller SupremaTouchDocument8 pagesMSA Controller SupremaTouchykresna1631No ratings yet

- B193 (R) RQ in 4019Document6 pagesB193 (R) RQ in 4019scribd_thakurNo ratings yet

- Watercut MeterDocument3 pagesWatercut MeterprabhuarunkumarNo ratings yet

- Safety - System ESD PSDDocument9 pagesSafety - System ESD PSDMakiber100% (1)

- 00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentDocument4 pages00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentFaizal AbdullahNo ratings yet

- High Integrity Pressure System HippsDocument16 pagesHigh Integrity Pressure System Hippspreetosh1No ratings yet

- IECEx Certificate of Conformity for Temperature TransmitterDocument3 pagesIECEx Certificate of Conformity for Temperature Transmittermlutfima100% (1)

- Aogc 036 Sa DSC 001 (B1)Document9 pagesAogc 036 Sa DSC 001 (B1)amini_mohiNo ratings yet

- Sheet 01 of 03 D03 1327804 A3 059-PD-B-044127 N/A 4JSG000001P6437Document3 pagesSheet 01 of 03 D03 1327804 A3 059-PD-B-044127 N/A 4JSG000001P6437abdulkidwai2009No ratings yet

- Yl 007M2BDocument34 pagesYl 007M2BFernando GarcíaNo ratings yet

- SEO-Optimized Title for Tie In Plan DocumentDocument4 pagesSEO-Optimized Title for Tie In Plan DocumentUlisses Lopes MatosNo ratings yet

- 700XA Rev CDocument248 pages700XA Rev CMiguel I. Roman BarreraNo ratings yet

- BAHREGAN CRUDE OIL STORAGEDocument9 pagesBAHREGAN CRUDE OIL STORAGEFatholla SalehiNo ratings yet

- WHCP PresentationDocument19 pagesWHCP PresentationMohamed HassanNo ratings yet

- 020-Tbe Gas FilterDocument6 pages020-Tbe Gas FilterSilpa Asti Nura100% (1)

- DP Architects Pte LTD: EmployerDocument1 pageDP Architects Pte LTD: EmployerArun KedlayaNo ratings yet

- AVK Pneumatic Gate Valves BrochureDocument2 pagesAVK Pneumatic Gate Valves BrochureCuong Nguyen ChiNo ratings yet

- Kidde Fire Protection FM200 GX20 Technical DatasheetsDocument56 pagesKidde Fire Protection FM200 GX20 Technical DatasheetsIndo AprilNo ratings yet

- Peq001-03-Dcom-0000-Pl-T601-3001-2 - General Drawing Tlt-La-3170Document1 pagePeq001-03-Dcom-0000-Pl-T601-3001-2 - General Drawing Tlt-La-3170Carlin BabuchasNo ratings yet

- Camera TenderNEW 1Document113 pagesCamera TenderNEW 1Pratheep PNo ratings yet

- Instrumentation: Method Statement ForDocument8 pagesInstrumentation: Method Statement ForWalid MarhabaNo ratings yet

- HSSDDocument3 pagesHSSDamijetomar08No ratings yet

- Design Control and Automation of Well Head Control Panel IJERTV5IS010492 PDFDocument6 pagesDesign Control and Automation of Well Head Control Panel IJERTV5IS010492 PDFahmedNo ratings yet

- 05-1 - EPC-GE-AEI-P-XR-00001 Process Emergency Shutdown Logic Diagram, Hierachy - Rev D4 PDFDocument2 pages05-1 - EPC-GE-AEI-P-XR-00001 Process Emergency Shutdown Logic Diagram, Hierachy - Rev D4 PDFCường Đặng ViếtNo ratings yet

- TENDER DOCUMENT FOR IP CCTV FOR WANJII AND TANA Final PDFDocument66 pagesTENDER DOCUMENT FOR IP CCTV FOR WANJII AND TANA Final PDFEdwin KemboiNo ratings yet

- 3325 - Orig MTO For Instrument Junction BoxDocument8 pages3325 - Orig MTO For Instrument Junction BoxGirish JhaNo ratings yet

- Teleflo Safety Relief Valves GuideDocument10 pagesTeleflo Safety Relief Valves GuideKarl NakouziNo ratings yet

- 12 MGDP I 1045 0 (Spec For WHCP)Document26 pages12 MGDP I 1045 0 (Spec For WHCP)Ricardo NapitupuluNo ratings yet

- SPI Typical Loops PDFDocument39 pagesSPI Typical Loops PDFanoopsreNo ratings yet

- Off-Skid Process DiagramDocument6 pagesOff-Skid Process DiagramAtty AttyNo ratings yet

- SDV PPTDocument58 pagesSDV PPTSai Kamala100% (2)

- Binded Hook Up & InstallationDocument44 pagesBinded Hook Up & InstallationrajNo ratings yet

- GOM-292-TQ-001 - Piping SystemsDocument12 pagesGOM-292-TQ-001 - Piping SystemsBhupatiNo ratings yet

- ShutDown PanelDocument3 pagesShutDown PanelShivam GuptaNo ratings yet

- Form Mto PipingDocument16 pagesForm Mto PipingrudiawanNo ratings yet

- Basics of Wellhead Control Panel (WHCP) Instrumentation ToolsDocument21 pagesBasics of Wellhead Control Panel (WHCP) Instrumentation ToolsJOHNSON SANYANo ratings yet

- Sos8229793 005 A 001Document13 pagesSos8229793 005 A 001muhammad nazmiNo ratings yet

- FM-200 Brochure PDFDocument6 pagesFM-200 Brochure PDFrodrigo.shaolimNo ratings yet

- 24191000-1, LACT Unit As BuiltDocument7 pages24191000-1, LACT Unit As BuiltAtty AttyNo ratings yet

- 1007 DISQ 0 E SS 27011 Specification For Power Generators (GEN 01, GEN 02 and GEN 03)Document32 pages1007 DISQ 0 E SS 27011 Specification For Power Generators (GEN 01, GEN 02 and GEN 03)Anonymous XbmoAFtINo ratings yet

- Software Redundancy For S7-300 S7-400Document4 pagesSoftware Redundancy For S7-300 S7-400Minhvuong TrannguyenNo ratings yet

- Datasheet PSV PDPDEDocument8 pagesDatasheet PSV PDPDERicardo NapitupuluNo ratings yet

- Lco Tank Relief Valve (2016.04.11.) - For ApprovalDocument87 pagesLco Tank Relief Valve (2016.04.11.) - For ApprovalEnoch TwumasiNo ratings yet

- MD (BD) - Eql-Cep-In-1001 Instrument Index Rev0 PDFDocument23 pagesMD (BD) - Eql-Cep-In-1001 Instrument Index Rev0 PDFKook PengNo ratings yet

- XH5 Self-Contained Wellhead Control Panel User ManualDocument12 pagesXH5 Self-Contained Wellhead Control Panel User ManualHardik Acharya100% (1)

- Supape Solare RomstalDocument1 pageSupape Solare RomstalCraciun DanielNo ratings yet

- Bulletin 1301Document8 pagesBulletin 1301Syed Haris Bin AkhterNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Gen Without ParallelDocument9 pagesGen Without ParallelSanjeev Kumar T MNo ratings yet

- Basic Signals and Systems PDFDocument7 pagesBasic Signals and Systems PDFSanjeev Kumar T MNo ratings yet

- Three Phase Transformer Basics ExplainedDocument22 pagesThree Phase Transformer Basics ExplainedSanjeev Kumar T MNo ratings yet

- Hotspot Detection and Fault Level Prediction On 6Document14 pagesHotspot Detection and Fault Level Prediction On 6Sanjeev Kumar T MNo ratings yet

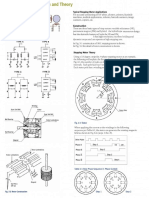

- Stepper TheoryDocument5 pagesStepper TheorySanjeev Kumar T MNo ratings yet

- High Voltage Partial Discharge LTD - Technical Introduction To Partial DischargeDocument3 pagesHigh Voltage Partial Discharge LTD - Technical Introduction To Partial DischargeSanjeev Kumar T MNo ratings yet

- 2wmm MethodDocument5 pages2wmm MethodSARITHA SNo ratings yet

- Low Voltage Switchboard SpecsDocument8 pagesLow Voltage Switchboard SpecsSanjeev Kumar T M100% (1)

- Real and Reactive Power Flow Control Using Flexible Ac Transmission System Connected To A Transmission Line: A Power Injection ConceptDocument5 pagesReal and Reactive Power Flow Control Using Flexible Ac Transmission System Connected To A Transmission Line: A Power Injection ConceptSanjeev Kumar T MNo ratings yet

- Park TransformationDocument14 pagesPark TransformationSanjeev Kumar T MNo ratings yet

- FactsDocument31 pagesFactsSanjeev Kumar T M0% (1)

- Facts - Flexible A.C. Transmission SystemsDocument7 pagesFacts - Flexible A.C. Transmission SystemsS Bharadwaj ReddyNo ratings yet

- FactsDocument1 pageFactsSanjeev Kumar T MNo ratings yet

- Solidworks Flow SimulationDocument7 pagesSolidworks Flow SimulationpatrickNX94200% (1)

- Open Hole Logs Introduction GR SP CALDocument21 pagesOpen Hole Logs Introduction GR SP CALmagedNo ratings yet

- VeEX OTN Quick Reference GuideDocument12 pagesVeEX OTN Quick Reference GuideDewan H S SalehinNo ratings yet

- Unit - L: List and Explain The Functions of Various Parts of Computer Hardware and SoftwareDocument50 pagesUnit - L: List and Explain The Functions of Various Parts of Computer Hardware and SoftwareMallapuram Sneha RaoNo ratings yet

- Nov. AbwDocument50 pagesNov. Abwjbyarkpawolo70No ratings yet

- QR Code Attendance Monitoring SystemDocument6 pagesQR Code Attendance Monitoring Systemjenny adlaoNo ratings yet

- Etap Help PDFDocument2 pagesEtap Help PDFRebeccaNo ratings yet

- Topic 8-Mean Square Estimation-Wiener and Kalman FilteringDocument73 pagesTopic 8-Mean Square Estimation-Wiener and Kalman FilteringHamza MahmoodNo ratings yet

- Virtual Retinal DisplayDocument17 pagesVirtual Retinal Displaysaket_mnNo ratings yet

- Methodology of Event StudiesDocument4 pagesMethodology of Event Studieshaichellam5577No ratings yet

- Cork Properties Capabilities and ApplicationsDocument22 pagesCork Properties Capabilities and ApplicationsVijay AnandNo ratings yet

- Dimensional Analysis AND Similarity: Chapter-5. (Frank White)Document46 pagesDimensional Analysis AND Similarity: Chapter-5. (Frank White)ShujaAmjadNo ratings yet

- Kitchen Chemistry ExperimentDocument7 pagesKitchen Chemistry ExperimentMss FaixaNo ratings yet

- Expanding Wired Connectivity For SOHO Networks: Plus Gigabit Ethernet SwitchesDocument4 pagesExpanding Wired Connectivity For SOHO Networks: Plus Gigabit Ethernet SwitchesAndré LinharesNo ratings yet

- Correct AnswerDocument120 pagesCorrect Answerdebaprasad ghosh100% (1)

- Gpa Calculation SheetDocument1 pageGpa Calculation SheetIryna HoncharukNo ratings yet

- Computational Intelligence in Communications and Business AnalyticsDocument369 pagesComputational Intelligence in Communications and Business AnalyticsSourasish NathNo ratings yet

- p-4500 Technical InformationDocument13 pagesp-4500 Technical InformationElhoiNo ratings yet

- A RANS-based Analysis Ool For Ducted Propeller Systems in Open Water ConditionDocument23 pagesA RANS-based Analysis Ool For Ducted Propeller Systems in Open Water ConditionLeonardo Duarte MilfontNo ratings yet

- Influence of Ring-Stiffeners On Buckling Behavior of Pipelines UnderDocument16 pagesInfluence of Ring-Stiffeners On Buckling Behavior of Pipelines UnderSUBHASHNo ratings yet

- Alkali MetalsDocument12 pagesAlkali MetalsSaki Sultana LizaNo ratings yet

- IMME19 Schedule PDFDocument39 pagesIMME19 Schedule PDFVikram JainNo ratings yet

- BIOLOGY Paper 1 Marking Scheme Asumbi Girls Final Prediction 2022Document4 pagesBIOLOGY Paper 1 Marking Scheme Asumbi Girls Final Prediction 2022balozi training InstituteNo ratings yet

- Fiziks: Basic Properties and Tools of ThermodynamicsDocument28 pagesFiziks: Basic Properties and Tools of ThermodynamicsSURAJ PRATAP SINGHNo ratings yet

- Ne7207 Nis Unit 2 Question BankDocument2 pagesNe7207 Nis Unit 2 Question BankalgatesgiriNo ratings yet

- Mechanical Engineering Conference ProgramDocument40 pagesMechanical Engineering Conference Programirinuca12No ratings yet

- Si™ Command Language (SCL) Software Manual: For 1240I 3540I 7080I Bl7080I Blsi7080 Si-100 Si2035 Si3540 Si5580Document23 pagesSi™ Command Language (SCL) Software Manual: For 1240I 3540I 7080I Bl7080I Blsi7080 Si-100 Si2035 Si3540 Si5580Agenor CarvalhoNo ratings yet

- Arm Assembly Language ProgrammingDocument170 pagesArm Assembly Language ProgrammingAnup Kumar Yadav100% (4)

- Ws2 PascalDocument3 pagesWs2 PascalsalahadamNo ratings yet

- Wojciech Gryc - Neural Network Predictions of Stock Price FluctuationsDocument44 pagesWojciech Gryc - Neural Network Predictions of Stock Price FluctuationsjohnsmithxxNo ratings yet