Professional Documents

Culture Documents

Construction Materials by Syed Kaleem Gilani

Uploaded by

Syed Kaleem GilaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction Materials by Syed Kaleem Gilani

Uploaded by

Syed Kaleem GilaniCopyright:

Available Formats

CE-214L Mechanics of solids Lab

Construction Materials

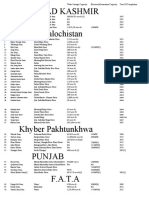

Table of Contents

ABSTRACT:........................................................................................................................................ 6

INTRODUCTION: .............................................................................................................................. 7

Construction Materials: ........................................................................................................................ 8

1.1

Cement: ................................................................................................................................. 8

INTRODUCTION: .............................................................................................................................. 8

HISTORY OF CEMENT:.................................................................................................................... 8

MANUFACURING PROCESS OF PROTLAND CEMENT:........................................................ 8

PROPERTIES OF PORTLAND CEMENT: ..................................................................................... 10

PHYSICAL PROPERTIES: .......................................................................................................... 10

CHEMICAL PROPERTIES: ......................................................................................................... 10

1.2

Aggregates:.......................................................................................................................... 13

INRODUCTION: ............................................................................................................................... 13

CLASSIFICATION OF AGGREGATES: .................................................................................... 13

ACCORDING TO SIZE: ............................................................................................................... 13

COARSE AGGREGATES: ........................................................................................................... 13

FINE AGGREGATES: .................................................................................................................. 13

ACCORDING TO SHAPE:........................................................................................................... 14

ROUND SHAPED AGGREGATES: ............................................................................................ 14

IRREGULAR SHAPED AGGREGATES: ................................................................................... 15

FLAKY AGGREGATES: ............................................................................................................. 15

ANGULAR AGGREGATES: ....................................................................................................... 16

ELONGATED AGGREGATES:................................................................................................... 16

FLACKY AND ELONGATED:.................................................................................................... 17

ACCORDING TO SURFACE TEXTURE: .................................................................................. 17

GLASSY: ....................................................................................................................................... 17

SMOOTH:...................................................................................................................................... 18

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 1 of 56

CE-214L Mechanics of solids Lab

Construction Materials

ROUGH: ........................................................................................................................................ 18

GRANULAR: ................................................................................................................................ 19

CRYSTALLINE: ........................................................................................................................... 19

ACCORDING TO WEIGHT:........................................................................................................ 19

NORMAL WEIGHT AGGREGATES: ......................................................................................... 20

LIGHT WEIGHT AGGREGATES: .............................................................................................. 20

HEAVY WEIGHT AGGREGATES: ............................................................................................ 20

GRADATION: ............................................................................................................................... 20

FINENESS MODULUS OF AGGREGATES: ................................................................................. 21

1.3

CONCRETE:....................................................................................................................... 21

INTRODUCTION: ............................................................................................................................ 21

PROPERTIES OF CONCRETE .................................................................................................... 22

TYPES OF CONCRETE ................................................................................................................... 24

Normal Concrete: ........................................................................................................................... 24

Properties of Normal Concrete ...................................................................................................... 24

High Performance Concrete:.......................................................................................................... 25

Properties of High Performance Concrete: .................................................................................... 25

Air Entrained Concrete: ................................................................................................................. 25

Self-compacting concrete: ............................................................................................................. 25

Shotcrete: ....................................................................................................................................... 26

Roller Compacted Concrete: .......................................................................................................... 26

Pervious Concrete: ......................................................................................................................... 26

1.4

ADMIXTURES:.................................................................................................................. 27

INTRODUTION: ............................................................................................................................... 27

AIR-ENTRAINING ADMIXTURES ........................................................................................... 27

WATER-REDUCING ADMIXTURES ........................................................................................ 28

MID-RANGE WATER REDUCING ADMIXTURES................................................................. 29

HIGH-RANGE WATER REDUCING ADMIXTURES .............................................................. 29

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 2 of 56

CE-214L Mechanics of solids Lab

Construction Materials

PLASTICIZERS FOR FLOWING CONCRETE .......................................................................... 30

RETARDING ADMIXTURES ..................................................................................................... 31

HYDRATION-CONTROL ADMIXTURES ................................................................................ 31

ACCELERATING ADMIXTURES .............................................................................................. 32

CORROSION INHIBITORS ......................................................................................................... 33

SHRINKAGE-REDUCING ADMIXTURES ............................................................................... 34

COLORING ADMIXTURES (PIGMENTS) ................................................................................ 34

DAMPPROOFING ADMIXTURES ............................................................................................. 34

PERMEABILITY-REDUCING ADMIXTURES ......................................................................... 34

PUMPING AIDS ........................................................................................................................... 35

BONDING ADMIXTURES AND BONDING AGENTS ............................................................ 35

GROUTING ADMIXTURES ....................................................................................................... 36

GAS-FORMING ADMIXTURES................................................................................................. 36

AIR DETRAINERS ....................................................................................................................... 36

COMPATIBILITY OF ADMIXTURES AND CEMENTITIOUS MATERIALS ....................... 36

STORING AND DISPENSING CHEMICAL ADMIXTURES ................................................... 37

1.5

LUMBER: ........................................................................................................................... 37

INTRODUCTION: ........................................................................................................................ 37

Lumber Grades: ............................................................................................................................. 38

TYPES OF LUMBER........................................................................................................................ 38

1.6

Adhesives: ........................................................................................................................... 43

INTRODUCTION: ............................................................................................................................ 43

ADVANTAGES OF ADHESIVE: ................................................................................................ 43

DISADVANTAGES: ..................................................................................................................... 44

TYPES OF ADHESIVES: ............................................................................................................. 45

Structural adhesives: ...................................................................................................................... 45

Pressure sensitive adhesives: ......................................................................................................... 45

Drying adhesives:........................................................................................................................... 46

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 3 of 56

CE-214L Mechanics of solids Lab

Construction Materials

NATURAL ADHESIVES: ............................................................................................................ 46

1.7

Paints: .................................................................................................................................. 46

INTRODUCTION: ............................................................................................................................ 46

COMPOSITION OF PAINTS: ...................................................................................................... 46

1. PIGMENTS............................................................................................................................... 47

2. BINDERS .................................................................................................................................. 47

3. VOLATILE SOLVENTS .......................................................................................................... 47

CLASSIFICATION OF PAINTS: ................................................................................................. 47

Oil Based Paints: ............................................................................................................................ 47

Water Based Paints: ....................................................................................................................... 47

Failure of a paint: ........................................................................................................................... 47

Contamination:............................................................................................................................... 47

VARNISHES: ................................................................................................................................ 48

COMPONENTS OF CLASSIC VARNISH: ................................................................................. 49

Drying oil ....................................................................................................................................... 49

Resin .............................................................................................................................................. 49

Solvent (traditionally turpentine): .................................................................................................. 49

TYPES OF VARNISHES: ............................................................................................................. 49

Violin: ............................................................................................................................................ 49

RESIN: ........................................................................................................................................... 50

SHELLAC...................................................................................................................................... 50

ALKYDS: ...................................................................................................................................... 51

SPAR VARNISH: .......................................................................................................................... 51

DRYING OILS: ............................................................................................................................. 51

POLYURETHANE: ...................................................................................................................... 52

LACQUER:.................................................................................................................................... 53

ACRYLIC: ..................................................................................................................................... 53

DISTEMPER: ................................................................................................................................ 54

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 4 of 56

CE-214L Mechanics of solids Lab

Construction Materials

REMOVING DISTEMPER: .......................................................................................................... 54

2.0 Conclusion: .................................................................................................................................. 54

Appendices:.................................................................................................................................... 55

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 5 of 56

CE-214L Mechanics of solids Lab

Construction Materials

ABSTRACT:

This report covers detailed discussion related to different construction materials used in modern

construction, that include cement, concrete, adhesives, admixtures, paints, varnishes and their

respective physical and chemical properties and types. Hopefully this report will answer any/all

related questions to the construction materials.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 6 of 56

CE-214L Mechanics of solids Lab

Construction Materials

INTRODUCTION:

Construction work in the past has always been very difficult and always had faults and failure, for

this reason researches were carried out to find better ways of construction, maintenance and

preservation of the civil constructions. This led to the discovery of different construction materials

that are used nowadays for various purposes. This include bonding materials for bricks and other

masonry, paints varnishes and adhesives etc. for preservation of surfaces and prevention from wear

and tear. Moreover, different chemicals are being used nowadays in concreting and cementing known

as adhesives providing extra properties to the construction material. Different construction materials

are discussed in this report to provide the knowledge of how they are used and how they affect the

modern construction.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 7 of 56

CE-214L Mechanics of solids Lab

Construction Materials

Construction Materials:

The following are different construction materials that are used in modern constructions:

1.1 Cement:

INTRODUCTION:

Cement is a type of bonding material that is used most commonly in todays constructions for

making concrete which is a mixture of cement water and aggregate. In case of fine aggregate used in

the mixture, it forms mortar used for bonding of brick masonry.

In modern construction Portland cement is most commonly used.

HISTORY OF CEMENT:

The history of cementing is as old as the history of engineering construction itself. Ancient Greeks

and Romans used cementing materials obtained by burning limestone. Later on they started

discovering and experimenting that adding suitable extra ingredients add more strength to the

cementing material. When they added volcanic ash and tuff, it resulted in good strength material, it

was named as Pozzolana because the volcanic ash and tuff was obtained near a village of Pozzuoli in

Italy.

It is found that the Romans added Blood, milk and lard to obtain better workability.

After this more builders started experimenting and obtaining better properties hence the investigations

of L.J. Vicat led him to prepare an artificial hydraulic lime by calcining and intimate mixture of

limestone and clay. This process may be regarded as the leading knowledge to manufacture of

Portland cement.

MANUFACURING PROCESS OF PROTLAND CEMENT:

The raw materials required for the manufacture of Portland cement are calcareous materials, such

as limestone or chalk and argillaceous material such as shale or clay. Cement factories are established

where these raw materials are available in plenty.

The process of manufacture of cement consists of grinding the raw materials, mixing them

intimately in certain proportions depending upon their purity and composition and burning them in a

kiln at a temperature of about 1300 to 1500C, at which temperature, the materials sinters and the

partially fuses to form nodular shaped clinker. The clinker is cooled and ground to fine powder with

addition of about 3 to 5% of gypsum. The product formed by using this procedure is Portland cement.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 8 of 56

CE-214L Mechanics of solids Lab

Construction Materials

There are two processes namely:

Wet Process.

Dry Process.

Depends on whether the ingredients are mixed in wet or dry conditions.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 9 of 56

CE-214L Mechanics of solids Lab

Construction Materials

PROPERTIES OF PORTLAND CEMENT:

PHYSICAL PROPERTIES:

Particle Size:

The particle size of the cement is ultra-fine i-e 0.002 micro meter if particle size is larger, it provides

less surface area for hydration and decreases strength.

CHEMICAL PROPERTIES:

Composition Of Cement:

The following are the main compunds in ordinary portland cement:

Main Compounds:

Dicalcium Silicate 2CaO.SiO2 (C2S)

Tricalcium Silicate 3CaO.SiO2 (C3S)

Tricalcium Aluminate 3CaO.Al2O3 (C3A)

Tricalcium Aluminoferrite 3CaO.Al2O3.Fe2O3 (C3AF)

Component Oxides:

CaO 60 67 %

SiO2 17 25 %

Al2O3 3 8 %

Fe2O3 0.5 0.6 %

Alkalis 0.2 1.3 %

SO3 1 3 %

MgO 1 4.0 %

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 10 of 56

CE-214L Mechanics of solids Lab

Construction Materials

Hydration Of Cement:

The process of addition of water to the cement such as ordinary Portland cement,

and the reaction of water with the silicates (C3S and C2S) and the alluminates (C3A) present in the

cement and the formation of the products of hydration as hydrates is known as the hydration of

cement.

The hydration of the silicates (C3S & C2S) present in the cement are the main cause of the hardening

of the cement. The C3S hydrates faster than C2S and hence is responsible for the initial set of the

cement paste.

In commercial cements, these silicates are in impure forms, and these impurities cause major changes

in the properties of these hydrated silicates.

C3S in its impure form is known as Alites while the C2S is known as Belite.

The product of hydration of the C3S forms microcrystalline hydrates (C3S2H3) while the lime present

separates out in the crystalline form as Ca(OH)2. On the other hand the C2S follows the same reaction

but less amount of lime crystallizes out.

The hydration reactions are as follows:

For C3S:

2C3S [100] + 6H [24] C3S2H3 [75] + 3Ca(OH)2 [49].

For C2S:

2C2S [100] + 4H [21] C3H2S3 [99] + Ca(OH)2 [22].

The numbers in the square brackets represents the corresponding masses, based on these masses the

C2S and C3S both require almost the same amount of water for the hydration process.

The presence of C3A in the cements is undesirable because it is the cause of Flash Set due to rapid

hydration even faster than the calcium silicates. But the hydration of C3A can be delayed by the

addition of gypsum.

The hydrated structure of the calcium aluminate is of cubical crystalline form surrounded by the

calcium silicate hydrate ( C-S-H). The hydration reaction of the C3A can be shown by the equation:

C3A [100] + 6H [40] C3AH6 [140]

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 11 of 56

CE-214L Mechanics of solids Lab

Construction Materials

It is cleear from the masses in the brackets that more water is required for the hydration of aluminates

than those of silicates.

Heat Of Hydration:

The hydration of the cement is an exothermic reaction, the heat evolved after complete

hydration at a given temprature is measured in joules per gram of unhydrated cement. The heat

evolved is called heat of hydration.

Between 1 & 3 days only half of the total heat is evolved, about three quarters after 7 days and almost

90 percent in 6 months.

The heat of hydration depends upon the composition of the cement and the total heat evolved is

approximately equal to the sum of the heat evolved by the hydration of the individual pure

compounds.

The amount of C3A and C3S are directly proportional to the heat of hydration, the heat can be

increased or decresed by increasing or decreasing the amount of C3A and C3S in the cement, but the

total amount of heat evolved remains the same although in concrete the total heat can be reduced by

controlling the amount of cement.

The heats of hydration of pure compounds:

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 12 of 56

CE-214L Mechanics of solids Lab

Construction Materials

1.2 Aggregates:

INRODUCTION:

Aggregates are the basic ingredient in the formation of concrete, they may be coarse or fine and be

added, to form mortar in case of fine and concrete in case of coarse aggregate in addition to cement

and water.

Classification of aggregates is discussed in detail as follows:

CLASSIFICATION OF AGGREGATES:

Generally aggregates are classified on the basis of size i-e ASTM classification of aggregates

namely:

ACCORDING TO SIZE:

COARSE AGGREGATES:

The type of aggregates which is retained at sieve #4 are known as coarse aggregates. The

aggregates of size greater than 4.75mm are placed in the category of coarse aggregates. In normal

construction coarse aggregates of the size 4.75 to 2 is used while in case of R.C.C maximum up to

1 is used to avoid stucking of it in the thick mesh of iron bars etc. while in case of mass concreting,

sizes range up to 5.

FINE AGGREGATES:

The type of aggregate which is retained at sieve # 200 is known as fine aggregate, or another

definition can be aggregates of sizes 4.75 and less are termed as fine aggregates. A mixture of

hydraulic cement and fine aggregate is known as mortar and it is mostly used for plastering of brick

walls as we see in our daily life.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 13 of 56

CE-214L Mechanics of solids Lab

Construction Materials

Figure 1 Fine and coarse aggregates

Figure 2 Sieves used for geadation

In the above figures on the left side is the coarse and fine aggregates shown while on the right side

different sized sieves are shown that are used for the sieve analysis and gradation of aggregates.

ACCORDING TO SHAPE:

Shape is actually the property of the coarse aggregates because they come in different shapes

and their shapes have positive as well as negative effects on the properties of both plastic and dry

concrete. Aggregates and classified in different categories based on their shape:

British standards:

ROUND SHAPED AGGREGATES:

Aggregates come in rounded shapes that are found mostly near seas and rivers it is because they

are water worn rounded aggregates, another factor also causes the aggregates to have rounded shape

that is wind and such aggregates are called as wind worn rounded aggregates, a figure shown below

is of rounded aggregates:

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 14 of 56

CE-214L Mechanics of solids Lab

Construction Materials

IRREGULAR SHAPED AGGREGATES:

Such aggregates are naturally irregular or are partly shaped, they done have well defined edges

because they are rounded in one corner while angular at the other and does not have a proper shape.

E.G Hard grey siliceous stone. The figure shown below shows different irregular shaped aggregates:

Irregular shaped aggregates.

FLAKY AGGREGATES:

Aggregates having little thickness as compared to the other two dimensions is known as flaky

aggregates. You can take the example of a potato chip but of course it is very thin aggregates that

thin are not good for use in concrete, the picture below shows different flaky aggregates:

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 15 of 56

CE-214L Mechanics of solids Lab

Construction Materials

ANGULAR AGGREGATES:

Aggregates which possess well defined angular edges at the intersection roughly planer faces is

known as angular aggregates. E.G. Crushed rocks of all types. The following image shows some

angular aggregates:

ELONGATED AGGREGATES:

In elongated aggregates, their length is more as compared to the other two dimensions such

aggregates are usually angular in shape. The following image shows elongated aggregates:

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 16 of 56

CE-214L Mechanics of solids Lab

Construction Materials

FLACKY AND ELONGATED:

Aggregates having length larger than the width and width larger than the thickness are termed as

flaky and elongated aggregates, the following picture shows flaky and elongated aggregates:

Flaky and Elongated

ACCORDING TO SURFACE TEXTURE:

According to the surface texture aggregates are divided in to the following types:

GLASSY:

Aggregates having shining surface which reflects light are termed as glassy aggregates. Such

aggregates are mostly rounded in shape. Glassy aggregates are shown in the image below:

Glassy aggregates

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 17 of 56

CE-214L Mechanics of solids Lab

Construction Materials

SMOOTH:

Such aggregates have smooth surface which provide sliding over one another and hence creating

a ball bearing effect when used in concrete and hence improves workability, they provide negligible

friction as compared to the rough surfaced aggregates, smooth surfaced aggregates are shown in the

image below:

Smooth surface aggregates

ROUGH:

Rough aggregates are those having rough surface which provides a lot of friction when rubbed

against each other due to the depression of one gets interlocked with the elevation of the other.

Rough aggregates are shown in the images below:

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 18 of 56

CE-214L Mechanics of solids Lab

Construction Materials

GRANULAR:

Aggregates with granular surface texture are placed in this category, such aggregates have their

surface like granules coagulated to it, for example sandstone; oolites. It can be well understood by

the image shown below:

CRYSTALLINE:

Aggregates having crystal like texture and a smooth touch is placed in this category for example

basalt, limestone, dolerite e-t-c, it can be well understood by the image shown below:

ACCORDING TO WEIGHT:

On the basis of weight, the aggregates are divided into three types namely:

Normal Weight Aggregates.

Light weight Aggregates.

Heavy weight Aggregates.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 19 of 56

CE-214L Mechanics of solids Lab

Construction Materials

NORMAL WEIGHT AGGREGATES:

Normal weight aggregates are those having the bulk density from 1520-1680 Kg/m3 and are

called normal weight aggregates. Normal weight aggregates are further classified into natural

aggregates and artificial aggregates.

The natural aggregates are; Sand, gravel, crush rock such as granite, quartzite, and sand stone etc.

The artificial aggregates are; broken bricks, fly ash, bloated clay and air-cool slag etcetera.

LIGHT WEIGHT AGGREGATES:

Light weight aggregates are those having bulk density less than 1100 Kg/m3 and are used in the

manufacturing of light weight concrete.

Light weight aggregates can be; Processed natural materials (e.g expanded clay or expanded shale),

processed by-products (e.g foamed slag), unprocessed materials (e.g pumice)

Light weight concrete results in significant benefits in terms of load bearing elements of smaller xsection and also give better thermal insulation than ordinary concrete.

HEAVY WEIGHT AGGREGATES:

Aggregates having bulk density more than 2080 Kg/m3 are termed as heavy weight aggregates.

Iron, steel, limonite etc all come in the category of heavy weight aggregates, these aggregates are

used in the manufacturing of heavy weight aggregates which serves for the construction of radiation

shields.

Radiation shields protect the operating personnel against the biological hazards in the nuclear

energy industry or x-ray, gamma ray at therapy centers.

GRADATION:

Gradation can be defined as The distribution of different sizes of the aggregate particles in a

sample.

Gradation is very important when it comes to concreting, because the way particles fit together in

the mix actually depends on it and it effects different properties of the fresh as well as hardened

concrete. It is well known that the strength of the concrete depends on the water to cement ratio

provided the concrete is workable.

Good grading means that the sample must contain all standard fractions of the aggregate in the

required proportions so that the concrete in which it is used contains minimum voids. There are

three types of grading namely:

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 20 of 56

CE-214L Mechanics of solids Lab

Construction Materials

Well Graded: contains all sizes of particles in standard proportions.

Poorly Graded: contains same sized particles.

Gap Graded: 0% retained at a number of sieves is known as gap graded aggregate.

FINENESS MODULUS OF AGGREGATES:

Abrams and others in their course of investigation found that the surface area of the aggregates

may vary widely without causing much appreciable change in the concrete strength, and the water

requirement to produce given consistency is dependent more on other characteristics than on the

surface area of aggregates. Therefore Abrams introduced a parameter called Fineness modulus. It

can be defined as Sum of all the retained cumulative divided by 100 is expressed in percentage

called fineness modulus of the aggregate sample. It means that any sieve analysis curve of

aggregate that will give the same fineness modulus will require the same amount of water.

Fineness modulus = sum of all the retained cumulative / 100

1.3 CONCRETE:

INTRODUCTION:

Concrete is a composite material composed mainly of water, aggregate, and cement. Usually there

are additives and reinforcements included to achieve the desired physical properties of the finished

material. When these ingredients are mixed together, they form a fluid mass that is easily molded into

shape. Over time, the cement forms a hard matrix which binds the rest of the ingredients together into

a durable stone-like material with many uses

Based on unit weight, concrete can be classified into three broad categories:

Ultra-light concrete <1,200 kg/m3

Lightweight concrete 1200- 1,800 kg/m 3

Normal-weight concrete ~ 2,400 kg/m3

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 21 of 56

CE-214L Mechanics of solids Lab

Construction Materials

Heavyweight concrete > 3,200 kg/m3

Based on strength (of cylindrical sample)

Low-strength concrete: < 20 MPa compressive strength

Moderate-strength concrete: 20 -50 MPa compressive strength

High-strength concrete: 50 - 200 MPa compressive strength

Ultra high-strength concrete: > 200 MPa compressive strength

Based on additives:

Normal concrete

Fiber reinforced concrete

Shrinkage-compensating concrete

Polymer concrete

PROPERTIES OF CONCRETE

Water-cement ratio: The single most important indicator of strength is the ratio of the water used

compared to the amount of cement (w/c ratio). Basically, the lower this ratio is, the higher the final

concrete strength will be. This concept was developed by Duff Abrams of The Portland Cement

Association in the early 1920s and is in worldwide use today. A minimum w/c ratio (water-to-cement

ratio) of about 0.3 by weight is necessary to ensure that the water comes into contact with all cement

particles (thus assuring complete hydration). Typical values are in the 0.4 to 0.6

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 22 of 56

CE-214L Mechanics of solids Lab

Construction Materials

Workability of concrete: that property of freshly mixed concrete that determines its working

characteristics, i.e. the ease with which it can be mixed, placed, compacted and finished

Mix Proportions: The ingredients of concrete can be proportioned by weight or volume. The goal is

to provide the desired strength and workability at minimum expense. A low w/c ratio is used to

achieve strong concrete.

Aggregate Size and Shape: Larger aggregate sizes have relatively smaller surface areas (for the

cement paste to coat). Use the largest practical aggregate size and the stiffest practical mix.

Hydration: When first mixed the water and cement constitute a paste which surrounds all the

individual pieces of aggregate to make a plastic mixture. A chemical reaction called hydration takes

place between the water and cement, and concrete normally changes from a plastic to a solid state in

about 2 hours. Concrete continues to gain strength as it cures.

Heat of hydration: The heat energy given off during hydration is called as heat of hydration.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 23 of 56

CE-214L Mechanics of solids Lab

Construction Materials

TYPES OF CONCRETE

Normal Concrete:

The concrete in which common ingredients i.e. aggregate, water, cement are used is known

as normal concrete. It is also called normal weight concrete or normal strength concrete.

It has a setting time of 30 - 90 minutes depending upon moisture in atmosphere, fineness of

cement etc.

The development of the strength starts after 7 days the common strength values is 10 MPa

(1450 psi) to 40 MPa (5800 psi). At about 28 days 75 - 80% of the total strength is attained.

Almost at 90 days 95% of the strength is achieved.

Properties of Normal Concrete

Its slump varies from 1 - 4 inches.

Density ranges from 140 pcf to 175 pcf.

It is strong in compression and weak in tension.

Air content 1 - 2 %.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 24 of 56

CE-214L Mechanics of solids Lab

Construction Materials

Normal concrete is not durable against severe conditions e.g. freezing and thawing

High Performance Concrete:

High-performance concrete (HPC) exceeds the properties and constructability of normal concrete.

Normal and special materials are used to make these specially designed concretes that must meet a

combination of performance requirements. Special mixing, placing and curing may also be needed.

High-performance concrete has been primarily used in tunnels, bridges etc.

Properties of High Performance Concrete:

High strength

High early strength

High modulus of elasticity

High abrasion resistance

High durability

Low permeability

Resistance to chemical attack, deicing etc.

ease of placement

volume stability

compaction without segregation

Air Entrained Concrete:

Air entrainment is the intentional creation of tiny air bubbles in concrete. The bubbles are introduced

into the concrete by the addition to the mix of an air entraining agent, a surfactant (surface-active

substance, a type of chemical that includes detergents). The air bubbles are created during mixing of

the plastic (easy flowing, not hardened) concrete, and most of them survive to be part of the hardened

concrete. The primary purpose of air entrainment is to increase the durability of the hardened concrete,

especially in climates subject to freeze-thaw; the secondary purpose is to increase workability of the

concrete while in a plastic state.

Self-compacting concrete:

Self-consolidating concrete or self-compacting concrete (SCC) is characterized by a low yield stress,

high deformability, and moderate viscosity necessary to ensure uniform suspension of solid particles

during transportation, placement (without external compaction), and thereafter until the concrete sets.

Such concrete can be used for casting heavily reinforced sections, places where there can be no access

to vibrators for compaction and in complex shapes of formwork which may otherwise be impossible

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 25 of 56

CE-214L Mechanics of solids Lab

Construction Materials

to cast, giving a far superior surface than conventional concrete. SCC was conceptualized in 1986 by

Prof. Okamura at Ouchi University, Japan.

Shotcrete:

Sprayed concrete is reinforced by conventional steel rods, steel mesh, and/or fibers. Fiber

reinforcement (steel or synthetic) is also used for stabilization in applications such

as slopes or tunneling.

Shotcrete is concrete (or sometimes mortar) conveyed through a hose and pneumatically projected at

high velocity onto

a

surface,

as

a

construction

technique.

Shotcrete is usually an all-inclusive term that can be used for both wet-mix and dry-mix versions.

Shotcrete undergoes placement and compaction at the same time due to the force with which it is

projected from the nozzle. It can be impacted onto any type or shape of surface, including vertical or

overhead areas.

Roller Compacted Concrete:

Roller-compacted concrete (RCC) or rolled concrete is a special blend of concrete that has essentially

the same ingredients as conventional concrete but in different ratios, and increasingly with partial

substitution of fly ash for Portland cement. RCC is a mix of cement/fly ash, water,

sand, aggregate and common additives, but contains much less water. The produced mix is drier and

essentially has no slump. RCC is placed in a manner similar to paving; the material is delivered

by dump trucks or conveyors, spread by small bulldozers or specially modified asphalt pavers, and

then compacted by vibratory rollers.

Pervious Concrete:

Pervious concrete (also called porous concrete, permeable concrete, no fines concrete and porous

pavement) is a special type of concrete with a high porosity used for concrete flatwork applications

that allows water from precipitation and other sources to pass directly through, thereby reducing

the runoff from a site and allowing groundwater recharge. Pervious concrete is made using large

aggregates with little to no fine aggregates. The concrete paste then coats the aggregates and allows

water to pass through the concrete slab. Pervious concrete is traditionally used in parking areas, areas

with light traffic, residential streets, pedestrian walkways, and greenhouses. It is an important

application for sustainable construction and is one of many low impact development techniques used

by builders to protect water quality.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 26 of 56

CE-214L Mechanics of solids Lab

Construction Materials

1.4 ADMIXTURES:

INTRODUTION:

Admixtures are those ingredients in concrete other than Portland cement, water, and aggregates that

are added to the mixture immediately before or during mixing. Admixtures can be classified by

function as follows:

Air-entraining admixtures

Water-reducing admixtures

Plasticizers

Accelerating admixtures

Retarding admixtures

Hydration-control admixtures

Corrosion inhibitors

Shrinkage reducers

Alkali-silica reactivity inhibitors

Coloring admixtures

Miscellaneous admixtures such as workability, bonding, damp proofing, permeability

reducing, grouting, gas-forming, anti washout, foaming, and pumping admixtures.

Concrete should be workable, finish able, strong, durable, watertight, and wear resistant. These

qualities can often be obtained easily and economically by the selection of suitable materials rather

than by resorting to admixtures (except air-entraining admixtures when needed). The major reasons

for using admixtures are:

To reduce the cost of concrete construction

To achieve certain properties in concrete more effectively than by other means

To maintain the quality of concrete during the stages of mixing, transporting, placing, and

curing in adverse weather conditions

To overcome certain emergencies during concreting operations

Despite these considerations, it should be borne in mind that no admixture of any type or amount can

be considered a substitute for good concreting practice. The effectiveness of an admixture depends

upon factors such as type, brand, and amount of cementing materials; water content; aggregate shape,

gradation, and proportions; mixing time; slump; and temperature of the concrete.

AIR-ENTRAINING ADMIXTURES

Air-entraining admixtures are used to purposely introduce and stabilize microscopic air bubbles in

concrete. Air- entrainment will dramatically improve the durability of concrete exposed to cycles of

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 27 of 56

CE-214L Mechanics of solids Lab

Construction Materials

freezing and thawing. Entrained air greatly improves concretes resistance to surface scaling caused

by chemical deicers. Furthermore, the workability of fresh concrete is improved significantly, and

segregation and bleeding are reduced or eliminated. Air-entrained concrete contains minute air

bubbles that are distributed uniformly throughout the cement paste. Entrained air can be produced in

concrete by use of an air-entraining cement, by introduction of an air- entraining admixture, or by a

combination of both methods. Air-entraining cement is a Portland cement with an air-entraining

addition underground with the clinker during manufacture. An air-entraining admixture, on the other

hand, is added directly to the concrete materials either before or during mixing.

WATER-REDUCING ADMIXTURES

Water-reducing admixtures are used to reduce the quantity of mixing water required to produce

concrete of a certain slump, reduce water-cement ratio, reduce cement content, or increase slump.

Typical water reducers reduce the water content by approximately 5% to 10%. Adding a waterreducing admixture to concrete without reducing the water content can produce a mixture with a

higher slump. The rate of slump loss, however, is not reduced and in most cases is increased. Rapid

slump loss results in reduced workability and less time to place concrete. An increase in strength is

generally obtained with water-reducing admixtures as the water-cement ratio is reduced. For

concretes of equal cement content, air content, and slump, the 28-day strength of a water-reduced

concrete containing a water reducer can be 10% to 25% greater than concrete without the admixture.

Despite reduction in water content, water-reducing admixtures may cause increases in drying

shrinkage. Usually the effect of the water reducer on drying shrinkage is small compared to other

more significant factors that cause shrinkage cracks in concrete. Using a water reducer to reduce the

cement and water content of a concrete mixture while maintaining a constant water-cement ratio can

result in equal or reduced compressive strength, and can increase slump loss by a factor of two or

more. Water reducers decrease, increase, or have no effect on bleeding, depending on the chemical

composition of the admixture. A reduction of bleeding can result in finishing difficulties on flat

surfaces when rapid drying conditions are present. Water reducers can be modified to give varying

degrees of retardation while others do not significantly affect the setting time.

ASTM C 494 (AASHTO M 194) Type A, water reducers can have little effect on setting, while

Type D admixtures provide water reduction with retardation, and Type E admixtures provide water

reduction with accelerated setting. Type D water-reducing admixtures usually retard the setting time

of concrete by one to three hours. Some water-reducing admixtures may also entrain some air in

concrete. Lignin-based admixtures can increase air contents by 1 to 2 percentage points. Concretes

with water reducers generally have good air retention. The effectiveness of water reducers on concrete

is a function of their chemical composition, concrete temperature, cement composition and fineness,

cement content, and the presence of other admixtures.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 28 of 56

CE-214L Mechanics of solids Lab

Construction Materials

MID-RANGE WATER REDUCING ADMIXTURES

Mid-range water reducers were first introduced in 1984. These admixtures provide significant water

reduction (between 6 and 12%) for concretes with slumps of 125 to 200 mm (5 to 8 in.) without the

retardation associated with high dosages of conventional (normal) water reducers. Normal water

reducers are intended for concretes with slumps of 100 to 125 mm (4 to 5 in.). Mid-range water

reducers can be used to reduce stickiness and improve finish ability, pump ability, and place ability

of concretes containing silica fume and other supplementary cementing materials.

HIGH-RANGE WATER REDUCING ADMIXTURES

High-range water reducers, ASTM C 494 (AASHTO M 194) Types F (water reducing) and G (water

reducing and retarding), can be used to impart properties induced by regular water reducers, only

much more efficiently. They can greatly reduce water demand and cement contents and make low

water-cement ratio, high-strength concrete with normal or enhanced workability. A water reduction

of 12% to 30% can be obtained through the use of these admixtures. The reduced water content and

water-cement ratio can produce concretes with

Ultimate compressive strengths in excess of 70 MPa (10,000 psi)

Increased early strength gain

Reduced chloride-ion penetration

Other beneficial properties associated with low water-cement ratio concrete.

High-range water reducers are generally more effective than regular water-reducing admixtures in

producing workable concrete. A significant reduction of bleeding can result with large reductions of

water content; this can result in finishing difficulties on flat surfaces when rapid drying conditions

are present. Some of these admixtures can cause significant slump loss. Significant retardation is also

possible, but can aggravate plastic shrinkage cracking without proper protection and curing. Drying

shrinkage, chloride permeability, air retention and strength development of concretes with high-range

water reducers are comparable to concretes without them when compared at constant water-cement

ratios (reduced cement and water contents). Concretes with high-range water reducers can have larger

entrained air voids and higher void-spacing factors than normal air-entrained concrete. This would

generally indicate a reduced resistance to freezing and thawing; however, laboratory tests have shown

that concretes with a moderate slump using high-range water reducers have good freeze-thaw

durability, even with slightly higher void-spacing factors. This may be the result of lower watercement ratios often associated with these concretes. When the same chemicals used for high-range

water reducers are used to make flowing concrete, they are often called plasticizers or super

plasticizers.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 29 of 56

CE-214L Mechanics of solids Lab

Construction Materials

PLASTICIZERS FOR FLOWING CONCRETE

Plasticizers, often called super plasticizers, are essentially high-range water reducers meeting ASTM

C 1017; these admixtures are added to concrete with a low-to-normal slump and water-cement ratio

to make high-slump flowing concrete. Flowing concrete is a highly fluid but workable concrete that

can be placed with little or no vibration or compaction while still remaining essentially free of

excessive bleeding or segregation. Following are a few of the applications where flowing concrete is

used:

thin-section placements

Areas of closely spaced and congested reinforcing steel

Pumped concrete to reduce pump pressure, thereby increasing lift and distance capacity,

Areas where conventional consolidation methods are impractical or cannot be used

For reducing handling costs

The addition of a plasticizer to a 75-mm (3-in.) slump concrete can easily produce a

concrete with a 230-mm (9-in.) slump. Flowing concrete is defined by ASTM C 1017 as a concrete

having a slump greater than 190 mm (712 in.), yet maintaining cohesive properties. ASTM C 1017

has provisions for two types of admixtures:

Type 1plasticizing, and

Type 2plasticizing and retarding.

Plasticizers are generally more effective than regular or mid-range water-reducing admixtures in

producing flowing concrete. The effect of certain plasticizers in increasing workability or making

flowing concrete is short-lived, 30 to 60 minutes; this period is followed by a rapid loss in workability

or slump loss. High temperatures can also aggravate slump loss. Due to their propensity for slump

loss, these admixtures are sometimes added to the concrete mixer at the jobsite. They are available in

liquid and powder form. Extended-slump-life plasticizers added at the batch plant help reduce slumploss problems. Setting time may be accelerated or retarded based on the admixtures chemistry, dosage

rate, and interaction with other admixtures and cementing materials in the concrete mixture. Some

plasticizers can retard final set by one to almost four hours. Strength development of flowing concrete

is comparable to normal concrete. While it was previously noted that flowing concretes are essentially

free of excessive bleeding, tests have shown that some plasticized concretes bleed more than control

concretes of equal water-cement ratio; but plasticized concretes bleed significantly less than control

concretes of equally high slump and higher water content. High-slump, low-water-content, plasticized

concrete has less drying shrinkage than a high-slump, high-water- content conventional concrete;

however this concrete has similar or higher drying shrinkage than conventional low- slump, lowwater-content concrete. The effectiveness of the plasticizer is increased with an increasing amount of

cement and fines in the concrete. It is also affected by the initial slump of the concrete. Plasticized

flowing concrete can have larger entrained air voids and greater void-spacing factors than

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 30 of 56

CE-214L Mechanics of solids Lab

Construction Materials

conventional concrete. Air loss can also be significant. Some research has indicated poor frost- and

deicer-scaling resistance for some flowing concretes when exposed to a continuously moist

environment without the benefit of a drying period.

RETARDING ADMIXTURES

Retarding admixtures are used to delay the rate of setting of concrete. High temperatures of fresh

concrete (30C [86F]) are often the cause of an increased rate of hardening that makes placing and

finishing difficult. One of the most practical methods of counteracting this effect is to reduce the

temperature of the concrete by cooling the mixing water and/or the aggregates. Retarders do not

decrease the initial temperature of concrete. The bleeding rate and bleeding capacity of concrete is

increased with Retarders. Retarding admixtures are useful in extending the setting time of concrete,

but they are often also used in attempts to decrease slump loss and extend workability, especially

prior to placement at elevated temperatures.

Retarders are sometimes used to:

Offset the accelerating effect of hot weather on the setting of concrete

Delay the initial set of concrete or grout when difficult or unusual conditions of placement

occur, such as placing concrete in large piers and foundations, cementing oil wells, or pumping

grout or concrete over considerable distances

Delay the set for special finishing techniques, such as an exposed aggregate surface.

The amount of water reduction for an ASTM C 494 (AASHTO M 194) Type B retarding

admixture is normally less than that obtained with a Type A water reducer. Type D

admixtures are designated to provide both water reduction and retardation. In general, some

reduction in strength at early ages (one to three days) accompanies the use of retarders. The

effects of these materials on the other properties of concrete, such as shrinkage, may not be

predictable. Therefore, acceptance tests of retarders should be made with actual job materials

under anticipated job conditions.

HYDRATION-CONTROL ADMIXTURES

Hydration controlling admixtures became available in the late 1980s. They consist of a two-part

chemical system:

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 31 of 56

CE-214L Mechanics of solids Lab

Construction Materials

A stabilizer or retarder that essentially stops the hydration of cementing materials

An activator that reestablishes normal hydration and setting when added to the stabilized

concrete. The stabilizer can suspend hydration for 72 hours and the activator is added to the

mixture just before the concrete is used. These admixtures make it possible to reuse concrete

returned in a ready-mix truck by suspending setting overnight. The admixture is also useful

in maintaining concrete in a stabilized non-hardened state during long hauls. The concrete is

reactivated when it arrives at the project.

ACCELERATING ADMIXTURES

An accelerating admixture is used to accelerate the rate of hydration (setting) and strength

development of concrete at an early age. The strength development of concrete can also be accelerated

by other methods:

Using Type III or Type HE high-early-strength cement

Lowering the water-cement ratio by adding 60 to 120 kg/m3 (100 to 200 lb./yd3) of additional

cement to the concrete

Using a water reducer

Curing at higher temperatures

Accelerators are designated as Type C admixtures under ASTM C 494 (AASHTO M 194). Calcium

chloride (CaCl2) is the chemical most commonly used in accelerating admixtures, especially for nonreinforced concrete. It should conform to the requirements of ASTM D 98 (AASHTO M 144) and

should be sampled and tested in accordance with ASTM D 345. The widespread use of calcium

chloride as an accelerating admixtures has provided much data and experience on the effect of this

chemical on the properties of concrete. Besides accelerating strength gain, calcium chloride causes

an increase in drying shrinkage, potential reinforcement corrosion, discoloration (a darkening of

concrete), and an increase in the potential for scaling. Calcium chloride is not an antifreeze agent.

When used in allowable amounts, it will not reduce the freezing point of concrete by more than a few

degrees. Undissolved lumps in the mix can cause pop outs or dark spots in hardened concrete. The

amount of calcium chloride added to concrete should be no more than is necessary to produce the desired results and in no case exceed 2% by mass of cementing material. When calculating the chloride

content of commercially available calcium chloride, it can be assumed that:

Regular flake contains a minimum of 77% CaCl2

Concentrated flake, pellet, or granular forms contain a minimum of 94% CaCl2

An overdose can result in placement problems and can be detrimental to concrete. It may cause: Rapid

stiffening, a large increase in drying shrinkage, corrosion of reinforcement, and loss of strength at

later ages.

Applications where calcium chloride should be used with caution:

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 32 of 56

CE-214L Mechanics of solids Lab

1.

2.

3.

4.

5.

6.

7.

Construction Materials

Concrete subjected to steam curing

Concrete containing embedded dissimilar metals, especially if electrically connected to steel

reinforcement

Concrete slabs supported on permanent galvanized- steel forms

Colored concrete Calcium chloride or admixtures containing soluble chlorides should not be

used in the following:

Construction of parking garages

Pre stressed concrete because of possible steel corrosion hazards

Concrete containing embedded aluminum (for example, conduit) since serious corrosion of

the aluminum can result, especially if the aluminum is in contact with embedded steel and the

concrete is in a humid environment

Concrete containing aggregates that, under standard test conditions, have been shown to be

potentially deleteriously reactive

Concrete exposed to soil or water containing sulfates

Floor slabs intended to receive dry-shake metallic finishes

Hot weather generally

CORROSION INHIBITORS

Corrosion inhibitors are used in concrete for parking structures, marine structures, and bridges where

chloride salts are present. The chlorides can cause corrosion of steel reinforcement in concrete.

Ferrous oxide and ferric oxide form on the surface of reinforcing steel in concrete. Ferrous oxide,

though stable in concretes alkaline environment, reacts with chlorides to form complexes that move

away from the steel to form rust. The chloride ions continue to attack the steel until the passivizing

oxide layer is destroyed. Corrosion-inhibiting admixtures chemically arrest the corrosion reaction.

Commercially available corrosion inhibitors include: calcium nitrite, sodium nitrite, dimethyl

ethanolamine, amines, phosphates, and ester amines. Anodic inhibitors, such as nitrites, block the

corrosion reaction of the chloride-ions by chemically reinforcing and stabilizing the passive protective

film on the steel; this ferric oxide film is created by the high pH environment in concrete. The nitriteions cause the ferric oxide to become more stable. In effect, the chloride-ions are prevented from

penetrating the passive film and making contact with the steel. A certain amount of nitrite can stop

corrosion up to some level of chloride-ion. Therefore, increased chloride levels require increased

levels of nitrite to stop corrosion. Cathodic inhibitors react with the steel surface to interfere with the

reduction of oxygen. The reduction of oxygen is the principal cathodic reaction in alkaline

environments.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 33 of 56

CE-214L Mechanics of solids Lab

Construction Materials

SHRINKAGE-REDUCING ADMIXTURES

Shrinkage-reducing admixtures, introduced in the 1980s, have potential uses in bridge decks, critical

floor slabs, and buildings where cracks and curling must be minimized for durability or aesthetic

reasons. Propylene glycol and polyoxy alkaline, alkyl ether have been used as shrink- age reducers.

Drying shrinkage reductions of between 25% and 50% have been demonstrated in laboratory tests.

These admixtures have negligible effects on slump and air loss, but can delay setting. They are

generally compatible with other admixtures.

COLORING ADMIXTURES (PIGMENTS)

Natural and synthetic materials are used to color concrete for aesthetic and safety reasons. Red

concrete is used around buried electrical or gas lines as a warning to anyone near these facilities.

Yellow concrete safety curbs are used in paving applications. Generally, the amount of pigments used

in concrete should not exceed 10% by weight of the cement. Pigments used in amounts less than 6%

generally do not affect concrete properties. Unmodified carbon black substantially reduces air

content. Most carbon black for coloring concrete contains an admixture to offset this effect on air.

Before a coloring admixture is used on a project, it should be tested for color fastness in sunlight and

autoclaving, chemical stability in cement, and effects on concrete properties. Calcium chloride should

not be used with pigments to avoid color distortions.

DAMPPROOFING ADMIXTURES

The passage of water through concrete can usually be traced to the existence of cracks or areas of

incomplete consolidation. Sound, dense concrete made with a water- cement ratio of less than 0.50

by mass will be watertight if it is properly placed and cured. Admixtures known as damp proofing

agents include certain soaps, stearates, and petroleum products. They may, but generally do not,

reduce the permeability of concretes that have low cement contents, high water- cement ratios, or a

deficiency of fines in the aggregate. Their use in well-proportioned mixes may increase the mixing

water required and actually result in increased rather than reduced permeability. Damp proofing

admixtures are sometimes used to reduce the transmission of moisture through concrete that is in

contact with water or damp earth. Many so-called damp proofers are not effective, especially when

used in concretes that are in contact with water under pressure.

PERMEABILITY-REDUCING ADMIXTURES

Permeability-reducing admixtures reduce the rate at which water under pressure is transmitted

through concrete. One of the best methods of decreasing permeability in concrete is to increase the

moist-curing period and reduce the water-cement ratio to less than 0.5. Most admixtures that reduce

water-cement ratio consequently reduce permeability. Some supplementary cementing materials,

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 34 of 56

CE-214L Mechanics of solids Lab

Construction Materials

especially silica fume, reduce permeability through the hydration and pozzolonic-reaction process.

Other admixtures that act to block the capillaries in concrete have been shown to be effective in

reducing concrete corrosion in chemically aggressive environments. Such admixtures, designed for

use in high-cement content/low-water-cement ratio concretes, contain aliphatic fatty acid and an

aqueous emulsion of polymeric and aromatic globules.

PUMPING AIDS

Pumping aids are added to concrete mixtures to improve pumpability. Pumping aids cannot cure all

unpumpable concrete problems; they are best used to make marginally pumpable concrete more

pumpable. These admixtures increase viscosity or cohesion in concrete to reduce dewatering of the

paste while under pressure from the pump. Some pumping aids may increase water demand, reduce

compressive strength, cause air entrainment, or retard setting time. These side effects can be corrected

by adjusting the mix proportions or adding another admixture to offset the side effect. Some

admixtures that serve other primary purposes but also improve pump ability are air- entraining agents,

and some water-reducing and retarding admixtures.

BONDING ADMIXTURES AND BONDING AGENTS

Bonding admixtures are usually water emulsions of organic materials including rubber, polyvinyl

chloride, polyvinyl acetate, acrylics, styrene butadiene copolymers, and other polymers. They are

added to Portland cement mixtures to increase the bond strength between old and new concrete.

Flexural strength and resistance to chloride-ion ingress are also improved. They are added in

proportions equivalent to 5% to 20% by mass of the cementing materials; the actual quantity

depending on job conditions and type of admixture used. Some bonding admixtures may increase the

air content of mixtures. Non reemulsifiable types are resistant to water, better suited to exterior

application, and used in places where moisture is present. The ultimate result obtained with a bonding

admixture will be only as good as the surface to which the concrete is applied. The surface must be

dry, clean, sound, free of dirt, dust, paint, and grease, and at the proper temperature. Organic or

polymer modified concretes are acceptable for patching and thin-bonded over layment, particularly

where feather-edged patches are desired. Bonding agents should not be confused with bonding

admixtures. Admixtures are an ingredient in the concrete; bonding agents are applied to existing

concrete surfaces immediately before the new concrete is placed. Bonding agents help glue the

existing and the new materials together. Bonding agents are often used in restoration and repair work;

they consist of Portland cement or latex- modified Portland cement grout or polymers such as epoxy

resins.

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 35 of 56

CE-214L Mechanics of solids Lab

Construction Materials

GROUTING ADMIXTURES

Portland cement grouts are used for a variety of purposes: to stabilize foundations, set machine bases,

fill cracks and joints in concrete work, cement oil wells, fill cores of masonry walls, grout prestressing tendons and anchor bolts, and fill the voids in pre-placed aggregate concrete. To alter the

properties of grout for specific applications, various air-entraining admixtures, accelerators, retarders,

and non-shrink admixtures are often used.

GAS-FORMING ADMIXTURES

Aluminum powder and other gas-forming materials are sometimes added to concrete and grout in

very small quantities to cause a slight expansion of the mixture prior to hardening. This may be of

benefit where the complete grouting of a confined space is essential, such as under machine bases or

in post-tensioning ducts of pre-stressed concrete. These materials are also used in larger quantities to

produce autoclaved cellular concretes. The amount of expansion that occurs is dependent upon the

amount of gas-forming material used, the temperature of the fresh mixture, the alkali content of the

cement, and other variables. Where the amount of expansion is critical, careful control of mixtures

and temperatures must be exercised. Gas-forming agents will not overcome shrinkage after hardening

caused by drying or carbonation.

AIR DETRAINERS

Air-detraining admixtures reduce the air content in concrete. They are used when the air content

cannot be reduced by adjusting the mix proportions or by changing the dosage of the air-entraining

agent and other admixtures. However, air-entrainers are rarely used and their effectiveness and dosage

rate should be established on trial mixes prior to use on actual job mixes.

ANTIWASHOUT ADMIXTURES

Anti-washout admixtures increase the cohesiveness of concrete to a level that allows limited exposure

to water with little loss of cement. This allows placement of concrete in water and under water without

the use of tremies. The ad- mixtures increase the viscosity of water in the mixture resulting in a mix

with increased thixotropy and resistance to segregation. They usually consist of water soluble

cellulose ether or acrylic polymers.

COMPATIBILITY OF ADMIXTURES AND CEMENTITIOUS MATERIALS

Fresh concrete problems of varying severity are encountered due to cement-admixture incompatibility

and incompatibility between admixtures. Incompatibility between supplementary cementing

materials and admixtures or cements can also occur. Slump loss, air loss, early stiffening, and other

factors affecting fresh concrete properties can result from incompatibilities. While these problems

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 36 of 56

CE-214L Mechanics of solids Lab

Construction Materials

primarily affect the plastic-state performance of concrete, long-term hardened concrete performance

may also be adversely affected. For example, early stiffening can cause difficulties with consolidation

of concrete, therefore compromising strength. Reliable test methods are not available to adequately

address incompatibility issues due to variations in materials, mixing equipment, mixing time, and

environmental factors. Tests run in a laboratory do not reflect the conditions experienced by concrete

in the field. When incompatibility is discovered in the field, a common solution is to simply change

admixtures or cementing materials.

STORING AND DISPENSING CHEMICAL ADMIXTURES

Liquid admixtures can be stored in barrels or bulk tankers. Powdered admixtures can be placed in

special storage bins and some are available in pre-measured plastic bags. Admixtures added to a truck

mixer at the jobsite are often in plastic jugs or bags. Powdered admixtures, such as certain plasticizers,

or a barrel of admixture may be stored at the project site. Dispenser tanks at concrete plants should

be properly labeled for specific admixtures to avoid contamination and avoid dosing the wrong

admixture. Most liquid chemical admixtures should not be allowed to freeze; therefore, they should

be stored in heated environments. Consult the admixture manufacturer for proper storage

temperatures. Powdered admixtures are usually less sensitive to temperature restrictions, but may be

sensitive to moisture. Liquid chemical admixtures are usually dispensed individually in the bath water

by volumetric means. Liquid and powdered admixtures can be measured by mass, but powdered

admixtures should not be measured by volume. Care should be taken to not combine certain

admixtures prior to their dispensing into the batch as some combinations may neutralize the desired

effect of the admixtures.

1.5 LUMBER:

INTRODUCTION:

Lumber or timber is wood that has been processed into beams and planks, a stage in

the process of wood production.

There are two general categories of lumber:

Hardwoods and

Softwoods.

Hardwood lumber is made from deciduous trees, whereas

Syed Kaleem Gilani

Abdul Basit

Asif Afridi

Hamza Sahibzada

Muneeb ur Rehman

Page 37 of 56

CE-214L Mechanics of solids Lab

Construction Materials

Softwood lumber is made from coniferous trees. Lumber grade is typically

determined by the surface of the wood and the number of knots present.

Lumber Grades:

Utility:

The roughest grade, utility grade lumber is affordable and can be used for rough

framing.

Standard (construction)

Standard lumber is strong but still rough, and can be used for general framing.

No. 3 Common

Knots in No. 3 Common lumber can be loose, and the surface of the wood is still

marred, as with standard and utility grades.

No. 2 Common

No. 2 Common lumber has a much smoother surface with tighter knots. This type of

lumber is a good choice for shelving.

Select or Select Structural Lumber:

This kind of lumber is extremely high-quality, and is divided into grades 1-3 and A-D.