Professional Documents

Culture Documents

The Projection Gradient Algorithm With Error Control For Structural Reliability

Uploaded by

Akshay ReddyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Projection Gradient Algorithm With Error Control For Structural Reliability

Uploaded by

Akshay ReddyCopyright:

Available Formats

Engineering Structures 32 (2010) 37253733

Contents lists available at ScienceDirect

Engineering Structures

journal homepage: www.elsevier.com/locate/engstruct

The projection gradient algorithm with error control for structural reliability

Frdric Duprat , Alain Sellier, Xuan Son Nguyen, Grard Pons

Universit de Toulouse, Laboratoire Matriaux et Durabilit des Constructions, LMDC UPS-INSA, 135 Avenue de Rangueil, 31077 Toulouse Cedex 4, France

article

info

Article history:

Received 22 February 2010

Received in revised form

24 June 2010

Accepted 9 August 2010

Available online 16 September 2010

Keywords:

Reliability

Probabilistic methods

RackwitzFiessler algorithm

Projection gradient

Design point

Error control

abstract

Nowadays, probabilistic approaches are frequently used in the design of new civil engineering structures

and the durability analysis of existing constructions. HasoferLinds reliability index is one of the most

popular reliability measures due to its relevance and ease of use, and is now referred to in many structural

design codes. This index can be determined by several algorithms dealing with minimization under

constraint such as the well known RackwitzFiessler algorithm based on the projection gradient method.

The drawback of this algorithm lies in the estimation of the gradient vector of the limit-state function,

which is often carried out by finite differences for non-explicit functions, resulting from the Finite Element

Method for instance. If the perturbation chosen in the estimation of the gradient vector gives a variation

of the output lower than the numerical accuracy of the limit-state function, the algorithm could lead to

erroneous results or even not converge. In order to circumvent this problem, an original technique is

suggested in this paper called Projection gradient with error control. The principle of the proposed

technique is to attach to RackwitzFiesslers algorithm a procedure for judiciously determining the

perturbation in the calculation of the gradient vector by finite differences, accounting for the numerical

precision of the limit-state function. The efficiency and interest of the proposed procedure is emphasized

through various examples.

2010 Elsevier Ltd. All rights reserved.

1. Introduction

The design of civil engineering structures is based on procedures and models integrating the design constraints such as

loads, material properties and geometry. The uncertainties affecting the design parameters are of a random nature. Probabilistic approaches are consequently suitable tools for assessing structural

risk and reliability as they include a probabilistic description of the

random uncertainties. A common practical measure of the structural reliability is HasoferLinds reliability index denoted [1].

This index is defined in the standardized space of reduced normal

and independent variables as the minimum distance from the origin to a point of the failure surface, the so-called design point P .

The reliability index can be determined by several algorithms

dealing with minimization under constraint such as the RackwitzFiessler algorithm [2]. This algorithm, like those derived from

it to improve its robustness and efficiency, or other gradient-based

algorithms, requires computation of the gradient vector composed

of the partial derivatives of the failure function with respect to the

standardized variables. When the failure function is defined from

a numerical model that only provides approximations of the exact solution to the mechanical problem, the partial derivatives are

Corresponding author. Tel.: +33 561 559 930; fax: +33 561 559 900.

E-mail address: frederic.duprat@insa-toulouse.fr (F. Duprat).

0141-0296/$ see front matter 2010 Elsevier Ltd. All rights reserved.

doi:10.1016/j.engstruct.2010.08.017

in turn computed approximately, which can lead to errors or even

non-convergence in some cases. Although fruitful developments

have been achieved in the finite element field for calculating the

sensitivity of model response to design variables, the finite difference method remains a practical and general tool for evaluating the

partial derivatives. The aforementioned problem may arise due to

poor choice of the perturbation applied to variables in this evaluation. In order to overcome this drawback, a simple and efficient

procedure is proposed for choosing the perturbation accounting for

the numerical precision of the model.

2. Determining the reliability index

The determination of HasoferLinds index is a constrained optimization problem. The function to be minimized is the Euclidean

distance u in the standardized space under the constraint G(u) =

0, where G() is the failure function. If u is the solution of the optimization with = OP = u , then

u = arg min(u)G(u)=0 .

(1)

G(u) = 0 defines the failure surface, the frontier between the

safe side with G(u) > 0 and the unsafe side with G(u) < 0.

According to design codes, G() defines a limit-state function, which

is expected to be continuous in the safe side and the unsafe side,

at least in the neighbourhood of the design point P . This explains

the reason why most optimization algorithms used in structural

3726

F. Duprat et al. / Engineering Structures 32 (2010) 37253733

reliability apply to differentiable constraint functions, although

other non-gradient-based algorithms exist that also aim to solve

Eq. (1), such as the simplex algorithm [3], tailored for structural

reliability analysis [4] or, more recently, the bundle algorithm [5].

Rackwitz and Fiessler proposed an iterative method which

solves Eq. (1) by generating a series of points converging towards

the optimal solution [2]. Every new point u(k+1) of the series at

iteration (k + 1) is determined from the previous point u(k) as

follows

u(k+1) =

G(u(k) )

(uT G(u(k) ) G(u(k) ))

G(u(k) )2 (k)

(2)

where G(u(k) ) is the gradient vector of G(u(k) ).

Iterations stop when the expected accuracy p is reached on two

successive coordinates for every axis i

|ui(k+1) ui(k) | P .

(3)

The descent or search direction vector reads:

d(k) =

G(u(k) )

(uT G(u(k) ) G(u(k) )) u(k) .

G(u(k) )2 (k)

(4)

Thus the new iteration point can be expressed as:

u(k+1) = u(k) + (k) d(k)

(5)

where (k) is the step size, constant and equal to 1 in the RackwitzFiessler algorithm. The main improvements made to this algorithm by researches have focused on how to optimize the step

size in order to make the convergence more robust and stable. Liu

et al. [6], Zhang et al. [7] suggested adding a line search scheme in

which the step size is selected to minimize a merit function.

Alternative algorithms to those derived from the gradient projection method exist, such as PolakHes algorithm [8] tailored for

reliability purposes [9] or algorithms based on the Lagrangian expression associated with Eq. (1):

L(u, ) = f (u) + G(u)

(6)

where f (u) is the objective function. The solution that minimizes

L(u) can be found by using a second order Taylor expansion of the

gradient of L(u) together with the optimality conditions L(u) = 0

and G(u) = 0. Finding this root sequentially is the principle of the

Sequential Quadratic Programming method in which an updating

scheme for the Hessian matrix of G(u) is needed. An iterative and

efficient scheme was proposed by Liu and Der Kiureghian [10] with

the objective function f (u) = u2 /2. Abdo and Rackwitz [11] suggested using the augmented Lagrangian

L(u, ) = f (u) + G(u) + cG(u)2 /2

(7)

as a merit function for optimizing the step size in the Rackwitz

Fiessler algorithm, with the objective function f (u) = u2 . This

choice considerably simplifies the updating scheme for the Hessian matrix.

The algorithms shortly described here are globally convergent and are expected to be more robust than the original RackwitzFiessler algorithm. However, a common feature among all the

algorithms is that they use the gradient vector G(u) of the limitstate function to define the search direction, and their efficiency

depends on the quality of the estimate of G(u). As the limit-state

function is defined in the physical space, it is necessary to calculate

partial derivatives in the standardized space from partial derivatives in the physical space as follows:

G(u)

x

T 1 ( u)

= G(u)i = G(x)T

= G(x)T

ui

ui

ui

G(u)

(8)

where u is the partial derivative of the limit-state function with

i

respect to the standardized variable ui , G(x) is the gradient vector

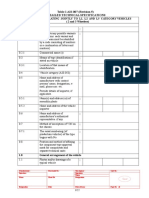

Fig. 1. Problem posed by the minimal perturbation value.

with respect to physical random variables and u = T (x) is the Nataf

transformation.

In practical problems where G(x) is computed from the finite

element method, analytical expressions of the partial derivatives

are rarely available. The direct differentiation method involves development of analytical derivatives of the finite element response

and its implementation as a part of the finite element code. Some

implementations have been carried out for static and dynamic inelastic problems, where response sensitivities were obtained with

respect to material parameters, nodal coordinates, cross-sectional

geometry and nodal loads for a variety of material models and element formulations [7,9,12,13]. However, for complex mechanical

models combining several types of element and problem (ageing

chemicalmechanical behaviour of concrete for example), these

implementations become somewhat cumbersome. For the sake of

simplicity, general purpose reliability programs often resort to the

finite difference method for computing the gradient vector [4,14

17], which remains attractive and easily practicable:

G(x)

G(x + 1xi ei ) G(x)

(9)

xi

1xi

where 1xi is the perturbation and ei is the unit vector for the axis xi .

The truncation error in Eq. (9) results from the neglected terms

in the Taylor series expansion of the perturbed function G(x), and

can be reduced by using a small perturbation 1xi . The perturbation

size should nevertheless be chosen in compliance with the mechanical model precision. The finite element response of a nonlinear mechanical model is twofold: one part is deterministic and

one part is random, resulting from the computational inaccuracies

accepted in the solving procedures (convergence threshold) and

the inevitable numerical round-off errors (machine code precision). It can be reasonably stated that the random part, denoted

1G(x) in Fig. 1, is proportional to the value of the response itself

with a working computational precision imposed by the engineers

knowledge as the proportionality factor. Hence, if the perturbation

1xi is too small, say 1xi < 1xmin in Fig. 1, it may lead to a difference G(x + 1xi ei ) G(x) that is smaller than the random part

1G(x) of the response, and thereafter lead to poor efficiency, even

non-convergence of the search algorithm whatever the underlying

method used for finding the design point.

In order to get a best estimate of a finite difference, it is necessary to impose a judicious value of the perturbation: sufficiently

large to make the random part of the mechanical response as

negligible as possible and small enough to avoid significant truncation error. Furthermore, as iterations of the search algorithm

proceed, the partial derivative for the axis xi should be estimated

using Eq. (9) only if the coordinate of the new iteration point is far

enough from the previous one.

To avoid the pitfalls of calculating the gradient vector response,

the response surface methods can alternatively be employed. By iteratively constructing an explicit approximation of the limit-state

function and combining it with a classical search algorithm for

finding the design point, these methods can give satisfactory results: the approximating function generally behaves very much

like the true limit-state function in the neighbourhood of the design point. Nevertheless, these methods often become dramatically

costly in computation resources for high dimension problems [18].

F. Duprat et al. / Engineering Structures 32 (2010) 37253733

Table 1

Input variables example #1.

3. Projection gradient method with error control

The above mentioned considerations regarding the problem

posed by the minimal perturbation value have been taken into consideration in the improvement to the RackwitzFiessler algorithm

proposed in this paper. The integrated procedure combines the

gradient vector calculated at the previous iteration and the working computational precision of the mechanical model in order to

state the new perturbation value. It is assumed that the limit-state

function of the structure is defined as the difference between a resource variable R(x) and a demand variable S (x):

G(x) = R(x) S (x).

(10)

Alternative expressions are sometimes used, for instance G(x)

= R(x)/S (x) 1. In most engineering fields however it is easier to

handle with limit-state functions or safety margins having a physical meaning and unity.

For the first iteration, as the sensitivity of the mechanical model

to variables is not known yet, a large perturbation is applied:

1xi = c1 (R + S )xi

(11)

where c1 is a magnifying factor (c1 > 1), R and S are working

computational precisions of both models. For the ongoing iteration

(k), 1xi is given by:

(1xi )(k)

1G(x(k1) )

= c2

G(x(k1) )i

R R(x(k1) ) + S S (x(k1) )

= c2

G(x(k1) )i

(12)

where c2 is a magnifying factor (c2 > 1), 1G(x(k1) ) = R R

(x(k1) ) + S S (x(k1) ) is the maximal numerical inaccuracy of the

G(x

(k1)

is the ith compolimit-state function and G(x(k1) )i =

xi

nent of the gradient vector at the previous iteration (k 1).

The working computational precisions are stated according to

the features of the limit-state function. If G() is analytical a usual

choice is R = S = 108 (for double precision floating numbers).

If G() results from an iterative numerical scheme, R and S must be

chosen according to the employed convergence criteria. From the

experience of the authors, relevant values of the magnifying factors

c1 and c2 lie between 5 and 10. The influence of these factors on the

results obtained is emphasized hereafter.

As previously mentioned, the distance between two consecutive points given by the iterative search procedure for finding the

design point should be a criterion for updating the partial derivative for the axis under consideration. Consequently the following

condition applies for updating the component G(x(k) )i :

((xi )(m) (xi )(m1) ) (1xi )(k0 )

m=k +1

3727

(13)

where ((xi )(m) (xi )(m1) ) is the algebraic distance between two

successive points along axis i, for which no update of the component G(x(k) )i has been achieved yet, (k0 ) denotes the iteration

number corresponding to the last update of the partial derivative and (k) is the ongoing iteration (see Fig. 1). (1xi )(k0 ) is the

minimum required perturbation stated by Eq. (12). The condition in Eq. (13) allows the overall computational cost to be reduced by avoiding useless computation of the partial derivatives

for axes where the optimum has already been reached. This is

similar to the use of omission sensitivity factors. The omission

sensitivity factor for a mean value is defined as the ratio of the reliability index determined, with the variable in question taken at

its mean value, to the original reliability index. An omission sensitivity factor very close to one exhibits that the variable could

be omitted in determining the reliability index, say fixed to its

Variable

Distribution

Mean

Stand. dev.

x1

x2

x3

x4

Lognormal

Normal

Normal

Lognormal

10

25

5

0.0625

5

0.8

0.2

0.0625

mean value. Based on approximate omission sensitivity factors,

an implementation of these factors in the search algorithm was

proposed by Madsen [19], requiring the number of variables to

be modified as iterations proceed. In PGEC, the sensitivity criterion given by Eq. (13) is equivalent to the use of omission sensitivity factors. It is finally found that the proposed improvement

of determining the perturbation 1xi as a function of the working

computational precision without systematically updating the partial derivatives in the course of iterations leads to the convergence

of the RackwitzFiessler algorithm being facilitated.

4. Examples

Five examples are presented below in order to illustrate the efficiency of the proposed method and the computational cost benefit

brought by not systematically updating the partial derivatives.

The two first examples deal with explicit limit-state functions

and detailed comparison is made with other frequently employed

algorithms. The results of interest are the value of the reliability

index , the coordinates of design point P , the value of the limitstate function at this point with respect to its value at the median

point (space origin) |G(u )/G(u0 )|, which is expected to be zero if

P lies exactly on the failure surface, and the number of runs of the

limit-state function Nr . Nr reflects the efficiency of the methods

with respect to the computational cost. The proposed technique is

subsequently referred to as the PGEC method (projection gradient

with error control).

The three last examples concern implicit failure functions:

some comparisons are made with results from the literature when

available.

4.1. Example #1

The limit-state function is a polynomial used as a response surface for reliability analysis of a pipeline [6]:

G(x) = 1.1 0.00534x1 0.0705x2 0.226x3 + 0.998x4

0.00115x1 x2 0.0149x1 x3 + 0.0717x1 x4

+ 0.0135x2 x3 0.0611x2 x4 0.558x3 x4

+ 0.00117x21 + 0.00157x22 + 0.0333x23 1.339x24 .

(14)

The following algorithms are under consideration: the LiuDer

Kiureghian algorithm (SQP) and the ZhangDer Kiureghian algorithm (iHLRF), implemented in OpenSees [10,11], the Abdo

Rackwitz algorithm (RFLS), the RackwitzFiessler algorithm (HLRF),

and the NelderMead algorithm (SPLX), implemented in Comrel [13].

The non-correlated random variables used in this example are

defined in Table 1. Convergence criteria in PGEC were p = 5

103 and R = S = 108 . Convergence criteria are also stated in

Comrel. In OpenSees the convergence criteria are:

|G(u )/G(u0 )| 1

(15)

checking for the proximity of P to the failure surface, and

u T u 2

(16)

checking that the gradient vector at P points towards the space

3728

F. Duprat et al. / Engineering Structures 32 (2010) 37253733

Table 2

Reliability index and convergence criteria example #1.

Technique

Nr

|G(u )/G(u0 )|

u T u

max |ui ui(k1) |

SQP

iHLRF

RFLS

HLRF

SPLX

PGEC (c1 = c2 = 1)

PGEC (c1 = c2 = 5)

PGEC (c1 = c2 = 104 )

1.5296

1.5296

1.5296

1.5296

1.5294

1.5296

1.5296

1.5298

57

49

25

25

55

25

23

20

4.24 106

2.40 105

2.10 107

2.10 107

1.14 106

2.10 107

1.84 107

1.44 106

8.71 104

6.95 104

n.a.

n.a.

n.a.

6.40 107

6.51 107

1.67 106

n.a.

n.a.

<5 103

<5 103

<5 103

1.70 103

1.71 103

7.37 104

Table 3

Design point example #1.

Technique

SQP

iHLRF

RFLS

HLRF

SPLX

PGEC (c1 = c2 = 5)

u1

u2

u3

1.499

1.499

1.496

1.496

1.496

1.496

1.152 10

1.142 101

1.147 101

1.147 101

1.187 101

1.148 101

1

u4

8.040 10

7.775 102

7.957 102

7.957 102

7.601 102

7.976 102

2

2.675 101

2.706 101

2.845 101

2.845 101

2.849 101

2.845 101

Table 4

Input variables example #2.

Variable

Description

Distribution

Mean value

Stand. dev.

x1

x2

x3

x4

x5

x6

x7

Bending moment (MN m)

Effective depth (m)

Steel yielding strength (MPa)

Reinforcing steel area (m2 )

Block factor

Width (m)

Concrete strength (MPa)

Normal

Normal

Lognormal

Normal

Normal

Normal

Lognormal

0.015

0.30

550

308 106

0.5

0.20

38

0.00525

0.015

55

30.8 106

0.05

0.01

5

Table 5

Reliability index and convergence criteria example #2.

Technique

Nr

|G(u )/G(u0 )|

u T u

max |ui ui(k1) |

SQP

iHLRF

RFLS

HLRF

PGEC (c1 = c2 = 1)

PGEC (c1 = c2 = 10)

PGEC (c1 = c2 = 5000)

4.2829

4.2829

4.2173

4.2174

4.2176

4.2176

4.2177

55

50

40

40

40

34

33

1.31 105

1.60 105

7.79 107

7.57 107

1.60 108

1.66 108

1.08 107

2.15 104

5.53 104

n.a.

n.a.

1.60 107

1.60 107

1.53 107

n.a.

n.a.

<5 103

<5 103

1.62 103

1.62 103

5.00 104

origin. Default values for these criteria are 1 = 2 = 102 . The

results are reported in Tables 2 and 3.

As it can be seen in Table 2, the influence of the magnifying

factors c1 and c2 remains limited in the case of an analytical limitstate function. Since the assessment of the gradient vector is fairly

accurate in such case, the sole expected effect of the magnifying

factors is globally to save runs of the limit-state function, that is

obtained for c1 = c2 5.

The reliability index results are almost the same for all the

techniques employed. As far as computational cost is concerned,

the algorithms that appear the most relevant are those in which the

optimization of the step size in the descent direction is made with

minimum effort, or even not made at all, say RFLS, HLRF and PGEC.

Five iterations are needed in these algorithms for convergence to

a design point very close to the failure surface to be achieved. By

saving two calculations of partial derivatives (with c1 = c2 =

5), PGEC is the least costly algorithm. It can be noted that the

convergence criterion used in PGEC (Eq. (3)) is as, or more, severe

than those in iHLRF and SQP (Eqs. (15) and (16)). For the latter,

requiring supplementary runs of gradient evaluation to optimize

the step size of the search direction, it is worth noting that the

computational cost is highly dependent on the perturbation value

used in finite difference for estimating the partial derivatives. In

OpenSees, the perturbation value is proportional to the standard

deviation of random variables: the results presented above were

obtained with proportionality factors of 1/1000 for SQP and

1/1500 for iHLRF. With the default value 1/1000 for iHLRF, the

number of computations jumps to Nr = 70 for identical reliability

results.

4.2. Example #2

The limit-state function is the safety margin of a reinforced

concrete section subjected to a bending moment:

G(x) = x2 x3 x4

x5 x23 x24

x6 x7

x1 .

(17)

The random variables are listed in Table 4. The same convergence criteria and magnifying factors were imposed here as in the

previous example. The results are reported in Tables 5 and 6, exhibiting again the influence of the magnifying factors c1 and c2 . As

already noticed this effect is the reduction of the computational

cost while maintaining the same accuracy of results.

As far as reliability outputs are concerned, values of the reliability index are slightly different when the SQP and iHLRF algorithms

are compared with the RFLS, HLRF and PGEC algorithms. For the

F. Duprat et al. / Engineering Structures 32 (2010) 37253733

3729

Table 6

Design point example #2.

Technique

SQP

iHLRF

RFLS

HLRF

PGEC (c1 = c2 = 10)

u1

u2

u3

3.074

3.076

3.016

3.013

3.011

9.854 10

9.855 101

9.560 101

9.535 101

9.526 101

1.610

1.609

1.718

1.716

1.715

Table 7

Computation of partial derivatives example #2.

u5

u6

2.307

2.305

2.194

2.201

2.206

4.939 10

4.937 102

4.774 102

4.710 102

4.665 102

2

u7

2.484 10

2.484 102

2.391 102

2.368 102

2.356 102

2

6.501 102

6.498 102

6.256 102

6.201 102

6.198 102

Table 9

Frame element properties example #3.

Table 8

Omission sensitivity factors example #2.

Variable

x1

x2

x3

x4

x5

x6

x7

i (i )

6.5159

1.545

4.3241

1.025

4.6407

1.100

4.8411

1.148

4.2179

1.000

4.2177

1.000

4.2190

1.000

Fig. 2. Structural system example #3 (Unit: m).

latter, the closeness of the design point to the failure surface and

the computational cost are more satisfactory. It is finally found that

the PGEC algorithm is the least costly (with c1 = c2 = 10): by

saving six computations of the partial derivatives with respect to

variables x5 x7 at iterations 4 and 5 (see Table 7) according to the

criterion given by Eq. (13), PGEC allows useless runs of the limitstate function to be avoided. The omission sensitivity factors have

been computed for this example. Results for these are reported in

Table 8. It can be seen that variables x5 x7 are the least influential.

4.3. Example #3

The case of a multi-storey multi-span metallic portal frame is

dealt with (see Fig. 2). The limit-state function is the margin with

respect to a prescribed value max of the displacement at the top

of the structure:

G(x1 , . . . , x21 ) = max (x1 , . . . , x21 ).

u4

(18)

The x-vector contains 21 basic variables translating different

properties of structural components. The structural data and the

statistical parameters are reported in Tables 9 and 10. Some

variables are assumed to be correlated. All loads are correlated by

a coefficient of correlation F = 0.95. All cross section properties

are correlated by AiAj = IiIj = AiIj = 0.13. The two different

modulus of elasticity E1 and E2 are correlated by E = 0.9. All other

Element

Modulus of elasticity

Moment of inertia

Cross section

1

2

3

4

5

6

7

8

E1

E1

E1

E1

E2

E2

E2

E2

I5

I6

I7

I8

I1

I2

I3

I4

A5

A6

A7

A8

A1

A2

A3

A4

variables are assumed to be uncorrelated. The internal language

of the CAST3M free finite element software [20] was used in this

study, as for the following examples, for both finite element and

probabilistic calculations. Convergence criteria in PGEC were p =

5 102 , R = 108 and S = 104 . The results are reported in

Table 11 for several values of max and c1 = c2 = 10.

It is worth noting that the convergence criteria are fulfilled satisfactorily, whatever the value of the reliability index is, which is

increased with larger value of max . In Table 11 Ns is the number

of saved runs of the finite element model resulting from the criterion given by Eq. (13). As seen in Table 12, this criterion allows

the gradient to be updated only when required as the computation goes along. The absence of update of a partial derivative is

hence not definitive in the course of the search procedure. This interesting feature gives the PGEC algorithm some adaptability in the

search procedure for finding the design point. The study of the effect of the magnifying factors c1 and c2 reveals in Table 13 that the

range [510] for these ones leads to a fairly good compromise between the precision and the saving of runs.

4.4. Example #4

In this example, the risk of depassivation of the reinforcements

embedded in concrete is addressed. Reinforcing bars are depassivated when pH decreases due to the ingress of pollutants such

as chlorides or carbon dioxide. Once depassivated, steel is prone

to corrosion if sufficient moisture and oxygen are available in the

neighbourhood of reinforcing bars. The case of a concrete beam exposed to carbonation is considered here. As cracks due to the applied load facilitate the ingress of carbon dioxide, the mechanical

behaviour is taken into account together with the diffusion process

and the chemical aspects. The overall modelling is detailed in [21].

The limit-state function for the durability limit-state is defined as

follows:

G(x) = x1 d(x2 , x3 , x4 , x5 ).

(19)

The carbonation depth is given by the function d() which is

computed from a finite element model. The steep slope profile

of the calcium content in concrete leads to strong non-linearity

in the function d(). In this model, a fine mesh in both space

and time was used in order to ensure satisfactory convergence of

computation procedures. The carbonation depth profiles obtained

for several exposure times can be seen in Fig. 3. In function d(), the

carbonation depth is given along the line AB.

The random variables are listed in Table 14. Convergence

criteria in PGEC were p = 5 102 , R = 107 and S = 104 .

3730

F. Duprat et al. / Engineering Structures 32 (2010) 37253733

Table 10

Input variables example #3.

Variable

Unit

Distribution

Mean value

Standard deviation

F1

F2

F3

E1

E2

I1

I2

I3

I4

I5

I6

I7

I8

A1

A2

A3

A4

A5

A6

A7

A8

kN

kN

kN

kN/m2

kN/m2

m4

m4

m4

m4

m4

m4

m4

m4

m2

m2

m2

m2

m2

m2

m2

m2

Gumbel max

Gumbel max

Gumbel max

Normal

Normal

Positive normal

Positive normal

Positive normal

Positive normal

Positive normal

Positive normal

Positive normal

Positive normal

Positive normal

Positive normal

Positive normal

Positive normal

Positive normal

Positive normal

Positive normal

Positive normal

133.454

88.97

71.175

2.173752 107

2.379636 107

0.813443 102

1.150936 102

2.137452 102

2.596095 102

1.081076 102

1.410545 102

2.327853 102

2.596095 102

0.312564

0.3721

0.50606

0.55815

0.253028

0.29116825

0.37303

0.4186

40.04

35.59

28.47

1.9152 106

1.9152 106

1.08344 103

1.298048 103

2.59609 103

3.028778 103

2.596095 103

3.46146 103

5.624873 103

6.490238 103

0.055815

0.07442

0.093025

0.11163

0.093025

0.10232275

0.1209325

0.195375

Table 11

Reliability index and convergence criteria example #3.

max (cm)

3

6

9

Nr

1.342

3.398

4.573

52

91

119

Ns

|G(u )/G(u0 )|

u T u

max |ui ui(k1) |

14

63

79

4.29 10

1.72 105

1.74 104

1.69 10

2.00 105

1.55 104

3.63 102

2.58 102

4.93 102

Table 12

Computation of partial derivatives example #3 (max = 6 cm).

Table 13

Influence of c1 and c2 factors example #3 (max = 9 cm).

c1 , c2

Nr

Ns

|G(u )/G(u0 )|

u T u

max |ui ui(k1) |

1

2

4

6

8

10

12

50

4.573

4.573

4.573

4.573

4.573

4.573

4.573

4.558

178

156

139

135

123

119

121

140

42

64

81

85

75

79

99

168

1.91 106

6.95 106

2.89 105

2.80 105

3.27 105

1.74 104

7.43 104

9.17 104

3.59 105

3.96 105

2.79 105

2.93 105

1.24 104

1.55 104

5.07 104

6.59 104

2.81 102

2.73 102

2.24 102

2.33 102

4.87 102

4.93 102

3.92 102

1.54 102

Table 14

Input variables example #4.

Variable

Description

Distribution

Mean value

Stand. dev.

x1

x2

x3

x4

x5

Concrete cover (mm)

Coefficient of diffusion (m2 /s)

Tortuousity

Concrete strength (MPa)

Live load (kN/m2 )

Lognormal

Lognormal

Uniform (0.10.9)

Lognormal

Gumbel max

20

1 108

0.5

35

1.04

4

0.8 108

0.23

5

0.4

The results for an exposure time of 5 years are reported in Tables 15

and 16.

The reliability indices and coordinates of the point P supplied

by PGEC and by the response surface method used in [20] are

F. Duprat et al. / Engineering Structures 32 (2010) 37253733

(a) 1 month.

(b) 5 years.

(c) 20 years.

3731

(d) 35 years.

Fig. 3. Carbonation fields at various times (half cross-section at mid-span).

Table 15

Reliability index and convergence criteria example #4.

Technique

RSM [20]

PGEC

HLRFa

a

3.998

3.923

Nr

|G(u )/G(u0 )|

u T u

max |ui ui (k 1)|

43

26

3.17 10

4.48 104

8.70 10

5.53 104

9.62 103

1.54 102

Not converged.

Table 16

Design point example #4.

Technique

RSM [20]

PGEC

u1

u2

3.601

3.076

1.312 10

7.814 102

u3

1

similar even though some differences exist. These latter probably

result from the approximation of the true failure function given

by the response surface, which might not be sufficiently accurate

in the vicinity of point P . In contrast, it is not surprising that

even satisfactory convergence results with PGEC are less tight than

with RSM. This is due to the fact that the approximate failure

function handled by RSM is explicit as are the gradients as well.

Nevertheless, PGEC exhibits an advantage regarding the numerical

cost: 10 runs of the mechanical model are saved as shown in

Table 17.

Like PGEC, the original HLRF algorithm was implemented in

the CAST3M software. The perturbation value for evaluating the

gradient vector in the HLRF algorithm was set at 1xi = i /1000,

where i is the standard deviation of the variable xi . It can be

seen in Table 18 that convergence is not reached after 6 iterations

(not even beyond); the value of reliability index is not stabilized

and the value of the limit state function is far from zero. This

arises because the perturbation value does not suit the numerical

inaccuracy of limit state function adequately, and is below the

optimum value. The non-convergence is not caused by an irregular

or discontinuous profile of the failure surface.

4.5. Example #5

The case of a wide prestressed footbridge is considered in this

example. The longitudinal cross-section and cross-section over the

support can be seen in Fig. 4. The structure was designed according to Eurocode 2 [22]. The prestressing force of 23 MN was determined in such a way that only the minimum area of reinforcing

steel was required: under the characteristic combination of loads

and for the upper and lower values of the prestressing force, the

tensile stress in concrete is limited to the average tensile strength.

9.212 10

2.547 102

4

u4

u5

1.731

2.026

1.601 102

4.837 102

Table 17

Computation of partial derivatives example #4.

Table 18

Comparison between PGEC and HLRF example #4.

Iteration

PGEC

|G(u )/G(u0 )|

3.298

0.375

5.210

0.220

3.951

0.026

3.984

0.016

3.926

0.0006

3.923

0.0004

HLRF

|G(u )/G(u0 )|

3.741

1.032

3.852

0.316

1.893

0.126

1.608

1.011

3.687

0.695

4.901

0.548

The structural durability is affected by the concrete cracking and

the requirement for durability is therefore that the effective stress

does not exceed the effective tensile strength, taking into account

the concrete damage. The limit state function is hence

G(x1 , . . . , x9 ) =

x1

1 dtp (x2 , . . . , x9 )

M (x2 , . . . , x9 )

1 dM (x2 , . . . , x9 )

(20)

where dtp () is the concrete damage on reaching the maximum

strength (variable x1 ), dM () is the effective concrete damage, and

M () is the normal stress, both computed at point M in Fig. 4.

3732

F. Duprat et al. / Engineering Structures 32 (2010) 37253733

Table 19

Input variables example #5.

Variable

Description

Distribution

Mean value

Stand. dev.

x1

x2

x3

x4

x5

x6

x7

x8

x9

Tensile strength (MPa)

Modulus of elasticity (MPa)

Modulus of compressibility (MPa)

Characteristic strain for the consolidation of spherical viscosity

Viscosity for the reversible creep (MPa/d)

Moisture pressure (MPa)

Drying creep stress (MPa)

Chemical factor

Pedestrian live load (kN/m2 )

Lognormal

Lognormal

Lognormal

Lognormal

Lognormal

Lognormal

Lognormal

Lognormal

Gumbel max

3

37 600

20 8890

104

62 668

58

11.7

3.1 104

2.437

0.6

9400

41 778

3.2 105

12 534

14.21

3.1

9.748 104

0.9748

Table 20

Reliability index and convergence criteria example #5.

Exposure time (y)

Nr

Ns

|G(u )/G(u0 )|

u T u

max |ui ui (k 1)|

10

50

90

3.261

2.582

1.897

55

38

40

15

2

10

1.99 105

6.90 104

9.01 104

4.22 104

6.45 103

1.50 103

8.60 103

3.48 102

3.01 102

Fig. 4. Prestressed footbridge studied (units: cm). Main design inputs: the concrete strength class is C40/50, the tensile strength of strands is 1860 MPa, and the pedestrian

live load is 3.71 kN/m2 .

Creep and shrinkage of the concrete are factors that reduce

the prestressing force, and have been included in the functions

M (), dtp () and dM () which are actually outputs of a global finite

element model, geometrically reduced to a quarter of the structure

(see Fig. 5). This global model comprises several comprehensive

coupled sub-models for creep, shrinkage and mechanical damage

of the concrete, accounting for the main parameters that influence

creep and shrinkage: the ambient humidity, the dimensions of

the element, the composition of the concrete, the maturity of

the concrete when the load is first applied and the duration and

magnitude of the loading. The mathematical formulation of the

sub-models derives from the damage theory for a visco-elastic

material submitted to consolidation. The modelling is detailed

in [23].

The random variables are listed in Table 18. Very few statistical

data exist in the literature for the creep and shrinkage of concrete:

most of the surveys are incomplete. Data are hence missing for

the parameters of the model, which are expected to be uncertain

in a broad range. From the assumption that creep and shrinkage

functions given in EC2 present an uncertainty of 20%30% [22],

and from available collected experimental data, propositions have

still been derived in Table 19. From a physical point of view, and

owing to possible numerical issues, lognormal distributions were

suggested.

Convergence criteria in PGEC were p = 5 102 , R = 105

and S = 104 . The results obtained for several exposure times are

reported in Table 20.

Fig. 5. Stresses just after tensioning.

It can be seen that the number of runs of the limit state function

remains reasonably low. The convergence criterion, Eq. (3), on

the distance between two successive search points, which is the

only one active in the procedure, allows the other convergence

criteria, Eqs. (15) and (16), to be satisfactorily fulfilled. The update

for estimating the coordinates of the gradient vector, as stated by

Eq. (13), again leads to a saving of runs of the limit state function

for this example, as shown in Table 21.

5. Conclusion

In this paper, an improvement of the RackwitzFiessler algorithm has been proposed for cases where the model associated

F. Duprat et al. / Engineering Structures 32 (2010) 37253733

Table 21

Computation of partial derivatives example #5 (10 year exposure).

3733

Acknowledgements

The CEA (french Atomic Energy Commission) is thanked for the

provision of the Cast3M software to the LMDC in its development

version for education and research.

References

with the limit-state function presents some random computational

inaccuracies. These are part of the outputs supplied by the Finite

Element Method when resorting to non-linear solving procedures.

If the computational inaccuracies are not accounted for in estimating the coordinates of the gradient vector by finite differences, the

iterative search procedure for finding the design point may converge erroneously or not at all. In order to circumvent this drawback, a dedicated procedure for calculating the perturbation to be

used in finite differences was achieved and attached to the RackwitzFiessler algorithm. Simultaneously, the procedure takes into

account the working computational precision assigned by the engineers knowledge and depending on the finite element modelling, and allows the number of runs to be reduced thanks a

criterion for the updating of the partial derivatives with respect

to the input variables. The overall algorithm, called the PGEC

algorithm, was compared to enhanced algorithms commonly implemented in dedicated software. From examples considered with

explicit failure functions, PGEC exhibits satisfactory behaviour: for

similar convergence constraints, the results obtained are very close

to those supplied by enhanced algorithms in terms of the reliability index and the coordinates of the design point. Furthermore,

PGEC is the least costly algorithm numerically speaking. Some examples with strongly non-linear finite element modelling were

also addressed, dealing with durability issues of concrete structures exposed to carbonation, or subjected to creep and shrinkage

effects. Beyond efficiently fulfilling the convergence criteria, the

PGEC algorithm allows a significant number of runs to be saved.

The proposed technique could also give rise to improvements in

the other search algorithms derived from the projection gradient

or gradient-based and resorting to finite differences for estimating

the gradient vector.

[1] Hasofer AM, Lind NC. An exact and invariant second moment code format.

J Eng Mech 1974;100:11121.

[2] Rackwitz R, Fiessler B. Structural reliability under combined random load

sequences. Comput Struct 1979;9:48994.

[3] Nelder JA, Mead R. A simplex method for function minimization. Comput J

1965;7:30813.

[4] COMREL & SYSREL users manual. RCP Consult. Munich; 19872004.

[5] Bonnans JF, Gilbert JC, Lemarechal C, Sagastizabal C. Optimisation numrique:

aspects thoriques et pratiques. In: Collection Mathmatiques et Applications.

Springer; 1999.

[6] Liu P-L, Der Kiureghian A. Optimization algorithms for structural reliability.

Struct Saf 1991;9:16178.

[7] Zhang Y, Der Kiureghian A. Finite element reliability methods for inelastic

structures. Report No. UCB/SEMM-97/05. Berkeley (CA): Department of Civil

and Environmental Engineering, University of California; 1997.

[8] Polak E. Optimization algorithms and consistent approximations. Applied

mathematical sciences, vol. 124. Springer Verlag; 1997.

[9] Haukaas T, Der Kiureghian A. Strategies for finding the design point in nonlinear finite element. Struct Saf 1991;9:16178; Probab Eng Mech 2006;21:

13347.

[10] Liu PL, Der Kiureghian A. Finite element reliability of geometrically non-linear

uncertain structures. J Eng Mech 1991;17:180625.

[11] Abdo T, Rackwitz R. A new -point algorithm for large time-invariant and

time-variant reliability problems. In: Der Kiureghian A, Thoft-Christensen P,

editors. Proc. of the 3rd IFIP WG 7.5; 1991.

[12] Haukaas T, Der Kiureghian A, Fujimura K. Structural reliability software at the

University of California, Berkeley. Struct Saf 2006;28:4467.

[13] Reh S, Beley JD, Mukherjee S, Khor EH. Probabilistic finite element analysis

using ANSYS. Struct Saf 2006;28:1743.

[14] Schuller GI, Pradlwarter HJ. Computational stochastic structural analysis

(COSSAN) a software tool. Struct Saf 2006;28:6882.

[15] Gollwitzer S, Kirchgner B, Fischer R, Rackwitz R. PERMAS-RA/STRUREL

system of programs for probabilistic reliability analysis. Struct Saf 2006;28:

10829.

[16] Lemaire M, Pendola M. PHIMECA-SOFT. Struct Saf 2006;28:13049.

[17] Tvedt L. Proban probabilistic analysis. Struct Saf 2006;28:15063.

[18] Nguyen XS, Sellier A, Duprat F, Pons G. Adaptive response surface method

based on a double weighted regression technique. Probab Eng Mech, available

online 27 April 2008.

[19] Madsen HO. Omission sensitivity factors. Struct Saf 1988;5:3545.

[20] CAST3M. Finite element software. Commissariat lEnergie Atomique.

http://www-cast3m.cea.fr.

[21] Duprat F, Sellier A. Probabilistic approach to corrosion risk due to carbonation

via an adaptive response surface method. Probab Eng Mech 2006;21:20716.

[22] Eurocode 2: EN 1992-2. ICS: 91.080.40; 93.040. Design of concrete structures,

part 2: concrete bridges.

[23] Sellier A, Buffo-Lacarrire L. Vers une modlisation simple et unifie du fluage

propre, du retrait et du fluage en dessiccation du bton. Eur J Environ Civil Eng

2009;13:116182.

You might also like

- Structural Organic Chemistry. The Shapes of Molecules. Functional GroupsDocument19 pagesStructural Organic Chemistry. The Shapes of Molecules. Functional Groupspatrik710No ratings yet

- Structural Organic Chemistry. The Shapes of Molecules. Functional GroupsDocument19 pagesStructural Organic Chemistry. The Shapes of Molecules. Functional Groupspatrik710No ratings yet

- Formulas and Theorems For ReferenceDocument11 pagesFormulas and Theorems For ReferenceLulabu BubaNo ratings yet

- Structural Organic Chemistry. The Shapes of Molecules. Functional GroupsDocument19 pagesStructural Organic Chemistry. The Shapes of Molecules. Functional Groupspatrik710No ratings yet

- RSA WebCRD - User ID (Kreddy39)Document1 pageRSA WebCRD - User ID (Kreddy39)Akshay ReddyNo ratings yet

- Mathematical InductionDocument13 pagesMathematical InductionTransfusianNo ratings yet

- Frame OutputDocument5 pagesFrame OutputAkshay ReddyNo ratings yet

- A Modified Reliability Index Approach For Reliability-Based Design OptimizationDocument7 pagesA Modified Reliability Index Approach For Reliability-Based Design OptimizationAkshay ReddyNo ratings yet

- Partial Level 4 Framing Plan - South: Bohlin Cywinski JacksonDocument1 pagePartial Level 4 Framing Plan - South: Bohlin Cywinski JacksonAkshay ReddyNo ratings yet

- Partial Level 4 Framing Plan - South: Bohlin Cywinski JacksonDocument1 pagePartial Level 4 Framing Plan - South: Bohlin Cywinski JacksonAkshay ReddyNo ratings yet

- Seismi-Resistant Steel Design - MRFsDocument58 pagesSeismi-Resistant Steel Design - MRFsAkshay Reddy100% (1)

- Exam PatternDocument1 pageExam PatternAkshay ReddyNo ratings yet

- Partial Level 4 Framing Plan - South: Bohlin Cywinski JacksonDocument1 pagePartial Level 4 Framing Plan - South: Bohlin Cywinski JacksonAkshay ReddyNo ratings yet

- Concentrically Braced FramesDocument121 pagesConcentrically Braced FramesAkshay Reddy100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Group B04 - MM2 - Pepper Spray Product LaunchDocument34 pagesGroup B04 - MM2 - Pepper Spray Product LaunchBharatSubramonyNo ratings yet

- Manual Do Usuario de Automatizadores Deslizantes CE2017 InglesDocument2 pagesManual Do Usuario de Automatizadores Deslizantes CE2017 InglesTasso ParteliNo ratings yet

- Selfdrive Autopilot CarsDocument20 pagesSelfdrive Autopilot CarsPavan L ShettyNo ratings yet

- Set-1-Index001-ERA - ERTMS - 003204 v500 Functional Requirements SpecificationDocument98 pagesSet-1-Index001-ERA - ERTMS - 003204 v500 Functional Requirements SpecificationShauna MooreNo ratings yet

- PDFDocument2 pagesPDFSalim AshorNo ratings yet

- MapObjects inVBNET PDFDocument34 pagesMapObjects inVBNET PDFWanly PereiraNo ratings yet

- HCF Spec 190 1.0 PDFDocument31 pagesHCF Spec 190 1.0 PDFvikulovNo ratings yet

- (L4) - (JLD 3.0) - Semiconductors - 30th DecDocument66 pages(L4) - (JLD 3.0) - Semiconductors - 30th DecAshfaq khanNo ratings yet

- Ruth Clark ResumeDocument2 pagesRuth Clark Resumeapi-288708541No ratings yet

- AIS - 007 - Rev 5 - Table - 1Document21 pagesAIS - 007 - Rev 5 - Table - 1Vino Joseph VargheseNo ratings yet

- Internship Opportunities PDFDocument2 pagesInternship Opportunities PDFMD MoizNo ratings yet

- New Text DocumentDocument246 pagesNew Text DocumentMustafa Al-RawiNo ratings yet

- Concrete Tech AssignmentDocument7 pagesConcrete Tech AssignmentShehan FernandoNo ratings yet

- Incident Report: Executive Vice PresidentDocument1 pageIncident Report: Executive Vice PresidentEvan MoraledaNo ratings yet

- Evoque Owners Club Manual PDFDocument258 pagesEvoque Owners Club Manual PDFmihai12moveNo ratings yet

- Cebu Technological University: Republic of The PhilippinesDocument2 pagesCebu Technological University: Republic of The PhilippinesEngelbert RespuestoNo ratings yet

- Tubewell Energy Audit PDFDocument172 pagesTubewell Energy Audit PDFshaheerdurrani100% (1)

- Electoral ListDocument189 pagesElectoral ListAhmadShazebAzharNo ratings yet

- EV 10 Best Practice - Implementing Enterprise Vault On VMware (January 2012)Document31 pagesEV 10 Best Practice - Implementing Enterprise Vault On VMware (January 2012)TekkieNo ratings yet

- Understanding ZTPFDocument41 pagesUnderstanding ZTPFsanjivrmenonNo ratings yet

- IGCC-OPM-QUA-FMT-0095 Rev.0 - EARTHING SYSTEM INSTALLATION CHECKSHEETDocument1 pageIGCC-OPM-QUA-FMT-0095 Rev.0 - EARTHING SYSTEM INSTALLATION CHECKSHEETAhmedNo ratings yet

- Lecture-4: Data Communication and Computer NetworksDocument24 pagesLecture-4: Data Communication and Computer NetworksSaifuddin Mohammed TarekNo ratings yet

- 2015 Lanzar Web Optimized PDFDocument58 pages2015 Lanzar Web Optimized PDFrecursowebNo ratings yet

- Team Mate+AM+IT+Overview+12Document41 pagesTeam Mate+AM+IT+Overview+12epajueloNo ratings yet

- Kinematic Analysis of 5 Dof Lynx ArmDocument6 pagesKinematic Analysis of 5 Dof Lynx ArmsathyaNo ratings yet

- Parthiban Kanavu Part 3Document98 pagesParthiban Kanavu Part 3ambalvananNo ratings yet

- HIU Range Design GuideDocument24 pagesHIU Range Design Guidesachinsaklani23No ratings yet

- Final Exam Review Questions Funds of SecurityDocument65 pagesFinal Exam Review Questions Funds of Securityidk80% (5)

- On Phase ChangesDocument28 pagesOn Phase Changesapi-313517608No ratings yet

- AN3785 MAX3421E Programming Guide PDFDocument63 pagesAN3785 MAX3421E Programming Guide PDFtaccituaNo ratings yet