Professional Documents

Culture Documents

Paper 83 - Spe 117121-Pp Total Well Integrity - Column Format

Uploaded by

alizareiforoushOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paper 83 - Spe 117121-Pp Total Well Integrity - Column Format

Uploaded by

alizareiforoushCopyright:

Available Formats

SPE 117121-PP

The Total Control of Well Integrity Management

L. Smith, and D. Milanovic, Intetech Ltd.

Copyright 2008, Society of Petroleum Engineers

This paper was prepared for presentation at the 2008 Abu Dhabi International Petroleum

Exhibition and Conference held in Abu Dhabi, UAE, 36 November 2008.

This paper was selected for presentation by an SPE program committee following review

of information contained in an abstract submitted by the author(s). Contents of the paper

have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material does not necessarily reflect any position of the

Society of Petroleum Engineers, its officers, or members. Electronic reproduction,

distribution, or storage of any part of this paper without the written consent of the Society of

Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to an

abstract of not more than 300 words; illustrations may not be copied. The abstract must

contain conspicuous acknowledgment of SPE copyright.

Abstract

This paper describes a web-based program which provides

a comprehensive approach to well integrity management

covering all potential integrity threats to the whole well.

This cradle-to-grave software, the Intetech Well

Integrity Toolkit (iWIT), provides well information and

data analysis for timely, informed, decision-making. Using

its own or existing client databases, this software carries

out quantitative data analysis in real-time and provides

feedback to the operator about the condition of individual

wells and also overviews of the whole field integrity

status.

The iWIT software has been used in fields with less than

50 up to over 1600 wells. Installations have been made in

primary recovery fields to tertiary recovery fields, both

onshore and offshore. The software has been installed in

new and mature fields; some fields with no automation in

place and some which have been automated for over a

decade.

All the operators that have installed the software to date

have decided to expand its use, either to incorporate more

assets (e.g. the integrity management of the flowlines up to

the manifold) and/or to install the system throughout their

group operations internationally. Current installations

include two Gulf operators in Abu Dhabi and Qatar.

The management of well integrity is a vital element in the

successful, economic and safe operation of all assets. Data

relevant to well integrity is widespread, including the

safety critical elements test results; monitoring of annulus

pressures; evaluation of tubing and casing integrity;

inspection results from well logs; evaluation of scaling

risks etc. The management of, and continuous evaluation

of, this vast range of data presents a huge challenge. The

system described in this paper has met that challenge

comprehensively.

Introduction

The essential function of an oil and gas

producing/injecting

well

is

to

transport

hydrocarbons/fluids in a cost effective and safe manner.

The importance of well integrity total control has been

recognized and accepted as a key part of safe operations

for a long time. Significant improvements concerning both

well design and operating procedures have been made.

Nevertheless, the integrity of all well barrier components

is continuously threatened and requires great vigilance to

ensure continuous active control without the risk of

unintentional leakage of wells fluid to the environment.

A well has the potential to create hazardous events, and

hence well risk must be acceptable. The release of

inflammable/explosive fluids (hydrocarbons) to the

surroundings is by far the most significant risk factor.

The extended lifetime of wells, and recent regulations and

standards demand that there is a need for a systematic

control during the entire life cycle of a well. Typical

scenarios exist where, for different reasons, total control of

well integrity is paramount for the continued safe and

economic operation:

1. The field operation with a large number of

wells which is unmanageable for engineers to

track actual changes in individual well status,

identify developing problems and deal with

ongoing routine and non-routine monitoring.

2. The field operation with few wells, each well

with high productivity and critical supply

value, where any time lost to well barrier

failure implies high lost revenue cost.

3. The field operation with old assets, already

nearing or beyond the original design life. All

well barrier elements will have experienced

degradation:

corrosion

of

tubulars;

degradation of fluids; wear of seals. The

reduction in integrity of well barriers is a huge

challenge to estimate the impact on risk and to

safely continue operation.

SPE 117121-PP

4.

5.

6.

The field operation with limited annual

workover capability based on availability of

rigs. Each workover has to be carefully

prioritised to address the root cause of

significant well barrier integrity problems on

the most productive-critical wells. Pro-active

planning of activities is critical rather than

reacting to problems as they develop in order

to reduce uneconomic shut-in of valuable

wells.

New fields where best practice is to be

enshrined from start-up. Real-time tracking of

production conditions enables an established

safe-operating-envelope condition for the

wells to be actively maintained in an auditable

manner.

Challenging fields with high pressure, or sour

products, or in highly environmentally

sensitive areas, where a breach of well

integrity leading to leakage of wells fluid to

the environment is not tolerable.

different aspects of well integrity within a company

structure. The impact of introducing new software also has

an impact upon these roles and responsibilities.

The first step we make with an operator is to study their

WIMS or (where there is no WIMS documentation) assist

in defining the key elements needed to monitor and control

the specific threats experienced under their unique

conditions. We also investigate who is responsible for all

the separate data which the well integrity engineer needs

to pull into the integrated data system and how they are

currently working. The challenge we find is that not only

has each operator had a different well integrity emphasis,

but even individual fields within one operators control

may need a special aspect to be dealt with in a different

way. As a consequence, our software allows the

customisation of test acceptance criteria and the safe

operating envelope to be made on a per field basis; and for

some parameters, per well type or per well.

Meeting the Well Integrity Challenges

Our experience indicates that almost all operations have a

lot to gain from implementing an active control system for

well integrity. Whilst well integrity management system

documentation provides the framework for decisionmaking and the organisational structure, total control of

well integrity requires a system to be implemented with a

sophisticated datahandling, analysis and communication

capability. Such a system, the Intetech Well Integrity

Toolkit (iWIT), has been in operation since 2006 with

various operators internationally and is especially

developed to meet the enormous challenge of providing

total well integrity control. This paper discusses some of

the challenges and some learning steps from a number of

case histories.

Meeting the WIMS Challenges

Increasingly, managers are demanding to see evidence of

the active management of their assets. Most operators have

established an Asset Integrity Management programme,

but many of these are focussed on visible surface assets.

More rarely, operators have a Well Integrity Management

System, WIMS, at least as a documented set of principles.

Typically a WIMS document outlines the underlying

company philosophy associated with well integrity

management, defines roles and responsibilities, defines the

safe operating envelope for all well barrier components

and puts in place the controls regarding the requirements

for monitoring frequency and data collection.

Whilst a WIMS document provides the essential

framework, it is only when the words on the page are

translated into an active day-to-day system of well

integrity management that its goal can be achieved. This is

where the use of software becomes the essential vehicle of

the WIMS implementation. One element of a WIMS

document is a description of roles and responsibilities for

The range of well integrity problems experienced

internationally is widespread and different issues are more

prevalent in different parts of the world. The most

frequently reported well integrity problems are:

o

o

o

o

o

o

o

Sustained annulus pressure,

Completion string leaks,

Wear/corrosion/erosion within the completion

string,

Casing corrosion,

Scaling,

Wellhead movement,

Xmas tree and wellhead safety critical element

(SCE) leaks.

Individual operators may be fortunate to face only some of

these problems, but for many operators the range of

problems to be managed is very widespread, either across

the whole field of wells, or within individual wells. Any

one of these issues is governed by many parameters: well

design, well construction practice and the daily changes in

operating conditions.

Hydrocarbon producing reservoirs contain acid gases

(carbon dioxide and hydrogen sulfide) and high salinity

formation water that are generally associated with

increasing the severity of tubular material degradation. A

great strength of the software, and a valuable feature for

operations, is its capability to evaluate quantitatively the

material degradation (corrosion & erosion) threats to the

well integrity. The corrosion model used has been fieldproven for over 10 years and is individually calibrated to

match each oilfield. The tubular material degradation

model takes into account the mass transport of the

corrosive species to the surface and therefore has a flow

dependency on the corrosion rate. This is a significant

influence on the calculated corrosion rates compared to

SPE 117121-PP

models which do not take flow effects into account. A

sand erosion model, is also incorporated and safe

operating envelopes for 13Cr and other alloy tubing. The

output gives, on a per well basis, the wall thickness loss of

individual well tubulars and a cross-field review of the

installed tubing identifying the percentage of wells having

wall thickness loss in various fractions, indicating the

future workover demand.

Annulus pressure records integrate automated readings

with manually entered data giving a total overview in

tabulated and graphical format. The data is automatically

trended and communication of adjacent annuli is

identified. Thermally imposed and sustained annulus

pressure (SAP) cases are distinguished. All pressures are

monitored relative to individual maximum allowed

annulus surface pressure (MAASP) values per annulus and

per well, derating with time dependent on well component

degradation and operating conditions (Fig.1). This allows

the field to be operated safely but with minimum annuli

bleed-off frequency. The transport of fluids within the

annulus may result in accelerated corrosion of the casing

strings and the resulting wall thickness loss impacts the

load carrying capability of the tubulars. Reducing bleedoff frequency reduces the risks of annulus degradation

resulting from replenishment of an aggressive annulus

fluid.

No well that exhibits sustained annulus pressure is

operated without problems. Managing operating risk

means not letting small annulus integrity problems become

big ones. What is often overlooked is the interaction of all

the potential problems. Yet, it is often the case that when a

well problem is investigated there are several factors

which have contributed. It is really critical to take a

holistic view to avoid overlooking combinations of

problems which together can present a major threat.

Integration of the tubular degradation model with the

annulus pressure management, wellhead movement and

SCE leak testing provides a uniquely powerful insight into

the possible root causes of one of the most critical well

integrity challenges.

Proactive well integrity management is the route to the

maintenance of well integrity while maximizing field

production. The methodology adopted here has proven to

be an effective tool for well barrier control and well

integrity management.

Introducing a new database system first requires an

evaluation of what already exists. In a typical long

established operation, collection of well design data in

various forms may be already established. Database

systems may already exist for certain classes of data.

Many operators have an established drilling information

system which will normally contain some details of the

casing design, the well deviation profile, the mud and

cementing program and possibly well handover

documentation with the completion diagram etc. Other

operators keep some or all of this information stored in a

document folder system where the usual filing of data is

by subject such as completion diagram, deviation

survey, within which all wells will be found. The data

retrieval concept therefore demands that if information is

sought for a particular well, several folders have to be

opened to pull together data for one well.

In a more logical set-up, all the critical well design data is

accessible logically organized by well. This gives

immediate access to the necessary information without

having to address various independent data sources or

open multiple folders. By properly configuring the system,

links can be made between different data sources and

document repositories so that data which is spread around

an existing data system, too long established and widely

utilized to be replaced, can be accessed seamlessly.

Similarly, the operational data collected in the context of

well integrity has often been captured in a variety of data

systems, ranging from the engineers favourite,

spreadsheets, to large multi-user relational databases. The

variety of situations encountered is very wide. One

operator already had over 20 years of production

information sitting in a dumb database with a typically

unfriendly outdated user-interface which kept the data

largely inaccessible. By interfacing to the well integrity

software on the front end the engineers now get access to

the true value of this substantial data resource. Other

operators have interfaced as many as five databases,

physically located in different offices, to the well integrity

system. This provides the capability to integrate multiple

data sources which to date could never talk to each other.

On the contrary, one operator had no pre-existing initial

data other than a folder system of document and

spreadsheets files and so a purpose built database was put

together for them with complete well design data for 300+

wells pulled from original records etc. and then interfacing

to their SCADA data source for the up to date real-time

operational data.

Meeting the System Challenges

Considering the cost of data collection, maximizing use of

the information is a key part of oilfield cost-efficiency.

The use of a web-based system makes the information

fully available to all persons able to access the company

intranet. Control of user rights ensures that access to the

system is correctly controlled.

Certain well integrity data is of quite specialist interest and

is frequently collected in a personal spreadsheet with all of

the lack of security which is associated:

- tendency for data entry errors such as typos or

autofill and copied mistakes;

- problem of version control as files get updated

and overwritten;

- problem of multiple versions as copies of files get

made and shared around groups of engineers;

SPE 117121-PP

easily lost data which is not formally backed up;

no continuity of system when engineers change

jobs.

By comparison, with formal data entry error trapping,

checks and approval of input data and automated data

format and back-up, the well integrity software enshrines

best data practice. Essentially, well integrity has to be built

on data integrity and system integrity, so easily

configurable controls are needed at every step.

The key message is to have a high level of flexibility to

allow the software to be configured to compliment the

existing operator strengths and to introduce better practice

where possible. Several operators have taken the

opportunity of implementing the new well integrity

approach to carry out an audit of their existing data

systems and decide which ones are obsolete and should be

replaced, and which ones are necessary to maintain.

Meeting the Task Management Challenges

International guidelines, national regulations and

individual company Well Integrity Management Systems

documentation will all provide guidance on the

requirements for well component testing. The wideranging diagnostic well integrity activities can include:

DIAGNOSTIC WELL

INTEGRITY ACTIVITIES

(examples)

Routine annulus pressure

monitoring.

Annulus pressure bleed-off

/build-up test.

Mechanical integrity test of

well barrier.

Routine valve functioning

and seal pressure testing of

wellhead and Xmas tree

components.

Routine SSSV testing.

Production and annulus

fluid sampling.

Scale sampling.

Tubing caliper logging.

Casing logging.

Corrosion coupon

monitoring.

ACTIVITY

FREQUENCY

(example)

Typically daily,

sometimes less

frequently.

Periodically, in

accordance with

the operators

annulus

management

policy.

Pre-rig testing,

leak evaluation,

underground

injection control

(UIC) testing,

Typically annually

or biannually.

Typically annually

or biannually.

Periodically.

Periodically

Periodically

Periodically

Biannually.

Microbial analysis.

Casing cathodic protection

potential.

Remote operated vehicle

survey.

Corrosion/scale inhibition

treatment.

Wellhead movement

monitoring.

Tracking of safety critical

element component changeout.

Tracking of other wellwork

activities.

Periodically

Annual.

Typically three

yearly.

Continuous/

periodically

Typically daily,

sometimes less

frequently.

Periodically

Periodically

The requirement for, frequency of, and acceptance criteria

for different diagnostic well integrity activities can be

dependent upon well type, well age and well location. The

result is a vast matrix of daily and periodical tasks which

can be managed down to an individual well-level with the

individual test results being checked against each wells

own safe-operating-envelope and unique acceptance

criteria.

The software needs to identify what work is required to be

done on any day; giving warning of upcoming work

demand and identifying tasks which are overdue. This

broad task-scheduling capability ensures that no critical

well barrier component inspections get overlooked and so

there is no risk that a required monitoring check is

forgotten. There is a capability also to ask for a reminder

of an upcoming ad hoc task with the email warning of that

task being sent to the responsible party. All these aspects

are critical to bring to life a planned well integrity

management approach as defined in a typical company

WIMS document, particularly in fields with large numbers

of wells.

Meeting The Data Communication Challenges

A key challenge of management is being able to monitor

in detail whilst not losing sight of the high-level overview.

Well integrity data is gathered with a per-well focus, with

immediate access to all the relevant well design

information. However, the bigger picture is how the

integrity status of the whole field of wells is changing on a

continuous basis as data is entered into the system. This

can really provide improved business efficiency by

gathering together key information from each well across

the field and presenting it in a way which helps to identify

possible integrity improvement steps.

One North Seabased well integrity engineer was faced

with a new set of Xmas tree pressure test results which

was indicating a leak. He was sure that the problem was

not isolated, but to investigate that question required

manually sifting through a lever-arch file of previous

SPE 117121-PP

sheets of test results. Once the new system was in place he

could not only review historical test data for an individual

well, but could retrieve form the software a reliability

report for all tested safety critical components for every

well across the whole field. This allowed rapid

identification of individual wells with consistent leaks,

specific components which were consistently failing and

requiring maintenance or replacement, and comparative

reliability performance of SCE from different

manufacturers.

The field manager has little time to devote to detailed well

integrity concerns, but they still have the ultimate

responsibility for the safety of their staff working within

company installations and for the protection of the

surrounding environment. Having this software in place

provides a map of the field with the well locations colour

coded according to their overall well integrity status

(Fig.2). It is easy and quick to identify problem wells and

seeing them located within the field helps to establish the

potential risk that they may pose. Similarly, a field status

overview shows in a single table how many wells of

different types are in operation or closed-in or other

company-defined well status codes. It tells the manager

how available his well-stock is and of the available wells,

what their integrity status is (Fig.3). This particular report

was considered to be the critical daily summary required

by one field manager of a giant onshore field in

Kazakhstan.

One major North American operator with more than 1000

wells wished to make forward planning of workover

requirements for future years not just based on historical

demand, but also taking into account the gradual transition

of tubing from L80 to 13Cr in his producers over time.

The software provided a complete statistical breakdown of

tubing metallurgy by well type and well location in the

field, with an estimated failure date of the remaining life

of the L80 tubing to assist in the estimation of future

failure rate.

incorporated within the normal work flow. Staff who have

previously carried out data-entry into a spreadsheet may

need support to adapt to the new concept of entering data

into a dedicated software package with a new user

interface. This is a classic Management of Change step

where the managers have to ensure there is a combination

of support and training to staff regarding the new system,

but also a demand that the new method of working is

adopted because of the added benefits it brings.

Streamlining data collection often means that data entry

into the system is distributed widely across many people

and is carried out primarily by those who collect the data.

Contracts to 3rd party service companies may need

adjusting to incorporate their role in data entry of test

results. In a North Sea example, the service company

carrying out routine well pressure tests and maintenance

was obliged to enter their test results into the well integrity

software whilst offshore before departing the installation.

They quickly realized the benefits in that results were

immediately visible onshore, meaning that follow-up

actions and additional test work could be immediately

authorized whilst the correct staff were still available. The

offshore installation manager requested a particular report

format to summarise test status of all his wells which

allowed him to keep up to date with regulatory required

testing and to have a clear audit trail of proven test work,

completely up to date at all times. With his enthusiastic

support increasing amounts of well activity work and test

results were entered into the system, greatly increasing the

visibility of well integrity controls both on- and offshore.

Meeting The Working Method Challenges

One on-land operator has to cope with the inspection and

monitoring of wells spread over wide distances, with some

operators travelling for several hours to reach the most

remote locations. Daily monitoring data has been slow to

be assessed in the past, waiting for the drivers to return to

the office. The implementation of the iWIT Notepad

system for remote data entry in the field has transformed

this situation. The handheld device recognizes the well

number through a GPS system and automatically asks for

the data to be entered relevant to that well location. Data,

once entered, is then automatically downloaded through a

variety of communication channels as they become

available on the journey through the field. Operators have

adopted the new system with enthusiasm. It reduces their

time back in the office for transferring results into a

computer system and they feel they are positively

contributing to the improved working system. The field

manager stated that the whole system was a great support

to improved efficiency of the business.

The success of the total control of well integrity software

implementation depends upon the enthusiasm with which

it is accepted in the company and this almost always

requires some adjustment in the method of working.

Success is driven from the top: where the management

team acknowledges the reporting and management control

benefits of the new software and supports staff training in

the new approach, the software gets most readily

In some cases individuals may feel defensive about

maintaining their personal spreadsheet or even concerned

that the report which used to take half a day a week to

produce is now available at the press of a button.

Understanding the human impact of new working

practices is vital if the system is to be a success. Freeing

staff time from some tedious data recording and report

preparation is very successful where they feel they have

Many of these reports have been specifically developed to

respond to the particular reporting demands of the

individual operator, whereas others pull together best

practice from our deployments. Communication of the

results of multiple well integrity evaluations in a succinct

way makes well integrity issues much more visible to

senior management which ensures better support for the

workover budget related to well integrity work.

gained time to devote to more valuable and interesting

activities such as problem-well diagnosis or workover

planning.

Value-Added Benefits Of Well Integrity Total

Control

The fundamental benefit of adopting the total control of

well integrity is to bring forward all the analysis of well

barrier failing tendency into a pro-active stage, before the

critical failure arises. This reduces the frequency of well

failures resuling in shut-in for long or short term, and

hence productivity is increased. Furthermore, workover

planning, a key cost element in a time of limited rig

resources, is greatly improved. Every operator who has

implemented the software for the total control of well

intregity has initially been shocked at the widespread

range of problems that are identified. Fortunately this has

led to various focused campaigns to address the issues and

after a year in operation, the overall well integrity status

has been significantly improved with far fewer warning

lights. One North Seal Well Integrity Manager explained

I could never get the budget approval for replacing the

faulty items identified by the software, but when it was

clear how significant and widespread the problem was the

money was made available and weve got the problem

fixed.

The overwhelming value of the software system identified

by one operating company was Protecting Baseline

Production through proper attention to all required well

integrity checks and maintenance. There are spin-off

benefits in other parameters which can be monitored. For

example, one of the features developed for one client is the

live monitoring of the wellhead (tubing head) pressure;

maintaining it between pre-set values, which are different

for each well, to optimize production in a giant onshore

field, originally developed without any on-site automation.

If the THP goes out of the target range, a clear visible

warning is given. One of the data-views is a live

continuous output of pressure readings per well. Wells

with pressure outside the allowed pressure range are

quickly highlighted for correction of the problem as soon

as it is noted. The operations department keep this critical

data-view continuously set-up on a large video display

screen on the wall so that problems are instantly noted by

the workers in the office. The previous system used a

spreadsheet collection of data which was compared at the

end of the day with the allowed THP ranges and then the

morning meeting heard about yesterdays bad players to

be checked up and corrected, after possible a full day of

low production. As a consequence of the introduction of

the new system production is now continuously closer to

target rates, with obvious financial benefits.

One operator has been using the software at two of their

operations for more than 2 years. Their feedback indicates

that they are required by regulators to be able to show

SPE 117121-PP

actively that their wells are fit-for-purpose. Use of the

dedicated software has provided them with a high level of

Visibility of Well Integrity, both within the company

and with their external well examiners and government

regulators. The comprehensive nature of the integrity

assessments has bee significantly raised the confidence of

the external authorities. At one key meeting the operator

was challenged to provide proof that they were in control

of the condition of the production tubing in the field.

Within seconds they were able to generate a report

summarizing all the caliper survey resuts for every well

over time and show the cumulative wall thickness loss

related to their production conditions.

Whilst the cost benefit of using the well integrity total

control approach are primarily felt in the operational

budgets, the benefit of more efficient use of personnel is

enormous too. Engineers are pleased to be relieved of

tedious data gathering and report preparation tasks, freeing

their time for the more in-depth evaluation of solutions to

identified well barrier breaches and detailed risk analysis.

A shift from the fire-fighting mode to planning greatly

reduces stress and improves work quality for all. In a time

of skill shortage, optimum use of skilled personnel is

critical to business success.

Conclusions

Response measures to avoid unintentional environmental

leakage of wells fluid require an awareness that well

barrier elements have failing tendency. The industry can

respond to the events when a well is suffering sustained

annulus pressure and prevent the increase in operational

risk from becoming more widespread across the field.

Total control of well integrity is an essential part of

achieving long term security of production, cost-effective

operation and a zero-leak goal. There are many challenges

to be faced:

The framework of the basic company

philosophy and well integrity aims needs to be

established.

The full range of well integrity threats has to

be understood and the safe operating envelope

for each threat has to be derived.

The existing data systems needs to be analysed

to make optimum use of everything which is

good, and replace the parts that are becoming

obsolete.

The scheduling of all the well integrity

monitoring activities and tests has to be

matched to the requirements, regulations and

resources.

The reporting requirements have to be

designed to optimise the communication of the

threats to the right personnel in the most

succinct way.

SPE 117121-PP

The management of the change in working

practice

and

individuals

roles

and

responsibilities requires support.

The operator must minimize the unintentional

environmental leakage risk of wells fluid by effective

control of well barrier elements status when in operation

and take necessary actions to avoid unacceptable risk.

Data relevant to well barrier elements control is

widespread, including the results of mechanical integrity

tests to safety critical elements; monitoring of elevated

annulus pressures; evaluation of tubing and casing actual

resistance to fluid containment; inspection results from

well logs; evaluation of scaling risks etc. The management

of, and continuous evaluation of, this vast range of data

presents a huge challenge. The system described in this

paper has met that challenge comprehensively.

Author Biographies

Liane Smith, Director of Intetech Ltd, formed the

company in 1991 after 10 years working for the Shell

Group of Companies in the UK and Netherlands. She has

been involved with solving well integrity problems,

modelling field corrosion in downhole tubing and

selecting materials for production tubing throughout her

career. She has a degree in metallurgy and materials

science from Cambridge University and a PhD in welding

from Sheffield University. She can be contacted at

liane@intetech.com.

Dragan Milanovic, Head of Well Integrity in Intetech Ltd.,

has over 28 years of oil industry experience as a drilling

manager, well designer (HPHT sour service), well control

specialist, fisherman, engineer, consultant and well

integrity expert. He has worked in Middle East, Caspian,

Far East, Europe, Caribbean and North America countries

including all the oil producing regions. He is the author of

numerous technical reports. He is now Head of Well

Integrity in Intetech Wells Ltd. Since 1992 he has been

working internationally, joining Intetech Ltd in 2003. He

has Master in petroleum engineering from the University

of Belgrade. He can be contacted at dragan@intetech.com.

SPE 117121-PP

Figure 1 Example annulus pressure monitoring graphs showing (red line) the annuli MAASP values derated with time.

Figure 2 Example views of offshore and onshore field maps with individual well status distinguished by traffic light colour

coding. Clicking on any well links directly to the individual well data.

SPE 117121-PP

Figure 3 Example well status overview report indicating the numbers of types of wells and their status on the requested date.

Separate columns identify the reservoir the well is producing from or injecting into and colour coding conveys the well

integrity status. Clicking on any well links directly to the individual well data.

You might also like

- JT - IPTC 13405. Well Integrity Management Systems, Achievements Vs ExpectationsDocument10 pagesJT - IPTC 13405. Well Integrity Management Systems, Achievements Vs ExpectationsjuantellezcoNo ratings yet

- ED Offshore Inspection Guide: Well Integrity (Operate Phase)Document46 pagesED Offshore Inspection Guide: Well Integrity (Operate Phase)IgorCencičNo ratings yet

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeFrom EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeRating: 4 out of 5 stars4/5 (2)

- Recommend Frequency of Well Integrity MonitoringDocument1 pageRecommend Frequency of Well Integrity MonitoringalizareiforoushNo ratings yet

- Well Integrity Analysis Applied To WorkoDocument8 pagesWell Integrity Analysis Applied To WorkoAdolfo AnguloNo ratings yet

- Chemical Sand Consolidation Trials (Shell)Document33 pagesChemical Sand Consolidation Trials (Shell)Nur Syaffiqa Mohamad RuzlanNo ratings yet

- Well Integrity ManagementDocument5 pagesWell Integrity ManagementSteve Ukoha100% (1)

- Riserless Drilling AppendixDocument2 pagesRiserless Drilling AppendixDr K GallowglaichNo ratings yet

- D-002 System Requirements Well Intervention EquipmentDocument70 pagesD-002 System Requirements Well Intervention Equipmentbrucce13No ratings yet

- Well Integrity Test ProgrammeDocument5 pagesWell Integrity Test ProgrammeDianna Ariza RNo ratings yet

- Completion Equipment Reliability Database Well Master SPE63112-PaperDocument7 pagesCompletion Equipment Reliability Database Well Master SPE63112-PapervjourNo ratings yet

- Underbalance CompletionsDocument7 pagesUnderbalance CompletionsNgo Van HieuNo ratings yet

- New Criterion for Jetting/Conductor DesignDocument35 pagesNew Criterion for Jetting/Conductor DesignAhmed Hassan100% (1)

- Well Intervention PDFDocument8 pagesWell Intervention PDFSneha HasithaNo ratings yet

- SPE-142449-MS - The Seven Pillars of Well Integrity ManagementDocument16 pagesSPE-142449-MS - The Seven Pillars of Well Integrity ManagementIsaias Castro ArmendarizNo ratings yet

- Angsi K StoneDocument9 pagesAngsi K StonerishitharanNo ratings yet

- SPE 101727 Reliable and Effective Downhole Cleaning System For Debris and Junk RemovalDocument9 pagesSPE 101727 Reliable and Effective Downhole Cleaning System For Debris and Junk RemovalCoolProphetNo ratings yet

- SPE-193424-MS Chevron 2018Document17 pagesSPE-193424-MS Chevron 2018LawNo ratings yet

- Introduction Well Integrity 2013Document21 pagesIntroduction Well Integrity 2013ClOudyo VirgílioNo ratings yet

- King - Barrier Failure and Well Integrity PDFDocument23 pagesKing - Barrier Failure and Well Integrity PDFNarváez VíctorNo ratings yet

- RIG ACCEPTANCE CHECKLIST PRIOR TO SPUDDocument2 pagesRIG ACCEPTANCE CHECKLIST PRIOR TO SPUDAhmedNo ratings yet

- Otc 15179 MSDocument10 pagesOtc 15179 MSHafiz AsyrafNo ratings yet

- WSL - Standing Orders - 7dec 2015 - 4924177 - 01 PDFDocument48 pagesWSL - Standing Orders - 7dec 2015 - 4924177 - 01 PDFKanutze SoarrNo ratings yet

- SPE 88525 Hybrid Monobore Completion Design: An Application For Multilayer ReservoirDocument6 pagesSPE 88525 Hybrid Monobore Completion Design: An Application For Multilayer ReservoirAhmadFauziNo ratings yet

- Dynamic Kill by Ravndal, Maiken PDFDocument130 pagesDynamic Kill by Ravndal, Maiken PDFIsendorf816100% (1)

- DC Sept08 DeepwaterCementingDocument6 pagesDC Sept08 DeepwaterCementinganon_634030219No ratings yet

- SPE Simplified Series Cherie Henshaw and Bill Latham Premier Oils Well Integrity Journey Leveraging Software To Manage Well Integrity 1Document24 pagesSPE Simplified Series Cherie Henshaw and Bill Latham Premier Oils Well Integrity Journey Leveraging Software To Manage Well Integrity 1Ghahremani SoheilNo ratings yet

- Pressurised Mud Cap Drilling Paper (Spe-125311-By Dany)Document7 pagesPressurised Mud Cap Drilling Paper (Spe-125311-By Dany)Hammad KhalidNo ratings yet

- Realistic Well Planning With Dynamic Well Control ModellingDocument7 pagesRealistic Well Planning With Dynamic Well Control ModellingAoun MuhammadNo ratings yet

- SPE 88736 Expandable Tubular Completions For Carbonate ReservoirsDocument5 pagesSPE 88736 Expandable Tubular Completions For Carbonate ReservoirsmsmsoftNo ratings yet

- SPE - Management of Well Integrity During Production OperationsDocument6 pagesSPE - Management of Well Integrity During Production OperationsdrexalvesNo ratings yet

- Completion ComponentsDocument28 pagesCompletion ComponentsnabiNo ratings yet

- IWCF Well Intervention Pressure Control Level 3 and 4 Cross Reference FormDocument82 pagesIWCF Well Intervention Pressure Control Level 3 and 4 Cross Reference FormairlinemembershipNo ratings yet

- Preventive Maintenance Records AB Field WellsDocument1 pagePreventive Maintenance Records AB Field Wellseng7mohamed7hashimNo ratings yet

- (Open Physics) Analysis of Impact Load On Tubing and Shock Absorption During PerforatingDocument8 pages(Open Physics) Analysis of Impact Load On Tubing and Shock Absorption During Perforatingjlbarretoa100% (1)

- Well Integrity AssessmentDocument2 pagesWell Integrity AssessmentAnubhuti Purohit BhatnagarNo ratings yet

- S2 2015 336441 Chapter1Document15 pagesS2 2015 336441 Chapter1arispriyatmonoNo ratings yet

- Good PDFDocument10 pagesGood PDFaliNo ratings yet

- InFlow Control Devices and Valves Optimize Troll Field ProductionDocument12 pagesInFlow Control Devices and Valves Optimize Troll Field Productionfazeel86100% (1)

- OTC 15191 Case History of A 5 Zone Multi-Drop Hydraulic Control Intelligent Offshore Completion in BruneiDocument7 pagesOTC 15191 Case History of A 5 Zone Multi-Drop Hydraulic Control Intelligent Offshore Completion in BruneihuongvieteventNo ratings yet

- Types of Well Completion: 1. Open Hole CompletionsDocument6 pagesTypes of Well Completion: 1. Open Hole CompletionsHidayatHandariantoNo ratings yet

- Completation Inteligent RevistaDocument9 pagesCompletation Inteligent RevistaGabriel Castellon HinojosaNo ratings yet

- OMV Contingency Relief Well Planning PDFDocument10 pagesOMV Contingency Relief Well Planning PDFmsm.ele2009No ratings yet

- Cwor-Brochure WebDocument8 pagesCwor-Brochure WebMartin McCaffreyNo ratings yet

- API 14A UpdateDocument13 pagesAPI 14A UpdateAnonymous 70lCzDJv100% (1)

- Deep Water Drilling Fluid Design ExampleDocument65 pagesDeep Water Drilling Fluid Design Examplecrown212No ratings yet

- Well StoryDocument7 pagesWell Storyrslisbon100% (1)

- SPE IADC 119746 Automated Drilling Performance MeasDocument14 pagesSPE IADC 119746 Automated Drilling Performance MeasBarrett BoucherNo ratings yet

- Completions OverviewDocument13 pagesCompletions OverviewsidharththerrothNo ratings yet

- Monitoring & Reporting Monitoring & Reporting Monitoring & Reporting Monitoring & Reporting Systems Systems Systems SystemsDocument180 pagesMonitoring & Reporting Monitoring & Reporting Monitoring & Reporting Monitoring & Reporting Systems Systems Systems SystemsVenus DobosNo ratings yet

- Spe 112869 MSDocument24 pagesSpe 112869 MSMike RossNo ratings yet

- King - DOE Well Integrity - Basics, Prevention, Monitoring, Red Flags and Repair Options 21 Nov 2014 v3Document27 pagesKing - DOE Well Integrity - Basics, Prevention, Monitoring, Red Flags and Repair Options 21 Nov 2014 v3Luis Eduardo Segura100% (1)

- Chief Counsel's Report on Blowout Preventer Failures in Deepwater Horizon IncidentDocument18 pagesChief Counsel's Report on Blowout Preventer Failures in Deepwater Horizon IncidentJorge Luis100% (1)

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- GP 10 10 11 June 2008 Well Control PRT 2Document22 pagesGP 10 10 11 June 2008 Well Control PRT 2alizareiforoushNo ratings yet

- GP 10 10 11 June 2008 Well Control PRT 1Document23 pagesGP 10 10 11 June 2008 Well Control PRT 1alizareiforoushNo ratings yet

- GP 10-20 26 August 2008 222Document41 pagesGP 10-20 26 August 2008 222alizareiforoushNo ratings yet

- GP 10-15 9 July 2008Document19 pagesGP 10-15 9 July 2008alizareiforoushNo ratings yet

- Moving and Securing of Mobile Offshore Drilling Units: Group PracticeDocument17 pagesMoving and Securing of Mobile Offshore Drilling Units: Group PracticealizareiforoushNo ratings yet

- Casing Design PreliminaryDocument29 pagesCasing Design Preliminaryalizareiforoush100% (2)

- GP 10-50 11 June 2008 Drilling EquipDocument26 pagesGP 10-50 11 June 2008 Drilling EquipalizareiforoushNo ratings yet

- Simultaneous Operations: Group PracticeDocument11 pagesSimultaneous Operations: Group PracticealizareiforoushNo ratings yet

- Drilling Rig Audits and Rig Acceptance: Group PracticeDocument14 pagesDrilling Rig Audits and Rig Acceptance: Group PracticealizareiforoushNo ratings yet

- GP 10 80 11 June 2008Document29 pagesGP 10 80 11 June 2008Yasmine ياسمينNo ratings yet

- GP 10-16 9 July 2008Document17 pagesGP 10-16 9 July 2008alizareiforoushNo ratings yet

- GP 10-20 26 August 2008Document41 pagesGP 10-20 26 August 2008alizareiforoushNo ratings yet

- Python Programming Tutorial for BeginnersDocument68 pagesPython Programming Tutorial for BeginnersFiktoriusKevinNo ratings yet

- Completion-Workover Riser Systems: Group PracticeDocument13 pagesCompletion-Workover Riser Systems: Group PracticealizareiforoushNo ratings yet

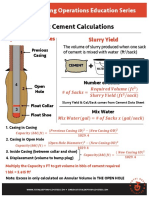

- Basic Cement CalculationsDocument1 pageBasic Cement Calculationsابوالحروف العربي ابوالحروفNo ratings yet

- An Expert System For Casing String Design SPE 20328 1990Document8 pagesAn Expert System For Casing String Design SPE 20328 1990alizareiforoushNo ratings yet

- Guidelines For Step Rate TestingDocument18 pagesGuidelines For Step Rate TestingweldsvNo ratings yet

- Secondary Well Control - Well Control EquipmentDocument43 pagesSecondary Well Control - Well Control EquipmentalizareiforoushNo ratings yet

- How To Improve Poor System Efficiencies of ESP Installations Controlled by Surface ChokesDocument9 pagesHow To Improve Poor System Efficiencies of ESP Installations Controlled by Surface ChokesjoreliNo ratings yet

- SLB Enhanced Dominator Motor - Product BulletinDocument15 pagesSLB Enhanced Dominator Motor - Product BulletinalizareiforoushNo ratings yet

- Well Integrity Management System - Leak Rate CriteriaDocument1 pageWell Integrity Management System - Leak Rate CriteriaalizareiforoushNo ratings yet

- Evaluate Gas Condensate Blockage with Reservoir Simulation and Lab ExperimentsDocument5 pagesEvaluate Gas Condensate Blockage with Reservoir Simulation and Lab ExperimentsMod Hah GhasdcNo ratings yet

- Coiled Tubing Running SpeedsDocument1 pageCoiled Tubing Running SpeedsalizareiforoushNo ratings yet

- Determination of Optimum N2 Rate For Unloading Gas Wells With Coiled Tubing 2011Document12 pagesDetermination of Optimum N2 Rate For Unloading Gas Wells With Coiled Tubing 2011alizareiforoushNo ratings yet

- 14A - E12 PADocument4 pages14A - E12 PAbeyNo ratings yet

- TWPCEDocument1 pageTWPCEalizareiforoushNo ratings yet

- Insulation Resistance Monitoring Prevents ESP Failure - 1Document1 pageInsulation Resistance Monitoring Prevents ESP Failure - 1alizareiforoushNo ratings yet

- Insulation Resistance Monitoring Prevents ESP FailureDocument1 pageInsulation Resistance Monitoring Prevents ESP FailurealizareiforoushNo ratings yet

- TWPCEDocument1 pageTWPCEalizareiforoushNo ratings yet

- 14A - E12 PADocument4 pages14A - E12 PAbeyNo ratings yet

- BFT 40503 A T E: Ntersection OntrolDocument12 pagesBFT 40503 A T E: Ntersection OntrolghajiniiNo ratings yet

- DirectX 11 Practical ProjectsDocument64 pagesDirectX 11 Practical Projectszubair ansariNo ratings yet

- Fico Exam GuideDocument2 pagesFico Exam GuideDANIELNo ratings yet

- Klasifikasi Material: Myrna Ariati Wahyuaji Narottama PutraDocument49 pagesKlasifikasi Material: Myrna Ariati Wahyuaji Narottama Putrachink07No ratings yet

- Manual de Partes y Operación de Trituradora Vsi Canica Modelo 65Document105 pagesManual de Partes y Operación de Trituradora Vsi Canica Modelo 65Jose AlfaroNo ratings yet

- Ansys Fluent 14.0: Workbench GuideDocument86 pagesAnsys Fluent 14.0: Workbench GuideAoife FitzgeraldNo ratings yet

- Environmental Tech.Document31 pagesEnvironmental Tech.csyena28225No ratings yet

- Partition WallDocument24 pagesPartition WallSHRADDHA GHUGENo ratings yet

- Regional Contest Package in EIM NC IIDocument3 pagesRegional Contest Package in EIM NC IIAlNo ratings yet

- EE105 - Fall 2015 Microelectronic Devices and Circuits: Prof. Ming C. Wu Wu@eecs - Berkeley.edu 511 Sutardja Dai Hall (SDH)Document5 pagesEE105 - Fall 2015 Microelectronic Devices and Circuits: Prof. Ming C. Wu Wu@eecs - Berkeley.edu 511 Sutardja Dai Hall (SDH)Kulanthaivelu RamaswamyNo ratings yet

- XPol Panel 806–960 65° 0°–14°TDocument3 pagesXPol Panel 806–960 65° 0°–14°TkenansabNo ratings yet

- Tender Evaluation FormDocument1 pageTender Evaluation FormbkimaxNo ratings yet

- Osciloscopio 1006Document74 pagesOsciloscopio 1006ERNESTO BRAVONo ratings yet

- Carbon Dioxide in RespirationDocument1 pageCarbon Dioxide in Respirationlolay01No ratings yet

- Hdpe Alathon H5520 EquistarDocument2 pagesHdpe Alathon H5520 EquistarEric Mahonri PereidaNo ratings yet

- PBM and PBZ Crown Techniques ComparedDocument6 pagesPBM and PBZ Crown Techniques ComparedDonanguyenNo ratings yet

- Military Standard for Circular Connector Insert ArrangementsDocument59 pagesMilitary Standard for Circular Connector Insert ArrangementsVadim RiabovNo ratings yet

- 2SC1344, 2SC1345: Silicon NPN EpitaxialDocument9 pages2SC1344, 2SC1345: Silicon NPN EpitaxialrolandseNo ratings yet

- CS5001 CourseworkDocument9 pagesCS5001 CourseworkpeteligijusNo ratings yet

- PE Electromagnetic Pump Unit PE GB T1101 01-02-182Document4 pagesPE Electromagnetic Pump Unit PE GB T1101 01-02-182li geneNo ratings yet

- Cava v6 1x Install enDocument29 pagesCava v6 1x Install enWael SalahNo ratings yet

- CST Design Studio - WorkflowDocument102 pagesCST Design Studio - WorkflowHeber Bustos100% (7)

- BPC BW HierarchyDocument8 pagesBPC BW HierarchyJulio RafaelNo ratings yet

- Demo-C Tfin52 67Document5 pagesDemo-C Tfin52 67namank005No ratings yet

- Engineering Data Sheet: 49187073 E 1145842 1 of 1 October 21, 2016 60HzDocument1 pageEngineering Data Sheet: 49187073 E 1145842 1 of 1 October 21, 2016 60HzGustavo VillarrealNo ratings yet

- Room Air Conditioner Owner's Manual GuideDocument19 pagesRoom Air Conditioner Owner's Manual GuideMunteanu LucianNo ratings yet

- Robohawks Team HandbookDocument11 pagesRobohawks Team Handbookapi-376756259No ratings yet

- PC Pump ManualDocument540 pagesPC Pump ManualtelephonicaNo ratings yet

- Optimal Transformer Tap Changing SettingDocument7 pagesOptimal Transformer Tap Changing Settingtrust4joshNo ratings yet

- BSBPMG410+Apply+project+time+management+techniques V170225Document35 pagesBSBPMG410+Apply+project+time+management+techniques V170225Sabrina Gao100% (1)