Professional Documents

Culture Documents

Storage Tanks

Uploaded by

fraemddCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Storage Tanks

Uploaded by

fraemddCopyright:

Available Formats

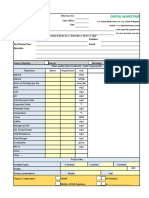

BELZONA SOLUTION GUIDE FOR STORAGE TANKS

Internal Protection

Internal Corrosion

solved using high performance

tank linings

Belzona 1321 (Ceramic S Metal)

Erosion/corrosion protection (to

60C)

Belzona 1341 (Supermetalglide)

Spray applied erosion/corrosion

protection

Belzona 1391 (Ceramic HT)

Erosion/corrosion protection at elevated temperatures (to 120C)

Belzona 1391S

Spray applied elevated temperature

corrosion protection (110C)

Belzona 1391T

Erosion/corrosion protection at

elevated temperatures (120C)

Belzona 4311 (Magma CR1)

Resistant to a range of aggresive

chemicals

Belzona 5811 (Immersion Grade)

Corrosion protection (to 50C)

Belzona 5891

(HT Immersion Grade)

Corrosion protection (to 90C)

External Protection

Nozzle Inserts

Exposure to Atmospheric

Corrosion

solved using high performance

barrier coatings

Corrosion Under Insulation

solved using high performance

barrier coatings

Small Bore Nozzle Corrosion

and Erosion

solved using nozzle inserts

Belzona 5111 (Ceramic Cladding)

UV and chemical resistant barrier

coating

Belzona 6111 (Liquid Anode)

Anodic protection for environmental

steelwork

Belzona 5831 (ST-Barrier)

surface tolerant protection

Belzona 5841

In service applied CUI protection

(30-80C)

Belzona 5851 (HA-Barrier)

In service applied CUI protection

(70-150C)

Belzona 5891

(HT Immersion Grade)

Elevated temperature protection

Key features:

Surface tolerant

On line application

Speed of application

Chemical resistance

By utilising a cost-effective

Belzona solution, maintenance

personnel can:

Reduce downtime

Lower maintenance costs

Improve efficiency

Simplify maintenance

procedures

Extend machinery and

equipment life

Flange Face Forming

Damage flanges

solved using flange face

reforming

Corrosion protection

solved using flange face coating

Internal Repairs

Corrosion pitting

solved using internal bonding

Damaged linings

solved using internal bonding

Leaking welds and joints

solved using internal bonding

Belzona 1111 (Super Metal)

General repairs

Belzona 1321 (Ceramic S Metal)

Erosion/corrosion protection (to 60C)

Belzona 4301

(Magma CR1 Hi-build)

Chemical resistant repairs

Key features:

Extra mechanical strength

Strong chemical resistance

Corrosion resistance

Removes need for stress relieving

www.belzona.com

Belzona Polymerics Ltd.,

Claro Road, Harrogate,

HG1 4DS, England.

Tel: +44 (0) 1423 567641

Fax: +44 (0) 1423 505967

E-mail: belzona@belzona.co.uk

Risk of Water Ingress into

Insulation/Under Insulation

solved using Lagseal solution

Belzona 3211 (Lagseal)

for sealing insulation

Key features:

Spray/brush application

Speed of application

Inspection (NDT/Visual) friendly

Fire rated (will not add to a fire)

External Repairs

Stressed joints and seams

solved using external bonding

Key features:

Extra mechanical strength

Strong chemical resistance

Corrosion resistance

Removes need for stress relieving

Key features:

No hot work necessary

Independently tested to ANSI

150#, 300# & 600# flange rating

Applied in minutes

Returned to service in hours

ISO 9001:2000

Q 09335

ISO 14001:2004

EMS 509612

Weatherproofing

Insulation

Belzona 1111 (Super Metal)

General repairs

Belzona 1221 (Super E Metal)

Emergency leak sealing

Belzona 1831

Surface tolerant repairs

Belzona 1251 (HA-Metal)

Hot surface repairs (70-150C)

Belzona 1111 (Super Metal)

General repairs

Belzona 1321 (Ceramic S Metal) /

Belzona 1391 (Ceramic HT)

Complete flange forming

Belzona 4301

(Magma CR1 Hi-build)

Maximum chemical resistance

Key features:

Explosive decompression

resistance

Cathodic disbondment resistance

Resist chemicals and aqueous

hydrocarbon solutions

This table is a guide. For accurate coating

selection and to check you have the latest

version of this guide, please consult a Belzona

Technical Consultant. Availability of some

products may be geographically limited.

The Oil & Gas industry demands

production techniques which

involve high operating

temperatures and pressures.

Belzona Inc.,

2000 N.W. 88 Court, Miami,

Florida 33172, U.S.A.

Tel: +1 (305) 594 4994

Fax: +1 (305) 599 1140

E-mail: belzona@belzona.com

Belzona Asia Pacific

Rattakit Building, 29/13 Moo 9,

Sukhumvit Road, Banglamung

Chonburi 20150, Thailand

Tel: +66 38 378099

Fax: +66 38 378098

E-mail: belzona@belzona.cn

Belzona 1111 (Super Metal)

General insert manufacture

Belzona 1321 (Ceramic S Metal)

/ Belzona 1391 (Ceramic HT)

Erosion resistant inserts

Belzona 4301

(Magma CR1 Hi-build)

Chemical resistant inserts

Key features:

Repairs defects/ holidays

Free lining assured

Can be engineered to solve

erosion problems

Repair Composites

Thin Wall/Through Wall Defect

solved using plate bonding and/

or composite systems

Belzona 1111 (Super Metal)

General plate bonding and

composite repairs

Belzona 1221 (Super E-Metal)

Extended working life

Belzona 1251 (HA-Metal)

Bonding dobuler plates and

composite wraps onto hot surfaces

Belzona 1831 (Super UW-Metal)

Surface tolerant repairs to damp,

wet or underwater surfaces

Belzona SuperWrap

(Belzona 1871, 1971, 9371)

ISO/ASME compliant repairs to

pressurised systems

Key features:

Compliant with international

codes and standards

An engineered solution that is fit

for purpose

Inspectable

Maintainable

Copyright 2008 by Belzona International Limited. All rights reserved. No part of this

work covered by the copyrights hereon may be

reproduced or used in any form or by any means - graphic,

electronic or mechanical including photocopying, recording, taping or information storage and retrieval systems

- without written permission of the publisher.

Belzona is a registered trade mark

33-10-08

You might also like

- 1 BelzonaDocument41 pages1 BelzonashakeelahmadjsrNo ratings yet

- Hydropower Asset Protection with Polymer TechnologiesDocument4 pagesHydropower Asset Protection with Polymer TechnologiesSara BrownNo ratings yet

- Klueberquiet BQH 72 102-EnDocument2 pagesKlueberquiet BQH 72 102-Enвлад камрNo ratings yet

- BELZONA 1111 Product Specification SheetDocument2 pagesBELZONA 1111 Product Specification Sheetsibi_s_rajNo ratings yet

- Belzona 1311 UnlockedDocument8 pagesBelzona 1311 UnlockedUud NasrullohNo ratings yet

- PaintingSpecifications T 8567 PDFDocument7 pagesPaintingSpecifications T 8567 PDFRaed ThakurNo ratings yet

- Belzona Protective LiningsDocument32 pagesBelzona Protective Liningsjose corrosion100% (2)

- High Performance Lubricants: Molykote Molykote MolykoteDocument4 pagesHigh Performance Lubricants: Molykote Molykote Molykoteestebang956No ratings yet

- Belzona 3111Document2 pagesBelzona 3111Bobby SatheesanNo ratings yet

- Viscosidades KluberDocument23 pagesViscosidades KluberRCMNo ratings yet

- Stanvac's 26 Core SolutionsDocument32 pagesStanvac's 26 Core SolutionsSunil SinghNo ratings yet

- Belzona 5892 - BrochureDocument2 pagesBelzona 5892 - BrochureANIBALLOPEZVEGANo ratings yet

- High Performance Lining Selection Chart For 90C Immersion - Belzona GuidesDocument2 pagesHigh Performance Lining Selection Chart For 90C Immersion - Belzona GuidesBobby SatheesanNo ratings yet

- Mobilgrease XHP 460Document3 pagesMobilgrease XHP 460Jaime Miloz Masle JaksicNo ratings yet

- Krytox Typical Properties GPL 227Document2 pagesKrytox Typical Properties GPL 227Ramu NallathambiNo ratings yet

- Bechem Lubricants For High Load and High TemperatureDocument3 pagesBechem Lubricants For High Load and High TemperatureShukor AzNo ratings yet

- Carriage Repair Workshop Training ReportDocument50 pagesCarriage Repair Workshop Training Reportrajat sharmaNo ratings yet

- Heavy-Duty, Reinforced Range Heavy-Duty, Reinforced Range Heavy-Duty, Reinforced RangeDocument8 pagesHeavy-Duty, Reinforced Range Heavy-Duty, Reinforced Range Heavy-Duty, Reinforced RangeengindmecNo ratings yet

- Aditivi Materiale PlasticeDocument4 pagesAditivi Materiale PlasticeLavinia CalinNo ratings yet

- Firex EC-43 DemoDocument10 pagesFirex EC-43 DemoBanani SahuNo ratings yet

- Why Superon SteelDocument83 pagesWhy Superon SteelArdh0072No ratings yet

- Coating Handout PDFDocument2 pagesCoating Handout PDFVictoria MirkoNo ratings yet

- Kirloskar Corrocoat GFC CaseStudyDocument35 pagesKirloskar Corrocoat GFC CaseStudyAbhishek SharmaNo ratings yet

- Insulating Coating PDFDocument55 pagesInsulating Coating PDFBaSant KohliNo ratings yet

- O&M MANUAL - Grease Lubrication System PDFDocument81 pagesO&M MANUAL - Grease Lubrication System PDFsundyaNo ratings yet

- Workshop All AnnexuresDocument18 pagesWorkshop All AnnexuresLavee ChandrakarNo ratings yet

- Plant Maintenance Lubricants 026224Document4 pagesPlant Maintenance Lubricants 026224Koohestani Afshin100% (1)

- Belzona 4111Document2 pagesBelzona 4111Bobby SatheesanNo ratings yet

- Manufacturer Brand Viscosity Base Oil Drop PointDocument8 pagesManufacturer Brand Viscosity Base Oil Drop PointPhillip Feng100% (1)

- Belzona 1391 T (Flyer)Document2 pagesBelzona 1391 T (Flyer)Bobby SatheesanNo ratings yet

- Belzona 5851 PDFDocument2 pagesBelzona 5851 PDFBobby SatheesanNo ratings yet

- Belzona 1391Document2 pagesBelzona 1391AsadAliNo ratings yet

- Mechanical Workshop Name Addresses 170118Document3 pagesMechanical Workshop Name Addresses 170118vk mishraNo ratings yet

- of NE Railway Summer TrainingDocument18 pagesof NE Railway Summer TrainingAkhilesh Singh80% (5)

- Equipment Reliability SondiniDocument9 pagesEquipment Reliability SondiniduhaimNo ratings yet

- Belzona Index FolderDocument3 pagesBelzona Index Foldersrikrish24No ratings yet

- Seala Tank Belzona Application Procedure For Tank Base Corrosion Protect...Document2 pagesSeala Tank Belzona Application Procedure For Tank Base Corrosion Protect...mspNo ratings yet

- Belzona Coating Guide For CUI and Atmospheric CorrosionDocument2 pagesBelzona Coating Guide For CUI and Atmospheric CorrosionfraemddNo ratings yet

- Sealing Compounds From Project Sales CorpDocument34 pagesSealing Compounds From Project Sales CorpProject Sales CorpNo ratings yet

- Power Plant Equipment Lubrication GuideDocument127 pagesPower Plant Equipment Lubrication GuideKrishnan SanthanarajNo ratings yet

- MEE Avoiding Bolt FailuresDocument2 pagesMEE Avoiding Bolt Failuresridwan347No ratings yet

- OB Escription Job Title: Purpose of The PositionDocument3 pagesOB Escription Job Title: Purpose of The PositionyagolainNo ratings yet

- Properties of LubricantDocument13 pagesProperties of LubricantabiandgeNo ratings yet

- Choosing the Right High-Speed Grease for Faster Rotating EquipmentDocument34 pagesChoosing the Right High-Speed Grease for Faster Rotating EquipmentArtur MkrtchyanNo ratings yet

- Conformal Coating Curing and Drying Technical Bulletin Apr 09Document2 pagesConformal Coating Curing and Drying Technical Bulletin Apr 09Lee HitchensNo ratings yet

- Turbine Oil Family CaltexDocument8 pagesTurbine Oil Family CaltexPeter_Phee_341No ratings yet

- Belzona - Pump BrochureDocument8 pagesBelzona - Pump BrochurePradyumnaMaluNo ratings yet

- In Focus Pipe Wraps BelzonaDocument4 pagesIn Focus Pipe Wraps BelzonaAhmed ELmlahyNo ratings yet

- Lubricants For The Manufacturing IndustryDocument20 pagesLubricants For The Manufacturing IndustrynarenjiNo ratings yet

- Loctite Solutions For Power PlantsDocument14 pagesLoctite Solutions For Power PlantsHusen TaufiqNo ratings yet

- Clock Spring Pipe Repair System PDFDocument2 pagesClock Spring Pipe Repair System PDFNeo_1982No ratings yet

- Grease Refill QtyDocument3 pagesGrease Refill QtyParmasamy SubramaniNo ratings yet

- Shell Omala S4 GX 220Document3 pagesShell Omala S4 GX 220Anonymous oAbjbl4HNo ratings yet

- Challenges and Solutions in Power Plant LubricationDocument37 pagesChallenges and Solutions in Power Plant LubricationSandeep100% (1)

- Reliability Engineer: J D Job Title: Purpose of The PositionDocument3 pagesReliability Engineer: J D Job Title: Purpose of The PositionyagolainNo ratings yet

- MBDAF and OZONE Data Sheet For Wastewater TreatmentDocument1 pageMBDAF and OZONE Data Sheet For Wastewater TreatmentjayNo ratings yet

- Solution Guide For Process VesselDocument1 pageSolution Guide For Process VesselfraemddNo ratings yet

- Belzona 1111 (Super Metal) - Epoxy-Based CompositeDocument2 pagesBelzona 1111 (Super Metal) - Epoxy-Based CompositeVALJEANYNo ratings yet

- Belzona Polimeros IndustrialesDocument12 pagesBelzona Polimeros Industrialestonymr1No ratings yet

- Thermography, Thermal Imaging, Energy Audit, Energy Conservation, Shashihushan Agrawal, Steam TrapDocument0 pagesThermography, Thermal Imaging, Energy Audit, Energy Conservation, Shashihushan Agrawal, Steam Trapvaluer99No ratings yet

- Classification of Heat ExchangersDocument77 pagesClassification of Heat Exchangers4605566vivek100% (1)

- Grocery List (Ideal For Single, Health-Conscious People) : Vegetable and Fruit AisleDocument3 pagesGrocery List (Ideal For Single, Health-Conscious People) : Vegetable and Fruit AislefraemddNo ratings yet

- Fastener BasicsDocument2 pagesFastener BasicsShridhar VaidyaNo ratings yet

- ANCC ProfileDocument35 pagesANCC ProfileMohammad RawoofNo ratings yet

- Notice of US Legal Document IncorporationDocument340 pagesNotice of US Legal Document IncorporationMaximilianoRodrigoCabestrero100% (1)

- Procedure For Opening ITIDocument11 pagesProcedure For Opening ITIUbaid BahussainNo ratings yet

- PRV Test ProcedureDocument56 pagesPRV Test ProcedureNatraji100% (3)

- Welding Equipment Guide and SpecificationsDocument97 pagesWelding Equipment Guide and SpecificationsfraemddNo ratings yet

- Procedure For Opening ITIDocument11 pagesProcedure For Opening ITIUbaid BahussainNo ratings yet

- Api 936 Practice TestDocument9 pagesApi 936 Practice TestfraemddNo ratings yet

- Api 936 Practice TestDocument9 pagesApi 936 Practice TestfraemddNo ratings yet

- Transformer LeaksDocument2 pagesTransformer LeaksfraemddNo ratings yet

- 32 Samss 031 PDFDocument8 pages32 Samss 031 PDFEagle SpiritNo ratings yet

- 32 Samss 031 PDFDocument8 pages32 Samss 031 PDFEagle SpiritNo ratings yet

- Chapter 022 - QualityDocument3 pagesChapter 022 - QualityfraemddNo ratings yet

- Saes C 001Document5 pagesSaes C 001fraemddNo ratings yet

- Saes e 015Document12 pagesSaes e 015AdnanAtifNo ratings yet

- Fluid Handling EquipmentsDocument2 pagesFluid Handling EquipmentsfraemddNo ratings yet

- WeldingofStainlesssSteelandotherJoiningMethods 9002Document0 pagesWeldingofStainlesssSteelandotherJoiningMethods 9002jvs11021102No ratings yet

- Belzona Coating Guide For CUI and Atmospheric CorrosionDocument2 pagesBelzona Coating Guide For CUI and Atmospheric CorrosionfraemddNo ratings yet

- Aramco Specific Evaluations For WeldingDocument6 pagesAramco Specific Evaluations For WeldingTrived MahankaliNo ratings yet

- Tank Base Corrosion LeafletDocument2 pagesTank Base Corrosion LeafletfraemddNo ratings yet

- Chapter 019 - Health and SafetyDocument7 pagesChapter 019 - Health and SafetyfraemddNo ratings yet

- Belzona Lining For Immersion in Process Vessel Above 90 Deg. CDocument1 pageBelzona Lining For Immersion in Process Vessel Above 90 Deg. CfraemddNo ratings yet

- Chapter 020 - Duties of An InspectorDocument5 pagesChapter 020 - Duties of An InspectorfraemddNo ratings yet

- Solution Guide For Process VesselDocument1 pageSolution Guide For Process VesselfraemddNo ratings yet

- NCPWBDocument8 pagesNCPWBfraemddNo ratings yet

- 2015 ICP Exam Schedule 070314Document2 pages2015 ICP Exam Schedule 070314fraemddNo ratings yet

- Parts Catalogue for 6BTAA5.9-G EngineDocument83 pagesParts Catalogue for 6BTAA5.9-G EnginehighNo ratings yet

- 17D Changes and How It Works With 6ADocument20 pages17D Changes and How It Works With 6Abevishal2006100% (6)

- Method Statement of Hydrostatic TestDocument28 pagesMethod Statement of Hydrostatic TestMassimo FumarolaNo ratings yet

- Assembly and Parts Drawing: Wuxi Kipor Power Co., LTDDocument2 pagesAssembly and Parts Drawing: Wuxi Kipor Power Co., LTDDuvan Garridt MillanNo ratings yet

- DCT 3D Welding Table CatalogDocument90 pagesDCT 3D Welding Table CatalogSusan ChenNo ratings yet

- Standards Referenced NS1 A4Document3 pagesStandards Referenced NS1 A4islam atifNo ratings yet

- Procedure System of Flange Management Procedure (Site)Document14 pagesProcedure System of Flange Management Procedure (Site)Imtiyaz Akhtar94% (16)

- Chapter 12 Vacuum ValvesDocument46 pagesChapter 12 Vacuum ValvesPardhu YellaNo ratings yet

- Char-Lynn (Eaton) - 158-2925-001 - Motion IndustriesDocument2 pagesChar-Lynn (Eaton) - 158-2925-001 - Motion Industriesgeovane cardosoNo ratings yet

- Basket Strainers: ApplicationsDocument15 pagesBasket Strainers: ApplicationsTu PhamNo ratings yet

- BoQ SewerageDocument12 pagesBoQ SeweragepavanbhavsarNo ratings yet

- Fast Fill Systems Product CatalogueDocument32 pagesFast Fill Systems Product CatalogueAgus Yulfizar100% (1)

- Best Swivel Joints CatalogDocument8 pagesBest Swivel Joints CatalogWalter PierNo ratings yet

- 2-1-2 - General Specification of Main Laying Materials For Waterworks LatestDocument112 pages2-1-2 - General Specification of Main Laying Materials For Waterworks LatestRaulSaavedra0% (1)

- Catalog: Dual Plate Wafer Check ValveDocument40 pagesCatalog: Dual Plate Wafer Check ValveБехар ТиагоNo ratings yet

- Asme BPVC 2017 - Summary of Changes: Location Change (Record Number) LVDocument10 pagesAsme BPVC 2017 - Summary of Changes: Location Change (Record Number) LVbhushan cNo ratings yet

- Catalogue of wastewater pumps and systemsDocument44 pagesCatalogue of wastewater pumps and systemsSameeraNo ratings yet

- Kawasaki KLX 150 L/S Drawing ArrangementDocument68 pagesKawasaki KLX 150 L/S Drawing ArrangementNIKODOMEUS100% (1)

- Gestra Steam Trap - Thermostatic Steam Trap BK 29: Class Rating: ANSI 900 Available SizesDocument2 pagesGestra Steam Trap - Thermostatic Steam Trap BK 29: Class Rating: ANSI 900 Available SizesdcarunchioNo ratings yet

- RAS System - Technical Spec 20141209Document11 pagesRAS System - Technical Spec 20141209TamNo ratings yet

- Butterfly ValveDocument2 pagesButterfly ValveKELVIN TECHNOLOGIESNo ratings yet

- SAES-L-350 PDF Download - Construction of Plant Piping - PDFYARDocument5 pagesSAES-L-350 PDF Download - Construction of Plant Piping - PDFYARZahidRafiqueNo ratings yet

- Publicaciones y EstandarizacionesDocument13 pagesPublicaciones y Estandarizacionesjose mirandaNo ratings yet

- API 6D - 6A - 607 - BS5351 BALL VALVE: Lanus Industries LLC USADocument61 pagesAPI 6D - 6A - 607 - BS5351 BALL VALVE: Lanus Industries LLC USANagendra SunkariNo ratings yet

- Pulsar RS200 (2020)Document92 pagesPulsar RS200 (2020)zonabike.infoNo ratings yet

- Ed D 02.00 I 01Document25 pagesEd D 02.00 I 01joseellargoNo ratings yet

- Sec1 1 1Document2 pagesSec1 1 1rajfmc100% (1)

- Tubes and PipesDocument40 pagesTubes and PipesAran ChandranNo ratings yet

- CS2500Document528 pagesCS2500David Muñoz CastroNo ratings yet

- 150s and 157s Replacement Parts - 3Document6 pages150s and 157s Replacement Parts - 3EverardJuanilloNo ratings yet