Professional Documents

Culture Documents

Trampa de Vapor

Uploaded by

ruben'sCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trampa de Vapor

Uploaded by

ruben'sCopyright:

Available Formats

873_Traps3.

qxd

4/4/06

8:46 AM

Page ST-65

Steam Trapping and

Steam Tracing Equipment

TVS 800 Series Cast Iron Trap Valve Station

Put the principle of the inverted bucket to work in a tough cast iron

package and you have the best of both worldsenergy efficiency

and long-lasting reliability. Add the advantages of valves integrated

into one compact trap/valve casting, and you extend the benefits

into installation, trap testing and maintenance.

All the components are concentrated in a single, accessible package

and can be dealt with in-line. And if you have existing Armstrong

cast iron traps in-line, identical face-to-face dimensions will make

retrofitting with the patented* Armstrong Trap Valve Station (TVS)

a snap. Youll also reduce your inventory requirements. So youll

eliminate what youre paying just to keep parts on hand.

Integral isolation valves

Rugged cast iron package

Reduced costs

TVS saves on these fronts: energy,

installation and maintenance.

Integration of trap and valves

Inverted bucket long life and energy efficiency,

plus the savings and convenience of components

merged into one space-saving package.

A full range of options

TVS will accommodate a test valve, strainer,

internal check valve, thermic vent bucket,

TrapAlert and SteamEyeremote steam

trap monitoring system for steam traps.

Energy-efficient

inverted bucket

steam trap

Easy, in-line repairability

Elimination of potential leak points

Optional integral strainer

Reduced design time

Permits combining products with exact

face-to-face dimensions.

*U.S. Patent 5,947,145

128

ST-65

Armstrong Steam and Condensate Group, 816 Maple St., Three Rivers, MI 49093 USA Phone: (269) 273-1415 Fax: (269) 278-6555

www.armstrong-intl.com

Next

873_Traps3.qxd

4/4/06

8:46 AM

Page ST-66

TVS 800 Series Cast Iron Trap Valve Station

Steam Trapping and

Steam Tracing Equipment

TVS makes a long storyshort.

Typical Installation

Trap Valve Station

Inverted bucket trap with two isolation

valves and strainer

Inverted bucket trap with two

isolation valves

Inverted bucket trap with two isolation valves,

strainer and check valve

The Innovation Is Integration

The Armstrong TVS makes what used to be long, complicated steam

installation stories simple and compact. It shortens installations by

integrating componentsspecifically an inverted bucket steam trap

with two or more valves.

this steam story: pipe-TVS-pipe. In other words, the TVS makes

it all one, delivering the functions of multiple components in a

dramatically smaller unit. It integrates two high-value products

in a package of revolutionary versatility.

For example, heres an old description for a typical installation:

valve-nipple-strainer-nipple-trap-nipple-valve. Its a long tale, even

for this simple piping arrangement. The Trap Valve Station rewrites

Look above to see how the Armstrong cast iron Trap Valve Station

has rewritten these typical steam installations.

Average Service Life for Different Trap Types 200 psi (14 bar)

0

7 Years

Thermodynamic disc

Float and thermostatic

Inverted bucket

Balanced pressure thermostatic

Bimetallic thermostatic

Above data from ICI Engineer January 1993 special issue

with permission from ICI Engineering.

129

Armstrong Steam and Condensate Group, 816 Maple St., Three Rivers, MI 49093 USA Phone: (269) 273-1415 Fax: (269) 278-6555

www.armstrong-intl.com

Next ST-66

873_Traps3.qxd

4/4/06

8:46 AM

Page ST-67

TVS 800 Series Trap Valve Station

Cast Iron for Horizontal Installation, With Integral Piston Valves

Steam Trapping and

Steam Tracing Equipment

For Pressures to 250 psig (17 bar)...Capacities to 4,400 lb/hr (2,000 kg/hr)

A

F

B

E

Model TVS 811

Series TVS 812/813

Same principle. Different package. Now the energy-saving performance

and reliability of the inverted bucket steam trap are available in a versatile

new package.

Series TVS 811/812/813 - Top View

Options

Stainless steel internal check valve

Thermic vent bucket

Stainless steel pop drain

Integral strainer

Scrub wire

Probe connection

Blowdown valve (TVS 811 and TVS 812 only)

Youll still enjoy all the familiar benefits. And the same efficient condensate

drainage from virtually every kind of steam-using equipment. But what

youll find new are all the benefits of a piston valve integrated into the same

space-saving package.

Maximum Operating Conditions

Maximum allowable pressure

(vessel design):

Maximum operating pressure:

30 F

Specification

Inverted bucket steam trap, type ... in cast iron, with continuous air venting

at steam temperature, free-floating stainless steel mechanism, and discharge

orifice at the top of the trap. Integral upstream and downstream shutoff piston

style valves in same dimensional space as standard bucket trap.

250 psig @ 450F (17 bar @ 232C)

250 psig (17 bar)

Connections

Screwed NPT and BSPT

How to Order

Specify:

Model number

Size and type of pipe connection

Maximum working pressure that will be encountered or orifice size

Any options required

Materials

Cap and body:

Internals:

Valve and seat:

Handwheel:

Internals:

Valve sealing rings:

Blowdown valve

ASTM A48 Class 30

All stainless steel304

Hardened chrome steel17-4PH

Ductile iron

Stainless steel

Graphite and stainless steel

Stainless steel

For a fully detailed certified drawing, refer to:

TVS 811

CD #1099

TVS 812/813 CD #1100

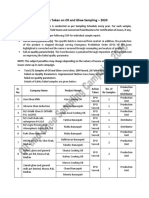

TVS 800 Series Trap Valve Station

Model No.

Pipe Connections

Test Plug

TVS 811

TVS 812

TVS 813

in

mm

in

mm

in

mm

1/2, 3/4

15, 20

1/2, 3/4

15, 20

3/4, 1

20, 25

1/4

1/2

15

3/4

20

A Width Across Handwheels

8-1/4

210

13-3/4

349

15-1/8

384

B Outlet Valve Open

10-1/4

260

11-3/4

298

14-1/4

362

127

6-1/2

165

7-3/4

197

3-11/16

94

4-3/4

121

7-1/4

184

7-5/8

194

13

330

14-3/8

365

76

4-1/2

114

4-7/8

124

Number of Bolts

C Face to Face

D Connection CL to Bottom

Weight lb (kg)

12 (5.4)

25 (11.3)

6

47 (24)

All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice.

130

ST-67

Armstrong Steam and Condensate Group, 816 Maple St., Three Rivers, MI 49093 USA Phone: (269) 273-1415 Fax: (269) 278-6555

www.armstrong-intl.com

Next

873_Traps3.qxd

4/4/06

8:46 AM

Page ST-68

TVS 800 Series Trap Valve Station

Cast Iron for Horizontal Installation, With Integral Piston Valves

For Pressures to 250 psig (17 bar)...Capacities to 4,400 lb/hr (2,000 kg/hr)

Model TVS 812 Capacity

Steam Trapping and

Steam Tracing Equipment

Model TVS 811 Capacity

Model TVS 813 Capacity

Options

Internal Check Valves are spring-loaded

stainless steel and screw directly into the

trap inlet or into an extended inlet tube

having a pipe coupling at the top to save

fittings, labor and money.

Thermic Vent Buckets have a bimetal

controlled auxiliary air vent for discharging

large amounts of air on start-up.

Integral Strainer is made from 20 x 20

stainless steel screen.

Thermic Air

Vent in Bucket

Probe Connections are available for

trap monitoring.

Blowdown Valve for clearing strainers

of dirt and debris.

Integral Strainer

Internal

Check Valve

131

Armstrong Steam and Condensate Group, 816 Maple St., Three Rivers, MI 49093 USA Phone: (269) 273-1415 Fax: (269) 278-6555

www.armstrong-intl.com

Next ST-68

You might also like

- Cogeneration BookDocument82 pagesCogeneration Bookruben's100% (1)

- Ecuaciones Basicas de Transferecia de CalorDocument6 pagesEcuaciones Basicas de Transferecia de Calorruben'sNo ratings yet

- 4 9 Steam TracingDocument20 pages4 9 Steam Tracingruben'sNo ratings yet

- SPP&ID Lines-Chute Duct PipingDocument7 pagesSPP&ID Lines-Chute Duct Pipingruben'sNo ratings yet

- R110J Instrument Symbols PDFDocument47 pagesR110J Instrument Symbols PDFruben'sNo ratings yet

- Special Closures Literature2Document2 pagesSpecial Closures Literature2ruben'sNo ratings yet

- OLGA 7 Offshore Low ResDocument16 pagesOLGA 7 Offshore Low Resruben'sNo ratings yet

- MicroStation Basic 2D GraphicsDocument70 pagesMicroStation Basic 2D Graphicsruben'sNo ratings yet

- Guide Micro Station V7 1Document755 pagesGuide Micro Station V7 1ruben'sNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tcu Module Pe1 Lesson 1Document7 pagesTcu Module Pe1 Lesson 1Remerata, ArcelynNo ratings yet

- Tackling Food Inflation: Ashwinkumar Kokku - 67 Malcolm Pinto - 89 Samir Vele - Nitin JadhavDocument9 pagesTackling Food Inflation: Ashwinkumar Kokku - 67 Malcolm Pinto - 89 Samir Vele - Nitin JadhavMalcolm PintoNo ratings yet

- UgpeDocument3 pagesUgpeOlety Subrahmanya SastryNo ratings yet

- Challenger 350 Recommended Operating Procedures and TechniquesDocument104 pagesChallenger 350 Recommended Operating Procedures and Techniquessebatsea100% (1)

- Me3391-Engineering Thermodynamics-805217166-Important Question For Engineering ThermodynamicsDocument10 pagesMe3391-Engineering Thermodynamics-805217166-Important Question For Engineering ThermodynamicsRamakrishnan NNo ratings yet

- 2021 Life Skills ATP Grade 5Document10 pages2021 Life Skills ATP Grade 5Koketso SekwenyaneNo ratings yet

- Full Test Bank For Health Economics and Policy 7Th Edition Henderson PDF Docx Full Chapter ChapterDocument34 pagesFull Test Bank For Health Economics and Policy 7Th Edition Henderson PDF Docx Full Chapter Chapterpeeepochaq15d100% (9)

- Ventura 4 DLX ManualDocument36 pagesVentura 4 DLX ManualRoland ErdőhegyiNo ratings yet

- Roto Fix 32 Service ManualDocument31 pagesRoto Fix 32 Service Manualperla_canto_150% (2)

- Dissertation On: To Asses The Impact of Organizational Retention Strategies On Employee Turnover: A Case of TescoDocument44 pagesDissertation On: To Asses The Impact of Organizational Retention Strategies On Employee Turnover: A Case of TescoAhnafTahmidNo ratings yet

- Jurnal SOL MeningiomaDocument6 pagesJurnal SOL MeningiomaConnie SianiparNo ratings yet

- Nfpa 502 Critical Velocity Vs Fffs EffectsDocument5 pagesNfpa 502 Critical Velocity Vs Fffs Effectsamir shokrNo ratings yet

- PulpectomyDocument3 pagesPulpectomyWafa Nabilah Kamal100% (1)

- Muscle and Fitness Hers Features Elite Lifestyle Chef Carlo FilipponeDocument4 pagesMuscle and Fitness Hers Features Elite Lifestyle Chef Carlo FilipponeCarlo FilipponeNo ratings yet

- A V N 2 0 0 0 9 Airspace Management and Air Traffic Services Assignment 1Document2 pagesA V N 2 0 0 0 9 Airspace Management and Air Traffic Services Assignment 1Tanzim Islam KhanNo ratings yet

- Catalogue CV. Traka Abadi UniversalDocument15 pagesCatalogue CV. Traka Abadi UniversalHackers StevenNo ratings yet

- Практичне 25. Щодений раціонDocument3 pagesПрактичне 25. Щодений раціонAnnaAnnaNo ratings yet

- COT RPMS Rating Sheet For MT I IV For SY 2021 2022 in The Time of COVID 19Document2 pagesCOT RPMS Rating Sheet For MT I IV For SY 2021 2022 in The Time of COVID 19Don Mariano Marcos Elementary SchoolNo ratings yet

- User Manual: 3603807 CONTACT US - 09501447202,8070690001Document1 pageUser Manual: 3603807 CONTACT US - 09501447202,8070690001Arokiaraj RajNo ratings yet

- AERO241 Example 10Document4 pagesAERO241 Example 10Eunice CameroNo ratings yet

- Action Taken On Oil and Ghee Sampling - 2020Document2 pagesAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiNo ratings yet

- Complaint: Employment Sexual Harassment Discrimination Against Omnicom & DDB NYDocument38 pagesComplaint: Employment Sexual Harassment Discrimination Against Omnicom & DDB NYscl1116953No ratings yet

- Series RL: Standards General DataDocument4 pagesSeries RL: Standards General DataBalamurugan SankaravelNo ratings yet

- Gay Costa Del Sol - 2010Document2 pagesGay Costa Del Sol - 2010gayinfospainNo ratings yet

- Muslim Marriage (Nikah) : Mutual Rights and ObligationsDocument10 pagesMuslim Marriage (Nikah) : Mutual Rights and ObligationsSachin Kumar Singh100% (1)

- Assignment On Inservice Education Sub: Community Health NursingDocument17 pagesAssignment On Inservice Education Sub: Community Health NursingPrity DeviNo ratings yet

- Iso 9227Document13 pagesIso 9227Raj Kumar100% (6)

- NCR RepairDocument4 pagesNCR RepairPanruti S SathiyavendhanNo ratings yet

- 10.1.polendo (Additional Patent)Document11 pages10.1.polendo (Additional Patent)Rima AmaliaNo ratings yet

- My Public Self My Hidden Self My Blind Spots My Unknown SelfDocument2 pagesMy Public Self My Hidden Self My Blind Spots My Unknown SelfMaria Hosanna PalorNo ratings yet