Professional Documents

Culture Documents

Lab Instruction Che 246

Uploaded by

Faradilah Binti Ajma'inCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab Instruction Che 246

Uploaded by

Faradilah Binti Ajma'inCopyright:

Available Formats

FACULTY OF CHEMCIAL ENGINEERING UITM PASIR GUDANG

CHE 246 SEPARATION

PROCESS

LAB INSTRUCTION

A. DISTILLATION COLUMN

B. GAS ABSORPTION

CHE 246

DEC-APR15

SECTION 1: DISTILLATION COLUMN

NOTES OF GUIDANCE

Lab work

Activity 1 Continuous distillation at constant reflux.

Learning outcome

1. Describe the operation of continuous distillation column.

2. Draw the PFD and P&ID of continuous distillation column.

3. Perform mass balance calculations on continuous distillation column.

4. Demonstrate effective team role and responsibility in the task execution.

Scenario

You have just joined as an assistant engineer in Maju Jaya Pte Ltd which produces methanol. The

process engineer asks you and your team to operate a continuous distillation column at constant reflux

ratio. In addition, you have to carry out mass balance calculations on the distillation column and

examine the effects of reflux ratio and feed conditions on the number of theoretical plates in a

continuous distillation. Refer to information of distillation column.

Objectives

This activity requires you to operate a continuous distillation column at constant reflux, carry out mass

balance calculations on the distillation column and examine the effects of reflux ratio and feed

conditions on the number of theoretical plates in a continuous distillation.

The process engineer has provided you the following information;

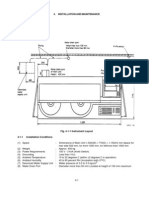

1. Schematic diagram of the distillation unit (Appendix: Figure 1)

2. X-Y Equilibrium Diagram for Methanol-Water System at 1 atm (Appendix: Figure 2)

Upon completion of the test, write a technical memo of the result obtained. The memo should include

(but not limited to) the following

a) Clearly states test parameters

b) Test results

c) Evaluation of results

Pre-Experiment Assessment

A. Planning/Preparation (10 marks)

All team members arrive at the process operation site to discuss on the plan to examine the effects of

reflux ratio and feed conditions on the number of theoretical plates in a continuous distillation. Please

record as the team members in the process operation site by video.

Task

I.

Distributed works and introduces the team.

II.

Familiarize with the distillation column by determining the line tracing of this system.

reference to Figure 1, identify the key components of the distillation column.

@R

With

Page 1

CHE 246

DEC-APR15

2. Understand how the distillation column works

a. The function of column, reflux drum, condenser and reboiler in distillation column.

b. Explain distillation principles; volatility prior to boiling point of the component

3. Decide on the test parameters

a. Reflux ratio and feed temperature

B. Allocation of Roles and Teamwork (10 marks)

1. Analyze the tasks to be performed and divide among your team who to perform the tasks.

No

1

2

3

4

5

Task description

Introduction and theory

Collecting data

Analyze the result

Safety awareness

(Add if necessary)

Member

2. Explain the basis for your groups task allocation.

3. Explain how will failure in performing the role of one of the above mentioned task affect the team

performance.

C. Hazard Identification and Safety Precaution (10 marks)

Before starting the operation of the distillation column, it is important to identify hazards and precautions

to be taken to ensure safety of operators.

Study the process equipment, utilities involved, process materials and procedures carefully to identify

potential hazards.

1. What are the hazards associated with ethanol?

2. What are the possible hazards if ethanol-water mixture is exchange to benzene-toluene mixture in

the process operation?

3. What safety precautions would you take in relation to the above mentioned hazards?

D. Performance Test Procedure

1. Perform the general start-up procedures.

a) Ensure all valves are closed.

b) Turn on the power for the control panel.

c) Prepare a 3040 L mixture containing ethanol and filtered water at the desired composition.

Charge the unit as follows:

i. Open the charge port cap at the reboiler B1, and fill the reboiler up to the level of the internal

overflow height.

ii. Pour the remaining ethanol-water mixture into the feed vessel B2 through the feed charge port.

d) Set the reflux divider KFS-101 to total reflux. This is to prevent any distillate from escaping when

starting up the distillation column.

@R

Page 2

CHE 246

DEC-APR15

e) Let the cooling water flow into the condenser W2 and product coolers W3 & W4 by opening valves

V13, V14 and V15.

f) Ensure that the tip of the level switch is located below the reboiler equator, which is at the liquid

inlet from the cartridge heaters.

g) Switch on the cartridge heaters at W1. Allow the liquid in the reboiler to boil.

h) Observe the vapor rising from the boiling liquid into the distillation column. As the vapor reaches

the condenser, it will condense and flow back into the column as liquid. Mass transfer will take place

between this liquid and vapor phase in the column.

i) Check that the condenser has sufficient cooling water flow to minimize escape of vapor into the

vent.

j) Let the distillation column run until a stable condition is observed. The stable condition is reached

when all temperature indicators on the column give a constant reading with an allowable fluctuation

of 0.2C.

2. Set the reflux divider to automatic reflux with a reflux ratio of 1 (e.g. 2 sec reflux and 2 sec distillate)

at the reflux divider controller (KFS-101).

4. Switch on the feed pump P1 and adjust the pump stroke and frequency in order to obtain a flow rate

between 5 to 10 L/hr (80 to 100% stroke at 120 to 150 strokes/minute).

5. Switch on the bottom pump P2 and adjust the bottom flow rate (V7) to desired value by taking into

account of the feed and distillate flow rate to maintain the level in the reboiler.

6. Once the distillation column has reached stable condition, record the trays, top and bottom

temperature.

7. Collect samples from the trays, distillate and bottom product. Samples can be taken from the

distillate and the bottom product for analysis:

a. Distillate sampling:

i) Drain any remaining liquid in the sampling valve V11.

ii) Place a vial below valve V11.

iii) Set the reflux divider to total distillate offtake for a few seconds.

iv) Open valve V11, collect enough sample and close the valve.

v) Switch the reflux divider back to the original setting.

b. Bottom sampling:

i) Drain any stagnated liquid above valve V8.

ii) Place a vial below valve V8.

iii) Open valve V8, collect enough sample and close the valve. Be careful of the hot liquid while

collecting a sample.

iv) Cool the sample by immersing the vial in cold water.

Note: Always re-cap the vials quickly after collecting samples to avoid excessive evaporation of

ethanol before analysis.

8. Measure the refractive index for all samples and determine their compositions.

Measure the refractive index of a sample and determine its composition from the calibration curve. If

the composition value is difficult to be determined accurately due to the calibration curves flat slope,

dilute the sample so that a more accurate reading can be obtained. Perform the dilution as follows:

a. Place a 10 mL measuring cylinder on a weighing scale (accurate to 0.01 g) and zero the scale.

@R

Page 3

CHE 246

DEC-APR15

b. Using a dropper, transfer 1 to 2 g of sample into the measuring cylinder. Record the sample

weight.

c. Add water into the measuring cylinder to dilute the sample. Obtain a total solution weight in the

range of 5 to 10 g. Record the solution weight.

d. Ensure that the diluted solution is well mixed before measuring its refractive index (RI).

e. Obtain the diluted solution's composition from the calibration curve.

f. Calculate the actual sample's composition.

g. Use the sample table in Appendix C for data recording and calculation

9. Measure the bottom and distillate product flow rates at FI-302 and FI-303.

10. Repeat the experiment (steps 3 to 8) with a different value of reflux ratio.

11. Repeat the experiment (steps 4 to 8) with a different feed temperature by switching on the feed

preheater W5 and setting the feed temperature set point to 50C.

E. Post-Experiment Assessment (10 marks)

You have completed the task. Carry out a team review on the test result.

1. Draw the PFD and P&ID of distillation column.

2. Write down the overall and component material balance equations for the distillation column.

3. Identify at least 2 observations (flaws or good features) made during the operation on the basic

function of the distillation column.

REPORT ASSESSMENT (10 MARKS)

F. Technical Memo

Draft a technical memo addressed to the Process Engineer on your teams evaluation of the distillation

unit. Your memo can take the technical format report.

Enclosed: Test results of distillation column at constant reflux ratio and key findings

The enclosed Test results of distillation column at constant reflux ratio and key findings of the memo

should include detailed test results and key findings as follows:

a) Test results. State the test parameters and provide proper tabulation with units clearly stated.

b) Evaluation of results.

For the section on Evaluation of results, you may use the following guiding questions to discuss the

results:

By using X-Y equilibrium diagram for ethanol-water system

1. Mark the trays, top and bottom compositions on the diagram

2. Determine the number of theoretical plates in the distillation column using the McCabe-Thiele

method.

@R

Page 4

CHE 246

DEC-APR15

SECTION 2: GAS ABSORPTION

NOTES OF GUIDANCE

Lab work

Activity 2: Gas Absorption.

Learning outcome

1. Describe the operation of gas absorption column.

2. Draw the process flow diagram (PFD) and piping and instrumentation diagram (P&ID) of gas

absorption column.

3. Demonstrate effective team role and responsibility in the task execution.

Scenario

You have just joined as an assistant engineer in Linde Pte Ltd. You and your teammates have given a

task to operate a gas absorption column of a carbon dioxide (CO2) with water as solvent. In addition,

you have to calculate the rate of absorption of CO2 into water. You can refer any references related to

the theory.

Objectives

This activity requires you to operate gas absorption column, carry out mass balance calculations on the

gas absorption column and examine the effects of flow rate of CO2 into water.

Upon completion of the test, write a technical memo of the result obtained. The memo should include

(but not limited to) the following:

a) Clearly states test parameters

b) Test results

c) Evaluation of results

@R

Page 5

CHE 246

DEC-APR15

A. Planning/Preparation (10 marks)

All team members arrive at the process operation site to discuss on the plan to examine the effect of

CO2 absorption rate into water.

1. Familiarize with the gas absorption column by determining the line tracing of this system.

2. Understand how the gas absorption works

a) The function of each component in the gas absorption column (receiving vessels, absorption

column, centrifugal pump).

b) Explain gas absorption principles.

3. Decide on the test parameters

B. Allocation of Roles and Teamwork (10 marks)

Analyze the tasks to be performed and divide among your team who to perform the tasks.

no

1

2

3

4

5

Task description

Introduction and theory

Collecting Data

Analyze the result

Safety awareness

(any if necessary)

Member

Explain the basis for your groups task allocation.

Explain how will failure in performing the role of one of the above mentioned task affect the team

performance.

C.

Hazard Identification and Safety Precaution (10 marks)

Before starting the operation of the gas absorption column, it is important to identify hazards and

precautions to be taken to ensure safety of operators. Study the process equipment, utilities involved,

process materials and procedures carefully to identify potential hazards.

1. What are the hazards associated with the operation of gas absorption column?

2. What safety precautions would you take in relation to the above mentioned hazards?

D.

Performance Test Procedure

1.0

1.1

OPERATING PROCEDURES

General Operating Procedures

It is important that the user read and fully understand all the instructions and precautions stated

in the manufacturer's manuals supplied with the absorption unit prior to operation. The following

procedures will serve as a quick reference for operating the unit.

1.2

General Start-Up Procedures

a) Ensure all valves are closed except the ventilation valve V13.

b) Check that all gas connections are properly fitted.

c) Open the valve on the compressed air supply line. Set the supply pressure to between 2 to 3

bar by turning the regulator knob clockwise.

@R

Page 6

CHE 246

DEC-APR15

d) Open the shut-off valve on the CO2 gas cylinder. Check that the CO2 cylinder pressure is

sufficient. Replace the cylinder if necessary.

e) Turn on the power for the control panel.

1.3

General Shut-Down Procedures

a) Switch off pump P1.

b) Close valves V1, V2 and V12.

c) Close the valve on the compressed air supply line and exhaust the supply pressure by

turning the regulator knob counterclockwise all the way.

d) Close the shut-off valve on the CO2 gas cylinder.

e) Drain all liquid in the column K1 by opening valve V4 and V5.

f) Drain all liquid from the receiving vessels B1 and B2 by opening valves V7 and V8.

g) Drain all liquid from the pump P1 by opening valve V10.

h) Turn off the power for the control panel.

1.4

Liquid Sampling Procedures

Samples can be taken from the liquid entering and exiting the absorption column for analysis.

The sampling valves are located at:

a) V8 for inlet liquid to absorption column K1

b) V7 for outlet liquid from absorption column K1

The procedures for collecting a sample are as follows:

a) Drain any stagnated liquid above the sampling valve.

b) ii) Place a vial below the sampling valve.

c) iii) Open sampling valve and collect about 100 mL of sample.

d) iv) Close the sampling valve.

1.5

Analysis of Dissolved CO2 in Water

Water used for absorption should be deionised because presence of dissolved salts could affect

the analysis method as described below.

CHEMICALS NEEDED:

a) Deionised and CO2 free water

b) Phenolphthalein indicator (AR grade)

c) 1.0 L of standard 0.05 M sodium hydroxide (NaOH) solution

d) 100 mL of standard 0.01M sodium bicarbonate (NaHCO3) solution

PROCEDURES:

a) Obtain a sample from Section 4.4.

b) Prepare exactly 100 mL of sample in a conical flask.

c) Add 510 drops of phenolphthalein indicator. If the sample turns red immediately, no free

CO2 is present. If the sample remains colourless, titrate with the standard 0.05 M NaOH

solution.

d) Measure the volume of 0.05 M NaOH required to reach the end point. The end point

occurs when a definite pink colour persists in the solution for longer than 30 seconds.

e) For best results, use a colour comparison standard. Prepare exactly 100 mL of 0.01 M

NaHCO3 solution in a conical flask and add 510 drops of phenolphthalein indicator.

@R

Page 7

CHE 246

2.0

DEC-APR15

EXPERIMENTAL PROCEDURES:

a) Fill the receiving vessel B2 through the charge port with 25 L of deionised water by opening

valve V3 and V5.

b) Close valve V3.

c) Open valve V10 and valve V9 slightly. Observe the flow of water from vessel B1 through

pump P1.

d) Open and adjust valve V1 to give a flow rate of 30 L/min air into column K1.

e) Open and adjust valve V2 to give a flow rate of 2 L/min CO2 into column K1.

f) For continuous monitoring of CO2 composition at the outlet gas flow, open valve V12 and

slowly close valve V13 to give a flow rate of 2 L/min at FT-304. Always maintain this flow

rate throughout the experiment.

g) Monitor the CO2 composition at QI-401 until it is constant. Record the value.

h) Switch on pump P1, then slowly open and adjust valve V11 to give a water flow rate of

around 0.5 L/min. Allow the water to enter the top of column K1, flow down the column and

accumulate at the bottom until it overflows back into vessel B2.

i) Start collecting liquid samples from both inlet and outlet of absorption column K1 (Section

4.4). Always collect the samples simultaneously.

j) To collect liquid sample for outlet of the adsorption column, close valve V5, open valve V4

and V7.

k) After finish collecting sample, close valve V4 and V7, open valve V5.

l) Analyse the collected samples to determine the composition of dissolved CO2 (Section 4.5).

m) At the same time, record the outlet CO2 composition at QI-401.

n) Continue to collect the liquid samples and record the outlet CO2 composition at every 5minute intervals until there are no more changes in CO2 composition over time.

o) Throughout the experiment, monitor and maintain the air, CO2 and water flow rates by

adjusting the appropriate valves.

p) At the end of the experiment, close valves V1, V2 and V12. Switch off pump P1. Transfer all

the CO2 rich water in receiving vessel B1 to vessel B2.

q) Repeat the experiment (steps 2 to 14) by changing the water flow rate from 0.5 to 1 L/min.

r) Perform shut down procedure

E.

@R

Post-Experiment Assessment (10 marks)

a) Use the sample table in Appendix A, B, for data collection.

b) Plot the CO2 concentration in the outlet water flow as a function of time.

c) Plot the CO2 concentration in the outlet gas flow as a function of time.

d) Compare the CO2 concentration plots for different water flow rates.

Page 8

CHE 246

DEC-APR15

REPORT ASSESSMENT (10 MARKS)

F. Technical Memo

Draft a technical memo addressed to the Process Engineer of Linde Pte Ltd. on your teams evaluation

of the distillation unit. Your memo can take the format of technical report format.

Enclosed: Test results of gas absorption and key findings

The enclosed Test results of gas absorption rate and key findings of the memo should include detailed

test results and key findings as follows:

a) Test results. State the test parameters and provide proper tabulation with units clearly stated.

b) Evaluation of results.

For the section on Evaluation of results, you may use the following guiding questions to discuss the

results:

a) Calculate the concentration of CO 2.

(Sample calculation of Concentration of CO 2 in Feed Tank)

Let say volume of NaOH needed to reach end point = y ml,

Molarity of NaOH = 0.05 mol/L,

Thus, concentration of CO2 in Feed Tank = (mol/l).

b)

c)

d)

e)

@R

Plot the graph CO2 concentration in the outlet water flow as a function of time.

Plot the CO2 concentration in the outlet gas flow as a function of time.

Compare the CO2 concentration plots for different water flow rates.

Calculate the rate of absorption into water.

Page 9

CHE 246

DEC-APR15

APPENDICES

@R

Page 10

CHE 246

DEC-APR15

APPENDIX A

Theory on Distillation Column

The principle for continuous distillation is the same as for normal distillation: when a liquid mixture is

heat so that it boils, the composition of the vapor above the liquid differs from the liquid composition. If

this vapor is then separated and condensed into a liquid, it becomes richer in the lower boiling

component(s) of the original mixture. This is what happens in a continuous distillation column. A mixture

is heated up, and routed into the distillation column. On entering the column, the feed starts flowing

down but part of it, richer in lower boiling component(s), vaporizes and rises. However, as it rises, it

cools and while part of it continues up as vapor, some of it (enriched in the less volatile component)

begins to descend again. Since a continuous distillation unit is fed constantly with a feed mixture and

not filled all at once like e a batch distillation, a continuous distillation unit does not need a sizable

distillation pot, vessel, or reservoir for a batch fill. Instead, the mixture can be fed directly into the

column, where the actual separation occurs. The height of the feed point along the column can vary on

the situation and is designed so as to provide optimal results. A continuous distillation is often a

fractional distillation and can be a vacuum distillation or a steam distillation.

Figure 1: A binary distillation separates a feed mixture stream into two fractions: one distillate and one

bottoms fractions

@R

Page 11

CHE 246

DEC-APR15

SAMPLE TABLE FOR PREPARATION OF CALIBRATION CURVE

Purity of ethanol = __________

Density of ethanol = _____ g/mL

Density of water = _____ g/mL

Molar volume of ethanol = _____ mol/mL

Molar volume of water = _____ mol/ml

@R

Page 12

CHE 246

DEC-APR15

SAMPLE TABLE FOR EXPERIMENTS 1

Initial reboiler composition=

Feed temperature =

Reflux ratio = _____

Feed flow rate = _____ LPM

Distillate flow rate = _____ LPM

Bottom product flow rate = _____ LPM

@R

Page 13

CHE 246

DEC-APR15

PHYSICAL PROPERTIES OF COMPONENTS

Properties of Pure Components

@R

Page 14

CHE 246

DEC-APR15

Figure: 2 X-Y Equilibrium Diagram for Methaol-Water System at 1 atm

@R

Page 15

CHE 246

DEC-APR15

APPENDIX B

Theory on Gas Absorption

Gas absorption is a unit operation in which soluble components of a gas mixture are dissolved into a

liquid phase. Absorption, in common with distillation, makes use of special equipment for bringing gas

and liquid phases into intimate contact. Gas absorption is a unit operation in which soluble components

of a gas mixture are dissolved into a liquid phase.

It is meant to demonstrate the absorption of carbon dioxide into water in a packed column. The gas and

liquid normally flow counter currently, and the packings serve to provide the contacting and

development of interfacial surface through which mass transfer takes place.

Consider a system in which a gaseous component A is in equilibrium with both air and water at a given

temperature. The equilibrium relationship between the partial pressure, pA in the gas phase and the

composition, xA in the liquid phase can often be expressed by a straight line Henrys Law equation at

low concentrations.

pA = H xA

[1]

where H is the Henrys Law constant for the given system expressed in atm/mole fraction. If both sides

of the equation is divided by the total pressure, P in atm, the composition, yA in the gas phase can be

related below:

yA = H xA

[2]

where H is equal to H/P. However, H is more often used because it is independent of the total system

pressure. Equilibrium data for most systems follow Henrys Law up to a concentration of about 1 mol%

in the liquid phase.

Single stage equilibrium process.

One in which two different phases are brought into intimate contact with each other and then are

separated. Various components transfer between the two phases and are essentially at equilibrium with

each other after considerable mixing. The process can be represented in Figure 2 below.

@R

Page 16

CHE 246

DEC-APR15

Figure 3: Gas absorption column.

@R

Page 17

CHE 246

DEC-APR15

SAMPLE TABLE FOR EXPERIMENT 2

Process: Absorption

Air flow rate :

CO2 flow rate :

CO2 inlet composition :

Liquid flow rate :

Time (min)

L/min

L/min

vol%

L/min

Outlet gas

Vol% of CO2 in outlet

gas

Outlet water

Vol% of NaOH for

Vol% of CO2 in outlet

sample titration (mL)

water

0

5

10

15

20

25

30

35

40

45

50

55

60

@R

Page 18

CHE 246

DEC-APR15

APPENDIX C

Assessment

This activity contributes 20% of the marks weighting for this course. The distribution of marks for the

various activity component is contain in Table 1

Criteria

Lab

Preparation

1

Unprepared

and needs

complete

directives from

demonstrator

2

Marginal

preparation,

needs

constant

supervision

3

Prepreparation is

satisfactory.

Requires

occasional

reminders.

Following

Procedure

Lacks the

appropriate

knowledge of

the lab

procedures

Demonstrates

general

knowledge of

lab

procedures

Demonstrates

good

knowledge of

the lab

procedures

Often requires

help from the

demomstrator

to even

complete

basic

procedures

Requires help

from

demonstrator

with some

steps in

procedures

Asks peers for

help with

problems in

lab

procedures

Measurements

are

incomplete,

inaccurate and

imprecise

Measurements

are somewhat

inaccurate and

very imprecise

Data

Collection

Observations

are incomplete

or not included

Symbols, units

and significant

figures are not

included

@R

Works to

follow each

step before

moving on to

the next step

Observations

are incomplete

or recorded in

a confusing

way

There are 3 or

more minor

errors using

symbols, units

and significant

digits or 2

major errors

Measurements

are mostly

accurate

Observations

are generally

complete

Work is

organized

Only 2 or 3

minor errors

using symbols,

units and

significant

digits

4

Prepreparation is

very good.

Seems to

know

everything that

is required.

Demonstrates

sound

knowledge of

lab

procedures

5

Prepreparation is

excellent. Will

often help

others in the

experiments.

Discuss with

peers to solve

problems in

procedures

Gladly helps

other students

to follow

procedures

Carefully

follows each

step

Thoroughly

and carefully

follows each

step before

moving on to

next step

Measurements

are accurate

with

reasonable

precision

Measurements

are both

accurate and

precise

Observations

are thorough

Work is

generally neat

and

organized.

Includes

symbols, units

and significant

digits

Points

Demonstrates

very good

knowledge of

the lab

procedures

Observations

are very

thorough and

may recognize

possible errors

in data

collection

Work is neat

and

organized.

Includes

appropriate

symbols, units

and significant

digits

Page 19

CHE 246

Safety

DEC-APR15

Proper safety

precautions

are

consistently

missed

Needs to be

reminded

often during

the lab

Proper safety

precautions

are often

missed

Proper safety

precautions

are generally

used

Needs to be

reminded

more than

once during

the lab

May need to

be reminded

once during

the lab

Proper safety

procedures

are

consistently

used

Proper safety

precautions

are

consistently

used

Uses general

reminders of

safe practices

independently

Consistently

thinks ahead

to ensure

safety

Will often help

other students

to conduct

labs safely

Q&A

Session

Very poor

responses to

questions.

Marginal

responses.

Needs

guideline to

the correct

answers.

Satisfactory

responses to

questions with

occasional

mistakes

Very good

responses to

questions and

exhibit above

average

knowledge on

experiments

Exhibit

excellent

responses to

questions and

able to discuss

the subject

matter

Clean-up

Proper cleanup procedures

are seldom

used

Needs to be

reminded

more than

once during

the lab to use

proper cleanup procedures

Proper cleanup procedures

generally used

Consistently

uses proper

clean-up

procedures

Consistently

uses proper

clean-up

procedures

help to

complete

clean-up

1 or 2 items

left at station

or not cleaned

Station

generally neat

and clean

Often will help

other students

to complete

tasks properly

3 or more

items left at

station or

station not

cleaned

Unacceptable

Station

generally left

clean

May need

some help on

occasion to

complete

tasks

Station always

left neat and

clean

Station

generally left

clean

Marginal

Acceptable

3 or more

items left at

station or

station not

cleaned

Exceptional

Overall

performance

@R

Excellent

Page 20

You might also like

- Working Guide to Reservoir Rock Properties and Fluid FlowFrom EverandWorking Guide to Reservoir Rock Properties and Fluid FlowRating: 3 out of 5 stars3/5 (1)

- Exp - 2 Bubble Cap Distillation ColumnDocument13 pagesExp - 2 Bubble Cap Distillation ColumnAdawiyah Al-jufri100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Exp 2 Bubble Cap DistillationDocument7 pagesExp 2 Bubble Cap DistillationFaris HamirNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Continuous Distillation UnitDocument3 pagesContinuous Distillation UnitHusna Hafiza Bt. R.AzamiNo ratings yet

- University of Aberdeen SESSION 2011-2012 Degree Examination in EG3570 Separation Processes 1 August 2012 2 PM - 5 PMDocument7 pagesUniversity of Aberdeen SESSION 2011-2012 Degree Examination in EG3570 Separation Processes 1 August 2012 2 PM - 5 PMtoastedcrumpetsNo ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Exp 1 Packed Column DistillationDocument12 pagesExp 1 Packed Column DistillationLuqman WasirNo ratings yet

- Experiment 2Document18 pagesExperiment 2Pravin NairNo ratings yet

- EXP 2B-Packed Column Distillation-Jan 2015Document5 pagesEXP 2B-Packed Column Distillation-Jan 2015Siti KhalidaNo ratings yet

- Solid Liquid Filtration Unit M6: Learning ObjectivesDocument4 pagesSolid Liquid Filtration Unit M6: Learning ObjectivesMayank VashishthaNo ratings yet

- Experiment 2 - Study of Packed Column DistillationDocument7 pagesExperiment 2 - Study of Packed Column DistillationAdawiyah Az-zahra100% (1)

- Packed Column Distillation ProcessDocument8 pagesPacked Column Distillation ProcessKhairin RenNo ratings yet

- Distillation Laboratory Script and Laboratory Report DefinitionDocument10 pagesDistillation Laboratory Script and Laboratory Report DefinitionVictor OdoyoNo ratings yet

- DistillationDocument2 pagesDistillationafic219473No ratings yet

- Experiment No: 3: ObjectivesDocument14 pagesExperiment No: 3: ObjectivesAlimah Azeli100% (1)

- Bubble Cap Distillation ColumnDocument3 pagesBubble Cap Distillation Columnnhalieza1067No ratings yet

- Fractional Distillation Experiment - ChEDocument6 pagesFractional Distillation Experiment - ChEmutencoNo ratings yet

- Distillation Dynamics and Control Workbook 2006 PDFDocument18 pagesDistillation Dynamics and Control Workbook 2006 PDFEr Mayur PatilNo ratings yet

- Exp - 2 Bubble Cap Distillation ColumnDocument13 pagesExp - 2 Bubble Cap Distillation ColumnAmmar FitriNo ratings yet

- Module-4: by Pandurangan.K Assistant Professor Senior VIT VelloreDocument51 pagesModule-4: by Pandurangan.K Assistant Professor Senior VIT VelloreUrvaNo ratings yet

- Bubble Cap Distillation Process: Experiment 2Document13 pagesBubble Cap Distillation Process: Experiment 2Nsv DineshNo ratings yet

- Objective:: Bubble Cap Distillation ColumnDocument3 pagesObjective:: Bubble Cap Distillation ColumnHusna Hafiza Bt. R.AzamiNo ratings yet

- Experiment: Packed Distillation ColumnDocument4 pagesExperiment: Packed Distillation Columnnhalieza1067No ratings yet

- Final Project ReportDocument15 pagesFinal Project Reportwhãts brøNo ratings yet

- Installation and MaintenanceDocument47 pagesInstallation and MaintenancehdlozanoaNo ratings yet

- Experiment No,-3 (A) : Mass Transfer Lab IIT KGPDocument3 pagesExperiment No,-3 (A) : Mass Transfer Lab IIT KGPSiddharth MohapatraNo ratings yet

- 1 Preparation of Ethyl Acetate Using Tubular Reactor: 1.1 Experimental PurposeDocument13 pages1 Preparation of Ethyl Acetate Using Tubular Reactor: 1.1 Experimental PurposeCollins MsipaNo ratings yet

- Tray Distillation Column With RefluxDocument26 pagesTray Distillation Column With RefluxMelvin MoorNo ratings yet

- CPS410 Exam 2015Document4 pagesCPS410 Exam 2015KarinaNo ratings yet

- Requirement:: 2009 - 2011 Waters CorporationDocument6 pagesRequirement:: 2009 - 2011 Waters CorporationRiad ManamanniNo ratings yet

- Re Seng ExamDocument7 pagesRe Seng Examweldsv100% (1)

- 786 - Well PerformanceDocument30 pages786 - Well PerformanceChaithanya Kumar DanduNo ratings yet

- Well Performance Case Study - Oil Well Design: Task 1. Develop A Calibrated Blackoil ModelDocument10 pagesWell Performance Case Study - Oil Well Design: Task 1. Develop A Calibrated Blackoil ModelAnonymous wOKNzWNo ratings yet

- Continuous Distillation Column Lab ReportDocument13 pagesContinuous Distillation Column Lab ReportAli AhmadNo ratings yet

- Report Distillation ColumnDocument20 pagesReport Distillation ColumnAzam Najmi33% (3)

- PROJECT 5. Problems at The Cumene Production Facility, Unit 800Document14 pagesPROJECT 5. Problems at The Cumene Production Facility, Unit 800migelNo ratings yet

- Exp 1 Packed Column DistillationDocument12 pagesExp 1 Packed Column DistillationMuhammad IzzatNo ratings yet

- LLE Assignment and Procedure - Fall 2021Document4 pagesLLE Assignment and Procedure - Fall 2021Kevin YangNo ratings yet

- PH SystemsDocument12 pagesPH Systemslux0008No ratings yet

- Tutorial1 (Withanswers)Document10 pagesTutorial1 (Withanswers)FatinnnnnnNo ratings yet

- Tuto 1Document10 pagesTuto 1ZafirahAhmadFauziNo ratings yet

- App B Case Studies - Pagg 707 - 720Document12 pagesApp B Case Studies - Pagg 707 - 720Daniel GarciaNo ratings yet

- Process Calculation ExercisesDocument3 pagesProcess Calculation ExercisesCaptEnai20% (5)

- HPLCDocument12 pagesHPLCviravangsoNo ratings yet

- Solteq: GAS ABSORPTION UNIT (Model: BP 751-B)Document10 pagesSolteq: GAS ABSORPTION UNIT (Model: BP 751-B)MAIMUNATUN NAWAR MOHD YAZANNo ratings yet

- Centum VP 6 ENG Project - GlobalDocument8 pagesCentum VP 6 ENG Project - GlobalNikhilesh MuraleedharanNo ratings yet

- PTT356 Lab Manual - Rev1Document47 pagesPTT356 Lab Manual - Rev1Fathihah AnuarNo ratings yet

- The Effect of The Reflux Ratio: Olvar Andrés Pedraza, Juan Pablo González YundaDocument8 pagesThe Effect of The Reflux Ratio: Olvar Andrés Pedraza, Juan Pablo González YundaAndres PedrazaNo ratings yet

- Batch Distillation at Total Reflux Using Sieve Tray DistillationDocument5 pagesBatch Distillation at Total Reflux Using Sieve Tray DistillationNurul Atikah JapryNo ratings yet

- Assignment# 1Document8 pagesAssignment# 1Muhamad QasimNo ratings yet

- Pump Simulation in Aspen PlusDocument47 pagesPump Simulation in Aspen Plusahmed elhamy mohamed100% (1)

- Exp4 Batch DistillationDocument10 pagesExp4 Batch DistillationSaidNo ratings yet

- Dr. K. Sivagami, Associate Professor, School of Chemical Engineering, VIT VelloreDocument57 pagesDr. K. Sivagami, Associate Professor, School of Chemical Engineering, VIT VelloreAmol RastogiNo ratings yet

- MSC DT275 Lab ManualDocument37 pagesMSC DT275 Lab ManualBoomdayNo ratings yet

- Che 481 Test 1Document7 pagesChe 481 Test 1Melissa HuynhNo ratings yet

- Depropanizer Design PDFDocument19 pagesDepropanizer Design PDFAli AlengineerNo ratings yet

- ChE312 Process Synthesis and Design Individual AssignmentDocument9 pagesChE312 Process Synthesis and Design Individual AssignmentasdfNo ratings yet

- Method To Prevent CorrosionDocument4 pagesMethod To Prevent CorrosionFaradilah Binti Ajma'inNo ratings yet

- Process Control & Instrumentations CEV 544 PrelabDocument9 pagesProcess Control & Instrumentations CEV 544 PrelabFaradilah Binti Ajma'inNo ratings yet

- ASSIGNMENT 1 - EIA Dila (AutoRecovered)Document5 pagesASSIGNMENT 1 - EIA Dila (AutoRecovered)Faradilah Binti Ajma'inNo ratings yet

- Cev544 Assignment Mar 2018 - Jul 2018Document4 pagesCev544 Assignment Mar 2018 - Jul 2018Faradilah Binti Ajma'inNo ratings yet

- Oxalic Acid E11a BDocument52 pagesOxalic Acid E11a BFaradilah Binti Ajma'inNo ratings yet

- Tutorial EASY (2 - 4 Marks) : (I) (Ii) (Iii) (Iv)Document2 pagesTutorial EASY (2 - 4 Marks) : (I) (Ii) (Iii) (Iv)Faradilah Binti Ajma'inNo ratings yet

- Assignment 1 (B.i, II) CEV544.VsdDocument2 pagesAssignment 1 (B.i, II) CEV544.VsdFaradilah Binti Ajma'inNo ratings yet

- Pressure Control P&IDDocument1 pagePressure Control P&IDFaradilah Binti Ajma'inNo ratings yet

- CEV 420 Case Study - May 2016Document4 pagesCEV 420 Case Study - May 2016Faradilah Binti Ajma'inNo ratings yet

- Fully Report Vs-Group 5Document25 pagesFully Report Vs-Group 5Faradilah Binti Ajma'inNo ratings yet

- Environmentl EthicsDocument16 pagesEnvironmentl EthicsFaradilah Binti Ajma'inNo ratings yet

- T2 12222016 0000Document6 pagesT2 12222016 0000Faradilah Binti Ajma'inNo ratings yet

- Book Review: Environment International 30 (2004) 871 - 872Document2 pagesBook Review: Environment International 30 (2004) 871 - 872Faradilah Binti Ajma'inNo ratings yet

- 00 Rubric Jsub Eh224 - Cev503 - Assignment 4-5Document1 page00 Rubric Jsub Eh224 - Cev503 - Assignment 4-5Faradilah Binti Ajma'inNo ratings yet

- Product Design and Development (Che227) Mini Project 3 EH110Document1 pageProduct Design and Development (Che227) Mini Project 3 EH110Faradilah Binti Ajma'inNo ratings yet

- The Effects of Sleep Deprivation On Your BodyDocument21 pagesThe Effects of Sleep Deprivation On Your BodyFaradilah Binti Ajma'inNo ratings yet

- Ar 2008Document153 pagesAr 2008Faradilah Binti Ajma'inNo ratings yet

- WEEK 7 - Linear Algebraic Equations-programming-STUDENTDocument2 pagesWEEK 7 - Linear Algebraic Equations-programming-STUDENTFaradilah Binti Ajma'inNo ratings yet

- CHE323 June 2015 - Assignment 1 - Template Cover PageDocument5 pagesCHE323 June 2015 - Assignment 1 - Template Cover PageFaradilah Binti Ajma'inNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EH/OCT 2012/CHE335/393Document7 pagesUniversiti Teknologi Mara Final Examination: Confidential EH/OCT 2012/CHE335/393Faradilah Binti Ajma'inNo ratings yet

- ENT300 SyllabusDocument5 pagesENT300 SyllabusFaradilah Binti Ajma'inNo ratings yet

- Administration PlanDocument2 pagesAdministration PlanFaradilah Binti Ajma'inNo ratings yet

- Black Mamba Vs Mongoose Vs King Cobra Vs Komodo Vs PhythonDocument44 pagesBlack Mamba Vs Mongoose Vs King Cobra Vs Komodo Vs PhythonmarcNo ratings yet

- Red Oaks Drive, Frankton, Queenstown-Lakes, Otago PDFDocument1 pageRed Oaks Drive, Frankton, Queenstown-Lakes, Otago PDFCintiah KenedyNo ratings yet

- Nastran Preference Guide Volume 1 Structural AnalysisDocument724 pagesNastran Preference Guide Volume 1 Structural AnalysisGuido RossiNo ratings yet

- A Practical Approach To Classical YogaDocument39 pagesA Practical Approach To Classical Yogaabhilasha_yadav_1No ratings yet

- AVEVA E3D Tutorial Equipment Modeling With Practical ExampleDocument8 pagesAVEVA E3D Tutorial Equipment Modeling With Practical ExampleRamon Alejandro Porras Hernandez100% (1)

- Reservoir Rock PropertiesDocument148 pagesReservoir Rock Propertiesiscribdusername100% (7)

- Nature 00869Document3 pagesNature 00869鍾宗霖No ratings yet

- Grand Vitara 2005Document35 pagesGrand Vitara 2005PattyaaNo ratings yet

- An Infallible JusticeDocument7 pagesAn Infallible JusticeMani Gopal DasNo ratings yet

- Bar Tending TerminologyDocument3 pagesBar Tending TerminologySiska WangNo ratings yet

- Aipl2009 V120000001Document7 pagesAipl2009 V120000001Olof HedinNo ratings yet

- Short Moritz - LiverGB PDFDocument3 pagesShort Moritz - LiverGB PDFPetra JobovaNo ratings yet

- 02K inDocument1 page02K inAbbode HoraniNo ratings yet

- Homoeopathy and MigraineDocument4 pagesHomoeopathy and MigraineEditor IJTSRDNo ratings yet

- Embedded Systems:: Hacking of Electronic EquipmentsDocument76 pagesEmbedded Systems:: Hacking of Electronic EquipmentsKailashi Chandra SekharNo ratings yet

- Material Safety Data Sheet: KOMATSU Supercoolant AF-NAC (50/50 Pre-Diluted)Document5 pagesMaterial Safety Data Sheet: KOMATSU Supercoolant AF-NAC (50/50 Pre-Diluted)Thais Roberta CamposNo ratings yet

- Balmatech Go Ep Tds 2022-03 GBDocument2 pagesBalmatech Go Ep Tds 2022-03 GBAnalista De CalidadNo ratings yet

- The Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageDocument6 pagesThe Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageFriska Rachmanita PrayogoNo ratings yet

- Catalogue Mp200Document33 pagesCatalogue Mp200Adrian TudorNo ratings yet

- Product CatalogDocument4 pagesProduct CatalogpeejayjacintoNo ratings yet

- Grocery GatewayDocument2 pagesGrocery GatewayKumari Mohan0% (2)

- Stock+List 6ct8.3g2 Esn#30549237 Cpl#2218 GeneradorDocument34 pagesStock+List 6ct8.3g2 Esn#30549237 Cpl#2218 GeneradorAlexis SanchezNo ratings yet

- Infineon IRFZ44N DataSheet v01 - 01 ENDocument9 pagesInfineon IRFZ44N DataSheet v01 - 01 ENIkram RidhoNo ratings yet

- DLP MonsoonDocument2 pagesDLP MonsoonjennifertariaoNo ratings yet

- VENUS e CatalogueDocument38 pagesVENUS e CatalogueGanesh BabuNo ratings yet

- Origami Undergrad ThesisDocument63 pagesOrigami Undergrad ThesisEduardo MullerNo ratings yet

- Wps Gtaw Monel b127 b164Document2 pagesWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- Emcoturn 365Document362 pagesEmcoturn 365mikadoturkNo ratings yet

- Lecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LDocument13 pagesLecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LRuth EnormeNo ratings yet

- MIKE21BW Step by Step GuideDocument124 pagesMIKE21BW Step by Step Guideflpbravo100% (2)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Guide to the Practical Use of Chemicals in Refineries and PipelinesFrom EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesRating: 5 out of 5 stars5/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Casing and Liners for Drilling and Completion: Design and ApplicationFrom EverandCasing and Liners for Drilling and Completion: Design and ApplicationRating: 5 out of 5 stars5/5 (3)

- An Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsFrom EverandAn Operations Guide to Safety and Environmental Management Systems (SEMS): Making Sense of BSEE SEMS RegulationsNo ratings yet

- Essentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsFrom EverandEssentials of Oil and Gas Utilities: Process Design, Equipment, and OperationsRating: 4.5 out of 5 stars4.5/5 (4)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- 100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonFrom Everand100 AI Use Cases in the Upstream Industry: A Comprehensive Guide for Professionals and Researchers to Overcome Industry Challenges Using AI and PythonNo ratings yet

- Acquisition and Processing of Marine Seismic DataFrom EverandAcquisition and Processing of Marine Seismic DataRating: 4 out of 5 stars4/5 (4)

- The Petroleum Engineering Handbook: Sustainable OperationsFrom EverandThe Petroleum Engineering Handbook: Sustainable OperationsRating: 3.5 out of 5 stars3.5/5 (5)