Professional Documents

Culture Documents

Process Solutions International: MAX2000 Agitators

Uploaded by

John Jairo SimancaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Solutions International: MAX2000 Agitators

Uploaded by

John Jairo SimancaCopyright:

Available Formats

Process Solutions International

TM

No matter the processing problem, PSI has the solution.

MAX2000 Agitators

UL /ATEX

Key Benefits Up to 55 kw / 75 hp available

Helical bevel geared right angle

or vertical mount agitators

Quiet, 95% efficient power transfer, and low

operating temperature

Small foot print

Rugged drop bearing design

extends gearbox life

C-face motor input eliminates troublesome

couplings and prevents misalignment

The Exclusive Line of PSI

Impellers are sized according to tank volume and

expected duty with optimal mixing lowering mud cost.

Flat Blade impellers have a radial flow.

Right- and Vertical-Angled Agitators

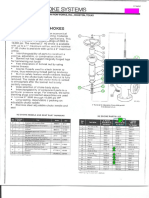

Features The MAX2000 Agitator features a

rugged cast iron gear box that houses

helical bevel gearing.

A unique feature of the MAX2000

Agitator is the drop bearing, which can

be maintained from the top of the tank.

Right angle drives have a 3 gear

reduction which produce less backlash.

Vertical mounted drives have a 2 gear

reduction which reduces vibrations.

Gearbox sight glass allows operator

to visually inspect gearbox lubrication.

Hydrofoil blade impellers have an axial flow.*

Canted blade impellers have a radial/axial flow.*

*PSI offers hydrofoil or canted

impellers in carbon or stainless steel.

For more information on our products, Please contact us at 7519 Prairie Oak Drive Houston, TX 77086

Local 281-893-4774 | (866) 866-4PSI (4774) | Fax 281-893-1027 www.PSIMAX2000.com

Process Solutions International

TM

No matter the processing problem, PSI has the solution.

MAX2000 Agitators

Shaker Screen Cleaner

PSI Shaft Holder with Removable Gearbox

Personnel safety has always been at the forefront of a maintaining a healthy work

environment, and having personnel enter the mud tank can now be avoided thanks

to PSIs new agitator shaft holder. This base allows for removal of the gearbox

without disassembling the agitator shaft and impeller.

Special Feature!

Having the ability to remove the gearbox so easily

contributes to a safer, time and energy efficient

method of doing maintenance and part replacement.

AGITATOR DRIVE CAN BE

SAFELY SERVICED/REMOVED

SHAFT RETAINERS ARE DISENGAGED FROM

THE SHAFT RETAINER BLOCK. SHAFT IS FREE.

RETAINERS ARE MOVED BY WORKING

THE RETAINER THREAD NUTS.

SHAFT RETAINERS ARE ENGAGED WITH

RETAINER BLOCK. THE SHAFT IS SECURE.

COUPLING CAN BE

SAFELY DISENGAGED

Our shaft to shaft coupling

has proven itself to be one

of the strongest and most

reliable in the industry.

RETAINERS ARE MOVED BY WORKING

THE RETAINER NUTS.

Bottom Shaft Stabilizers reduce lower shaft

movement and increases gearbox life.

Teflon insert stabilizers extend life of stabilizer.

Pipe stabilizers offer a reduced cost option.

The Exclusive Line of PSI

Right Angle Agitators...

Our Right Angle Agitators are derived from original, industry-standard right

angle agitators. Due to the strength of the casting, you can secure a

MAX2000 Right Angle Agitator directly to the tank structure without a

fabricated base, which allows for a more compact installation.

C

G

yF

OH

Note 1Recommended height for impeller blades is .75 x Impeller Diameter (off bottom of tank)

SEE NOTE 2

B

C

D F

G H

I J K L

M

13-9/16 16 16 14 14 7/8 24 K-M-6 10-1/2

13-9/16 16 16 14 14 7/8 28 K-M-6 10-1/2

11-11/16

16 16 14 14 7/8 32 K-M-6 10-1/2

11-11/16

16 16 14 14 7/8 32 K-M-6 10-1/2

15-11/16

22 22 18-1/2 19 1-1/8 40 K-M-6 15-1/2

16-15/16

22 22 18-1/2 19 1-1/8 44 K-M-6 15-1/2

18-1/2 22 22 18-1/2 19 1-1/8 48 K-M-6 15-1/2

SEE NOTE 1

MODELS A

M2A3-C 32-3/4

M2A5-C 34-3/8

M2A7-C 38-1/16

M2A10-C 38-1/16

M2A15-C 48-1/2

M2A20-C 49-9/16

M2A25-C 52-1/16

Note 2Measured from top of structure supporting agitator to tank bottom

Vertical Agitators...

The MAX2000 Vertical Agitators share many of the features of our

Right Angle Agitators, but are designed for use when there is a horizontal

space limitation. Depending on the size you need, you can save between 12 to 24 in horizontal space.

Page 10

A

17

17

17-1/4

22

22

22

22

B

C

D F

31-5/8 16 16

31-11/16

16 16

32-15/16

16 16

41-3/16 22 22

42-7/8 22 22

47-7/16 22 22

48-15/16

22 22

Note 1Recommended height for impeller blades is .75 x Impeller Diameter (off bottom of tank)

G H

I J K L

M

14 7/8 32 K-M-6 10-1/2

14 7/8 34 K-M-6 10-1/2

14 7/8 36 K-M-6 15-1/2

19 1-1/8 40 K-M-6 15-1/2

19 1-1/8 44 K-M-6 15-1/2

19 1-1/8 48 K-M-6 15-1/2

19 1-1/8 52 K-M-6 15-1/2

SEE NOTE 2

MODELS

M2A05V

M2A07V

M2A10V

M2A15V

M2A20V

M2A25V

MSA30V

OH

SEE NOTE 1

yF

Note 2Measured from top of structure supporting agitator to tank bottom

For more information on our products, Please contact us at 7519 Prairie Oak Drive Houston, TX 77086

Local 281-893-4774 | (866) 866-4PSI (4774) | Fax 281-893-1027 www.PSIMAX2000.com

Process Solutions International

TM

No matter the processing problem, PSI has the solution.

Toll-Free (866) 866-4PSI

WWW.PSIMAX2000.COM

Download our full line of

INSTALLATION, OPERATION, & MAINTENANCE MANUALS

at www.psimax2000.com

The Exclusive Line of PSI

In short, PSIs agitators are customized to fit perfectly with your drilling project. Its blade impellers, the vertical and

horizontal versions that work with space limitations, the shaft holder with removable gearbox (that are the strongest and

most reliable in the industry), and PSIs high-level protection of its gearboxes minimizes deterioration of equipment, protects

work crew, and consumes less power.

You might also like

- Catalogo Power ChokeDocument4 pagesCatalogo Power ChokeJohn Jairo SimancaNo ratings yet

- CM Construction and Features: One Moving ComponentDocument4 pagesCM Construction and Features: One Moving ComponentJohn Jairo SimancaNo ratings yet

- MTU12V2000DS800 800kW Standby PDFDocument4 pagesMTU12V2000DS800 800kW Standby PDFJohn Jairo SimancaNo ratings yet

- Slip Type ElevatorDocument15 pagesSlip Type ElevatorJohn Jairo Simanca100% (1)

- Manual XQ 140 en Ingles PDFDocument61 pagesManual XQ 140 en Ingles PDFJohn Jairo SimancaNo ratings yet

- Completion Equipment: One Company Unlimited SolutionsDocument4 pagesCompletion Equipment: One Company Unlimited SolutionsJohn Jairo SimancaNo ratings yet

- Manual XQ 140 en Ingles PDFDocument61 pagesManual XQ 140 en Ingles PDFJohn Jairo SimancaNo ratings yet

- SS 7154026 18397814 001Document6 pagesSS 7154026 18397814 001Amr Abd ElrahmanNo ratings yet

- Rotary Slips PDFDocument118 pagesRotary Slips PDFJohn Jairo Simanca100% (3)

- T3 Annulars BOP Operators Manual 7022 PDFDocument28 pagesT3 Annulars BOP Operators Manual 7022 PDFJohn Jairo Simanca100% (2)

- Pump Performance Chart (General Pumps)Document27 pagesPump Performance Chart (General Pumps)John Jairo SimancaNo ratings yet

- Especificaciones D 2Document8 pagesEspecificaciones D 2John Jairo SimancaNo ratings yet

- G-40 Cameron 4 7500 Psi DMDocument2 pagesG-40 Cameron 4 7500 Psi DMJohn Jairo SimancaNo ratings yet

- Gate Valve CameronDocument13 pagesGate Valve CameronJohn Jairo Simanca100% (1)

- DuraDeck 1 Specifications W Detailed Testing ResultsDocument1 pageDuraDeck 1 Specifications W Detailed Testing ResultsJohn Jairo SimancaNo ratings yet

- Choke H2Document1 pageChoke H2John Jairo SimancaNo ratings yet

- TESIS DISEO PUENTE GRUA 5 TN PDFDocument104 pagesTESIS DISEO PUENTE GRUA 5 TN PDFAndres RestrepoNo ratings yet

- Top DrveDocument2 pagesTop DrveJohn Jairo SimancaNo ratings yet

- SRS Engineering NOC List Managers Added CommsDocument1 pageSRS Engineering NOC List Managers Added CommsJohn Jairo SimancaNo ratings yet

- Brochure Trailers HerculesDocument43 pagesBrochure Trailers HerculesJohn Jairo SimancaNo ratings yet

- King-Pin Walking Foot: Technical SpecificationsDocument1 pageKing-Pin Walking Foot: Technical SpecificationsJohn Jairo SimancaNo ratings yet

- Process Solutions International: MAX2000 AgitatorsDocument4 pagesProcess Solutions International: MAX2000 AgitatorsJohn Jairo Simanca100% (1)

- SRS Engineering NOC List Managers Added CommsDocument1 pageSRS Engineering NOC List Managers Added CommsJohn Jairo SimancaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Denim Factory Setup: A Plant Layout AssignmentDocument55 pagesDenim Factory Setup: A Plant Layout Assignmenttanya gupta100% (1)

- Tork 1100seriesDocument2 pagesTork 1100seriesjpcc1986100% (1)

- Final Bioenergy PresentationDocument22 pagesFinal Bioenergy Presentationblossoms_diyya2998No ratings yet

- DesignGuide150 EN 20110401 V1-1 NDocument38 pagesDesignGuide150 EN 20110401 V1-1 NgrenleyNo ratings yet

- 2 Annual Power and Desalination Summit: 17 - 18 March 2013 Bader M Al-SaleemDocument16 pages2 Annual Power and Desalination Summit: 17 - 18 March 2013 Bader M Al-Saleemcvolkan1100% (1)

- Free American Pharoah Stakes 2018 Past PerformancesDocument2 pagesFree American Pharoah Stakes 2018 Past PerformancesJonathanNo ratings yet

- AC 4solar PV SyllabusDocument2 pagesAC 4solar PV SyllabusshreemantiNo ratings yet

- Lakshya List of Papers Selected For Presentation From Dept. of EeeDocument7 pagesLakshya List of Papers Selected For Presentation From Dept. of EeeDilip TheLipNo ratings yet

- Bomba de EngranagesDocument0 pagesBomba de EngranagesPablo OrtegaNo ratings yet

- Sizing - Task 3 - v2Document18 pagesSizing - Task 3 - v2Nascent OnrNo ratings yet

- Modern Electric, Hybrid Electric & Fuel Cell Vehicles - Mehrdad EhsaniDocument8 pagesModern Electric, Hybrid Electric & Fuel Cell Vehicles - Mehrdad EhsaniPunit100% (2)

- Interocan ProfileDocument7 pagesInterocan Profilesayad_007No ratings yet

- IRENA Africa 2030 REmap 2015 Low-ResDocument72 pagesIRENA Africa 2030 REmap 2015 Low-ResVitor MartinsNo ratings yet

- Energy Storage TechDocument4 pagesEnergy Storage TechGodfrey EmilioNo ratings yet

- Improved Operation of Cables Connecting Offshore Wind Farms To The Power Grid H. J. Joergensen, J. Hjerrild, C. Jensen and J. Havsager Defu, Eltra and Elkraft System DenmarkDocument8 pagesImproved Operation of Cables Connecting Offshore Wind Farms To The Power Grid H. J. Joergensen, J. Hjerrild, C. Jensen and J. Havsager Defu, Eltra and Elkraft System DenmarkramsesiNo ratings yet

- Fyp 001Document2 pagesFyp 001Moazzam IrshadNo ratings yet

- Solar PV Pumping System (Training Manual) PDFDocument129 pagesSolar PV Pumping System (Training Manual) PDFSameet RazaNo ratings yet

- Overview On Fuel CellsDocument6 pagesOverview On Fuel CellsCarol BrigagãoNo ratings yet

- Rehabilitating and Upgrading Hydro Power Plants A Hydro Power Technology Round-Up Report, Volume 2Document92 pagesRehabilitating and Upgrading Hydro Power Plants A Hydro Power Technology Round-Up Report, Volume 2szizaNo ratings yet

- Viability Study of Grid Connected Solar PV System in EthiopiaDocument8 pagesViability Study of Grid Connected Solar PV System in EthiopiaWubishet AsratNo ratings yet

- Brochure Doosan GV222TIDocument4 pagesBrochure Doosan GV222TIGabriel Andres Valencia0% (1)

- Retiming CamshaftDocument1 pageRetiming CamshaftArun SNo ratings yet

- The Ultimate TailwindDocument8 pagesThe Ultimate TailwindMohamad AsrulNo ratings yet

- Atelier Lorentzen LangkildeDocument1 pageAtelier Lorentzen LangkildePatrascu Cristian EmanuelNo ratings yet

- Biofuels Production and Processing Technology: M.R. Riazi, David ChiaramontiDocument47 pagesBiofuels Production and Processing Technology: M.R. Riazi, David ChiaramontiBirjesh YaduvanshiNo ratings yet

- DG Optimal DistributionDocument5 pagesDG Optimal DistributionAemiroNo ratings yet

- NNPCDocument21 pagesNNPCtsar_philip2010100% (1)

- Axial Generator Calculator - English VersionDocument55 pagesAxial Generator Calculator - English VersionMihai ApostoliuNo ratings yet

- 132 KV GSSDocument26 pages132 KV GSSPhillip LongNo ratings yet

- BSB DB Operation ManualDocument15 pagesBSB DB Operation ManualEris Osman RifkiNo ratings yet