Professional Documents

Culture Documents

Airpro Max™ Air Valves Specifications: Air Release Valve Specification

Uploaded by

Astri Ngent0 ratings0% found this document useful (0 votes)

13 views2 pagesbook

Original Title

avspec

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbook

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views2 pagesAirpro Max™ Air Valves Specifications: Air Release Valve Specification

Uploaded by

Astri Ngentbook

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

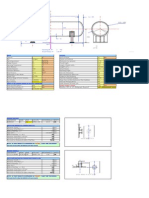

AirPro Max Air Valves Specifications

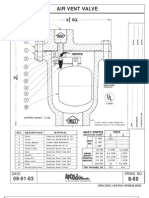

Air Release Valve Specification

The Air Release Valve shall be float operated, simple lever or compound lever type, designed to automatically vent accumulated air

from the pipeline while the system is pressurized and operating.

An adjustable designed orifice button shall be used to seal the valve discharge port with drip-tight shut-off. The diameter of the orifice

must be sized to vent air within a given operating pressure range to insure maximum air venting capacity.

The float and connection shall be all 316 stainless steel construction and guaranteed to withstand the designed system surge pressure

without failure. The body and cover shall be ductile iron construction and valve internal parts and cover bolts shall be 316 stainless

steel. The rubber seat shall be Buna-N for water tight shut-off. A vent cap with screen must be provided to prevent debris from entering

the valve.

The Air Release Valve shall be manufactured per ANSI/ AWWA C512 and shall be Series WAR AirPro Max Air Release Valves manufactured by the Henry Pratt Company, Aurora, IL USA.

Air Vacuum Valve Specifications

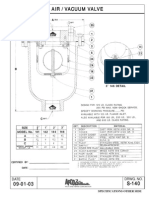

Air Vacuum valve shall allow large volumes of air to be exhausted from the pipeline during filling and large volumes of air to re-enter

when draining the pipeline occurs for any reason.

The size of the Air Vacuum Valve shall have the same cross-section area as the valve inlet size. A stainless steel single bottom guide shaft

shall guide the float. The 4 and larger air vacuum valve floats shall have top and bottom guide shafts to accurately guide the float, without hunting, into the seat for shut-off. A steel valve hood shall be provided to protect the valve discharge orifice from debris.

The float shall be of all stainless steel construction guaranteed to withstand the design system surge pressure without failure. The body

and cover shall be concentrically located for vertical float rising accurately into the seat shut-off position to prevent water spilling. The

valve body and cover shall be constructed of ductile iron and the valve internal parts shall be of 316 Stainless Steel with Buna-N rubber

seat.

The Air Vacuum Valve shall be manufactured per ANSI/ AWWA C512 and shall be Series WAV AirPro Max Air Vacuum Valves

manufactured by the Henry Pratt Company, Aurora, IL USA.

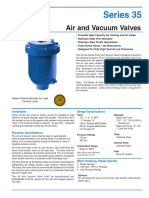

Combination Air Valve Suggested Specifications

The Combination Air Valve shall function as an air vacuum valve and air release valve in a single or dual body design. The large air

vacuum orifice shall allow large volumes of air to be exhausted during pipeline filling and large volume of air intake while draining, or

in the event of a break in the pipeline, to prevent a vacuum from forming.

The inlet/outlet and seat of the valve shall have the same flow area. The stainless steel poppet shall be guided by a stainless steel guide

shaft and seal drip tight against a Buna-N seat. 4 and larger valves shall have dual guided stainless steel shafts of hexagonal cross section and a protective discharge hood.

The float shall be of all stainless steel construction and capable of withstanding maximum system surge pressure without failure. The

body and cover shall be concentrically located and of ductile iron and the valve internal trim shall be of 316 Stainless Steel. Seat shall be

Buna-N for water tight shut off.

The Combination Air Valve shall be manufactured per ANSI/AWWA C512 and shall be Series WCV AirPro Max Combination Air

Valves manufactured by the Henry Pratt Company, Aurora, IL USA.

5/30/2013

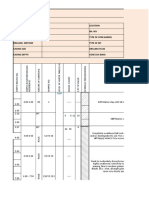

AirPro Max Air Valves Specifications

Wastewater Air Release Valve Specifications

The Air Release Valve shall be of the float operated, compound lever type, and capable of automatically venting accumulated air, gas or

vapor from a fluid system while the system is pressurized and operating.

An adjustable designed orifice button shall be used to seal the valve discharge port with drip-tight shut-off. The diameter of the orifice

must be sized for use within a given operating pressure range to insure maximum air venting capacity.

The float shall be of all stainless steel construction and guaranteed to withstand the maximum system surge pressure without failure.

The body and the cover shall be of ductile iron and all valve internal parts shall be of stainless steel. The rubber seat is Buna-N for water

tight shut-off.

The air release valve shall be manufactured per ANSI/ AWWA C512 and shall be Series WWAR AirPro Max Wastewater Air Release

Valves manufactured by the Henry Pratt Company, Aurora, IL USA.

Wastewater Air Vacuum Valve Specifications

The Wastewater Air Vacuum Valve shall be able to automatically exhaust large quantities of air during filling of a pipeline and allow air

to re-enter pipeline during the draining or when a negative pressure occurs.

The inlet and outlet of the Air Vacuum Valve shall have the same cross-section area as the valve size. A stainless steel bottom guide shaft

shall guide the float. The 4 and larger valve floats shall have top and bottom guide shafts of hexagonal cross section and have a protective steel discharge hood.

The float shall be of all stainless steel construction and capable of withstanding maximum system surge pressure without failure. The

body and cover shall be concentrically located and of ductile iron and the valve internal parts shall be of 316 stainless steel with Buna-N

rubber seat.

The Wastewater Air Vacuum Valve shall be manufactured per ANSI/AWWA C512 and shall be Series WWAV AirPro Max Air

Vacuum Valves manufactured by the Henry Pratt Company, Aurora, IL USA.

Wastewater Combination Air Valve Specifications

The Combination Air Valve shall combine the operating features of both the large orifice Air Vacuum Valve and the small orifice Air

Release Valve into one unit. The large orifice Air Vacuum Valve portion shall automatically exhaust large quantities of air during the

filling of the pipeline and automatically allow large volumes of air to reenter the pipeline when the internal pressure of the pipeline approaches a negative value due to vacuum column separation, draining of the pipeline, or other emergency condition. The small orifice

Air Release Valve portion shall automatically release small pockets of air from the pipeline while it is under pressure.

The inlet and outlet of the valve shall have the same size and cross-section flow area. The float shall be center guided by a single or

double stainless steel guide shaft and shut drop tight against a resilient Buna-N seat.

The float shall be of all stainless steel construction and capable of withstanding maximum system surge pressure without failure. The

body and cover shall be concentrically located to accurately guide the float, without hunting, to shut-off to prevent spillage. The body

and cover shall be ductile iron and the valve internal parts shall be of 316 stainless steel with Buna-N rubber seat.

The Combination Air Release and Vacuum Valve shall be manufactured per ANSI/AWWA C512 and shall be Series WWCV AirPro

Max Combination Air Valves manufactured by the Henry Pratt Company, Aurora, IL USA.

5/30/2013

You might also like

- Apco Vacuum Reliefair Inlet Valves Avr 1500 PDFDocument8 pagesApco Vacuum Reliefair Inlet Valves Avr 1500 PDFTanmoy Dutta100% (1)

- VELMATIC Well Service Air ValveDocument2 pagesVELMATIC Well Service Air Valvecarlos37No ratings yet

- Informacion Valvula DesaireadoraDocument4 pagesInformacion Valvula DesaireadoraCesar GraterolNo ratings yet

- Combination Air Valves Guide for PipelinesDocument4 pagesCombination Air Valves Guide for PipelinesFelipe OliverosNo ratings yet

- CLAV - Threaded & Flanged Air Release & Vacuum BreakerDocument2 pagesCLAV - Threaded & Flanged Air Release & Vacuum BreakerGiriDharanNo ratings yet

- APCO #50 air vent valve specsDocument2 pagesAPCO #50 air vent valve specsAhmad MarthaNo ratings yet

- Air Release & Air & Vacuum Valves: How They Work Pressurized Potable Water ValvesDocument1 pageAir Release & Air & Vacuum Valves: How They Work Pressurized Potable Water ValvesMASOUDNo ratings yet

- Catalogo Valvulva VaeDocument4 pagesCatalogo Valvulva VaeDenaibeliNo ratings yet

- Air Release Valve E-34 Series FireDocument5 pagesAir Release Valve E-34 Series FireUghojor ElohoNo ratings yet

- Air / Air / Air / Air / Air / V V V V VA A A A Acuum Cuum Cuum Cuum Cuum V V V V VAL AL AL AL Alve VE VE VE VEDocument2 pagesAir / Air / Air / Air / Air / V V V V VA A A A Acuum Cuum Cuum Cuum Cuum V V V V VAL AL AL AL Alve VE VE VE VEnazar750No ratings yet

- Air Release Valve Cla-ValDocument4 pagesAir Release Valve Cla-Valventas2.fireproofcolNo ratings yet

- I. Specify Ii. Specify Iii. SpecifyDocument2 pagesI. Specify Ii. Specify Iii. SpecifygjoeNo ratings yet

- Air Release ValveDocument8 pagesAir Release Valveneels06274No ratings yet

- Pressure Releif ValveDocument24 pagesPressure Releif Valvemtalha_loveNo ratings yet

- Series 34: Fire Protection System Air Release ValveDocument4 pagesSeries 34: Fire Protection System Air Release ValvecccNo ratings yet

- Valvula DesaireadoraDocument4 pagesValvula DesaireadoracccNo ratings yet

- Spring Loaded Safety Valve Selection GuideDocument4 pagesSpring Loaded Safety Valve Selection GuidePoojan ThakoreNo ratings yet

- Rps-Rr-Surge Anticipating Pressure ReliefDocument3 pagesRps-Rr-Surge Anticipating Pressure ReliefhakseoNo ratings yet

- T1002-PSV-1453 Type - 2600Document2 pagesT1002-PSV-1453 Type - 2600Jonson CaoNo ratings yet

- PR - Pressure Reducing ValveDocument2 pagesPR - Pressure Reducing ValveNajaf HussainNo ratings yet

- Av 813 W (1-Av)Document1 pageAv 813 W (1-Av)SrStrikeNo ratings yet

- Air Release Vacuum Breaker ValveDocument16 pagesAir Release Vacuum Breaker ValveLao Zhu100% (1)

- ON-OFF FLOAT VALVE Sizes R11/4" - DN 600Document2 pagesON-OFF FLOAT VALVE Sizes R11/4" - DN 600sergethomas2010No ratings yet

- Material Specification For FLANGED RUBBER SEATED BUTTERFLY VALVESDocument4 pagesMaterial Specification For FLANGED RUBBER SEATED BUTTERFLY VALVESMASOUDNo ratings yet

- Apco Air Release Valves Arv Arv Air Release Valves Sales 600Document4 pagesApco Air Release Valves Arv Arv Air Release Valves Sales 600RashedNo ratings yet

- Inlet ValveDocument5 pagesInlet Valveujwol_phaijuNo ratings yet

- Literature For Blow-Off ValveDocument16 pagesLiterature For Blow-Off Valvevon18100% (1)

- 07 ValvesDocument33 pages07 Valvesshiva_ssk17No ratings yet

- Válvula de SeguridadDocument8 pagesVálvula de Seguridadmark_59No ratings yet

- Tamper Proof Kinetic Air Valve PDFDocument4 pagesTamper Proof Kinetic Air Valve PDFmekanikaNo ratings yet

- ValvesDocument42 pagesValvesSundara MoorthyNo ratings yet

- These Are Two Different Types of Ball ValvesDocument18 pagesThese Are Two Different Types of Ball Valvesgabi_nanaNo ratings yet

- Broady 3500 BrochureDocument12 pagesBroady 3500 Brochureahmedm2020No ratings yet

- AAP S19 Check Valves & Strainers SDocument13 pagesAAP S19 Check Valves & Strainers SAppleuk SudarNo ratings yet

- Ball Valve Seat Seal Injection SystemDocument28 pagesBall Valve Seat Seal Injection SystemmudrijasmNo ratings yet

- Series 44 Ball Valves: Worcester ControlsDocument8 pagesSeries 44 Ball Valves: Worcester ControlsRubenn54No ratings yet

- E-35 - 2016 NewDocument1 pageE-35 - 2016 NewjpalauguillemNo ratings yet

- Apco Airvacuum Valves Avv Sales 601Document8 pagesApco Airvacuum Valves Avv Sales 601Jhony MedranoNo ratings yet

- Air Release 2014Document4 pagesAir Release 2014Aly AnisNo ratings yet

- Vane de Control DebitDocument2 pagesVane de Control Debitsergethomas2010No ratings yet

- Teleflo Safety Relief Valves GuideDocument10 pagesTeleflo Safety Relief Valves GuideKarl NakouziNo ratings yet

- Products Cataloge AbbDocument6 pagesProducts Cataloge AbbakankshaNo ratings yet

- Constant Speed Vertical Turbine Irrigation Pumping StationDocument11 pagesConstant Speed Vertical Turbine Irrigation Pumping StationGie Mak0% (1)

- Vane de Protectie La Soc HidraulicDocument2 pagesVane de Protectie La Soc Hidraulicsergethomas2010No ratings yet

- Sewage Air ValveDocument10 pagesSewage Air ValveAhmed TalaatNo ratings yet

- Fire HydrantDocument6 pagesFire HydrantdileepsiddiNo ratings yet

- Pressure Vacuum Valves PDFDocument5 pagesPressure Vacuum Valves PDFFelipe Correa MahechaNo ratings yet

- Exp Fire Hydrants 929Document3 pagesExp Fire Hydrants 929Cesar CoronelNo ratings yet

- Grove G9 Wafer Gate ValveDocument9 pagesGrove G9 Wafer Gate Valvetxlucky80No ratings yet

- Section 2 (Understanding Warren Rupp) KLMDocument67 pagesSection 2 (Understanding Warren Rupp) KLMMaulia SabrinaNo ratings yet

- Valves Details and UsageDocument72 pagesValves Details and UsageKagira Drawing Soltuion100% (1)

- Gate Valve: Typical Use Valve ConstructionDocument4 pagesGate Valve: Typical Use Valve ConstructionCegrow Ber BersabalNo ratings yet

- MS Series Metal Seated Sampling ValvesDocument4 pagesMS Series Metal Seated Sampling ValvesGiovanni TrinidadNo ratings yet

- Apollo ValvesDocument44 pagesApollo ValvesDevdatt WaghuleNo ratings yet

- Flowserve Vlatb001Document20 pagesFlowserve Vlatb001Selva KumarNo ratings yet

- F 83179Document6 pagesF 83179pcmfilhoNo ratings yet

- Mud Barge Sea ChestDocument1 pageMud Barge Sea ChestAstri NgentNo ratings yet

- Data Dial IndikatorDocument2 pagesData Dial IndikatorAstri NgentNo ratings yet

- 10 11Document9 pages10 11PrashannaNo ratings yet

- D Value CalcDocument5 pagesD Value CalcAstri NgentNo ratings yet

- Bekomat Produk DisplayDocument4 pagesBekomat Produk DisplayAstri NgentNo ratings yet

- Slide Bearing PTFE Tes ReportDocument6 pagesSlide Bearing PTFE Tes ReportAstri NgentNo ratings yet

- Beam Desain1Document2 pagesBeam Desain1Astri NgentNo ratings yet

- Plate and Box Girder DesignDocument60 pagesPlate and Box Girder DesignKrishna ChandranNo ratings yet

- Design of Welded ConnectionsDocument8 pagesDesign of Welded ConnectionsAstri NgentNo ratings yet

- Bearing Layout PDFDocument1 pageBearing Layout PDFAstri NgentNo ratings yet

- Assy Joint Pipa Line 1Document1 pageAssy Joint Pipa Line 1Astri NgentNo ratings yet

- Gantry Crane CalculatedDocument1 pageGantry Crane CalculatedAstri NgentNo ratings yet

- Surge TankDocument4 pagesSurge TankAstri NgentNo ratings yet

- ZX 100 K-Truss Support PadDocument4 pagesZX 100 K-Truss Support PadAstri NgentNo ratings yet

- Flange Example CalcDocument14 pagesFlange Example CalcAstri NgentNo ratings yet

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Weld Analysis-IC Method v1.1Document5 pagesWeld Analysis-IC Method v1.1jefersonpimentelNo ratings yet

- Hydroelectric Hydro Power 4 3 1 DesignDocument28 pagesHydroelectric Hydro Power 4 3 1 DesignLouise UmaliNo ratings yet

- Over Head Water Tank DesignDocument5 pagesOver Head Water Tank DesignAstri Ngent100% (1)

- NTN Pillow BlockDocument54 pagesNTN Pillow BlockteguheafNo ratings yet

- 6000 EN 00 04 Friction BearingDocument30 pages6000 EN 00 04 Friction BearingAstri NgentNo ratings yet

- Spherical Roller Thrust Bearing PDFDocument16 pagesSpherical Roller Thrust Bearing PDFAstri NgentNo ratings yet

- Reinforced PadDocument3 pagesReinforced PadAstri NgentNo ratings yet

- Plugin Bushes PDFDocument3 pagesPlugin Bushes PDFAstri NgentNo ratings yet

- ValveDocument4 pagesValveAstri NgentNo ratings yet

- Calculating The Time Required To Empty A Vessel: ExamplesDocument1 pageCalculating The Time Required To Empty A Vessel: ExamplesKabir KhanNo ratings yet

- Motor Selection, Inertia PDFDocument6 pagesMotor Selection, Inertia PDFIswar Rauf Aboo 'AqilahNo ratings yet

- Hammer Product Data SheetDocument2 pagesHammer Product Data SheetAstri NgentNo ratings yet

- Limit State DesignDocument26 pagesLimit State DesignAstri NgentNo ratings yet

- Gang SawDocument55 pagesGang SawAstri NgentNo ratings yet

- Staad Training Day 1Document116 pagesStaad Training Day 1Bee AnquilianoNo ratings yet

- Reliable Model DDX Deluge Valve, 4-6 Inches (G-G - Single - Interlocked - PreAction)Document18 pagesReliable Model DDX Deluge Valve, 4-6 Inches (G-G - Single - Interlocked - PreAction)Aqil SiddiquiNo ratings yet

- Contractor Design and Standard Form ContractsDocument14 pagesContractor Design and Standard Form ContractskuvjNo ratings yet

- Puddle Flanges - FlexsealDocument6 pagesPuddle Flanges - FlexsealApoorvaNo ratings yet

- Western Power's - Udia-Streetlighting-List PDFDocument1 pageWestern Power's - Udia-Streetlighting-List PDFTTaanNo ratings yet

- Maintenance of Railway TrackDocument39 pagesMaintenance of Railway TrackvennillaNo ratings yet

- Transportation of ConcreteDocument12 pagesTransportation of Concretesagar devidas khot100% (3)

- Investigation of Risk Management Perception in Albanian Construction IndustryDocument12 pagesInvestigation of Risk Management Perception in Albanian Construction IndustryTaqwa HadidiNo ratings yet

- UL - PotterDocument3 pagesUL - PotterMaged Lotfy Abdel-aalNo ratings yet

- Ied Product Disassembly Chart 1Document8 pagesIed Product Disassembly Chart 1api-668364903No ratings yet

- Weld Fit-Up Verification: Employee TrainingDocument10 pagesWeld Fit-Up Verification: Employee TrainingMohammad RizwanNo ratings yet

- 04 Basic Schematic Diagram of A Rotary Drilling Rig PDFDocument3 pages04 Basic Schematic Diagram of A Rotary Drilling Rig PDFSakthivel Swaminathan50% (2)

- TOYOTA Yaris 1.33 VVT-i 1NR-FE: Timing Chain: Removal/installationDocument17 pagesTOYOTA Yaris 1.33 VVT-i 1NR-FE: Timing Chain: Removal/installationMapaqui Mapaqui100% (1)

- (Asce) Co 1943-7862 0000567Document6 pages(Asce) Co 1943-7862 0000567ilhamNo ratings yet

- Pile Design CalculationDocument69 pagesPile Design Calculationhessian123No ratings yet

- New Power Supply Installation for 8 Aircon UnitsDocument2 pagesNew Power Supply Installation for 8 Aircon UnitsJohn Ralph VegaNo ratings yet

- Bore LogDocument4 pagesBore LogVardhanNo ratings yet

- Real Estate and Destination Development in TourismDocument331 pagesReal Estate and Destination Development in Tourismfarah fadillahNo ratings yet

- PMBI WorkflowDocument3 pagesPMBI WorkflowBrian MigueNo ratings yet

- Energy Series Dynamic Dome SkylightsDocument2 pagesEnergy Series Dynamic Dome SkylightsoutmatchNo ratings yet

- Time Saver Standards For Housing and Residential Development - TextDocument1,110 pagesTime Saver Standards For Housing and Residential Development - TextPsr Krishna100% (3)

- Ansi Classes Body Material SelectionDocument3 pagesAnsi Classes Body Material SelectionManh Tien HoangNo ratings yet

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

- Tube StructureDocument27 pagesTube StructureI Gede Arta RismawanNo ratings yet

- Operator's Manual for 662420-B Air Motor Oil PumpDocument11 pagesOperator's Manual for 662420-B Air Motor Oil PumpgnunezisventecNo ratings yet

- Design of Reactor With Agitator Shaft 1Document40 pagesDesign of Reactor With Agitator Shaft 1gholiNo ratings yet

- A I R P O R T S Construction Program Management 56Document56 pagesA I R P O R T S Construction Program Management 56Carl WilliamsNo ratings yet

- Value Management PDFDocument3 pagesValue Management PDFManVasNo ratings yet

- Hyundai Dash 9 Posi - Nega SytemDocument70 pagesHyundai Dash 9 Posi - Nega SytemRobert Zehender99% (76)

- Workshop 2011 - 03121936Document551 pagesWorkshop 2011 - 03121936FR100% (2)