Professional Documents

Culture Documents

Micro Epsilon Wire Sensor P60 P96 en

Uploaded by

kirubakaranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Micro Epsilon Wire Sensor P60 P96 en

Uploaded by

kirubakaranCopyright:

Available Formats

More Precision.

wireSENSOR

Draw-wire displacement sensors

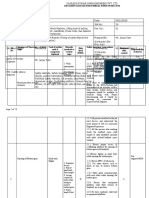

Draw-wire sensors wireSENSOR

P60 analog

- Robust aluminium profile housing

- Customized versions for OEM

- Potentiometer, current and voltage output

Model P60

Output P

mounting

grooves for M4

10.7

37

38.6

129

10

38.6

10.7

Model P60

Measuring range (mm)

A (mm)

100 / 300 / 500 / 1000

16.15

150 / 750 / 1500

24.2

Measuring range (mm)

A (mm)

100 / 300 / 500 / 1000

16.15

150 / 750 / 1500

24.2

40

60

76.5

Output U/I

mounting

grooves for M4

A

129

10

58

38.6

10.7

24

38.6

60

10.7

40

95

25

WDS-100P60

Model

WDS-150P60

WDS-300P60

Output

WDS-500P60

WDS-750P60

WDS-1000P60

WDS-1500P60

P/U/I

Measuring range

Linearity

mm

100

150

300

500

750

1000

1500

0.1% FSO mm

0.5

0.75

1.5

0.25% FSO mm

0.75

0.5% FSO mm

0.5

0.75

Resolution

quasi infinite

Sensor element

conductive plastic/wire potentiometer

Temperature range

hybrid potentiometer

-20 ... +80C

housing

Material

aluminium

draw wire

coated polyamid stainless steel ( 0.45mm)

Sensor mounting

mounting grooves in the housing

Wire mounting

wire clip

Wire acceleration

appr. 10 - 15g (dependent upon measuring range)

Wire retraction force (min)

6.5

4.5

3.5

Wire extension force (max)

7.5

5.5

7.5

7.5

5.5

7.5

5.5

Protection class

IP 65 (only if connected)

Vibration

20g, 20Hz - 2kHz

Mechanical shock

50g, 10ms

P

Electrical connection

U/I

Weight

integrated cable, radial, 1m long

flange connector, radial, 8-pin, DIN45326

appr. 370g

FSO = Full Scale Output

Specifications for analog outputs on page 43.

Article description

WDS - 100 - P60 - CR - P

Output option:

P = potentiometer (with connection CR)

U = voltage (with connection SR)

I = current (with connection SR)

Connection:

SR: radial plug

CR: integrated cable, radial, 1m

Model P60

Measuring range in mm

Draw-wire sensors wireSENSOR

26

P60 digital

- Robust aluminium profile housing

- Customized versions for OEM

- Incremental/absolute encoder

Output HTL/TTL

Model P60

MR (mm)

A (mm)

1000

16.15

24.2

mounting

mounting

A for M4

grooves for M4grooves

60

Model P60

10.738.6

60

10

58

58

58

38.6

10.7

129

38.6

10.7

38.6

10

10

129

1500

Output SSI

75

40

40

40

10.7

97

75

Output CO/PB

MR (mm)

A (mm)

1000

16.15

1500

24.2

mounting

grooves for M4

A

10.7

58

38.6

129

10

38.6

60

81

10.7

40

21.3

129

27

Model

WDS-1000-P60

WDS-1500-P60

Output

HTL/ TTL/ PB/ CO/ SSI

Measuring range

Linearity

0.02% FSO

HTL, TTL

Resolution

SSI, PB, CO

1000mm

1500mm

0.2mm

0.3mm

0.067mm (15 Pulses/mm)

0.1mm (10 Pulses/mm)

0.024mm

0.03mm

Sensor element

incremental encoder

Temperature range

-20 ... +80C

housing

Material

aluminium

draw wire

coated polyamid stainless steel ( 0.45mm)

Sensormontage

mounting grooves in the housing

Wire mounting

wire clip

Wire acceleration

10g

15g

Wire retraction force (min)

5N

3.5N

Wire extension force (max)

7.5N

5.5N

Protection class

IP 65 (only if connected)

Vibration

20g, 20Hz - 2kHz

Mechanical shock

50g, 10ms

HTL/TTL

Electrical connection

SSI

PB/CO

Weight

integrated cable, radial, 1m long

flange connector, radial, 12-pin

bus cover

appr. 1kg

FSO = Full Scale Output

Specifications for digital outputs on page 44.

Article description

WDS - 1000 - P60 - CR - TTL

Output option:

HTL

TTL

CO: CANopen

PB: Profibus DP

SSI

Connection:

SR (Output SSI): radial plug

CR (Output HTL, TTL): integrated cable, radial, 1m

BH (Output CO, PB): bus cover

Model P60

Measuring range in mm

Draw-wire sensors wireSENSOR

P96 analog

- Robust aluminium profile housing

- Customized versions for OEM

- Potentiometer, current and voltage output

Output P

A

10

MR (mm)

A (mm)

2000

32

2500

41.4

36

70

50

70

13

96

Model P96

4x M

58

124

184

2x set screw M4

70

Model P96

118

Output U/I

A

10

MR (mm)

A (mm)

2000

32

2500

41.4

2x set screw M4

36

58

50

70

96

123

70

124

184

4x

70

28

M6

29

Model

WDS-2000-P96

Output

WDS-2500-P96

P/U/I

Measuring range

mm

Linearity

0.1% FSO

mm

2000

2500

2.0

2.5

Resolution

quasi infinite

Sensor element

hybrid potentiometer

Temperature range

-20 ... +80C

housing

Material

aluminium

draw wire

0.8mm

Sensor mounting

slot nuts

Wire mounting

wire clip

Wire acceleration

8g

Wire retraction force (min)

7.5N

5.5N

Wire extension force (max)

11N

9N

Protection class

IP 65 (only if connected)

Vibration

20g, 20Hz - 2kHz

Mechanical shock

50g, 10ms

P

Electrical connection

U/I

Weight

integrated cable, radial, 1m long

flange connector, axial, 8-pin DIN45326

appr. 1.1kg

FSO = Full Scale Output

Specifications for analog outputs on page 43.

Article description

WDS - 2000 - P96 - CA - P

Output option:

P = potentiometer (with connection CA)

U = voltage (with connection SR)

I = current (with connection SR)

Connection:

SR: radial plug

CA: integrated cable, axial, 1m

Model P96

Measuring range in mm

Draw-wire sensors wireSENSOR

P96 digital

- Robust aluminium profile housing

- Incremental/absolute encoder

Model P96

Output HTL/TTL

MR (mm)

A (mm)

2000

26

3000

41.4

A

10

184

13

2x slot nut

4x M6

70

13

58

70

70

124

36

2x set screw M4

13

56

123

96

Output CO/PB

Output SSI

10

10

13

13

13

13

58

58

30

170.7

56

56

138.7

31

Model

WDS-3000-P96

Output

HTL/ TTL/ SSI/ PB/ CO

Measuring range

3000mm

Linearity

0.02% FSO

Resolution

HTL, TTL

Resolution

SSI, PB, CO

Sensor element

0.6mm

0.087mm (11.53 pulses/mm)

0.032mm

Incremental/absolute encoder

Temperature range

-20 ... +80C

housing

Material

draw wire

aluminium

coated polyamid stainless steel ( 0.8mm)

Sensor mounting

slot nuts

Wire mounting

wire clip

Wire acceleration

7g

Wire retraction force (min)

5.5N

Wire extension force (max)

9N

Protection class

IP 65 (only if connected)

Vibration

20g, 20Hz - 2kHz

Mechanical shock

50g, 10ms

HTL, TTL

Electrical connection

SSI

PB, CO

Weight

integrated cable, radial, 1m long

flange connector, radial, 12-pin

bus cover

appr. 1.7kg

FSO = Full Scale Output

Specifications for digital outputs on page 44.

Article description

WDS - 3000 - P96 - CR - TTL

Output option:

HTL

TTL

CO: CANopen

PB: Profibus DP

SSI

Connection:

SR (Output SSI): radial plug

CR (Output HTL, TTL): integrated cable, radial, 1m

BH (Output CO, PB): bus cover

Model P96

Measuring range in mm

wireSENSOR Accessories and mounting

Wire extension x=length

TR1-WDS

Pulley wheel, adjustable

TR3-WDS

Pulley wheel, fixed

GK1-WDS

Attachment head for M4

MH1-WDS

Magnetic holder for wire mounting

MH2-WDS

Magnetic holder for sensor mounting

MT-60-WDS

Mounting clamp for WDS-P60

FC8

Female connector for WDS, 8-pin

FC8/90

Female connector 90 for WDS

PC 3/8

Sensor cable, lenght 3 m

PS 2010

Power supply (chassis mounting 35 x 7.5 mm);

input 120/230 VAC; output 24 VDC/2.5 A;

L/B/H 120 x 20 x 40 mm

WDS-MP60

Mounting plate for P60 sensors

Application example with accessories

MH1-WDS

magnetic holder

measuring range

WE-x-M4, WE-x-Clip

MT-60-WDS

mounting clips

WE-x-Clip

wire extension

TR3-WDS

pulley wheel, fix

TR1-WDS

pulley wheel, adjustable,

85

78.5

40

6.5

20

42

2x 4.5

2x 5.3

Mounting plate WDS-MP60

Installation information:

Wire attachment: The free return of the measurement wire is not permissible and it is

essential that this is avoided during installation.

Wire exit angle:

When mounting a draw-wire displacement sensor, a straight wire exit (3 tolerance)

must be taken into account. If this tolerance is exceeded, increased material wear on

the wire and at the wire aperture must be expected.

wire aperture 0 (3 tolerance)

Output specifications analog

ground

signal

Potentiometric output (P)

Supply voltage

100 %

Resistance

R1K

input +

43

1 = white

2 = brown

3 = green

0%

Temperature coefficient

Sensitivity

max. 32VDC at 1kOhm / 1 Wmax

1kOhm 10% (potentiometer)

0.0025% FSO/C

depends on measuring range

individually shown on test report

Voltage output (U)

Supply voltage

supply

ground

signal

ground

Current consumption

zero

gain

Output voltage

Load impendance

Signal noise

6

7

Temperature coefficient

0-10 Vdc

Electromagnetic

compatibiity (EMC)

14 ... 27VDC (non stabilized)

30mA max

0 ... 10VDC

Option 0 ... 5 / 5V

>5kOhm

0.5mVeff

0.005% FSO/C

EN 50081-2

EN 50082-2

Adjustment ranges

Zero

Sensitivity

supply

ground

gain

Supply voltage

Current consumption

6

7

20 %

Current Output (I)

zero

3

4

20 %FSO

4-20 mA

14 ... 27VDC (non stabilized)

35mA max

Output current

4 ... 20mA

Load

<600Ohm

Signal noise

Temperature coefficient

Electromagnetic

compatibility (EMC)

<1.6Aeff

0.01% FSO/C

EN 50081-2

EN 50082-2

Adjustment ranges

Zero

Sensitivity

18% FSO

15%

44

Output specifications SSI

Contact description

1 UB

Encoder power supply connection.

2 GND

Encoder ground connection. The voltage drawn to

GND is UB.

3 Pulses +

4 Data +

5 ZERO

Positive SSI pulse input. Pulse + forms a current

loop with pulse -. A current of approx. 7 mA in

direction of pulse + input generates a logical 1 in

positive logic.

Positive, serial data output of the differential line

driver. A High level at the output corresponds to

logical 1 in positive logic.

Zero setting input for setting a zero point at any

desired point within the entire resolution. The zeroing

process is triggered by a High pulse (pulse duration

100 ms) and must take place after the rotating

direction selection (UP/DOWN). For maximum

interference immunity, the input must be connected

to GND after zeroing.

6 Data -

Negative, serial data output of the differential line

driver. A High level at the output corresponds to

logical 0 in positive logic.

7 Pulses -

Negative SSI pulse input. Pulse - forms a current

loop with pulse +. A current of approx. 7 mA in

direction of pulse - input generates a logical 0 in

positive logic.

8 / 10

Diagnosis outputs DV and DV MT Jumps in data

DATAVALID

word, e.g. due to defective LED or photoreceiver, are

DATAVALID MT displayed via the DV output. In addition, the power

supply of the multiturn sensor unit is monitored and

the DV MT output is set when a specified voltage

level is dropped below. Both outputs are Low-active,

i.e. are switched through to GND in the case of an

error.

9 UP/DOWN

11 / 12

UP/DOWN counting direction input. When not

connected, this input is on High. UP/ DOWN-High

means increasing output data with a clockwise shaft

rotating direction when looking at the flange.

UP/ DOWN-Low means increasing values with a

counter-clockwise shaft rotating direction when

looking at the flange.

Not in use

Anschlussbelegung

Pin

Cable color

Assignment

brown

UB

black

GND

blue

Pulses +

beige

Data +

green

ZERO

yellow

Data -

violet

Pulses -

brown/yellow

DATAVALID

pink

UP/ DOWN

10

black/yellow

DATAVALID MT

11

12

9 1

12 10

7

6

Please use leads twisted in pairs for

extension cables.

11

2

3

Inputs

Control signals UP/DOWN and Zero

Level High

> 0.7UB

Level Low

< 0.3UB

Connection:

UP/DOWN input with 10kohms to

UB, zeroing input with 10kohms to GND.

SSI pulse

Optocoupler inputs for electrical isolation

Outputs

SSI data

RS485 driver

Diagnostic outputs

Push-pull outputs are short-circuit-proof

Level High

> UB -3.5V

(with I = -20mA)

Level Low

0.5V

(with I = 20mA)

Output specifications CANopen

45

CANopen features

parameterized so that the position value is

not sent until after a defined number of

synch telegrams.

Acyclic Mode (synch-acyclic)

Preset value

Rotating direction

Scaling:

Diagnose

Default setting

With the Preset parameter the encoder

can be set to a desired actual process

value that corresponds to the defined axis

position of the system. The offset value

between the encoder zero point and the

mechanical zero point of the system is

saved in the encoder.

With the operating parameter the rotating

direction in which the output code is to

increase or decrease can be parameterized.

Scaling The steps per revolution and the total

revolution can be parameterized.

The steps per revolution and the total

revolution can be parameterized.

The encoder supports the following error

messages:

- Position and parameter error

- Lithium cell voltage at lower limit

(Multiturn)

GND

Cyclic Mode (asynch-cyclic) The encoder

cyclically sends the current process

actual value without a request by a

master. The cycle time can be

parameterized for values between 1 and

65535 ms. Synch Mode (synch-cyclic)

The encoder sends the current actual

process value after receiving a synch

telegram sent by a master. The synch

counter in the encoder can be

UB

(with SDO progr.)

CAN_H

Polling Mode (asynch, via SDO)

GND

Operating modes

CAN_L

Device Class 2, CAN 2.0B

UB

CANopen

Features

CAN_H

CANopen - CiA DSP 406, V 3.0

CAN_L

Device profile

ON

CANopen

Bus protocol

ON

Setting of terminating

Resistor for CANopen

ON

1

ON = Last user

OFF = User X

Setting CANopen baud rate

Baud rate

10kBit/s

Setting Dip Switch

1

2

OFF

OFF

3

OFF

20kBit/s

OFF

OFF

ON

50kBit/s

OFF

ON

OFF

125kBit/s

OFF

ON

ON

250kBit/s

ON

OFF

OFF

500kBit/s

ON

OFF

ON

800kBit/s

ON

ON

OFF

1MBit/s

ON

ON

ON

Contact description CANopen

CAN_L

CAN Bus Signal (dominant Low)

CAN_H

CAN Bus Signal (dominant High)

UB

Versorgungsspannung 10...30VDC

GND

Ground contact for UB

(Terminals with the same designation are

internally interconnected)

50kbit/s, node number 1

Settings of user address for CANopen

Address can be set with rotary switch. Example: User address 23

Output specifications Profibus

Profibus-DP features

Preset value

With the Preset parameter the encoder can

be set to a desired actual value that

corresponds to the defined axis position of the

system.

Parameter

functions

Rotating direction: With the operating

parameter the rotating direction for which the

output code is to increase or decrease can be

parameterized.

Diagnose

The encoder supports the following error

messages:

- Position error

- Lithium cell voltage at lower limit (Multiturn)

Default setting

User address 00

GND

UB

Input: Position value

Additional parameterized speed signal

(readout of the current rotary speed)

Output: Preset value

GND

Data exch.

functions

Device Class 1 and 2

UB

Profibus features

ON

Profibus-DP

1 2

Bus protocol

46

Settings of terminating

resistors for Profibus-DP

ON

1 2

ON = last user

OFF = user X

Settings of user address for Profibus-DP

Contact description Profibus-DP

Address can be set with rotary switch. Example: User address 23

A A negative serial data line

B Positive serial data line

UB Supply voltage 10...30VDC

GND Ground contact for UB

(Terminals with the same designation are internally interconnected)

Output specifications Incremental encoder

Signal output

47

Pin assignment TTL, HTL

A

A

B

B

0

0

Output TTL

Linedriver (5VDC)

Level High

Level Low

Load High

Output

2.5V

(with I = -20mA)

0.5V

(with I = 20mA)

20mA

A, A, B, B, O

Output HTL

Push-pull (10 ... 30VDC)

Level High

Level Low

Load High

Output

UB -3V (with I = -20mA)

1.5V

(with I = 20mA)

40mA

A, A, B, B, O

Pin

Cable color

Assignment

pink

B inv.

blue

UB Sense

red

N (Nullimpulses)

black

N inv. (Nullimpulses inv.)

brown

green

A inv.

grey

10

white/green

GND

11

white

GND Sense

12

brown/green

UB

8

7

9 1

12 10

6

5

Pin 2 and Pin 12 are internally connected as

well as Pin 11 and 10.

For cable length >10m twisted pair wires are

required.

11

2

3

Connection assignment E, E830

Pin

Cable color

Assignment

white

0V

brown

+UB

Output E

Push-pull (5VDC)

Level High

Level Low

Load High

Output

UB -2.5V

0.5V

50mA

A, B, O

green

yellow

grey

Output E830

Push-pull (8 ... 30VDC)

Level High

Level Low

Load High

Output

UB -3V

2.5V

50mA

A, B, O

High performance sensors made by Micro-Epsilon

Sensors and systems for displacement,

position and dimension

Eddy current displacement sensors

Optical and laser sensors

Capactive sensors

Linear inductive sensors

Draw wire displacement sensors

Laser micrometer

2D/3D profile sensors (laser scanner)

Image processing

MICRO-EPSILON Headquarters

Koenigbacher Str. 15 94496 Ortenburg / Germany

Tel. +49 (0) 8542 / 168-0 Fax +49 (0) 8542 / 168-90

info@micro-epsilon.com www.micro-epsilon.com

Modifications reserved / Y9761111-F031031DGO

Sensors and systems for

non-contact temperature measurement

IR handheld

Stationary IR sensors

Thermal imager

Turn key systems for quality inspection

of plastics and film

of tires and rubber

of endless band material

of automotive components

of glass

MICRO-EPSILON UK Ltd.

Unit 1 Pioneer Business Park Ellesmere Port CH65 1AD

Phone +44 (0) 151 355 6070

info@micro-epsilon.co.uk www.micro-epsilon.co.uk

MICRO-EPSILON USA

8120 Brownleigh Dr. Raleigh, NC 27617 / USA

Phone +1/919/787-9707 Fax +1/919/787-9706

info@micro-epsilon.us www.me-sensor.com

You might also like

- Reliable Pressure Transmitter for Industrial AppsDocument4 pagesReliable Pressure Transmitter for Industrial Appsgliga vasileNo ratings yet

- Catálogo TransductoresDocument18 pagesCatálogo TransductoreszerogruntNo ratings yet

- AWE 110 Technical DocumentDocument2 pagesAWE 110 Technical Documentmb1314No ratings yet

- TsaDocument4 pagesTsaAlexandra GrigoreNo ratings yet

- Hohner Katalog 2009 EnglischDocument62 pagesHohner Katalog 2009 Englischbradutu72No ratings yet

- Pressure Transmitter For General Industrial Applications Model A-10Document7 pagesPressure Transmitter For General Industrial Applications Model A-10brunotavernaNo ratings yet

- Contactless Linear Position TransducerDocument5 pagesContactless Linear Position TransducerRONALDECCONANo ratings yet

- Displacement Transducer Data Sheet and SpecificationsDocument6 pagesDisplacement Transducer Data Sheet and SpecificationsMilan BanicNo ratings yet

- 520 enDocument7 pages520 enthanhduong88No ratings yet

- Wika DS - Pe8160 - GB - 1631Document8 pagesWika DS - Pe8160 - GB - 1631Francisco Mozart B. MeirellesNo ratings yet

- 500 Pressure SensorDocument5 pages500 Pressure SensorMabel Lorena Ochoa ContrerasNo ratings yet

- Pressure Transmitter ATM: Drucktransmitter Mit Piezoresitivem Messelement. Features Typical ApplicationsDocument4 pagesPressure Transmitter ATM: Drucktransmitter Mit Piezoresitivem Messelement. Features Typical ApplicationsJoseph TaylorNo ratings yet

- Tradutor Diferencial PD-9 DRUCKDocument2 pagesTradutor Diferencial PD-9 DRUCKjcbizarretaNo ratings yet

- DS PE A 10 Product Profile en Us 52381Document2 pagesDS PE A 10 Product Profile en Us 52381behnamatgNo ratings yet

- Ec Axial Fan W3g800gu2501 EngDocument5 pagesEc Axial Fan W3g800gu2501 EngmacmottaNo ratings yet

- 699 Pressure Sensor PDFDocument5 pages699 Pressure Sensor PDFEnriqueQNo ratings yet

- RCB600 :: ROAL Living EnergyDocument10 pagesRCB600 :: ROAL Living EnergyroalscribdNo ratings yet

- Pressure Gauge With TransmitterDocument4 pagesPressure Gauge With TransmittercvNo ratings yet

- 177232D1Document6 pages177232D1Muhammad Usman SindhuNo ratings yet

- TRIO-20.0/27.6-TL-OUTD 20 To 27.6 KW: ABB String InvertersDocument4 pagesTRIO-20.0/27.6-TL-OUTD 20 To 27.6 KW: ABB String InvertersVarazhdinecNo ratings yet

- Ib Il Ai 4/I-Pac: Inline Analog Input Terminal, 4 Inputs For Connecting Current SignalsDocument11 pagesIb Il Ai 4/I-Pac: Inline Analog Input Terminal, 4 Inputs For Connecting Current SignalsPaulo Renato AlvesNo ratings yet

- RAMC GS E Ed26 Pub21112016Document28 pagesRAMC GS E Ed26 Pub21112016Alvaro Quinteros CabreraNo ratings yet

- RSF Electronik Incremental Rotary Encoder DG 116 SpecsheetDocument1 pageRSF Electronik Incremental Rotary Encoder DG 116 SpecsheetElectromateNo ratings yet

- Yokogawa FlowmeterDocument24 pagesYokogawa FlowmeterMadha VanNo ratings yet

- Pressure Sensors OEM: Description FeaturesDocument4 pagesPressure Sensors OEM: Description FeaturessmejiagonzalesNo ratings yet

- Sick w280Document14 pagesSick w280cor01No ratings yet

- Transducer OEM Ext Pres 3000SDocument2 pagesTransducer OEM Ext Pres 3000SAffinity AFNo ratings yet

- Snimac Nizkeho Tlaku ADZ SILDocument4 pagesSnimac Nizkeho Tlaku ADZ SILslecka2658No ratings yet

- Adam 4018Document1 pageAdam 4018anggoro_gasnNo ratings yet

- AQU4518R0Document2 pagesAQU4518R0term1natorNo ratings yet

- BTL5-E10-M0150-K-SR32 Ordering Code: BTL014Y: 4 20 Ma 150 MMDocument2 pagesBTL5-E10-M0150-K-SR32 Ordering Code: BTL014Y: 4 20 Ma 150 MMSrinivasa RaoNo ratings yet

- Brosur EuromagDocument4 pagesBrosur EuromagAnnisa Dipva MaryamNo ratings yet

- Encoder SickDocument20 pagesEncoder Sickrodrigo_trentiniNo ratings yet

- MK 2 PiDocument7 pagesMK 2 PiA Whick Bumbum TralalaNo ratings yet

- P3251 TecsisDocument4 pagesP3251 TecsisJHONNJANNo ratings yet

- Presuure TX WetcoDocument6 pagesPresuure TX Wetcoramjee prasad jaiswalNo ratings yet

- API-compliant non-contact vibration transducer monitors critical rotating machinery safelyDocument6 pagesAPI-compliant non-contact vibration transducer monitors critical rotating machinery safelyesakkiraj1590No ratings yet

- Features: Digital ControllerDocument2 pagesFeatures: Digital Controlleravinash250250No ratings yet

- Mini Mcr-Sl-Pt100-Ui-Nc: Order No.: 2864273Document7 pagesMini Mcr-Sl-Pt100-Ui-Nc: Order No.: 2864273vijicsaNo ratings yet

- Linear Scales Measuring DevicesDocument5 pagesLinear Scales Measuring DevicesKAMAL BEHLNo ratings yet

- Electromagnetic Flowmeter Type MAGNETOFLOW™ M2000: DescriptionDocument4 pagesElectromagnetic Flowmeter Type MAGNETOFLOW™ M2000: DescriptionAlphatech1No ratings yet

- ACURO Industry Parallel Interface: Absolute Shaft Encoders Type AC 58Document5 pagesACURO Industry Parallel Interface: Absolute Shaft Encoders Type AC 58Leslie ClarkNo ratings yet

- PLC-BH Sma5Document1 pagePLC-BH Sma5miki983No ratings yet

- ABB Adjustable Frequency DrivesDocument17 pagesABB Adjustable Frequency DrivesEddie Ipenza VargasNo ratings yet

- Pressure Transmitter For General Purpose Type MBS 1700 and MBS 1750Document8 pagesPressure Transmitter For General Purpose Type MBS 1700 and MBS 1750mquaiottiNo ratings yet

- Transmitter For Pressure and Temperature Atm/T: Features Typical ApplicationsDocument4 pagesTransmitter For Pressure and Temperature Atm/T: Features Typical ApplicationsJoseph TaylorNo ratings yet

- Adam-6017 DS20110819104118Document1 pageAdam-6017 DS20110819104118Dago GonzalezNo ratings yet

- Dit 48 Technical Data: Accuracy Grade: 1 MDocument2 pagesDit 48 Technical Data: Accuracy Grade: 1 MElectromateNo ratings yet

- Bus Bar Truncking Design For SandwichDocument31 pagesBus Bar Truncking Design For SandwichSanjeev Dhariwal100% (1)

- Datasheet Trio 20.0 - 27.6 TL en (1) InvertorDocument4 pagesDatasheet Trio 20.0 - 27.6 TL en (1) InvertorAnonymous LNdiNQNo ratings yet

- Relative and Absolute Pressure Transmitter Type 507Document5 pagesRelative and Absolute Pressure Transmitter Type 507Thachbich NguyenNo ratings yet

- RCB600 :: ROAL Living EnergyDocument10 pagesRCB600 :: ROAL Living EnergyroalscribdNo ratings yet

- Dme3000 DatashetDocument6 pagesDme3000 DatashetFrancisco A. ValenzuelaNo ratings yet

- APFC Epcos 6Document8 pagesAPFC Epcos 6Sriman ChinnaduraiNo ratings yet

- MCB600 :: ROAL Living EnergyDocument10 pagesMCB600 :: ROAL Living EnergyroalscribdNo ratings yet

- Dualband CombinerDocument24 pagesDualband CombinerCourtney HernandezNo ratings yet

- CA3140Document19 pagesCA3140samNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Dernord Dn40 220v380v 3kw 4.5kw 6kw 9kw Sus304 He... - VicedealDocument1 pageDernord Dn40 220v380v 3kw 4.5kw 6kw 9kw Sus304 He... - Vicedealadrianchelaru21No ratings yet

- Mr3-Sepm-Ins-Dwg-2000it-30001 - B1 - 1 - SeplDocument114 pagesMr3-Sepm-Ins-Dwg-2000it-30001 - B1 - 1 - SeplcelonevesNo ratings yet

- Alien Gear ShapeShift Shoulder HolsterDocument4 pagesAlien Gear ShapeShift Shoulder HolsterTwobirds Flying PublicationsNo ratings yet

- Brake System (E45-65XM)Document21 pagesBrake System (E45-65XM)Mario AguirreNo ratings yet

- Hydraulic System Veth-Compact-Jet Thruster (11 KW / 100 Ltrs. Steering Power Pack)Document1 pageHydraulic System Veth-Compact-Jet Thruster (11 KW / 100 Ltrs. Steering Power Pack)Costel Ava ConstantinNo ratings yet

- Document: (1) Workspace: (2) BOM of Assembly: (4) Curta Assembly BOM Type: Description Created: Part Number: Revision: StateDocument7 pagesDocument: (1) Workspace: (2) BOM of Assembly: (4) Curta Assembly BOM Type: Description Created: Part Number: Revision: StateMarcelo StancaNo ratings yet

- G2 Smart Price ListDocument13 pagesG2 Smart Price ListHarsh JainNo ratings yet

- Ryobi ERT1250RG Manual 1Document15 pagesRyobi ERT1250RG Manual 1Timothy Christian RicafortNo ratings yet

- df-617 PM A0HUDocument41 pagesdf-617 PM A0HUdatajerzyNo ratings yet

- Service Manual Vox Vt40+: Block Diagram:2 Schematic Diagram:3 Hookup:5 Testmode:7 Parts List:15Document16 pagesService Manual Vox Vt40+: Block Diagram:2 Schematic Diagram:3 Hookup:5 Testmode:7 Parts List:15jyginformatica avilaalonsoNo ratings yet

- Checking and Charging Brake System ComponentsDocument3 pagesChecking and Charging Brake System ComponentsЖеня СавченкоNo ratings yet

- NATIONAL SERIES "A & AADocument12 pagesNATIONAL SERIES "A & AAJames O'DonnellNo ratings yet

- Project Report On Cable Manufacturing (Copper and Aluminium)Document6 pagesProject Report On Cable Manufacturing (Copper and Aluminium)EIRI Board of Consultants and PublishersNo ratings yet

- EUPEN Radiating Cables Installation Guide Ed 1Document24 pagesEUPEN Radiating Cables Installation Guide Ed 1Carlos BritoNo ratings yet

- Isolating Switching Amplifier for 2 Channels Under 40 CharactersDocument3 pagesIsolating Switching Amplifier for 2 Channels Under 40 CharactersadrianioantomaNo ratings yet

- Bar Cutting Machine Inspection ChecklistDocument1 pageBar Cutting Machine Inspection ChecklistRicardo Dalisay100% (4)

- How To Use: Button and IndicatorDocument1 pageHow To Use: Button and IndicatorRonald GuadronNo ratings yet

- Stages of Power SupplyDocument29 pagesStages of Power SupplyBerlin AlcaydeNo ratings yet

- HammersDocument5 pagesHammersBenedictus Torres MoldesNo ratings yet

- Wiring XJ JeepDocument516 pagesWiring XJ Jeepcougar350_723411783100% (15)

- Kodak - Tool CatalogDocument973 pagesKodak - Tool CatalogNikolay PenevNo ratings yet

- Building Creative Thinking in Science TeachersDocument15 pagesBuilding Creative Thinking in Science TeachersJudarlyn Madria100% (1)

- Lesson Plan in Tle Computer Hardware andDocument6 pagesLesson Plan in Tle Computer Hardware andmichelle hao100% (1)

- Anern Integrated Solar Street Light (AN-ISSL-M) - 201604Document3 pagesAnern Integrated Solar Street Light (AN-ISSL-M) - 201604Godofredo VillenaNo ratings yet

- JSA Format Internal ReactorDocument13 pagesJSA Format Internal Reactorsakthi venkatNo ratings yet

- Fire Risk Assessment ChecklistDocument10 pagesFire Risk Assessment ChecklistSupendi NanangNo ratings yet

- Electronic Instrumentation PracticalDocument3 pagesElectronic Instrumentation PracticalABHISHEK PATELNo ratings yet

- PT CITRA INTERLINDO COMPONENT LISTDocument3 pagesPT CITRA INTERLINDO COMPONENT LISTDwi HaryantoNo ratings yet

- SFVL & DSVL Data Sheet RD7FE102 PDFDocument8 pagesSFVL & DSVL Data Sheet RD7FE102 PDFLuciano CaireNo ratings yet

- Domestic Appliances - Cook-TablewareDocument8 pagesDomestic Appliances - Cook-TablewareJay M RajaNo ratings yet