Professional Documents

Culture Documents

Crosshead Lubrication

Uploaded by

rajishrrrOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crosshead Lubrication

Uploaded by

rajishrrrCopyright:

Available Formats

The crosshead on a slow speed 2 stroke is a difficult bearing to lubricate effectively.

The load is continually downward

and because the con rod swings about the pin, changing direction each stroke, true hydrodynamic lubrication cannot take

place. Instead the lubrication starts as boundary, and as the rubbing speed increases, a hydrodynamic film is built up. As

the rubbing speed decreases the lubrication becomes boundary once again.

As engine powers and thus gas loads have increased, the difficulties with achieving effective lubrication have increased.

Larger pin diameters have helped by increasing the linear rubbing speeds, and the continuous lower bearing has reduced

the loading/unit area.

The older forked type crosshead as found in earlier engines (up to the mid

1980s) used various methods to improve the lubrication of the crosshead.

Oil grooves in the lower bearings were used to distribute the oil. The

grooves in some cases extended to the edge of the bearing, although with a

reduced csa, to ensure a flow of oil through the bearing.

THE MAN B&W MC ENGINE CROSSHEAD

The lower half of the bearing housing is formed by the top end of the

connecting rod. It supports the crosshead pin over its entire length, the

piston rod being bolted to the top half of the crosshead pin through a cut

out in the bearing top half. Oil supply to the crosshead is via a telescopic

pipe from the main LO supply at a pressure of about 2.5 bar.

Lower Bearing Shell Showing Arrangement of Grooves.

The lower bearing shell (tin aluminium with overlay) has oil grooves with machined wedges as shown in the diagram and

photo. The oil enters via the cut out channel in the centre. The grooves extend right to the edges of the bearing to ensure a

flow of oil, thus cooling the bearing.

THE SULZER RTA ENGINE CROSSHEAD

The early RTA had a forked crosshead with the

piston rod passing through a hole in the

crosshead pin and secured underneath with a

nut. Oil entered the bearing through holes in the

shell. via a groove machined in the the lower

bearing housing.

Crosshead Bearing Shell - Old RTA

The Modern RTA has a continuous lower

bearing, the housing formed by the top of

the conrod. Only a lower bearing shell is

fitted, the top bearing housing being

lined with white metal. Oil boosted in

pressure to 10 - 12 bar is supplied via a

swinging arm.

The swinging arm also carries oil at

system pressure (4 bar) for piston

cooling.

Con Rods - Modern RTA. Note Oil Supply Grooves in Bearing Housing.

Swinging Arm (Piston and Rod Removed)

OIL SUPPLY PRESSURE.

A Question sometimes asked is why do Sulzer need to boost their crosshead oil supply pressure to 12 bar whilst MAN

B&W supply oil to their crosshead at system pressure. The answer lies in the design of the bearing.

More than 90% of the circulated oil has the sole purpose of cooling the bearings. If you study antique machines with open

crankcases, you will see that the amount of oil for lubrication is a few drops per minute. This is enough for maintaining

the oil film in the bearing and with an open crankcase the friction heat is removed by air-cooling. Modern engines have

closed crankcases and a much higher bearing load - hence the need for oil cooling.

In a main bearing, the oil is pumped into the upper shell and it will cool the upper part of the joumal. Since the shaft is

rotating, it is cooled on all sides and because the oil film thickness is very small in the loaded part, the shaft will cool the

loaded bearing half as well.

A crosshead bearing is only oscillating and the lower shell is always loaded. The cooling oil must be injected between

shaft (crosshead pin) and lower bearing.

In MAN B&W engines, a set of channels have been machined in the lower crosshead bearing, in which the cooling oil can

pass. The geometry is designed in such a way that all the loaded square centimetres of the pin are flushed with cooling oil

twice every engine cycle. In contrast, the Sulzer crosshead has a plain lower bearing without channels. In order to inject

oil between pin and bearing, they have to supply oil at a much higher pressure. The injection will take place at around 20

degrees crank angle before TDC, where the cylinder pressure is still low and upward inertia forces on piston is still high.

There is a short interval, in which the bearing pressure is lower than the oil pressure.

You might also like

- Differences in crosshead lubrication arrangements between Sulzer and MAN B&W enginesDocument1 pageDifferences in crosshead lubrication arrangements between Sulzer and MAN B&W enginesVijay A100% (3)

- Crosshead With Connecting Rod PurposeDocument14 pagesCrosshead With Connecting Rod Purposeapi-3701567100% (9)

- Cross Head BearingsDocument14 pagesCross Head BearingsjohansolNo ratings yet

- The 4 Stroke Medium Speed Trunk Engine PistonDocument23 pagesThe 4 Stroke Medium Speed Trunk Engine PistonBharatiyulamNo ratings yet

- Running Gear of Diesel Engines: Crankshaft, Main Bearings, Lubrication SystemDocument26 pagesRunning Gear of Diesel Engines: Crankshaft, Main Bearings, Lubrication SystemAlaine Jan de Tablan100% (2)

- Crosshead Lubrication and Telescopic PipeDocument4 pagesCrosshead Lubrication and Telescopic PipeSWASTIK MISHRANo ratings yet

- Function 4BDocument55 pagesFunction 4BSiva PrakasamNo ratings yet

- Motor Short AnswersDocument97 pagesMotor Short AnswersRachitNo ratings yet

- Class 2 AssignmentDocument58 pagesClass 2 AssignmentshahedNo ratings yet

- PPD ReportingDocument46 pagesPPD ReportingFernando CruzNo ratings yet

- Piston - WikipediaDocument30 pagesPiston - WikipediaLAliNo ratings yet

- X HeadDocument5 pagesX Headkyaw yaNo ratings yet

- NOTES 16 NOV Class 2Document15 pagesNOTES 16 NOV Class 2Anthony xavierNo ratings yet

- Cooling and Lubrication of EnginesDocument6 pagesCooling and Lubrication of EnginesAmr EhabNo ratings yet

- X Head LubricationDocument3 pagesX Head LubricationArun SNo ratings yet

- Piston RingsDocument7 pagesPiston RingsMudassir HussainNo ratings yet

- Comparisons of Cross Head and Trunk Piston EnginesDocument1 pageComparisons of Cross Head and Trunk Piston EnginesJitendra KumarNo ratings yet

- OIL COOLED PISTONDocument3 pagesOIL COOLED PISTONPranjyoti SaikiaNo ratings yet

- R8Document15 pagesR8Dieguis Bruno100% (1)

- Pistons: (Figure 1-13) The Piston Acts As A Moving Wall Within TheDocument4 pagesPistons: (Figure 1-13) The Piston Acts As A Moving Wall Within TheVanreal 25No ratings yet

- PPD ReviewerDocument4 pagesPPD ReviewerMark Alvin CuyaNo ratings yet

- Solving Ring-Oiled Bearing Problems TechNote - 2009 - 04Document6 pagesSolving Ring-Oiled Bearing Problems TechNote - 2009 - 04NookerNo ratings yet

- Lubrication System: Internal Combustion EnginesDocument24 pagesLubrication System: Internal Combustion EnginesAnonymous LFgO4WbIDNo ratings yet

- 4 ReportDocument89 pages4 ReportRajesh KesapragadaNo ratings yet

- Harsh Parihar 0818ME181009 Practical No. 1: Study of Lubricating System in CI EnginesDocument8 pagesHarsh Parihar 0818ME181009 Practical No. 1: Study of Lubricating System in CI EnginesPro GamerssNo ratings yet

- Crosshead LubricationDocument8 pagesCrosshead Lubricationdolu vermaNo ratings yet

- Wet SumpingDocument3 pagesWet SumpingBimal Amarnath MenonNo ratings yet

- Diesel Engine ConstructionDocument53 pagesDiesel Engine ConstructionLasse HansenNo ratings yet

- Differences Between Crosshead and Trunk EnginesDocument12 pagesDifferences Between Crosshead and Trunk Engineshpss77No ratings yet

- BMW Engine Lubrication Key to ReliabilityDocument2 pagesBMW Engine Lubrication Key to ReliabilitySerkan DilverNo ratings yet

- P - Automotive Lubrication System Service RevisedDocument22 pagesP - Automotive Lubrication System Service Reviseddmc constructionNo ratings yet

- Diesel Engine TestDocument9 pagesDiesel Engine TestSamuel Blandes RwegasiraNo ratings yet

- Tech Information From Mahle Clevite Inc.: TB-2043 Issued: June 10, 2000 Revised: May 11, 2010Document4 pagesTech Information From Mahle Clevite Inc.: TB-2043 Issued: June 10, 2000 Revised: May 11, 2010eng_ebrahim_2000No ratings yet

- AMTE126 - 10B Wet and Dry Sump Advantages and DisadvantagesDocument3 pagesAMTE126 - 10B Wet and Dry Sump Advantages and DisadvantagesRebecca Lepon Legaspi50% (2)

- Engine Lubrication SystemDocument2 pagesEngine Lubrication SystemYemaneDibetaNo ratings yet

- Cylinder Lubrication Developments and Lubricants Drain AnalysisDocument14 pagesCylinder Lubrication Developments and Lubricants Drain AnalysisAnto KattikkaranNo ratings yet

- SAAB WIS - Engine BlockDocument4 pagesSAAB WIS - Engine Blockyen-shu liNo ratings yet

- Royal Enfield - Re - Oil PumpDocument3 pagesRoyal Enfield - Re - Oil Pumpsandeep_shinuNo ratings yet

- Diesel Engine ConstructionDocument42 pagesDiesel Engine Constructionanon_322442463100% (1)

- Engine Lubrication SystemsDocument8 pagesEngine Lubrication SystemsMentsnot GetuNo ratings yet

- Basic Engine: Operación de SistemasDocument5 pagesBasic Engine: Operación de SistemasEduardo Alvarez100% (1)

- Himsen Cat h1728Document12 pagesHimsen Cat h1728Mohsen100% (1)

- Fuel InjectorDocument10 pagesFuel InjectorMc G VANo ratings yet

- 04 LinerDocument30 pages04 LinernareshNo ratings yet

- Design of The SR20Document11 pagesDesign of The SR20hugostvNo ratings yet

- Reciprocating Compressor IIDocument66 pagesReciprocating Compressor IIAli O Dalki100% (1)

- Motor Oil Four-Stroke Two-Stroke Piston Internal Combustion Engines Oil Pumps Wet-Sump SumpDocument2 pagesMotor Oil Four-Stroke Two-Stroke Piston Internal Combustion Engines Oil Pumps Wet-Sump SumpPrinceNo ratings yet

- Gipsy Twelve ProductionDocument1 pageGipsy Twelve Productionseafire47No ratings yet

- Purpose of CrossheadDocument1 pagePurpose of CrossheadVijay ANo ratings yet

- Basic 2 stroke Tuning GuideDocument6 pagesBasic 2 stroke Tuning GuideMarcelo Tapia MaureiraNo ratings yet

- 08 PistonDocument40 pages08 PistonnareshNo ratings yet

- Om639 EngineDocument4 pagesOm639 EngineFayez AlnamarnehNo ratings yet

- Engine Lubrication Purpose of Lubrication: K. V Karanth, M.I.T ManipalDocument3 pagesEngine Lubrication Purpose of Lubrication: K. V Karanth, M.I.T ManipalishanrathnakarNo ratings yet

- 2 Stroke Cycle, Marine EngineeringDocument27 pages2 Stroke Cycle, Marine EngineeringRohit PandeyNo ratings yet

- Basic 2 stroke Tuning GuideDocument6 pagesBasic 2 stroke Tuning GuideCodaNorm S DevNo ratings yet

- Lubrication SystemDocument4 pagesLubrication SystemArun BoseNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Shiva Ultimate OutlawDocument55 pagesShiva Ultimate Outlawరహ్మానుద్దీన్ షేక్100% (5)

- Measure To Be Taken: Scavenge FireDocument2 pagesMeasure To Be Taken: Scavenge FirerajishrrrNo ratings yet

- Hindu Philosophy Life After DeathDocument144 pagesHindu Philosophy Life After Death4titude100% (1)

- 5.5 - TU - Protection Against Noise On Board Ships - SHURIDocument17 pages5.5 - TU - Protection Against Noise On Board Ships - SHURIrajishrrrNo ratings yet

- Propeller Power CurveDocument13 pagesPropeller Power Curverajishrrr100% (1)

- Turbochargers 120720041601 Phpapp01Document52 pagesTurbochargers 120720041601 Phpapp01rajishrrrNo ratings yet

- 02 BPCrankshaftDocument129 pages02 BPCrankshaftrajishrrrNo ratings yet

- Intertanko SeminarDocument59 pagesIntertanko Seminar18847No ratings yet

- 4.2.1 FeyerabendDocument18 pages4.2.1 FeyerabendCosmin KoszorNo ratings yet

- PD Vs Cetrifugal Pump PDFDocument3 pagesPD Vs Cetrifugal Pump PDFneharoybhushanNo ratings yet

- Matter Is Not Matter PDFDocument10 pagesMatter Is Not Matter PDFrajishrrr100% (6)

- ABB Turbocharging - Operating Turbochargers PDFDocument35 pagesABB Turbocharging - Operating Turbochargers PDFrajishrrrNo ratings yet

- 06 LubricationDocument22 pages06 LubricationrajishrrrNo ratings yet

- Boiler SurveyDocument7 pagesBoiler SurveyrajishrrrNo ratings yet

- Refrigeration: Learning Objective: Describe The Stages of Heat Theory and The Principles InvolvedDocument98 pagesRefrigeration: Learning Objective: Describe The Stages of Heat Theory and The Principles Involvedgopinathan_karuthedaNo ratings yet

- Anchor Cable PDFDocument21 pagesAnchor Cable PDFrajishrrrNo ratings yet

- Stern Tubes PDFDocument8 pagesStern Tubes PDFrajishrrr100% (1)

- Shaft Align 1Document5 pagesShaft Align 1rajishrrrNo ratings yet

- 04 Tie Rods or Tie BoltsDocument12 pages04 Tie Rods or Tie BoltsrajishrrrNo ratings yet

- Ybi1.co M: Notes On Reading SOLASDocument14 pagesYbi1.co M: Notes On Reading SOLASrajishrrrNo ratings yet

- Governor BasicsDocument14 pagesGovernor BasicsrajishrrrNo ratings yet

- 15A TurbochargerDocument38 pages15A TurbochargerVinay Kumar NeelamNo ratings yet

- Over SpeedingDocument7 pagesOver SpeedingrajishrrrNo ratings yet

- Recent Development in MarineDocument44 pagesRecent Development in MarinerajishrrrNo ratings yet

- 04 Tie Rods or Tie BoltsDocument12 pages04 Tie Rods or Tie BoltsrajishrrrNo ratings yet

- Ism and NewDocument20 pagesIsm and NewrajishrrrNo ratings yet

- Scotch BoilerDocument52 pagesScotch Boilerrajishrrr100% (1)

- Preparation For Dry DockingDocument4 pagesPreparation For Dry Dockingrajishrrr0% (1)

- OdmeDocument18 pagesOdmerajishrrr100% (1)

- Marine EngineDocument159 pagesMarine EnginerajishrrrNo ratings yet

- Chevrolet Thailand Trailblazer My17 En211116Document12 pagesChevrolet Thailand Trailblazer My17 En211116Mas Hary100% (1)

- 2005 VRSCB V Rod Owner's ManualDocument136 pages2005 VRSCB V Rod Owner's ManualThömpsöñ Témbö IñfìnìtèNo ratings yet

- Toyota Fortuner 2018 - Hood Deflector - Installation InstructionDocument9 pagesToyota Fortuner 2018 - Hood Deflector - Installation InstructionThan Win HtikeNo ratings yet

- Rolls Royce WraithDocument13 pagesRolls Royce WraithJeff RiantoNo ratings yet

- Tranztar Trailers Brochure PDFDocument32 pagesTranztar Trailers Brochure PDFAbhi jayaswalNo ratings yet

- C Force 520 Service Manual V1Document294 pagesC Force 520 Service Manual V1ApKNo ratings yet

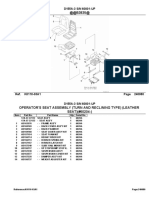

- Seat SuspensionDocument1 pageSeat SuspensionaliNo ratings yet

- 242B Series 2: KID Teer OaderDocument2 pages242B Series 2: KID Teer OaderjunilokoNo ratings yet

- Sale Order (Movable Items) : SI - No Items LotnoDocument18 pagesSale Order (Movable Items) : SI - No Items Lotnoanoopiit2012No ratings yet

- 2010 Audi Q5 Fluid Cap Chart - 25june10 PDFDocument1 page2010 Audi Q5 Fluid Cap Chart - 25june10 PDFJOHNNY5377No ratings yet

- CFM Leap ComponentlocationDocument69 pagesCFM Leap ComponentlocationGurunath Phadke100% (5)

- DRIVES ARRANGEMENt + WEIGHT RDocument1 pageDRIVES ARRANGEMENt + WEIGHT RSurya AdiNo ratings yet

- H2ICEDocument10 pagesH2ICElucasNo ratings yet

- WIRING DIAGRAMS LHD 000201 To 057871 PDFDocument113 pagesWIRING DIAGRAMS LHD 000201 To 057871 PDFliviu axinteNo ratings yet

- Motor de Partida Leve e PesadoDocument37 pagesMotor de Partida Leve e PesadoLeandro Ornelas FerreiraNo ratings yet

- Automotive Abbreviations: /min °C °DK °F °KW °NW 1/CM3 1L 1R 2L 2R 2WD 3L 3R 4was 4WD 4WS 4X4 A A/DDocument45 pagesAutomotive Abbreviations: /min °C °DK °F °KW °NW 1/CM3 1L 1R 2L 2R 2WD 3L 3R 4was 4WD 4WS 4X4 A A/DAlin AlexandruNo ratings yet

- Doosan G GC SpecificationDocument8 pagesDoosan G GC SpecificationHamed KhorasaniNo ratings yet

- HM Stock 20 Januari 2023Document1 pageHM Stock 20 Januari 2023ADI YANTONo ratings yet

- 2006 Audi A6 4.2L V8 Engine Ribbed Belt GuideDocument139 pages2006 Audi A6 4.2L V8 Engine Ribbed Belt Guideakmal15No ratings yet

- Ucm03 - 089428 Makas LiftDocument2 pagesUcm03 - 089428 Makas LiftwenigmaNo ratings yet

- Gway SP000095Document2 pagesGway SP000095mtgoldwayNo ratings yet

- Solar y CaterpillarDocument48 pagesSolar y CaterpillarRobert BlancoNo ratings yet

- DTC CodeDocument2 pagesDTC CodetataeNo ratings yet

- ECU - Engine Control Unit Diagnostic Trouble Codes 2 (6135 JD Control Unit, Level 15)Document9 pagesECU - Engine Control Unit Diagnostic Trouble Codes 2 (6135 JD Control Unit, Level 15)Benjamin HouseNo ratings yet

- 8 Series LRC Leaflet English WuxiDocument8 pages8 Series LRC Leaflet English WuxiChicago PneumaticNo ratings yet

- Manual de Partes 2545Document24 pagesManual de Partes 2545Andres MonteroNo ratings yet

- Lto Violations and FinesDocument7 pagesLto Violations and FinesArman Arizala Brioso PerezNo ratings yet

- Electric Tool Parts List: Air Compressor 2007 - 04 - 02 Model EC 119 (E3)Document3 pagesElectric Tool Parts List: Air Compressor 2007 - 04 - 02 Model EC 119 (E3)Ivan GallegosNo ratings yet

- Citroen C4 PICASSO - Grand C4 PICASSO Owners Handbook - UnknownDocument256 pagesCitroen C4 PICASSO - Grand C4 PICASSO Owners Handbook - UnknownPetar100% (2)

- B7R RangeDocument12 pagesB7R RangePhilippine Bus Enthusiasts Society0% (1)