Professional Documents

Culture Documents

Flange

Uploaded by

nandhamech25Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flange

Uploaded by

nandhamech25Copyright:

Available Formats

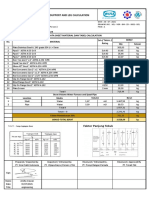

3 Jun 2013 10:05:31 - ASMESecVIIIDiv2_WNFlangeDesign.

sm

Design of Weld Neck Flange as per ASME Section VIII Division 2 Part 4.16

Design Bolt Loads

STEP 1:

Design Condition

Design Pressure

10.2 MPa

Design Temperature T

80 C

STEP 2:

Gasket Factors 'm' and Minimum Design Seating Stress 'y' from Table 4.16.1

Gasket Factor

Min. Des. Seating Stress

69 MPa

Gasket Dimensions are from ASME B16.20, Spiral Wound from Table 9

Gasket OD

OD

463.6 mm

Gasket ID

ID

412.8 mm

STEP 3:

G

N

Gasket Contact Width

OD

2

ID

N 25.4 mm

For Gasket fully within Bolt Circle and in full contact with Raised face flange

b

N

2

if b

12.7 mm

6 mm

0

G

G

OD

ID

2

else

C

25.4 mm

ul

Equation 4.16.1, 4.16.2 and 4.16.3

b

b

G

G

0.5 C

G

C

G

ul

ul

OD

2 b

b 8.9803 mm

G 445.6395 mm

STEP 4:

Design Bolt Load for Operating Condition Wo

W

W

o

o

0.785 G

2 b G m P

Equation 4.16.4 For non-self Energizing Gasket

2359.5847 kN

1/7

3 Jun 2013 10:05:31 - ASMESecVIIIDiv2_WNFlangeDesign.sm

Allowable stress for bolt at Design Temperature

Allowable stress for bolt at Seating Temperature

bo

bg

172.369 MPa

172.369 MPa

STEP 5:

Design Bolt Load for Gasket Seating Condition Wg

Bolt Dimensions

d

Diameter of bolt

33.97 mm

Number of Bolts n

20

Total Actual Cross Sectional Area of Bolts

A

A

b

b

d

b 4 b

1.8126 10

mm

Total Minimum Required Cross Sectional Area of Bolts

Axial Force

F

4 M

W

A

C

W

m1

Bending Moment

39.477 kN m

A

G

S

bo

1.5845 10

m1

mm

0.006894757

us

b G C

gs

W

A

17.293 kN

m2

us

5981.2274 N

gs

gs

A

bg

34.7001 mm

m2

A

m1

m2

A

A

m

m1

else

A

A

m

m2

Equation 4.16.8

if A

1.5845 10

Equation 4.16.7

mm

if A

A

b

m

IsBoltSafe "Yes"

else

IsBoltSafe "No. Increase Bolt Size or Reduce Loads on Flanges"

IsBoltSafe "Yes"

A

A

PercentBoltStrengthUsed

W

100

b

W

PercentBoltStrengthUsed 87.4151

2/7

Equation 4.16.6

bg

2927.8216 kN

3 Jun 2013 10:05:31 - ASMESecVIIIDiv2_WNFlangeDesign.sm

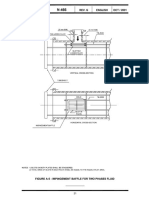

Flange Design

STEP 1:

Design Pressure, Temperature, Net Axial Force and Moment are as previously mentioned

P 10.2 MPa

80 C

17.293 kN

39.477 kN m

STEP 2:

Design Bolt load for Operating and Gasket seating are as previously Calculated

W

2359.5847 kN

2927.8216 kN

STEP 3:

Flange Dimensions from ASME B16.5

Flange OD

685.8 mm

Flange ID

Bolt Circle Diameter

603.25 mm

Thickness of Flange t

Hub Thickness @ small end

Hub Length

21.4 mm

363.52 mm

76.2 mm

Hub Thickness @ big end

65.75 mm

102 mm

STEP 4:

Flange stress factors using the equations in Tables 4.16.4 and 4.16.5

A

B

K 1.8866

K

K

1 8.55246 log

T

1.0472 1.9448 K

1.36136 K

K

h

2

2

g

X

h

h

0

10

10

Y 3.2263

1

T 1.5499

K 1

1

U 3.5453

K 1

Z 1.7815

B g

10

2

1 8.55246 log

log

0.66845 5.7169

K 1

0

X

88.2005 mm

3.0724

1.1565

3/7

3 Jun 2013 10:05:31 - ASMESecVIIIDiv2_WNFlangeDesign.sm

0.897697 0.297012 ln X

if X

9.5257 10

ln X

0.123586 ln X

F

h

0

0.1

2

g

e 0.0076

0.0358580 ln X

1

mm

0.194422 ln X

ln X

0.0181259 ln X

3

g

0.012936 ln X

3

h

0.0377693 ln X

ln X

2

h

0.0273791 ln X

2

g

ln X

For Integral type Flange

0.5

X

2

0.227914

0.34441

h

2.49189 X

0.500244

1.87071 X

0.873446

h

h

X

2

X

g

g

X

g

2

h

3

0.189953

1.06082 X

1.4997

h

3

X

g

2

h

X

g

0.719413

h

2

X

g

else

V

0.135977

X

g

0.0144868

0.0461919

X

h

0.560718

2

X

g

0.0529829

2

X

h

0.244313

X X

g h

0.113929

3

X

g

0.00928265 0.0266293

3

2

X

X X

h

g h

0.217008

2

X

X

g

h

V 0.0696

U g

d

2

h

0

0

V

d 2.0566 10

3

t

d

t e 1

T

1 5.96093 10

if f

1

f f

mm

For Integral type Flange

L 1.2332

0.0927779 0.0336633 X

f

0.964176 X

3

2

g

0.0566286 X

1.62904 X

3.49329 X

0.347074 X

2

h

4.18699 X

1.39052 X

3

h

3

h

1

1

else

f 1

f 1

STEP 5:

Flange Forces

Total Hydrostatic End Force

H

0.785 B

1058.0994 kN

0.785 G

G

H 1590.1466 kN

769.4381 kN

H H

532.0472 kN

STEP 6:

Flange Moment for Operating Condition

C B g

h

86.99 mm

C G

2

4/7

78.8053 mm

1

2

C B

2

h

G

99.3351 mm

3 Jun 2013 10:05:31 - ASMESecVIIIDiv2_WNFlangeDesign.sm

C

n

b

B

B

SC

30.1625 mm

0.4574

SC

a 33.97 mm

For Non Split flange Fs=1

0.5 A B

2 a t

0.0874 L g

I

I 2.2729 10

mm

161.14 mm

avg

0.5 g

avg

43.575 mm

if t G

avg

A

A

R

B

t

B

C

h

C

D

G

DG

avg

else

A

h t

A

B

G

B

avg

C

A

G

C

R

avg

D

t

DG

A

AB

OE

4 M

1

3

B

0.21

I

E 0.3846 I

1

12

B

A

4

B

D

C 2 h

SC

F

D

OE

CD

OE

3

DG

1

3

D

1.05

26.7725 kN m

DG

C

C

1

192

AB

CD

DG

C

C

Equation 4.16.16

120.7921 kN m

Equation 4.16.14 - For Internal Pressure

STEP 7:

Flange Moment for Gasket Seating

W

M

C G B

SC

105.5459 kN m

Equation 4.16.17 - For Internal Pressure

5/7

1.5743 10

mm

3 Jun 2013 10:05:31 - ASMESecVIIIDiv2_WNFlangeDesign.sm

STEP 8:

Flange Stress for Operating and Gasket Seating Condition using Equations in Table 4.16.8

Operating Condition

f M

S

HO

L g

O

2

RO

L t

Y M

TO

62.3284 MPa

f M

S

RO

Z S

TO

HG

82.0756 MPa

g

2

L g

RG

38.4091 MPa

RO

TG

L t

Y M

54.4614 MPa

Z S

RG

71.7161 MPa

B

S

HG

1.33 t e 1 M

S

B

S

HO

1.33 t e 1 M

S

Seating Condition

TG

33.5611 MPa

RG

STEP 9:

Flange Stress Acceptance Criteria based on Table 4.16.9

Allowable stress for flange at Design Temperature

Allowable stress for Pipe at Design Temperature

fo

no

153.029 MPa

Allowable stress for flange at Seating Temperature

151 MPa

Allowable stress for Pipe at Seating Temperature

IF all the Ratios below are Greater than 1, Flange Leakage check is PASS

if 1.5 S

S

HOR

2.5 S

fo

no

1.5 S

fo

S

HO

HOR

3.6828

if 1.5 S

S

else

HOR

S

S

ROR

S

S

TOR

OAvg1

2.5 S

no

HO

S

fo

ROR

fo

TOR

S

S

HO

RGR

3.9842

OAvg1

S

S

TO

fo

S

HGR

1.8645

RO

S

S

TGR

HGR

4.4343

fg

fg

GAvg1

S

OAvg2

HO

fo

S

2.245

TGR

4.7972

TG

S

RO

RGR

RG

2.1195

S

ng

HG

HG

else

2.5 S

HGR

2.5 S

fg

ng

1.5 S

fg

S

HG

fg

S

GAvg1

2.552

RG

2

S

OAvg2

3.0382

S

S

TO

GAvg2

HG

fg

S

6/7

S

TG

GAvg2

3.6582

fg

ng

161 MPa

151 MPa

3 Jun 2013 10:05:31 - ASMESecVIIIDiv2_WNFlangeDesign.sm

STEP 10:

Flange Rigidity Criteria

Modulus of Elasticity at Operating Temperature

yo

Modulus of Rigidity at Gasket Seating Temperature

198569.104MPa

For Integral type flange

L E

yo

2

0

52.14 V M

J

h

203395.392MPa

0.3

yg

Flange Rigidity at Gasket Seating Temperature

Flange Rigidity at Operating Temperature

52.14 V M

L E

0.1478

yg

2

0

0.1261

if J

1

g

FlangeRigidityPassSeating "Yes"

else

FlangeRigidityPassSeating "No - Reproportion dimension and GoTo STEP 3"

if J

1

o

FlangeRigidityPassOperating "Yes"

else

FlangeRigidityPassOperating "No - Reproportion dimension and GoTo STEP 3"

FlangeRigidityPassOperating "Yes"

FlangeRigidityPassSeating "Yes"

7/7

You might also like

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Specification DiverterDocument9 pagesSpecification Diverterhappale2002No ratings yet

- Clevis Pin Specifications ChartDocument1 pageClevis Pin Specifications Chartbincoleto5536No ratings yet

- Texas Flange - Product Catalog PDFDocument47 pagesTexas Flange - Product Catalog PDFFranco Saenz SolisNo ratings yet

- Body Flange .PVDB FlangeDocument1 pageBody Flange .PVDB FlangeAnonymous aBg51lbe18No ratings yet

- WRC 107 WRC 297 Co MP PDFDocument11 pagesWRC 107 WRC 297 Co MP PDFIqbal Muhammad100% (1)

- Api 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim MccabeDocument11 pagesApi 16A 3 Edition: Api 16A Chairman: John Busby Co-Chair: Jim Mccabesaeed65No ratings yet

- Support and Leg Calculation: Data Sheet Material Dan Tabel CalculationDocument3 pagesSupport and Leg Calculation: Data Sheet Material Dan Tabel CalculationliusNo ratings yet

- Drawing SallDocument81 pagesDrawing Sall90070878002No ratings yet

- Pipe Support Load Calculation SheetDocument3 pagesPipe Support Load Calculation SheetHassan Muhammad TundeNo ratings yet

- Bolting-Up CalcDocument21 pagesBolting-Up CalcJayanth TSNo ratings yet

- BOP PlateDocument30 pagesBOP PlatezsmithNo ratings yet

- Volume Iiia r1Document447 pagesVolume Iiia r1Muhammed FawazNo ratings yet

- ANSI B16.5 Flange CatalogueDocument14 pagesANSI B16.5 Flange Catalogue김명래No ratings yet

- Anchor Flange Design Data SheetDocument4 pagesAnchor Flange Design Data SheetALENo ratings yet

- Flanges With External LoadDocument15 pagesFlanges With External LoadMohan VarkeyNo ratings yet

- Dynamic Analysis of Slug by Advance Input MethodDocument53 pagesDynamic Analysis of Slug by Advance Input MethodYogesh PangareNo ratings yet

- ThickAndThin JointsDocument31 pagesThickAndThin JointsHùng Mạnh NguyễnNo ratings yet

- D4516503033 Pib 001Document2 pagesD4516503033 Pib 001Edmo VirgensNo ratings yet

- Design of Blowout Preventer Lifting FramDocument10 pagesDesign of Blowout Preventer Lifting FramAndreansyah PratamaNo ratings yet

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 pagesCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Calculation Cover Sheet: Mechanical Generic Project Name Pipe Wall Thickness Calculations System Name Wall ThicknessDocument2 pagesCalculation Cover Sheet: Mechanical Generic Project Name Pipe Wall Thickness Calculations System Name Wall Thicknessjmclaug502No ratings yet

- PSV Reaction Force CalculationDocument2 pagesPSV Reaction Force CalculationSuthanNo ratings yet

- PSV Reaction Force - Closed SystemDocument5 pagesPSV Reaction Force - Closed SystemWayne MonneryNo ratings yet

- Enviando DS-Cameron-In-Service Condition of Cameron® D-DL Annular BOPDocument2 pagesEnviando DS-Cameron-In-Service Condition of Cameron® D-DL Annular BOPcarlosorizabaNo ratings yet

- MUD KING BUTTERFLY VALVE FEATURESDocument8 pagesMUD KING BUTTERFLY VALVE FEATURESGhinet Teodor-ioanNo ratings yet

- Materials Compatibility Guide for Specialty GasesDocument34 pagesMaterials Compatibility Guide for Specialty GasesStefanoNo ratings yet

- FE107 Experimental ResultsDocument11 pagesFE107 Experimental ResultsEsapermana RiyanNo ratings yet

- Modelling BOP Closing TimesDocument80 pagesModelling BOP Closing Timesscibduser001No ratings yet

- Quick Union Reference: HydrolexDocument2 pagesQuick Union Reference: HydrolexBrian DoorenbosNo ratings yet

- Calculation Cover SheetDocument8 pagesCalculation Cover SheetYogesh PangareNo ratings yet

- FPS-09 - Tee Recta PDFDocument2 pagesFPS-09 - Tee Recta PDFOscar AmvalNo ratings yet

- Flange DesignDocument4 pagesFlange DesignJilu Easow RajuNo ratings yet

- Maintain & operate Regan Type K BOPDocument4 pagesMaintain & operate Regan Type K BOPAshok SureshNo ratings yet

- Vortex Shedding Load On PipingDocument1 pageVortex Shedding Load On Pipingananyo_sengupta100% (1)

- Steel Pipe VesselDocument122 pagesSteel Pipe VesselHarish HarishNo ratings yet

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- Tech Manual 1222B: Booster Cylinder Assembly EH34-BC03Document21 pagesTech Manual 1222B: Booster Cylinder Assembly EH34-BC03jose perozoNo ratings yet

- Flange DesignDocument12 pagesFlange DesignSantoshNo ratings yet

- Materials Selection GuidelinesDocument316 pagesMaterials Selection GuidelinesGarthSandersNo ratings yet

- Jiangsu Deenpu Petrochemical Machinery Co.,ltdDocument12 pagesJiangsu Deenpu Petrochemical Machinery Co.,ltdJIN WANGNo ratings yet

- Narrow Face Flange - Slip On Hub TypeDocument17 pagesNarrow Face Flange - Slip On Hub TypeEng-CalculationsNo ratings yet

- Coiled TubingDocument1 pageCoiled TubingMohamed SaeedNo ratings yet

- Spring - Hanger - Basic PSA Inc PDFDocument26 pagesSpring - Hanger - Basic PSA Inc PDFViji SvrNo ratings yet

- Xplore Orld Iping: Definition and Details of FlangesDocument3 pagesXplore Orld Iping: Definition and Details of FlangesKyle StackNo ratings yet

- EB878G Gate Valves Trim Cross-ReferenceDocument4 pagesEB878G Gate Valves Trim Cross-Referencejose eduardoNo ratings yet

- Design of lifting frame for Blowout Preventer stackDocument10 pagesDesign of lifting frame for Blowout Preventer stackSisu StefanNo ratings yet

- Studbolt and Wrench Sizes for Piping SystemsDocument1 pageStudbolt and Wrench Sizes for Piping SystemsThomas Van BeeckNo ratings yet

- Flange Data: Bolt Reference Charts For ASME B16.5 FlangesDocument4 pagesFlange Data: Bolt Reference Charts For ASME B16.5 FlangesMilena Lemus FonsecaNo ratings yet

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 pagesASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNo ratings yet

- Calcs 4Document19 pagesCalcs 4Syariful Maliki NejstaršíNo ratings yet

- SCH 40 Steel Pipe Chart with Dimensions, Weight & Pressure RatingDocument8 pagesSCH 40 Steel Pipe Chart with Dimensions, Weight & Pressure RatingSaira WaqasNo ratings yet

- Front End Engineering Design (FEED) for Gas Lift Compression Project Pipeline DesignDocument14 pagesFront End Engineering Design (FEED) for Gas Lift Compression Project Pipeline Designsutomo rochmandaNo ratings yet

- Product Safety Alert: 22 February 2021Document4 pagesProduct Safety Alert: 22 February 2021carlosorizabaNo ratings yet

- Flare Scrubber DSDocument8 pagesFlare Scrubber DSsudjonoNo ratings yet

- Anchor Flange Dimensions and SpecificationsDocument8 pagesAnchor Flange Dimensions and SpecificationsHanda Bin AdiNo ratings yet

- Piping Engineering - Tank Nozzle Loads 1Document1 pagePiping Engineering - Tank Nozzle Loads 1Nasrul AdliNo ratings yet

- ASMESectionVIIIDivision1 WeldNeckFlangeCalcDocument8 pagesASMESectionVIIIDivision1 WeldNeckFlangeCalcMaheshwar A KundaikarNo ratings yet

- Calc DocumentDocument8 pagesCalc DocumentbalaNo ratings yet

- Body Flange Design-Appx-2Document4 pagesBody Flange Design-Appx-2Matthieu100% (1)

- 5Document1 page5nandhamech25No ratings yet

- 4Document1 page4nandhamech25No ratings yet

- Shell and Tube Heat Exchanger Design PDFDocument3 pagesShell and Tube Heat Exchanger Design PDFBaha Eddine Gharbi100% (1)

- UseDocument2 pagesUsenandhamech25No ratings yet

- Rev. G English OCT / 2001Document5 pagesRev. G English OCT / 2001nandhamech25No ratings yet

- FVC Studding OutletDocument1 pageFVC Studding Outletnandhamech25No ratings yet

- Tube Material Compatibility Heat Exchanger StandardsDocument6 pagesTube Material Compatibility Heat Exchanger Standardsnandhamech25No ratings yet

- 5 He PDFDocument2 pages5 He PDFnandhamech25No ratings yet

- 5 He PDFDocument2 pages5 He PDFnandhamech25No ratings yet

- N-466 Mechanical Design of Shell-And-Tube Heat Exchanger: ProcedureDocument4 pagesN-466 Mechanical Design of Shell-And-Tube Heat Exchanger: Procedurenandhamech25No ratings yet

- Heat ExchangerDocument21 pagesHeat ExchangerArun Prakash NatesanNo ratings yet

- Heat Exchanger Crossover AnalysisDocument5 pagesHeat Exchanger Crossover AnalysisMuhammad KhurramNo ratings yet

- FVC 25Document2 pagesFVC 25nandhamech25No ratings yet

- Studding Outlet1Document2 pagesStudding Outlet1nandhamech25No ratings yet

- Coalesce RDocument1 pageCoalesce Rnandhamech25No ratings yet

- FVC Studding OutletDocument1 pageFVC Studding Outletnandhamech25No ratings yet

- Horizontal FiltersDocument1 pageHorizontal Filtersnandhamech25No ratings yet

- FVC Catalog 150#Document2 pagesFVC Catalog 150#nandhamech25No ratings yet

- JIS FittingsDocument1 pageJIS Fittingsnandhamech25No ratings yet

- JIS FittingsDocument1 pageJIS Fittingsnandhamech25No ratings yet

- Dish Metal FormingDocument1 pageDish Metal Formingnandhamech25No ratings yet

- JIS FittingsDocument1 pageJIS Fittingsnandhamech25No ratings yet

- Dish Metal FormingDocument1 pageDish Metal Formingnandhamech25No ratings yet

- JIS Fittings 2Document1 pageJIS Fittings 2nandhamech25No ratings yet

- Metal Forming SequenceDocument1 pageMetal Forming Sequencenandhamech25No ratings yet

- 40kg/Cm 30kg/Cm: JIS B 2220-1984 (KS B 1503-1999) 30 / Slip-On Welding Steel Pipe FlangesDocument1 page40kg/Cm 30kg/Cm: JIS B 2220-1984 (KS B 1503-1999) 30 / Slip-On Welding Steel Pipe Flangesnandhamech25No ratings yet

- Head MaterialDocument1 pageHead Materialnandhamech25No ratings yet

- Dish Metal FormingDocument1 pageDish Metal Formingnandhamech25No ratings yet

- Agitated Vessel Heat Transfer DesignDocument2 pagesAgitated Vessel Heat Transfer Designnandhamech25No ratings yet

- Ansi b16 WeightDocument3 pagesAnsi b16 Weightvincentvin111No ratings yet