Professional Documents

Culture Documents

Solvent Data

Uploaded by

Anonymous PO7VwbBnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solvent Data

Uploaded by

Anonymous PO7VwbBnCopyright:

Available Formats

148

I. M. Abdulagatov and S. M. Rasulov: Viscosity of N-Pentane, N-Heptane and Their Mixtures

Viscosity of N-Pentane, N-Heptane and Their Mixtures within the Temperature

Range from 298K up to Critical Points at the Saturation Vapor Pressure

I.M. Abdulagatov and S.M. Rasulov

Institute for Geothermal Problems of the Dagestan Scientific Center of The Russian Academy of Sciences, 367030 Makhachkala,

Kalinina 39-A, Dagestan, Russian Federation

Key Words: Critical Point / Mixtures / N-Pentane / N-Heptane / Viscosity / Saturation Line

The viscosity of n-pentane, n-heptane and their mixtures has been measured with a capillary flow method between 298 K and the critical temperatures at the saturation vapor pressure. The concentrations studied were 0.259,

0.419 and 0.745 mole fraction of n-heptane. The maximal error of the experimental values of the viscosity is estimated to be 1.2% in the region far from the critical point and k5vo in the immediate vicinity of the critical

point. The viscosity obtained was compared to data by other authors with satisfactory agreement. The validity

of the method has been confirmed by the measurement of the viscosity of standard liquids as water and toluene.

1. Introduction

N-pentane and n-heptane has been investigated by a number of authors [I - 371. In Tables 1 and 2 selected primary

data sets are collected with their individual pressure and

temperature ranges, the experimental method used and their

uncertainty. Most of the measurements were performed at

atmospheric pressure [lo - 20, 32 - 371. At higher pressures

only a limited amount of data is available [I5 - 291. In

papers [12-14, 18, 24, 25, 32-37] the viscosities of

gaseous n-pentane and n-heptane were measured in the temperature range from 298 - 576 K at atmospheric pressure.

The viscosities of liquid n-pentane and n-heptane at atmospheric pressure has been measured in papers [lo, 15 - 17,

261 at temperatures from 292 K to 346 K. The measurements were obtained with different techniques. The viscosi-

Table 1

Primary experimental data for the viscosity of n-pentane and n-heptane at atmospheric pressure

Reference

n-Pentane

Titani [I21

Bleakney [ 141

Lambert et al. [36]

Day [I31

Sage and Lacey [18]

Agaev et al. [24]

McCoubrey et al. [32]

Diaz Pena et al. [33]

This paper

Shepard et al. [ I S ]

Agaev et al. [24]

Geist and Cannon [I61

Khalilov [21]

Thorpe and Rodger [I71

Oliveira et al. [lo]

This paper

n-Heptane

Melaven and Mack [37]

Lambert et al. [36]

Agaev et al. [25]

Carmichael et al. [35]

Diaz Pena et al. [34]

This paper

Knapstad et al. [26]

Kashiwagi et al. [4]

Assael et al. [I]

Khalilov [2]

Golubev [3]

This paper

Technique

C

RC

C, OD

RC

RB

C

C

C

C

C

C

C

C

C

vw

C

C

C, OD

C

RC

C

C

oc

TC

vw

C

C

Temperature range

[KI

State

395 - 576

298, 373

308 - 363

298

298 - 523

298 - 548

303 - 363

295 - 423

322 524

298

298

293

293 - 353

303 - 348

303

298

Gas

Gas

Gas

Gas

Gas

Gas

Gas

Gas

Gas

Liquid

Liquid

Liquid

Liquid

Liquid

Liquid

Liquid

313 - 524

338 - 363

373 - 474

294 - 377

333 - 423

314 - 550

292 - 346

298 - 348

303, 323

297 - 51 3

183 - 453

298 - 350

Gas

Gas

Gas

Gas

Gas

Gas

Liquid

Liquid

Liquid

Liquid

Liquid

Liquid

Uncertainty

[%I

3

1

2

2

1

2

1.2

1

1

0.5

-

0.5

1.2

1

3

1.6

1

2

1.2

0.6

2

3

-

1.6

1.2

VW, Vibrating wire; C, Capillary; RC, Rotating cylinder; FB, Falling body; OD, Oscillating disk; RB, Rolling ball; OC, Oscillating cylinder;

TC, Torsional crystal

Ber. Bunsenges. Phys. Chem. 100, 148-154 (1996) No. 2

0 VCH Verlagsgesellschaft mbH,

0.69451 Weinheim, 1996

0005-9021/96/0202-0148 S 10.00+ .25/0

I. M. Abdulanatov and S. M. Rasulov: Viscosity of N-Pentane, N-HeDtane and Their Mixtures

149

Table 2

Primary experimental data for the viscosity of n-pentane and n-heptane under pressure

Reference

Technique

Temperature range

[Kl

n-Pentane

Sage et al. [I81

Golik et al. [22]

Hubbard et al. [I91

Remer et al. [20]

Collings et al. [29]

Khalilov [21]

Bridgman [23]

Agaev et al. [24]

Oliveira et al. [lo]

Brazier et al. [30]

This paper

n-heptane

Kashiwagi et al. [4]

Assael et al. [I]

Khalilov [2]

Golubev [3]

Agaev et al. [25]

This paper

RB

FB

RB

RC

TC

C

FB

C

vw

RB

C

TC

vw

C

C

C

C

300 - 377

283 -473

298 - 523

311-411

303, 323

373 -423

303, 348

298 - 548

303, 323

303, 323

298 - 524

298 - 348

303, 323

293 - 5 13

323 - 573

298 - 548

298 - 550

Pressure range

[MPal

14

-

7

35

200

ps

I200

50

252

250

50

110

70

Uncertainty

[0701

0.5

2

2

2

1

-

2

1.6

0.5

0.5

I .2

2

0.5

-

ps

60

50

50

1.6

1.6

1.2

VW, Vibrating wire; C, Capillary; RC, Rotating cylinder; FB, Falling body; OD, Oscillating disk; RB, Rolling ball; TC, Torsional crystal;

OC, Oscillating cylinder

ty of n-pentane and n-heptane under pressure was measured

for temperatures between 298 K and 423 K at pressures up

to 252 MPa in works [I - 4, 18 - 25, 28 - 301. However, the

earlier measurements for pure components did not extend

to the saturation line so that a modest extrapolation to the

saturated vapor pressure has been necessary.

An extensive review of the viscosity data of gaseous

hydrocarbons at atmospheric pressure has recently been

presented by Tarzimanov et al. [34]. In the literature, for

the binary mixtures of n-pentane-n-heptane viscosity data

are lacking. The purpose of this work is to provide a reliable

set of (viscosity q , pressure P , temperature 7')values for

pure n-pentane and n-heptane along the saturation lines and

their mixtures along the dew point and bubble point lines,

to extend the temperature range and to complete preliminary results reported earlier.

2. Experimental

The viscosity was measured with a capillary-flow viscometer. A schematic diagram of the experimental apparatus is

shown in Fig. 1. The apparatus consists of the following

main parts, a high-pressure viscometric vessel - 1, a

capillary viscometer - 2, a copper block - 3, a heater 4, a stainless steel1jacket - 5, two connecting high-pressure

vessels - 6, and a frequencymeter (FM-5041) - 7. The viscometer is mounted inside a high-pressure viscometric

vessel. The viscometric vessel is made of type 321 stainless

steel and has a length of 265 mm and an inner diameter of

18 mm and outside diameter of 66 mm. A massive copper

block - 3 is slipped over the high-pressure steel vessel by

hot pressing in order to improve the temperature control. A

stainless steel jacket is put over the copper block by means

Fig. 1

Schematic diagram of the experimental apparatus for high-temperature

and high-pressure measurements of the viscosity. High-pressure

viscometric vessel - 1; capillary viscometer - 2; copper block - 3;

heater - 4; stainless steel jacket - 5; two connecting high-pressure

vessels - 6 ; frequencymeter (FM-5041) - 7

of hot pressing. The whole system is covered with a thick

layer of glass cloth from the outside for better heat insulation.

Fig. 2 shows the construction and geometric characteristics of the viscometer. The viscometer consists of a lower

bulb - 1 , a connecting tube - 2, a preliminary bulb - 3,

a measuring bulb - 4, a capillary - 5, and platinum contacts - 6. The viscometer was made from refractory glass

(supremax). The capillary has a length of 50mm and a

diameter of 0.10 mm. The length of the capillary is measured with a cathetometer whose accuracy for each end is

150

I. M. Abdulagatov and S . M. Rasulov: Viscosity of N-Pentane, N-Heptane and Their Mixtures

the fluid through the capillary takes place. While lowering,

the mercury successively disconnects contacts at the inlet

and the outlet of the measuring bulb - 4 and the flow time

is fixed.

The platinum contacts of the viscometer are welded to insulated nichrome wires with a diameter of 0.2 mm which are

connected to the outs of the pressure vessel by an electrically

insulated feed-through. The viscometer is fixed to the feedthrough and installed in the high-pressure vessel which can

bear pressures of more than 100MPa.

The viscosity was calculated from equation:

Fig. 2

Construction and geometric characteristics of the high-pressure capillary viscometer. Lower bulb - 1; connecting tube - 2; preliminary bulb

- 3; measuring bulb - 4; capillary - 5 ; platinum contacts - 6

-

about 0.1 mm. T o examine the uniformity, roundness and

straightness of a glass capillary, an optical method was

used. A glass capillary is filled with mercury and immersed

in a liquid with a refractive index nearly equal to that of a

capillary material. The changes of diameter of the mercury

thread are then determined at various points with the aid of

a microscope. The volumes of the preliminary and measuring bulbs of the viscometer were determined by the mercury-weighing method. The height of the mercury column

in the viscometer and the difference of the mercury levels

corresponding to the beginning and the end of the mercury

flow from the measuring bulb were determined by the

cathetometer.

The time of mercury flowing from the upper contact of

the measuring bulb to the lower bulb was measured automatically by a frequencymeter (FM-5041) with an accuracy

of k 1 ms. The upper contact of the viscometer was connected to brand start and the middle to brand stop.

The measurement of the flow time was repeated 6 - 7 times

for each temperature and pressure in order to confirm the

reproducibility of the results. The flow time for the investigated hydrocarbons was more than 220 s. The dead-weight

gauge (MP-600) was used to generate and to measure the

pressure.

The accuracy of the measurements of pressure was estimated to be k 1.5 kPa. The temperature was measured with

a platinum resistance thermometer (PTR-10 N4419). The

uncertainty of the temperature measurements is estimated

to be less than k 15 mK. The temperature of the high-pressure viscometric vessel containing the capillary viscometer is

controlled by means of a high-precision temperature

regulator (HPTR-3). The temperature of the viscometer was

kept constant to within k 10 mK. Fig. 2 shows the principle

of operation of the capillary viscometer. Initially mercury is

in the lower bulb - 1 (position A). When the high-pressure

viscometric vessel - 1 (Fig. 1) is turned by a n angle of 90

the viscometer is in a horizontal position (position-B) and

the mercury spills over the whole viscometer. When the

viscometer returns to its initial vertical position-C, the level

of mercury will be higher than the upper contact. Due to the

difference of the mercury levels in the viscometer, flow of

with

H,=-

H1-H2

, a=--,

In Hl

H2

HO

Vo= 1.1444k0.0001 cm,

Ho = 57.938 k 0.029 mm,

= 0.83872+0.00056, where g = 9.81 m . C 2 is the acceleration due to gravity, Ro and Lo are the radius and

length of the capillary at room temperature; a is the coefficient of linear expansion of the capillarys glass;

A T = (7- To) is the difference between the experimental

temperature T and room temperature To 293.1 5 K;

p ( T , P ) and po(To,P)are the densities of the sample at the

experimental conditions ( T ,P ) and at room temperature

and experimental pressure (To,P ) ; p * (To,P ) and

po*(To,O.lMPa) are the density of the mercury at room

temperature and experimental pressure and atmospheric

pressure, respectively; rn is the kinetic-energy correction

factor (m = 1.12); Vo is the volume of the sample flowing

through the capillary at room temperature; and z is the efflux time; H , and H2 are the heights of the mercury column

in the viscometer at the beginning and the end of a measurement; h is the height of the mercury column in the lower

bulb. The values of H , , H2,L , , L 2 , h are given in Table 3.

In Eq. (1) the pressure difference between the two ends of

a capillary, AP, has been replaced by the mean hydrostatic

pressure, AP = @ * - p ) g A in which p is the density of the

Table 3

Values of the geometric characteristics of the viscometer

H,/mm

H,/mm

L,/mm

L2/mm

h/mm

77.1744

42.1999

107.9337

84.1140

48.5941

I. M. Abdulagatov and S. M. Rasulov: Viscositv of N-Pentane. N-HeDtane and Their Mixtures

sample, p * is the density of mercury, H is the mean effective height of the mercury column. In fact, H is the height

where the actual volumetric flow rate becomes equal to the

mean flow rate V / T .Here I/ is the volume of the upper bulb

and T denotes the time required for liquid of volume I/ to

flow through the capillary. In this study, the density data of

the sample are needed for the calculation of the viscosity.

The density values were mostly calculated from the equation of state for n-pentane and n-heptane of [28, 381. For

n-pentane-n-heptane mixtures we employed the density data

reported by Gummings et al. [41]. Eq. (1) takes into account

the following corrections: 1. Gas expansion in the capillary.

2 . Imparting of kinetic energy to the liquid. 3. Time-averaging of the calculated values. 4. Gas compression in the

viscometer volume. 5. Thermal expansion of the viscometer

and variations of the geometric size of the viscometer with

temperature.

The pressure drop determination error is within

kO.003 MPa. To avoid the effect of sample density variations along the capillary on the viscosity measurement, the

experiments were carried out with small pressure drops

(0.007 - 0.01 bar) across the capillary. In this case, the

For the

Reynolds number was within 600-800.

250 - 400 kg.m-3 range, the experiments were carried out

with pressure drops of 0.005 MPa and Re of 500-600.

The accuracy of the viscosity measurements depends on

the accuracy of the values entering into the working Eq. (1).

The relative error in the viscosity in terms of the errors of

the measured parameters R,, a, T , Vo,Ho, p, p * , and Lo is

given by the relation:

ARo AHo

AT Ap

-4-+-+2-+-+2-+-

Ro

Ho

AVO

Ap*

vo

P*

+2-+-

ALo h a

Lo

151

The total error in determining q of the sample is k 1.2% in

the region far from the critical point and k 5% in the region

very near the critical point.

In order to calculate the viscosity from working Eq. (I),

the radius of the capillary has to be known. The capillary

radius, Ro, enters this equation as R:, and because the

radius is small it is extremely difficult to be determined accurately. The mercury-weighing method has been used for

the determination of the radius (or the diameter) of the

capillary. The radius, Ro, of the capillary is calculated as:

(3)

where p $ is the density of mercury at room temperature, rn

is the mass of the mercury column, Lo its length. The

length of the mercury column was measured with a

cathetometer (CM-8). The mass of the mercury column was

determined by weighing on a chemical balance with an accuracy of f 1.5 mg.

For our capillary viscometer the Reynolds number is

calculated as:

4v*p

Re=-,

p.d*q-r

(4)

where V is the volume of the sample flowing through the

capillary, T is the flow time, p is the density of the sample

at experimental temperature and pressure, d is the diameter

of the capillary, q is the viscosity of the sample at given T

and P . In all cases, the Reynolds number Re was not higher

than 800.

We tested our viscometer using liquid n-heptane, toluene

and pure water for which a large amount of concording

data exists. Table 4 gives a comparison of our data obtained

with the capillary-flow viscometer with literature data. The

agreement of our results for water, toluene and n-heptane

Table 4

The results of check measurements on the viscosity of n-heptane, water, and toluene

Reference

sample

T

[KI

P

[MPal

n-Heptane

303

0.1

Water

293

303

313

Toluene

436.01

0.1

0. I

0.1

30

25

20

15

10

7. 103

[Pa.s]

Ref. 1

rl. 103

[Pa. s]

This paper

[Pa. s]

Ref. 2

r1.103

[Pa.s]

Ref. 3

r1.103

[Pa.s]

Ref. 4

0.3689

0.3707

0.3688

0.3691

0.3692

This paper

Ref. 6

Ref. 7

Ref. 8

Ref. 9

1.0017

0.7975

0.6528

1.OW5

0.7988

0.6548

1.0020

0.7975

0.6526

1.0020

0.7978

0.6531

1.0015

0.7971

0.6513

d.103

This paper

Ref. 5

0.2413

0.2352

0.2220

0.2612

0.2063

0.1951

0.2432

0.2340

0.2242

0.2626

0.2049

0.1944

I52

1. M. Abdulagatov and S. M. Rasulov: Viscosity of N-Pentane, N-Heptane and Their Mixtures

Table 5

The viscosity of n-pentane in the liquid ( q ' ) and vapour (q") phases

along the saturation line

0.067

0.114

0.212

0.363

0.583

0.887

1.320

1.579

I .874

2.208

2.566

2.810

2.982

3.113

3.210

3.262

3.286

3.330

298

313

333

353

373

393

413

423

433

443

453

459

463

466

468

469

469.60

469.95

0.2155

0.1905

0.1617

0.1354

0.1 141

0.0961

0.0805

0.073 1

0.0652

0.0577

0.0500

0.0456

0.0418

0.0393

0.0364

0.0342

0.0325

0.0263

621.3

606.2

585.0

562.4

537.7

510.7

478.7

460.4

439.4

416.1

386.7

364.3

344.5

325.3

306.5

291.5

280.9

232.0

0.0070

0.0075

0.0081

0.0087

0.0094

0.0103

0.0107

0.01 14

0.0125

0.0143

0.0154

0.0167

0.0186

0.0202

0.0220

0.0239

0.0263

3.36

6.02

10.1

16.3

25.0

38.6

47.6

59.1

73.5

93.5

110.9

126.9

144.0

160.9

174.6

184.1

232.0

Table 6

The viscosity of a 0.741 n-pentane-0.259 n-heptane mixture along the

dew point (a") and bubble point (q') lines

to4

T

[K]

P"

[MPa]

P'

[MPa]

,1J.~04 q r r .

[Pa.s]

[Pa.sl

p'

P"

[ k g . r ~ - ~ ] [kg.m-3]

443

453

463

473

483

488

490

491

491.6

492.6

1.342

1.584

1.897

2.250

2.684

2.968

3.063

3.122

3.162

3.320

1.686

I .965

2.257

2.603

3.012

3.213

3.280

3.309

3.328

3.320

0.7555

0.6840

0.6145

0.5460

0.4665

0.4090

0.3790

0.3550

0.3360

0.2650

0.1135

0.1221

0.1362

0. I548

0.1800

0.2005

0.2170

0.2335

0.2510

0.2650

467.0

449.0

424.0

382.5

346.0

323.2

307.0

296.0

233.0

'-@

0.8

0.6

0.4

0.2

42.8

52.5

66.1

83.8

114.2

139.0

154.9

164.5

169.0

233.0

o?

0

a

0

450

500

550

Tern pe ra tu re/ K

Fig. 3

Viscosity of pure n-pentane and n-heptane as functions of temperature

along the saturation lines. 1 - Pure n-pentane; 2 - pure n-heptane

Table 7

The viscosity of a 0.581 n-pentane-0.419 n-heptane mixture along the

dew point (q") and bubble point (q') lines

T

[K]

P"

[MPa]

P'

[MPa]

q'.104

q f t .to4

[Pa.s]

[Pa.s]

pi

[kg.m-3]

P"

[ k g . ~ ~ ~ ]

463

413

483

488

493

497

499

501

503

504

504.6

505.0

1.492

1.806

2.145

2.331

2.534

2.716

2.818

2.923

3.034

3.084

3.115

3.308

1.895

2.191

2.520

2.696

2.877

3.027

3.098

3.175

3.251

3.268

3.276

3.308

0.7020

0.6341

0.5700

0.5360

0.4970

0.4577

0.4350

0.4095

0.3795

0.3580

0.3350

0.2660

0.1190

0.1280

0.1425

0.1535

0.1673

0.1820

0.1915

0.2010

0.2185

0.2335

0.2470

0.2660

458.0

441.0

419.5

406.5

387.7

365.5

349.0

328.1

299.0

281.5

270.0

233.5

47.6

60.0

77.0

87.5

100.5

113.4

121.2

131.4

144.0

153.0

159.0

233.5

with values considered as standard data [I - 91, is good and

sufficient to confirm the validity of our method. The

viscosities calculated from the working Eq. (1) for n-heptane, water and toluene agreed with the reference viscosities

to within t 0 . 5 V o . The deviations are well within the mutual

error limits. Near the critical point it is difficult to keep the

flow in a laminar condition since the kinematic viscosity is

very low. The flow rate must therefore be kept sufficiently

small to maintain the Reynolds number at a sufficiently low

value.

The hydrocarbons were purified by double distillation.

We estimate the final purity of our hydrocarbons to be

99.98 mass per cent by gas chromatography. For both fluids

and their mixtures, samples were taken from the cell after

the measurements and were again analyzed. There was no

evidence of any change in the level of impurities.

3. Results and Comparison

The measured values of the viscosity of pure n-pentane,

n-heptane along the saturation line and the three binary

mixtures of n-pentane-n-heptane along the dew point and

bubble point lines are given in Tables 5 to 9 as a function

of pressure and temperature. The measurements have all

been carried out a little above the saturation vapor pressure

along the different isotherms. The values given in the tables

were obtained by applying a n extrapolation technique along

each isotherm fitting a simple polynomial by least squares.

Each isotherm is discontinuous at the saturation pressure

except the supercritical isotherms. For pure n-pentane and

n-heptane, a total of 38 and, respectively, 50 experimental

points were measured in the range from 298 K to the critical

temperatures. The dependence of the viscosities on temperature T for pure components are illustrated graphically in

Fig. 3.

The measurements were compared with the values obtained by other authors [21, 241. The deviations are shown

in Figs. 4 and 5. The measurements of Agaev and Golubev

[24] are in excellent agreement with present results in the

overlapping range. At temperatures from 298 K to T, for n-

I. M. Abdulagatov and S. M. Rasulov: Viscositv of N-Pentane. N-Heotane and Their Mixtures

Table 8

The viscosity of a 0.255n-pentane-0.745 n-heptane mixture along the

dew point (q") and bubble point ( q ' ) lines

T

[K]

P"

[MPa]

P'

[MPa]

v,.104

vfr.1o4

p'

P,!

[Pa.s]

[Pa.s]

[kg.m-3]

[kg.m-3]

1.211

1.438

1.708

1.997

2.155

2.325

2.490

521

2.671

523

2.756

524

2.798

525

2.840

525.6 2.876

526.2 3.060

1.480

1.709

1.970

2.268

2.421

2.580

2.709

2.847

2.913

2.949

2.978

2.997

3.060

0.7855

0.7110

0.6355

0.5630

0.5248

0.4857

0.4550

0.4145

0.3900

0.3765

0.3585

0.3370

0.2681

0.1100

473

483

493

503

508

513

517

461.6

0.1155 443.9

0.1267 420.2

0.1428 392.3

0.1530 377.8

0.1645 359.5

0.1755 331.0

0.1900 317.5

0.2036 301.5

0.2120 290.0

0.2265 277.0

0.2375 269.5

0.2681 234.4

39.0

48.1

60.0

75 .o

84.5

96.8

112.5

134.6

149.0

158.0

167.8

173.5

234.4

Table 9

The viscosity of n-heptane in the liquid ( q ' ) and vapour ( q " ) phases

along the saturation line

T

vf.103

v,f. lo3

p'

P"

[K]

[MPa]

[Pa.s]

[Pa.s]

[kg.m-3]

[kg.m-3]

298

313

333

353

373

393

413

433

453

473

483

493

503

513

518

523

527

529

531

533

535

537

538

539

539.6

540.1

0.006

0.012

0.028

0.056

0.105

0.181

0.294

0.454

0.669

0.959

1.136

1.337

1.566

1.825

1.964

2.111

2.239

2.303

2.366

2.433

2.504

2.569

2.618

2.661

2.685

2.701

0.3879

0.3368

0.2799

0.2377

0.1967

0.1660

0.1420

0.1208

0.1017

0.0864

0.0794

0.0723

0.0650

0.0583

0.0548

0.0518

0.0494

0.0479

0.0462

0.0443

0.0422

0.0394

0.0375

0.0357

0.0344

0.0269

0.0073

0.0078

0.0083

0.0089

0.0097

0.0105

0.0112

0.0118

0.0127

0.0136

0.0145

0.0153

0.0161

0.0166

0.0172

0.0177

0.0187

0.0200

0.0215

0.0231

0.0248

0.0269

1.8

153

n-pentane

eJ?

.*

0.6

.*

.*

0.0

*

-0.6

I l l , r ~ r l r l l l l , l , l . I , I l

270

320

370

,,,,',

420

470

Te m peratu re/K

Fig. 4

Relative deviations of the measured viscosity of n-pentane from the

Agaev and Golubev [24]data. * - in the vapor phase; 0 - in the liquid phase

1.5

If

n-heptane

679.3

666.5

649.1

631.1

612.4

592.6

571.1

548.1

523.2

495.2

479.3

461.6

441.4

417.7

404.6

387.7

375.0

366.4

357.4

345.7

333.2

316.6

305.9

290.7

281.9

235.0

0.25

0.50

pentane and n-heptane their results deviate from ours by

less than ko.5%. Only for a few experimental points the

deviation reach f 1 Vo.

For liquid n-pentane along the saturation line, the differences between our new viscosity measurements obtained

with the capillary-flow method and those obtained by

Khalilov [21] with the same method at temperatures from

353 K to 423 K are less than k 1 %, however, at temperature

lower than 353 K the differences reach + 6%. For liquid nheptane, the differences between our results and Khalilov's

* *

*

0

*.

*

* *

1.10

2.00

3.60

6.08

9.79

15.1

22.4

33.0

40.1

48.9

60.0

74.5

83.6

94.6

105.0

111.7

119.1

128.7

139.7

153.8

163.1

177.8

189.5

235.0

**

* *

290

340

390

440

490

540

Temperature/K

Fig. 5

Relative deviations of the measured viscosity of n-heptane from the

Agaev and Golubev [24]data. * - in the vapor phase; 0 - in the liquid phase

[21] measurements in the temperature range from 313 K to

493 K are less than k 0.7%. However, for the vapour phase

of n-heptane the relative deviations of the Khalilov's data

[21] from the present results are very large (about - 30%).

There are no previous results of measurements of the

viscosity of n-pentane-n-heptane mixtures available.

4. Conclusions

New measurements of the viscosity of n-pentane and nheptane along the saturation line and their mixtures at the

dew point and bubble point lines have been reported. The

results show the behavior of the viscosity of n-pentane, n-

154

I. M. Abdulagatov and S. M. Rasulov: Viscosity of N-Pentane, N-Heptane and Their Mixtures

heptane and their mixtures over wide ranges of temperature

and pressure, including the critical region. The accuracy of

the viscosity data is estimated to be 5 I .2%.

The research was supported by the Russian Science Foundation

under Grant 93-05-8627.

References

M. Assael and M. Papadaki, Int. J. Thermophys. 12, 801 (1991).

Kh.M. Khalilov, Izvestie Akademii Nauk Azerbajdzana I , 69

(1 962).

I. F. Golubev and N.A. Agaev, Vayzkost predelnikh uglevodorodov. Azerneshir. Baku. 1964.

H. Kashiwagi and T. Makita, Int. J . Thermophys. 3, 289 (1982).

A. H. Krall and J.V. Sengers, J. Chem. Eng. Data 37, 349 (1992).

N.A. Agaev and A.D. Yasibova, Teploenergetika 7, 75 (1967).

J. Kestin, N. Imaishi, S.H. Nott, J.C. Nieuwoundt, and J.V.

Sengers, Physica A 134, 38 (1985).

C. J. James, D.E. Mulcahy, and B. J. Steel, J. Phys. D. Appl.

Phys. 17, 225 (1984).

M . P . Vukalovich, S. L. Rivkin, and A.A. Aleksandrov, Teplofizicheskie svoistva vody i vodyanogo para. Moskow. Izd. Standartov. 1969.

C.M. B.P. Oliveira and W.A. Wakeham, Int. J. Thermophys.

13, 773 (1992).

E.B. Giller and H.G. Drickamer, Ind. Eng. Chem. 41, 2069

(1949).

T. Titani, Bull. Chem. SOC.Jpn. 8 , 255 (1933).

R. Day, Phys. Rev. 40,281 (1932).

W . J . Bleakney, Gen. Appl. Phys. 3, 123 (1932).

A.F. Shepard, A.L. Henne, W. J. Midgley, J. Amer. Chem. SOC.

53, 1948 (1931).

J . M . Geist and M. R. Cannon, Ind. Eng. Chem. Ind. Ed. 18, 61 1

(1946).

T.E. Thorpe and J . W . Rodger, Phil. Trans. 185, 397 (1894).

B. H. Sage and W.N. Lacey, Trans. Amer. Inst. Mining. Met.

Eng. 127, 118 (1938).

R.M. Habbard and G.G. Brown, Ind. Eng. Chem. 35, 1276

( 1943).

[20] H.H. Remer, G.M. Coklet, and B. H. Sage, Analit. Chem. 31,

1422 (1959).

[21] Kh.M. Khalilov, JETP 9, 335 (1939) (in Russian).

[22] A.Z. Golik, 1.1. Adamenko, A.A. Tkachenko, and A.R. Zelenchuk, Ukr. Phys. J. 21, 53 (1976).

[23] P.W. Bridgman, Proc. Amer. Acad. 61, 57 (1926).

[24] N.A. Agaev and I.F. Golubev, Gazovay promyshlennost 8 , 45

(1963).

[25] N.A. Agaev and I.F. Golubev, Gazovay promyshlennost 3 , 50

(1963).

[26] B. Knapstad, P. A. Skjolsvik, and H.A. Oye, J. Chem. Eng. Data

34. 37 (1989).

.

,

I.F. Golubev, Viscosity of Gases and Gas Mixtures, p. 84, Israel

Program for Scientific Translations, Jerusalem, 1970.

B.A. Grigorev, D. S. Kurumov, I.M. Abdulagatov, and Ya. L.

Vasilev, Teplofizika Vyasokikh Temperature 24, 1096 (1 986).

A.F. Collings and E.McLaughlin, Trans. Faraday SOC.67, 340

(197 I).

D. W. Brazier and G. R. Freeman, Can. J. Chem. 47, 893 (1969).

A.A. Tarzimanov, V. E. Lyusternik, and V.A. Arslanov, Vayzkost gazoobraznykh uglevodorodov, Moskow. IVTAN 1987.

J. S. McCoubrey and N. M. Singh, J. Phys. Chem. 63, 517 (1963).

M. Diaz Pena and J.A. R. Cheda, An. Quim. Real. SOC.Esp. fis.

yquem. 71, 34 (1975).

M. Diaz Pena and J. A. R. Cheda, An. Quim. Real. SOC.Esp. fis.

yquem. 70, 107 (1974).

L.T.Carmichael and B. H. Sage, J. Amer. Inst. Chem. Eng. 12,

559 (1966).

I.D. Lambert, K.I. Cotton, M.W. Pailthorpe, Proc. R. SOC.

A 2 3 2 , 280 (1955).

R.M. Melaven and E.Y. Mack, J. Amer. Chem. SOC.54, 888

(1932).

D. S. Kurumov, Teplofizika Vyasokikh Temperature 28, 1107

(1990).

J.V. Sengers, in: Transport Phenomena - 1973, p. 229, ed. by

J. Kestin, ASP Conf. Proc. 11, 1973.

G.A. Olchowy and J.V. Sengers, Phys. Rev. Lett. 61, 15 (1988).

L. W.T. Gummings, F. W. Stones, and M.A. Volante, Ind. Eng.

Chem. 25, 728 (1933).

(Received: January 19, 1995

final version: October 13, 1995)

E 8879

You might also like

- Zúñiga Moreno Galicia Luna2007 Article CompressedLiquidDensitiesOf1 PDocument17 pagesZúñiga Moreno Galicia Luna2007 Article CompressedLiquidDensitiesOf1 Pjasontodd22031995No ratings yet

- Effect of Pressure On Thermal Conductivity of PolymersDocument12 pagesEffect of Pressure On Thermal Conductivity of PolymersJESUS DAVID ANGARITA IBARBUENNo ratings yet

- Critical Properties of Hydrogen Peroxide Determined From Direct MeasurementsDocument8 pagesCritical Properties of Hydrogen Peroxide Determined From Direct MeasurementsMarcelo Sebastian HerreraNo ratings yet

- Galicia Luna2000Document7 pagesGalicia Luna2000Moltimer Folchart CrawNo ratings yet

- Mec 214 Fluid Mechanics PracticalxDocument51 pagesMec 214 Fluid Mechanics PracticalxVietHungCao0% (1)

- O.G. Penyazkov Et Al - Autoignitions of Diesel Fuel/Air Mixtures Behind Reflected Shock WavesDocument6 pagesO.G. Penyazkov Et Al - Autoignitions of Diesel Fuel/Air Mixtures Behind Reflected Shock WavesJuaxmawNo ratings yet

- Gozalpour Fluid StudyDocument10 pagesGozalpour Fluid StudyPatsy RamirezNo ratings yet

- Auto-Ignition of Hydrogen-Air Mixture at Elevated PressuresDocument6 pagesAuto-Ignition of Hydrogen-Air Mixture at Elevated PressuresAlly EnemmyNo ratings yet

- Kinetics of The Thermal Isomerization Bicyclo) Hexane1Document3 pagesKinetics of The Thermal Isomerization Bicyclo) Hexane1Adelmo FilhoNo ratings yet

- Heat Transfer Augmentation Using Twisted Wire Mesh InsertsDocument5 pagesHeat Transfer Augmentation Using Twisted Wire Mesh InsertsVeeresh FuskeleNo ratings yet

- Gillibrand 1967Document8 pagesGillibrand 1967laxmikant girwalkarNo ratings yet

- Experimental Study Onheat Transfer Andpressure Drop in Micro-Fin Tubes Withand Without Coiled Wire InsertDocument5 pagesExperimental Study Onheat Transfer Andpressure Drop in Micro-Fin Tubes Withand Without Coiled Wire InsertInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- 2011 IJAMELaminarDocument15 pages2011 IJAMELaminarVikash SinghNo ratings yet

- Vapor Pressures and Boiling Points of Sixty API-NBS HydrocarbonsDocument9 pagesVapor Pressures and Boiling Points of Sixty API-NBS HydrocarbonsKhanh PhamNo ratings yet

- 1998 - Klimeck - Kleinrahm - Wagner - An Accurate Single-Sinker Densimeter and Measur of PRoT Rel of Argon and Nitrogen in 235 520 K Up To 30 MPaDocument18 pages1998 - Klimeck - Kleinrahm - Wagner - An Accurate Single-Sinker Densimeter and Measur of PRoT Rel of Argon and Nitrogen in 235 520 K Up To 30 MPaAlexanderNo ratings yet

- Creep of PolyurethaneDocument33 pagesCreep of PolyurethaneubdubNo ratings yet

- SPE 93831 Effect of Temperature On Relative Permeability For Heavy-Oil Diatomite ReservoirsDocument8 pagesSPE 93831 Effect of Temperature On Relative Permeability For Heavy-Oil Diatomite Reservoirsmsmsoft90No ratings yet

- Chen2019-Thermal Response Characteristics of A SPRIGT Primary Thermometry SystemDocument6 pagesChen2019-Thermal Response Characteristics of A SPRIGT Primary Thermometry SystemJacyNo ratings yet

- Ethanol PVT DataDocument26 pagesEthanol PVT DataMahesh ParitNo ratings yet

- Lab Report - Temperature Experiments - MDocument11 pagesLab Report - Temperature Experiments - MAliyu AbdulqadirNo ratings yet

- Fdocuments - Us Stabilization of Methylacetylene and Propadiene MixturesDocument7 pagesFdocuments - Us Stabilization of Methylacetylene and Propadiene MixturesPedro BrandãoNo ratings yet

- Vapor Pressure Measurements For Metal Chloride Systems by The Knudsen Effusion MethodDocument6 pagesVapor Pressure Measurements For Metal Chloride Systems by The Knudsen Effusion MethodHerdiana KristiNo ratings yet

- Measurement of Enthalpies of Vaporization of Volatile Heterocyclic Compounds by DSCDocument6 pagesMeasurement of Enthalpies of Vaporization of Volatile Heterocyclic Compounds by DSCwilfred gomezNo ratings yet

- Field Study of Temperature Simulator Applications For Quantitative Interpretation of Transient Thermal Logging in A Multipay WellDocument26 pagesField Study of Temperature Simulator Applications For Quantitative Interpretation of Transient Thermal Logging in A Multipay WellEduardoNo ratings yet

- Phase Equilibrium (Solid-Liquid-Gas) in Polyethyleneglycol-Carbon Dioxide SystemsDocument9 pagesPhase Equilibrium (Solid-Liquid-Gas) in Polyethyleneglycol-Carbon Dioxide SystemsCu ExNo ratings yet

- Surface Tension and Molar Surface Free Energy and Entropy of Water To - 27.2Document4 pagesSurface Tension and Molar Surface Free Energy and Entropy of Water To - 27.2ANGELICA ALEJANDRA MORENO CONTEREASNo ratings yet

- VAPOR PRESSURE OF NITROGENDocument4 pagesVAPOR PRESSURE OF NITROGENnirmalmthpNo ratings yet

- Convective Heat Transfer of Molten Salt Inside TubeDocument6 pagesConvective Heat Transfer of Molten Salt Inside TubeYe ZHANGNo ratings yet

- CJC24 893 1969Document7 pagesCJC24 893 1969Milan DjumicNo ratings yet

- HFC 134aDocument10 pagesHFC 134a4 AMNo ratings yet

- 2005 Viscosity of Molten Sodium NitrateDocument18 pages2005 Viscosity of Molten Sodium NitrateAdrian CaraballoNo ratings yet

- Thermodynamic Properties of Methanol in The CriticDocument42 pagesThermodynamic Properties of Methanol in The CriticNiken SitoresmiNo ratings yet

- Experimental Investigation of Fluid Flow and Heat Transfer in MicrochannelsDocument6 pagesExperimental Investigation of Fluid Flow and Heat Transfer in MicrochannelsRam MurtyNo ratings yet

- Hot Spot Temperatures in Power TransformersDocument8 pagesHot Spot Temperatures in Power TransformersHosni Mohamed KassimNo ratings yet

- Measurement and Modeling of The Solubility of Water in Supercritical Methane and Ethane From 310 To 477 K and Pressures From 3.4 To 110 MpaDocument8 pagesMeasurement and Modeling of The Solubility of Water in Supercritical Methane and Ethane From 310 To 477 K and Pressures From 3.4 To 110 MpaArindam DasNo ratings yet

- 2006 Experimental Investigation of Oxide Nanofluids Laminar Flow Convective Heat TransferDocument7 pages2006 Experimental Investigation of Oxide Nanofluids Laminar Flow Convective Heat TransferAnonymous 7BQxlt8cNo ratings yet

- CFD Studies in The Prediction of Thermal Striping in An LMFBRDocument12 pagesCFD Studies in The Prediction of Thermal Striping in An LMFBRjofredjosephNo ratings yet

- Refrigerant in Capillary Tube PDFDocument6 pagesRefrigerant in Capillary Tube PDFMayank Kumar100% (2)

- Viscosity Measurements of Ammonia, R32, and R134a. Vapor Buoyancy and Radial Acceleration in Capillary ViscometersDocument34 pagesViscosity Measurements of Ammonia, R32, and R134a. Vapor Buoyancy and Radial Acceleration in Capillary Viscometersmostafa shahrabiNo ratings yet

- Experimental Investigation of An Ejector: Received 6 September 1985 Revised 16 September 1985Document3 pagesExperimental Investigation of An Ejector: Received 6 September 1985 Revised 16 September 1985donyaNo ratings yet

- Laboratory Manual: Measurements & Instrumentation (ME-318-F)Document40 pagesLaboratory Manual: Measurements & Instrumentation (ME-318-F)Tony K PaulNo ratings yet

- Vinyl AcetateDocument13 pagesVinyl AcetateRahmahPuspitaSariNo ratings yet

- Benedict-Webb-Rubin Equation of State For An AlterDocument8 pagesBenedict-Webb-Rubin Equation of State For An AlterSantiago AguirreNo ratings yet

- Rajagopal Luis Augusto Prosciba 2010Document7 pagesRajagopal Luis Augusto Prosciba 2010rajabrasilNo ratings yet

- Postponing sharkskin through molecular parametersDocument8 pagesPostponing sharkskin through molecular parametersJuliano SouzaNo ratings yet

- 1.-Galicia-J. Chem. Eng. Data 2007, 52, 1773-1783 - 12Document11 pages1.-Galicia-J. Chem. Eng. Data 2007, 52, 1773-1783 - 12Moltimer Folchart CrawNo ratings yet

- Effect of Temperature on Acetone DiffusivityDocument11 pagesEffect of Temperature on Acetone DiffusivitySharing CaringNo ratings yet

- Blowdown of LPG PipelinesDocument10 pagesBlowdown of LPG PipelinesBehnam HosseinzadehNo ratings yet

- Mechanical Engineering - Lab Manual For Measurement and InstrumentationDocument18 pagesMechanical Engineering - Lab Manual For Measurement and InstrumentationanonNo ratings yet

- Determining circulation velocities in vacuum pansDocument10 pagesDetermining circulation velocities in vacuum pansArtit BoonkoomNo ratings yet

- Experimental study of high-pressure turbulent premixed flamesDocument13 pagesExperimental study of high-pressure turbulent premixed flamesAbdulaziz Ali M AlahmadiNo ratings yet

- Performance of Thermal Energy Storage Unit Using Solid Ammoniated Salt (Cacl - NH System)Document6 pagesPerformance of Thermal Energy Storage Unit Using Solid Ammoniated Salt (Cacl - NH System)ajayNo ratings yet

- Hydraulic Behaviour of Higleig-Portsudan Pipeline PDFDocument15 pagesHydraulic Behaviour of Higleig-Portsudan Pipeline PDFhishamNo ratings yet

- Compressible Flow Bench Experiment AnalysisDocument5 pagesCompressible Flow Bench Experiment AnalysisAhmad AbukhashabehNo ratings yet

- PressurenDrop in Double Pipe Heat ExchangersDocument5 pagesPressurenDrop in Double Pipe Heat ExchangersdikimNo ratings yet

- 86 Measuring A Discharge Coefficient of An Orifice For An Unsteady Compressible FlowDocument5 pages86 Measuring A Discharge Coefficient of An Orifice For An Unsteady Compressible FlowKayla DollenteNo ratings yet

- Experiments of Premixed Hydrogen - Air Flame Propagation in DuctsDocument36 pagesExperiments of Premixed Hydrogen - Air Flame Propagation in DuctsgovindNo ratings yet

- Mech. Engg. DepartmentDocument37 pagesMech. Engg. DepartmentHamza AhmadNo ratings yet

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- CHAPTER 6 - MOTION - 1994 - Continuum MechanicsDocument51 pagesCHAPTER 6 - MOTION - 1994 - Continuum MechanicsAnonymous PO7VwbBnNo ratings yet

- CHAPTER 5 - DEFORMATION - 1994 - Continuum MechanicsDocument73 pagesCHAPTER 5 - DEFORMATION - 1994 - Continuum MechanicsAnonymous PO7VwbBnNo ratings yet

- Sciadv Abd3083 Full PDFDocument11 pagesSciadv Abd3083 Full PDFjudith retanaNo ratings yet

- Entropy 19 00048Document18 pagesEntropy 19 00048Anonymous PO7VwbBnNo ratings yet

- Mark Et Al. (1992) PDFDocument13 pagesMark Et Al. (1992) PDFAnonymous PO7VwbBnNo ratings yet

- Monroyloperena2012 Posible RespeustaDocument5 pagesMonroyloperena2012 Posible RespeustaJair Carmona GonzálezNo ratings yet

- Sciadv Abd3083 Full PDFDocument11 pagesSciadv Abd3083 Full PDFjudith retanaNo ratings yet

- CHAPTER 4 - CONTINUUM HYPOTHESIS - 1994 - Continuum MechanicsDocument12 pagesCHAPTER 4 - CONTINUUM HYPOTHESIS - 1994 - Continuum MechanicsAnonymous PO7VwbBnNo ratings yet

- CHAPTER 3 - CALCULUS OF TENSORS - 1994 - Continuum MechanicsDocument46 pagesCHAPTER 3 - CALCULUS OF TENSORS - 1994 - Continuum MechanicsAnonymous PO7VwbBnNo ratings yet

- Mark Et Al. (1992) PDFDocument13 pagesMark Et Al. (1992) PDFAnonymous PO7VwbBnNo ratings yet

- Face Masks Against Covid 19 PDFDocument8 pagesFace Masks Against Covid 19 PDFTel Avid YaredNo ratings yet

- Sciadv Abd3083 Full PDFDocument11 pagesSciadv Abd3083 Full PDFjudith retanaNo ratings yet

- Mechanism of Fluid Displacement in SandsDocument10 pagesMechanism of Fluid Displacement in SandsSolenti D'nouNo ratings yet

- Sagd Technologies Ogm LightbownDocument12 pagesSagd Technologies Ogm LightbownAdeel Nizami100% (1)

- Sebastian Et Al. (1980)Document3 pagesSebastian Et Al. (1980)Anonymous PO7VwbBnNo ratings yet

- Scheidt and Caers (2010)Document23 pagesScheidt and Caers (2010)Anonymous PO7VwbBnNo ratings yet

- Stone (1970)Document5 pagesStone (1970)Anonymous PO7VwbBnNo ratings yet

- Lake and Hirasaki (1981) (SPE-8436-PA)Document10 pagesLake and Hirasaki (1981) (SPE-8436-PA)Anonymous PO7VwbBnNo ratings yet

- Thermodynamic Properties of Water and SteamDocument49 pagesThermodynamic Properties of Water and SteamBalthasar Sebastian LumbanTobingNo ratings yet

- McMurray Formation GeologyDocument123 pagesMcMurray Formation GeologyAnonymous PO7VwbBnNo ratings yet

- Gringarten Deutsch 2001 - Variogram Interpretation and ModelingDocument28 pagesGringarten Deutsch 2001 - Variogram Interpretation and ModelingFabián CárdenasNo ratings yet

- Mechanisms of NucleationDocument10 pagesMechanisms of NucleationAnonymous PO7VwbBnNo ratings yet

- Thermodynamic Properties of Heavy Water and Light WaterDocument55 pagesThermodynamic Properties of Heavy Water and Light Waternirbhay111No ratings yet

- Effect of Reservoir Heterogeneity On SAGDDocument8 pagesEffect of Reservoir Heterogeneity On SAGDAnonymous PO7VwbBnNo ratings yet

- McMurray GeologyDocument17 pagesMcMurray GeologyAnonymous PO7VwbBnNo ratings yet

- Gibbs Energy Analysis of Phase EquillibriaDocument12 pagesGibbs Energy Analysis of Phase EquillibriaAnonymous PO7VwbBnNo ratings yet

- Reservoir Property UpscalingDocument58 pagesReservoir Property UpscalingAnonymous PO7VwbBnNo ratings yet

- McGarry (1983)Document10 pagesMcGarry (1983)Anonymous PO7VwbBnNo ratings yet

- Peneloux and Rauze (1982)Document17 pagesPeneloux and Rauze (1982)Anonymous PO7VwbBnNo ratings yet

- Latent Print DevelopmentDocument20 pagesLatent Print Developmentapi-272036460100% (1)

- Mock Exam P2Document13 pagesMock Exam P2Abin LalNo ratings yet

- Background Glass - Part-2 - Plate CalculationDocument16 pagesBackground Glass - Part-2 - Plate CalculationusonNo ratings yet

- Appendix JA2 Reference Weather and Climate Zone DataDocument66 pagesAppendix JA2 Reference Weather and Climate Zone DataJoseph DavidNo ratings yet

- Manifest Your Desires with The Quantum CookbookDocument14 pagesManifest Your Desires with The Quantum CookbookAgarta1111No ratings yet

- Phased Array Probes and Wedges: Probe CatalogDocument3 pagesPhased Array Probes and Wedges: Probe CatalogDavidMontillaNo ratings yet

- Bridge Design Report - Docx 150Document17 pagesBridge Design Report - Docx 150nephembaniNo ratings yet

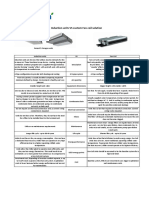

- HotelSolution: Induction Units VS Fan-Coil SolutionDocument1 pageHotelSolution: Induction Units VS Fan-Coil SolutionMoriyasu NguyenNo ratings yet

- EE221 Solution Problem Set2Document10 pagesEE221 Solution Problem Set2srinivasanNo ratings yet

- Factors that Determine Paper StrengthDocument23 pagesFactors that Determine Paper StrengthNur Ariesman Salleh100% (2)

- FDG Production-Theory Operations-FDG Synthesis Chemistr1Document25 pagesFDG Production-Theory Operations-FDG Synthesis Chemistr1Cesar Adolfo SanchezNo ratings yet

- Measuring Elastic Modulus of Beams Using Deflection MethodDocument14 pagesMeasuring Elastic Modulus of Beams Using Deflection MethodHaziq PazliNo ratings yet

- Daftar PustakaDocument5 pagesDaftar PustakamaisyaraaaahNo ratings yet

- Waste Incineration Insert v2Document2 pagesWaste Incineration Insert v2Namik HadziibrahimovicNo ratings yet

- ES 15 Lec 9 Dimensional Analysis and SimilitudeDocument28 pagesES 15 Lec 9 Dimensional Analysis and SimilitudeAngela Mae LopezNo ratings yet

- Lilin Downhole MotorDocument35 pagesLilin Downhole MotorIAN.SEMUT100% (2)

- Introducing JiFi ST Petersburg 2014Document4 pagesIntroducing JiFi ST Petersburg 2014danjohhnNo ratings yet

- Analysis of Truss Using Abaqus SoftwareDocument7 pagesAnalysis of Truss Using Abaqus SoftwareKarthick NNo ratings yet

- Motion 1Document3 pagesMotion 1Fenil ShahNo ratings yet

- Mid-Term Math Exam for Grade 5Document18 pagesMid-Term Math Exam for Grade 5李安逸No ratings yet

- Real Gas ThermodynamicsDocument112 pagesReal Gas ThermodynamicsJohn AllenNo ratings yet

- Lightning Protection Systems Advantages and DisadvantagesDocument11 pagesLightning Protection Systems Advantages and DisadvantagesRamiro Magbanua FelicianoNo ratings yet

- 02 Jaulas de Agujas PDFDocument52 pages02 Jaulas de Agujas PDFRodrigo Schaider Dos SantosNo ratings yet

- Welding Journal PDFDocument7 pagesWelding Journal PDFraisalfiansyahNo ratings yet

- Developing a Solar-Biomass Integrated Drying System for SpicesDocument30 pagesDeveloping a Solar-Biomass Integrated Drying System for SpicesSantosh AngadiNo ratings yet

- Time Allowed: 20 Minutes Marks: 12: Section - ADocument3 pagesTime Allowed: 20 Minutes Marks: 12: Section - AAliNo ratings yet

- Activated Carbon From Cherry StonesDocument6 pagesActivated Carbon From Cherry StonesQussay AhmedNo ratings yet

- Schrodinger Equation DerivationDocument12 pagesSchrodinger Equation DerivationAndrés López Martínez100% (1)

- Section I: Logical Reasoning: Free ThrowsDocument7 pagesSection I: Logical Reasoning: Free ThrowsPuja AgarwalNo ratings yet

- A Brief Overview of The Holographic TechnologyDocument5 pagesA Brief Overview of The Holographic TechnologyAltiel Ltd.No ratings yet