Professional Documents

Culture Documents

1 06 Floyd

Uploaded by

Jacob ChezzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 06 Floyd

Uploaded by

Jacob ChezzCopyright:

Available Formats

PROCEEDINGS, Fire and Evacuation Modeling Technical Conference 2011

Baltimore, Maryland, August 15-16, 2011

COUPLING A NETWORK HVAC MODEL TO A COMPUTATIONAL FLUID DYNAMICS

MODEL USING LARGE EDDY SIMULATION

Jason Floyd

Hughes Associates, Inc

3610 Commerce Dr #817

Baltimore, MD 21227 USA

e-mail: jfloyd@haifire.com

ABSTRACT

An HVAC network model was coupled to FDS v5.5.

The HVAC model allows a user to specify the

topology of an HVAC system along with dampers,

fans, and forward/reverse flow loss through ducts and

fittings. The model was indirectly coupled with the

FDS flow solver. The HVAC model uses prior time

step values as its boundary conditions and provides to

FDS wall boundary conditions of temperature,

velocity, and species for prediction of the next FDS

time step. The current implementation does not

account for transport times with the HVAC network.

This paper describes the governing equations for the

HVAC network model which is based upon the

MELCOR, a nodal network model used for nuclear

power plant containment buildings, solver. The

specific numerical implementation of the equations

within FDS is described.

A series of verification exercises demonstrate that the

network model correctly models HVAC flows and

that its coupling with FDS maintains mass

conservation. A simple and a complex validation

exercise show that the combined solvers can

accurately predict HVAC flows for a duct network in

a complex geometry with fire effects

INTRODUCTION

In the built environment, fire protection engineers

have been limited in their ability to model large

structures. Two-zone models (e.g. CFAST (Jones,

2009)) and air quality models (e.g. CONTAM

(Walton, 2008)) allow one to model an entire

building and include the effects of mechanical

ventilation systems. Neither class of model, however,

is in itself an adequate solution. Zone models have

generally limited ability to model HVAC (heating,

ventilating, and air conditioning) systems and air

quality models do not contain all the necessary

physics to model the effects of a fire. One-zone

models providing both a high level of HVAC

capability along with the ability to model fire effects

have been developed (Floyd, 2004), but as with any

lumped parameter method, one cannot obtain detailed

solutions in regions of interest such as the room of

origin.

CFD (computational fluid dynamics) models can

provide a very high level of detail, but modeling

HVAC systems in a CFD model is a difficult task.

Grid resolutions to accurately predict flow and

pressure loss within a duct network would make

gridding a duct network unaffordable for most CFD

users. Even if it were affordable, a significant

validation effort would be required to demonstrate

that reasonable predictions of pressure loss were

being made.

Recent FDS (McGrattan, 2010) development has

greatly improved the stability of FDS when using

multiple computational meshes and added the

capability to compute pressure rises on a room-byroom basis. This added capability means that one

could take a large structure and grid some regions

very coarsely (where detailed resolution is not

needed) and some regions finely and have an

affordable whole building computation. However,

FDS v5.5 contains only rudimentary HVAC

capabilities. One can specify inlet and outlet flows,

but one cannot couple inlets to outlets. Additionally

there is no manner in which pressurization effects,

flow losses, or other HVAC related phenomena can

be addressed.

A solution to this is to couple an HVAC network

model to the CFD model. This concept was proposed

by Schaelin (1993) and a variety of efforts have been

undertaken to couple a CFD model to an HVAC or

other building air quality model. Wang and Chen

(2007) discuss that this coupling can take one of three

basic forms: 1) The network model and the CFD

model exchange pressures at common boundaries, 2)

the network model exchanges pressure and the CFD

model exchanges flow rate, and 3) the network model

exchanges flow rate and the CFD model exchanges

pressure.

In their effort, Wang and Chen coupled CONTAM to

the CFD0 model. This effort was not focused on

HVAC modeling so much as reducing the CFD

expense to model room-to-room flows through open

doors. They concluded that method 1) from above

was the most stable approach. This method, however,

is not easily implemented in the solution scheme used

by FDS, whereas method 2) is. Other efforts to

couple CFD models with network models have also

primarily focused on reducing the computation

expense for modeling room to room

oom flows rather than

either HVAC functionality or fire effects [[7]. The

effort in this paper will focus on both HVAC

functionality and fire effects.

This paper will describe the model equations, the

solution method, and details of the coupling with the

CFD solver. Verification of the model for some

simple test cases will be demonstrated as well as

comparisons of the model predictions for a series of

tests involving a four level,, twenty

twenty-three

compartment building with three HVAC systems.

Since nodes have no volume, the mass and energy

conservation equations are merely that what flows

into a node, must also flow out of the node. In the

momentum equation the terms on the right hand side

are: the pressure gradient between the upstream and

the downstream node, the buoyancy head, pressure

rise due to an external source (e.g. a fan or blower),

and the pressure losses due to wall friction or the

presence of duct fittings. The momentum equation is

discretized in time which yields:

u nj = u nj +1

HVAC NETWORK MODEL

Overall Algorithm

The overall HVAC solver is based on the MELCOR

(Gauntt, 2000) thermal hydraulic solver. MELCOR is

a computer code for simulating accidents in nuclear

power plant containment buildings. The Fire and

Smoke Simulator (FSSIM) (Floyd, 2003)

2003), a network

fire model, has shown prior success in using the

MELCOR solver to model fire spread and smoke

movement in the presence of complex ventilation

systems.

The MELCOR solver uses an explicit conservation of

mass and energy combined with an implicit so

solver for

the conservation of momentum. An HVAC system is

represented as network of nodes and ducts where a

node represents where a duct joins with the FDS

computational domain or where multiple ducts are

joined such as a tee. A duct segment in the network

represents any continuous flow path not interrupted

by a node and as such may include multiple fittings

(elbows, expansion or contractions, etc.) and may

have varying area over its length. The current

implementation of the model does not account for

mass storage

torage with an HVAC network. The

conservation equations are:

t n K j

2L j

t n ~ n ~ n

n 1

Pi Pk + (gz ) j + Pjn

jLj

((

(u

n

j

u nj + u nj u nj+ u nj

Note that the node pressures are not expressed as Pi n

~

, but rather as Pi n . This indicates an extrapolated

pressure at the end of the current time step rather than

the actual pressure. The pressure in a compartment is

a function of the mass and energy flows into and out

of that compartment. If that compartment is

connected to other compartments by doors or other

openings, then the pressure is also dependent upon

flows into and out those other compartments. Those

mass and energy flows include

clude both those being

predicted by the HVAC model and those being

predicted by the CFD model. For example, in Fig.

Fig 1,

the un-shaded

shaded compartments have pressure solutions

that are dependent upon the flows predicted by both

the HVAC model and the CFD model and

a all of those

compartments need to be included in the extrapolated

pressure for those compartments.

Mass:

ju j Aj

j connected to i

=0,

Energy:

ju j Aj h j

j connected to i

= 0 , and

Momentum:

jLj

du j

dt

Figure 1: Example of pressure coupled (white) and

uncoupled (gray) compartments.

compartments

= (Pi Pk ) + (gz ) j + Pj

1

K j j uj uj

2

Since the two models are not fully coupled, the

extrapolated pressure is an estimate of the pressure at

the end of the time step based upon the pressure rise

for the prior time-step.

FDS decouples the pressure into a series of zone

background pressures which vary with height but are

otherwise constant in a pressure zone (a pressure

zone is a region of the domain without a direct flow

opening to another region such as a room with a

closed door) and a dynamic pressure. The

background pressure can change as a function of the

mass and energy flows into or out of a pressure zone

and is computed by summing the divergence inside

of a pressure zone with the volume flows in and out

of that pressure zone:

dPm

= DdV u dS

dt

d m

m

PdV

m

We can therefore estimate the extrapolated pressure

at the next time step as:

n1

m

dP

~

Pmn = Pmn1 +

t n

dt

By removing the contribution of the prior time-steps

HVAC contribution to the pressure rise, the

extrapolated pressure can be expressed in terms of

the HVAC solution for the current time step:

n 1

m

dP

~

Pmn = Pmn 1 +

+

dt

u nj1 A nj 1 u nj A nj PdV =

j in m

j in m

m

~n

n n

Pm ,non hvac u j A j PdV

j in m

j in k

n

j

A nj

PdV

t n ~ n

~

n 1

Pi ,non hvac Pkn,non hvac + (gz ) j + Pj

jLj

Kj

2L j

u nj + u nj

speed convergence when duct flows are near zero to

avoid large changes in K if the forward and reverse

losses are marked different.

In the previous equation, if either duct node is an

internal node (i.e. it is not connected to the domain

the CFD model is solving for), then extrapolated

pressure terms are not included for that node and the

node pressure is solved for directly. For example if

node i were an internal node, the equation would

become:

K j n

u nj 1 +

u u nj +

2L j

j

P + t n u n A n

PdV

i

j

j

j in k

k

t n

~

n 1

= u nj 1 +

Pkn,non hvac + (gz ) j + Pj

j Lj

t n

jLj

Kj

2L j

u nj + u nj

The above equation for each duct along with a mass

conservation equation for each internal duct node

results in a set of linear equations for duct velocities

and node pressures. The set of equations is solved,

and the solution checked for error in mass

conservation, flow reversal in a duct, and the

magnitude change of the duct velocity from the prior

iteration (or time step if the first iteration). If any

convergence check fails, the solution is re-iterated.

Substituting into the velocity equation above:

This approach, rather than u nj u nj u nj 1 , is used to

K j n

u nj 1 +

u j u nj +

2L

2

t n

u nj A nj PdV

j L j j in i

i

n 1

= uj +

The superscripts n+ and n- on the velocity are used to

linearize the flow loss in a duct to avoid a non-linear

differential equation for velocity. The n+ superscript

is the prior iteration value and the n- is either the

prior iteration value or zero if flow reversal occurred.

Boundary Conditions of the HVAC Solver

The HVAC solver requires boundary conditions of

pressure, temperature, and species for each duct node

coupled to the CFD domain. For flows from a duct to

the CFD domain, temperature and species are those

of the duct. For flows from the CFD domain to a

duct, the temperature and species are taken as the

density weighted average of the gas cells adjacent to

the vent coupling the CFD domain to the HVAC

domain. Pressure is taken as the area weighted total

pressure (background pressure plus dynamic

pressure) over the vent. The total pressure is used so

that the HVAC solver properly accounts for the direct

impingement of fire driven flows onto a vent.

Boundary Conditions of the CFD Solver

The flows predicted by the HVAC solver are coupled

to the CFD domain as vents of specified mass flux

and temperature. The mass flux boundary condition

is given by:

2.

a = Y j ,a u j A j j ACFD VENT

m& w,

5.

The wall temperature boundary condition is the duct

temperature for flows into the CFD domain and the

neighboring gas cell temperature for flows from the

CFD domain. The boundary conditions for velocity,

density, and species are given by:

Ww P

; Ww = f (Yw )

RTw

(D )w Y

a+

m& w,

g ,a

xw

=

(D )w + u

w w

x w

a

m& w,

w =

Yw, a

uw =

w Aw

These variables are all coupled to one another;

therefore, the solution is iterated. In most cases the

boundary values change slowly from time step to

time step and thus little iteration is required.

Limitations of the Current Implementation of the

HVAC Solver

The current implementation of the HVAC solver has

a number of limitations. These include:

No reactions within the HVAC network (if hot

unburned fuel from one room mixes with air

from another room, it will not burn within the

duct)

No heat transfer from ducts to the FDS

computational domain

No mass storage in the HVAC network (what

flows in also flows out in the same time step and

there is no time delay in the transport of species

through long ducts

Dampers are binary (fully open or fully closed)

All of the limitations above could be addressed by

modifications to the solver.

Solution Scheme

The HVAC solution is updated in both the predictor

and the corrector step of FDS. The sequence is as

follows:

1. FDS updates the density solution.

3.

4.

At each HVAC node coupled to the FDS gas

phase solution, determine the average

temperature, pressure, density, and species.

Execute the HVAC solver.

Use the solution of the HVAC solver to update

the FDS wall boundary conditions.

FDS continues on to its next step (updating the

divergence).

VERIFICATION

Case 1 Verify Flow Losses

In verification Case 1, a ceiling mounted supply duct

is defined with an exit flow of 0.3 m3/s. Two floor

mounted intake ducts, each with an area of 0.1 m2,

are connected via a tee to the exhaust duct. One leg

of the tee (left vent in Fig. 2) is given a flow loss of

16 and the other a flow loss of 4 (right vent in Fig. 2).

Since the two intakes are in the same compartment

and have the same elevation, the pressure drop from

intake to exhaust is the same in both cases. Therefore,

the ratio of the duct velocities is given as the ratio of

the square root of the flow losses, or 2:1. Figure 2

shows the results of this verification case. FDS

predicts average duct velocities of 2.00 m/s and 1.00

m/s vs. the expected values of 2.00 m/s and 1.00 m/s.

The fluctuations in duct velocity are expected and

result from slight changes in the stagnation pressure

at the inlets due to the time dependence of the flow in

the FDS computational domain.

Case 3 Verify Mass Conservation (Non-Uniform

Temperature)

In verification Case 3, two equal compartments are

separated by a vertical wall. One compartment is

initialized to twice the absolute temperature as the

other compartment. Two ducts of equal area, one at

the top and one at the bottom, connect the two

compartments. The bottom duct is given a specified

volume flow of 0.1 m3/s from the hot compartment to

the cold compartment. Similar to Case 2, we expect

at the onset to see the hot compartment temperature

in the outflow to the cold compartment and the cold

compartment temperature in the outflow to the hot

compartment until the outflow streams mix into the

inlet flow. Figure 4 shows the results of the

simulation where it is seen the behavior is as

expected, that mass is conserved (< 0.01% mass

error), and that equal velocities (and hence volume

flow) are seen at steady state. The initial fluctuations

in mass (< 0.05% of the total mass) result from

numerical errors primarily due to the coarse grid used

in the gas phase portion of the computation.

Duct Velocity (m/s)

2.5

2.0

1.5

1.0

0.5

0

10

Time (s)

Figure 2: Results of verification Case 1.

1.3

1.1

Mass (kg)

Case 2 Verify Species Conservation

In verification Case 2, a sealed compartment is

initialized with another species in the bottom half of

the compartment. This species is given the same

molecular weight as air. Two ducts are specified with

the same volume flow rate. One duct takes suction

from the upper half of the compartment and

discharges to the lower, and the other duct does the

reverse. It is expected that for a brief period of time

at the beginning of the simulation that the two

outflow vents will show pure background species and

pure other species until such time that the outflow

plume reaches the intake. Figure 3 shows the results

of this verification test. The image on the left is the

species mass fraction at the beginning of the

simulation and it shows (as expected) pure

background species in the lower outflow and pure

other species in the upper outflow. The middle image

shows a short time later, when the outflow reaches its

opposite intake. As expected, the outflow streams are

now a mix of the two species. Plot on the right

shows, as expected, that the total mass and the other

species mass which does not change over time.

0.9

Total

Species 1

0.7

0.5

0

10

Time (s)

Figure 3: Results of verification Case 2.

Dust

Collector

Fan

Figure 5: ASHRAE Problem #7 HVAC layout.

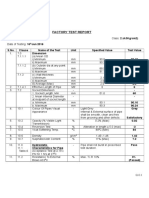

Table 1:

Figure 4: Results of verification Case 3.

VALIDATION

This section presents the results from two validation

cases. One is a simple duct network solution from a

handbook and the other is a complexly

compartmented fire test facility.

Validation Case 1

The first validation case is example Problem #7 from

the ASHRAE Fundamentals handbook (ASHRAE,

2007). This problem was designed to demonstrate

how to perform a hand calculation to size a duct

system to achieve desired flow rates. The HVAC

system is depicted in Fig. 5, and it represents a metal

working exhaust system where three pieces of

equipment are exhausted through a cyclone dust

collector. The numbered boxes indicate duct

segments. Duct lengths, areas, and flow losses were

specified in the example problem description. A

quadratic fan curve was created that included the

pressure vs. flow point determined in the ASHRAE

solution. Table 1 compares the FDS predicted

pressure drop over each duct segment with the

pressure drop in the hand calculation. It is noted that

the hand calculation assumes constant density,

whereas the FDS calculation accounts for density

changes that result from the pressure changes along

the duct segments. Therefore, slight differences (on

the order of a couple of Pascals) are expected in

addition to any numerical error resulting from the

HVAC solver.

FDS vs ASHRAE pressure drops

ASHRAE

Error

FDS P

Segment

P

(%)

(Pa)

(Pa)

1

739

731

1.1

2

457

449

1.8

3

283

282

0.4

4

124

124

0.0

5

748

744

0.5

6

33

33

0.0

7

324

321

0.9

Validation Cases 2 and 3 Confined Space

Validation Cases 2 and 3 are fire tests in a confined

space test facility (Floyd, 2005). The test facility

consisted of 23 compartments over 4 levels with

airtight external boundaries. 20 wall and ceiling

openings were present in the facility. The facility

contains three HVAC systems: a supply system

which takes suction from a fan room and discharges

to all compartments, an exhaust system which takes

suction from all compartments and discharges to the

fan room, and a smoke control system which takes

suction from the L4-2 compartment and discharges it

to the outside. The exhaust system had a second

mode of operation where two dampers could be

realigned to allow fresh air to be brought into the fan

room while closing off the exhaust from the

remainder of the facility. The facility is depicted in

Fig. 6. For some tests two sets of four additional

ducts were added. These ducts connected the ceiling

of L2-1 to the floor of L4-1 with four ducts and the

ceiling of L2-2 and the fire room to the floor of L4-2.

The HVAC systems were input based on as-built

drawings and a walk down of the facility with loss

coefficients developed using the ASHRAE

Fundamentals handbook. Fan curves were taken from

the manufacturer supplied data for the fans. Heat

release rates were derived from load cell data for the

weight of the fuel pan. Major sources of experimental

uncertainty are the heat release rate, the soot yield

(yield was estimated based on CO to CO2 ratio), and

Two tests were simulated. The first test simulated

was Test 4-10

10 which had a 1.05 m diesel pool fire, all

the HVAC louvers blanked off (i.e. no

no-HVAC), no

bypass ducts installed, no external closures opened,

and all internal closures opened. The second test

simulated was Test 5-14

14 which had a 0.68 m diesel

pool fire, the bypass ducts installed, the external

closure on Trunk 2 opened, most internal closures

closed

losed (many doors had ventilation grills in their

lower third), and the supply and exhaust were run for

one minute and then shut off and realigned for smoke

control (exhaust bypass to the outside opened and the

smoke control system on).

the manufacturers data on fan performance. Given

those uncertainties, the FDS predictions of duct

velocities are excellent. Similarly the buoyancy

driven flow through the bypass ducts are also well

we

predicted. The largest prediction error is for the

bypass ducts in the fire room and is likely a

combination of errors in the loss specification, errors

in the heat release specification, and overall

predictive errors in FDS.

4-10

100

90

80

70

Visibility (%)

the actual vs. handbook flow losses in the HVAC

system.

60

Exp:L4-2 2.5

50

Exp:L4-2 1.5

Exp:L4-2 0.5

40

FDS:L4-2 2.5

30

FDS:L4-2 1.5

20

FDS:L4-2 0.5

10

0

0

50

100

150

Time (s)

(a)

4-10

100

90

80

Figure 7 shows visibility measurements made in

rooms 1 and 2 on the 4th level. In Test 44-10 with no

HVAC present, FDS performs as expected. The delay

time for smoke transport and the rates of decrease in

visibility are well predictedd (given the uncertainties

in heat release rate, soot yield, and that soot

deposition is not accounted for). In Test 55-14, FDS is

predicting a shorter delay time than seen in the data,

however, the current HVAC implementation does not

account for transport delays which is contributing to

this error. FDS predicts an equivalent overall rate of

decrease in visibility.

Figure 8 shows velocities measured in doorways and

floor openings. Figure 9 shows velocities measured

in the HVAC system. These measurements we

were

made with bi-directional

directional probes. With the exception

of the trunk inflow in Test 5-14,

14, FDS predictions of

door and floor opening velocities match the measured

data. FDS predictions of flows in the mechanical

HVAC systems agree with the measured data. Tim

Time

to spin up and spin down the fans was not modeled in

FDS which accounts for much of the difference in

slope seen at one minute. A portion of the remaining

error can be attributed to differences in the assumed

duct losses (based on value in a handbook) vs

vs. the

actual duct losses and the actual fan performance vs.

60

Exp:L4-1 3.5

50

Exp:L4-1 2.5

Exp:L4-1 1.5

40

FDS:L4-1 3.5

30

FDS:L4-1 2.5

20

FDS:L4-1 1.5

10

0

0

50

100

150

Time (s)

(b)

5-14

100

90

80

70

Visibility (%)

Figure 6: Confined space layout.

Visibility (%)

70

60

Exp:L4-2 2.5

50

Exp:L4-2 1.5

Exp:L4-2 0.5

40

FDS:L4-2 2.5

30

FDS:L4-2 1.5

20

FDS:L4-2 0.5

10

0

0

100

200

300

Time (s)

(c)

400

500

5-14

5-14 HVAC

100

12

90

Visibility (%)

70

60

Exp:L4-1 3.5

50

Exp:L4-1 2.5

Exp:L4-1 1.5

40

FDS:L4-1 3.5

30

FDS:L4-1 2.5

20

Velocity (m/s)

80

Supply

Exhaust

LP

Induction

-4

Supply Fan

Exhaust Fan

-8

FDS:L4-1 1.5

LP Inlet

10

Induction

-12

0

0

100

200

300

400

500

100

Time (s)

400

500

(a)

Test

Test

Test

Test

4-10

4-10

5-14

5-14

5-14 Bypass Ducts

5

Exp:L2-1ab

Velocity (m/s)

(a)

(b)

(c)

(d)

4-10

5

Exp:L2-1cd

Exp:L2-2ab

Exp:Fire ab

FDS:L2-1a

FDS:L2-1b

FDS:L2-1c

FDS:L2-1d

Velocity (m/s)

300

Time (s)

(d)

Figure 7: Level 4 visibility:

compartment L4-2;

compartment L4-1;

compartment L4-2;

compartment L4-1.

FDS:L2-2a

FDS:L2-2b

-1

Exp:L3/4-2B

100

Exp:L3/4-1

2

1

Exp:Fire Door

300

400

500

FDS:Fire a

FDS:Fire b

(b)

FDS:L3/4-2B

200

Time (s)

Exp:L2/3-2

FDS:L3/4-1

FDS:L2/3-2

-1

FDS:Fire Door

-2

0

50

100

150

(a)

5-14

2

1

0

Exp:Trunk2 Out

Exp:L3/4-2B

-1

Exp:L3/4-1

-2

Exp:L2/3-2

FDS:Trunk2 Out

-3

FDS:L3/4-2B

FDS:L3/4-1

-4

FDS:L2/3-2

-5

0

100

200

300

400

Figure 9: Duct velocities for test 5-14 (a) HVAC;

(b) bypass ducts.

CONCLUSIONS

Time (s)

Velocity (m/s)

200

500

Time (s)

(b)

Figure 8: Door and floor opening velocities: (a)

Test 4-10; (b) Test 5-14.

A network HVAC model based on the MELCOR

algorithm has been coupled to FDS. The model

includes fans, dampers, and forward and reverse flow

losses. The model was coupled indirectly to FDS.

The HVAC model uses prior time step gas cell values

as the boundary conditions for the HVAC solver. The

HVAC solution becomes the boundary condition for

the current FDS time step. Since the pressure

solutions are not directly coupled, some error will

exist in the overall solution; however, since pressure

typically changes slowly, this error is not likely to be

large.

Verification of the HVAC model shows that the

model properly accounts for flow losses in the input

specifications. Verification also demonstrates that the

model conserves mass for both isothermal and nonisothermal cases. Lastly the verification demonstrates

that the use of FDS pressure zone data results in the

correct HVAC system behavior.

Validation results were shown for a simple HVAC

system that could be computed as a hand calculation

as well as a complex set of HVAC systems that

change operational state over time in a confined

space, multi-compartment facility with a fire. The

simple system validation shows that the model

correctly predicts pressure drops over a duct network.

The confined space results show that the HVAC

model allows for changes in operational state,

correctly predicts HVAC duct flows for a complex

network, and the coupling with FDS correctly

captures buoyancy effects with the HVAC network.

FUTURE WORK

While the current HVAC implementation adds a

tremendous amount of capability to FDS, there are a

number of areas where additional work is needed:

The HVAC solution is currently separate from

the FDS leakage model which could result in

stability issues in some circumstances. Since the

leakage flow equation is similar to the

momentum equation used in the HVAC model,

the leakage solution should be merged in with

the HVAC solution.

Dampers are currently modeled as 100% open

and 100% closed with instantaneous changes and

similarly with fans. The process of opening and

closing a damper or turning on and off a fan

should include a brief transient period.

There is currently no model for filtration

(although a constant flow loss could be added to

a duct to represent a filter). There are

applications where loading of filters by soot is a

concern and a filter model is desirable.

Enthalpy additions or losses to duct flows are

currently not modeled (e.g. heat transfer to duct

walls or the presence of heat and cooling

equipment).

Expand the suite of verification and validation

test cases.

NOMENCLATURE

A

cp

E

g

h

K

L

M, m

P

R

S

t

Y

u, u

V

W

area (m2)

specific heat (J/kg/K)

energy (J)

gravity (9.80665 m/s2)

enthalpy (J/kg)

loss coefficient (dimensionless)

length (m)

mass (kg)

pressure (Pa)

gas constant (8.314472 J/mol/K)

surface Area (m2)

time (s)

mass fraction (kg/kg)

velocity (m/s)

volume (m3)

molecular weight (kg/mol)

z

elevation (m)

Greek

FDS divergence term

D

computational mesh

density (kg/m3)

subscripts

a

species

g

gas cell

i,k

node

j

duct

m

pressure zone

w

wall cell

superscripts

n

current time-step

n-1

prior time-step

n+

prior iteration

nguess

~

extrapolated value

REFERENCES

American Society of Heating Refrigeration and AirConditioning Engineers, Inc. (2007), ASHRAE

Handbook Fundamentals, ASHRAE, Atlanta,

GA.

Floyd, J., Hunt, S., Williams, F., and Tatem, P.

(2004), Fire and Smoke Simulator (FSSIM)

Version 1 Theory Manual, Naval Research

Laboratory

NRL/MR/6180-04-8765,

Washington, DC.

Floyd, J., Hunt, S., Williams, F., and Tatem, P.,

(2005) A Network Fire Model for the

Simulation of Fire Growth and Smoke Spread in

Multiple

Compartments

with

Complex

Ventilation, Journal of Fire Protection

Engineering,

15(3),199-229,

http://dx.doi.org/10.1177/1042391505051358.

Gauntt, R. Cole, R., Erickson, R., Gido, R., Gasser,

R., Rodriquez, S., Young, M., Ashbaugh, S.,

Leonard, M., Hill, A. (2000), MELCOR

Computer Code Manuals: Reference Manuals

Version 1.8.5, Volume 2, Rev. 2, US Nuclear

Regulatory Commission NUREG/CR-6119.

Washington, DC.

Jones, W., Peacock, R., Forney, G. and Reneke, P.

(2009), CFAST Consolidated Model of Fire

Growth and Smoke Transport (Version 6)

Technical Reference Guide, National Institute of

Standards and Technology NIST SP-1026,

Gaithersburg, MD.

McGrattan, K., Hostikka, S., Floyd, J., Baum, H.,

Rehm, R., Mell, W., and McDermott, R. (2010),

Fire Dynamics Simulator (Version 5) Technical

Reference Guide, Volume 1: Mathematical

Model, National Institute of Standards and

Technology NIST SP-1018-5. Gaithersburg,

MD.

Schaelin, A. and Dorer, V., (1993) Improvement of

Multizone Model Predictions by Detailed Flow

Path Values from CFD Calculation, ASHRAE

Transactions, 105(2), 414-427.

Walton, G. and Dols, W. (2008), CONTAM 2.4

Users Guide and Program Documentation,

National Institute of Standards and Technology

NISTIR 7251, Gaithersburg, MD.

Wang, L., and Chen, Q.,(2007) Theoretical and

Numerical Studies of Coupling Multizone and

CFD Models for Building Air Distribution

Simulations, Indoor Air, 17, 348-361,

http://dx.doi.org/10.1111/j.16000668.2007.00481.x.

Zhai, Z., Gao, Y. and Chen, Q. (2004), Pressure

Boundary Conditions in Multi-Zone and CFD

Program

Coupling,

SimBuild

2004,

International Building Performance Simulation

Association, Texas.

You might also like

- Wrap Thesis Jouvray 2003Document247 pagesWrap Thesis Jouvray 2003Jacob ChezzNo ratings yet

- Air Pressure and The Building EnvelopeDocument19 pagesAir Pressure and The Building EnvelopejackleesjNo ratings yet

- 5-TB - Ventilation Air For Indoor PoolsDocument4 pages5-TB - Ventilation Air For Indoor Poolsakhlaq_hssainkotaNo ratings yet

- Expansion Tank SizingDocument2 pagesExpansion Tank SizingSK NGNo ratings yet

- Study and Practice On Hvac System Commissioning: A40-A2.D2-M5-J-NESTEC-1Document18 pagesStudy and Practice On Hvac System Commissioning: A40-A2.D2-M5-J-NESTEC-1Swaraj Rajan100% (1)

- High-Performance VAV Systems PDFDocument11 pagesHigh-Performance VAV Systems PDFTonyChuangNo ratings yet

- Drona ParvaDocument16 pagesDrona ParvaArun MaliNo ratings yet

- 28880miller SpreadDocument7 pages28880miller SpreadJacob ChezzNo ratings yet

- 07 ABelhocine PDFDocument7 pages07 ABelhocine PDFShaheen S. RatnaniNo ratings yet

- 2000 5Document22 pages2000 5Jacob ChezzNo ratings yet

- The Impact of Ventilation On Air Quality in Indoor Ice Skating ArenasDocument6 pagesThe Impact of Ventilation On Air Quality in Indoor Ice Skating ArenasJacob ChezzNo ratings yet

- Essential HVAC Calculations Spreadsheet for Load Estimation, Psychrometrics, Duct DesignDocument52 pagesEssential HVAC Calculations Spreadsheet for Load Estimation, Psychrometrics, Duct DesignSyed ShahbazNo ratings yet

- Drawing1 ModelDocument1 pageDrawing1 ModelJacob ChezzNo ratings yet

- Drawing1 ModelDocument1 pageDrawing1 ModelJacob ChezzNo ratings yet

- $MP 008 01Document10 pages$MP 008 01Jacob ChezzNo ratings yet

- Inspection and Welding Repairs of Pressure VesselsDocument9 pagesInspection and Welding Repairs of Pressure VesselsClaudia Mms100% (1)

- Drawing1 ModelDocument1 pageDrawing1 ModelJacob ChezzNo ratings yet

- Drawing1 ModelDocument1 pageDrawing1 ModelJacob ChezzNo ratings yet

- Heat Ex Changers Operation and MaintenanceDocument27 pagesHeat Ex Changers Operation and Maintenancegladiatork00750% (2)

- Drawing1 ModelDocument1 pageDrawing1 ModelJacob ChezzNo ratings yet

- Drawing1 ModelDocument1 pageDrawing1 ModelJacob ChezzNo ratings yet

- Drawing1 ModelDocument1 pageDrawing1 ModelJacob ChezzNo ratings yet

- Brake Operation and Load Limits for Flameproof MotorsDocument2 pagesBrake Operation and Load Limits for Flameproof MotorsRkantvyas100% (1)

- Cooling Load CalcsDocument79 pagesCooling Load CalcsBharath B Nayak100% (1)

- L 105 4Document17 pagesL 105 4Jacob ChezzNo ratings yet

- Manual On Boiler Tube FailureDocument69 pagesManual On Boiler Tube Failureyogeshmangal1974100% (2)

- GRE-Indispensable G R E GuideDocument152 pagesGRE-Indispensable G R E Guideapi-3701836No ratings yet

- Manual On Boiler Tube FailureDocument69 pagesManual On Boiler Tube Failureyogeshmangal1974100% (2)

- Boilers Mountings 1Document3 pagesBoilers Mountings 1Jacob ChezzNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SyllabusDocument2 pagesSyllabusDev RanaNo ratings yet

- Cooler Condenser Design for Vapor-Gas MixturesDocument1 pageCooler Condenser Design for Vapor-Gas MixturesNind's Chef0% (1)

- Checklist TextiletestingDocument2 pagesChecklist TextiletestingVinay GuptaNo ratings yet

- Prosthodontics 2007-08Document57 pagesProsthodontics 2007-08Nisha Madan100% (2)

- Fujikura 12S CDocument2 pagesFujikura 12S CCristian BolañosNo ratings yet

- Pengaruh Rentang Suhu Distilasi Fraksinasi Terhadap Kadar Patchouli Alcohol (PA) Pada Minyak NilamDocument7 pagesPengaruh Rentang Suhu Distilasi Fraksinasi Terhadap Kadar Patchouli Alcohol (PA) Pada Minyak NilamBagusSatriyaNo ratings yet

- FTRDocument1 pageFTRanon_127491670No ratings yet

- Hot Forming IntroductionDocument19 pagesHot Forming IntroductionElaine JohnsonNo ratings yet

- Tratamientos de FlotacionDocument35 pagesTratamientos de FlotacionGiroshi Roberth Reyes VillarNo ratings yet

- C C CCCCCCCCCCCC C CDocument62 pagesC C CCCCCCCCCCCC C CGaurav VashishtNo ratings yet

- Checklight's AquaVerity Early Warning Water Contamination DetectionDocument16 pagesChecklight's AquaVerity Early Warning Water Contamination DetectionTomer MalchiNo ratings yet

- Specific HeatDocument2 pagesSpecific HeatVanessa Christonette SistosoNo ratings yet

- Ion ExchangeDocument25 pagesIon ExchangeArie Ikhwan SaputraNo ratings yet

- Karkim Kar Ben enDocument1 pageKarkim Kar Ben enIqbal batchaNo ratings yet

- Pressure Relief ValvesDocument6 pagesPressure Relief ValvesShashank Sudhakar PathakNo ratings yet

- Chapter 15 Acid Base Equilibrium and BuffersDocument9 pagesChapter 15 Acid Base Equilibrium and Buffersmememe123123No ratings yet

- Culinary Biophysics On The Nature of The 6X°C Egg 2011Document8 pagesCulinary Biophysics On The Nature of The 6X°C Egg 2011Kenesei GyörgyNo ratings yet

- MCAT 2015 - MiniTest - Ebook PDFDocument36 pagesMCAT 2015 - MiniTest - Ebook PDFamelinaNo ratings yet

- AMIE Material Science Engineering Notes PDFDocument59 pagesAMIE Material Science Engineering Notes PDFSrimannarayana Nandam100% (4)

- Fibre Optics GuideDocument34 pagesFibre Optics GuideMuthu EzhilanNo ratings yet

- Safe Flare System Design: John Zink CompanyDocument10 pagesSafe Flare System Design: John Zink CompanyAniket S Jadhav100% (3)

- Introduction To Heat ExchangerDocument19 pagesIntroduction To Heat Exchangerboy fachriNo ratings yet

- A Comparison of The Environmental Impacts of Different Categories of Insulation MaterialsDocument9 pagesA Comparison of The Environmental Impacts of Different Categories of Insulation Materialsminsara madtNo ratings yet

- Is 4031 Part 4 - ConsistencyDocument4 pagesIs 4031 Part 4 - ConsistencyCrypto AbhishekNo ratings yet

- Revision Test 1-KPT and Separation TechniquesDocument18 pagesRevision Test 1-KPT and Separation TechniquesFangru CaoNo ratings yet

- x40602 - Concrete Technology PDFDocument12 pagesx40602 - Concrete Technology PDFJay PatelNo ratings yet

- Tolerances of A Polystyrene Film: 2.2.25. ABSORPTION Spectrophotometry, Ultraviolet and VisibleDocument3 pagesTolerances of A Polystyrene Film: 2.2.25. ABSORPTION Spectrophotometry, Ultraviolet and Visibleivan cuadradoNo ratings yet

- Unsymmetrical Bending: DR Alessandro PalmeriDocument40 pagesUnsymmetrical Bending: DR Alessandro PalmeriPrivat ZouobaNo ratings yet

- FCCU Reliability and Mechanical IntegrityDocument5 pagesFCCU Reliability and Mechanical IntegrityLyunlyunNo ratings yet

- 3 D Printing Material Information SheetDocument2 pages3 D Printing Material Information SheetNirav DesaiNo ratings yet