Professional Documents

Culture Documents

TSB 46 2005

Uploaded by

OliverCalderbankOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TSB 46 2005

Uploaded by

OliverCalderbankCopyright:

Available Formats

FordEtis - TECHNICAL SERVICE BULLETIN 46/2005

http://127.0.0.1:8888/tsb/tsbView.do?regionalNumberYear=2005&print...

TECHNICAL SERVICE BULLETIN

Circulate to:

No.46/2005

24 June 2005

Service Manager Body Shop Manager Parts Manager Foremen Receptionists Technicians

Ford Motor Company

All rights reserved.

This bulletin represents technical service information only. Without exception all gratis repairs and

replacements are subject to the individual warranty and policy procedures of the supervisory Ford

Company. The illustrations, technical information, data and descriptive text in this issue, to the

best of our knowledge, were correct at the time of publication.

Subject/Concern:

Model:

Markets:

Section:

Summary

List of common concerns on the Delphi HPCR system

All

All

303-14

This bulletin covers a list of the common concerns on the Delphi HPCR system and fault analysis.

Please take the time to read through and understand this bulletin. An understanding of the

complex nature and special features of the Delphi Common Rail systems is an essential

prerequisite for performing effective diagnosis and repairs. For additional information, refer to TSB

124/2003.

Common concerns on the Delphi Common Rail System and fault analysis

The customers' concerns often relate to the same fault symptoms (engine stalls, engine will not

start, rough running/idling etc.). For this reason it is extremely important to start by reading out

the diagnostic trouble codes (DTC's) with the aid of WDS and to then use this information to

diagnose the actual cause of the concern. Never use the description of the problem or trouble

symptoms alone to determine the possible cause.

P0251 (Fuel metering valve (IMV) control error)

Symptoms:

Extremely poor engine performance - glow plug warning lamp flashes.

Engine cuts out - glow plug warning lamp flashes.

Engine will not start.

Cause:

The fuel rail pressure demanded by the system cannot be achieved without the IMV

opening beyond the tolerance specified for that pressure.

NOTE: The fault descriptions listed below should be worked through in order.

1. Restriction in the low-pressure fuel system, which could be caused by a blockage of a fuel line or

the fuel filter, or a damaged fuel line. For additional information, refer to Workshop Manual

Section 303-04, Diagnosis and Testing for a blocked filter.

2. Air in the low-pressure system: Check using transparent hoses (see TSB 107/2003) or remote

feed the fuel injection pump with a filtered proprietary fuel supply to eliminate the vehicle

low-pressure fuel system entirely. Leaking fuel lines or connections can cause air in fuel.

NOTE: When using transparent hoses a small amount of air in the fuel system is normal due to

a permanent bleed hole in the fuel filter. Recirculation of fuel will occur through the fuel filter

until the temperature of the return fuel is over 40C (hence any air in the system will

re-circulate until the fuel is above 40C and is being returned to the fuel tank).

3. Faulty fuel injection pump, transfer pump part, or pressure control valve. Fuel injection pump

internal transfer pressure needs to be at least 6 bar to achieve high pressure chamber filling (to

generate the required fuel rail pressure). Check the following (if the engine does not start):

Remote feed the fuel injection pump with a filtered, proprietary fuel supply. If the engine will

start when the fuel supply is pressurized or held above the fuel injection pump intake (gravity

1 of 6

14.03.2010 00:18

FordEtis - TECHNICAL SERVICE BULLETIN 46/2005

http://127.0.0.1:8888/tsb/tsbView.do?regionalNumberYear=2005&print...

fed), but will not start when the fuel supply is not pressurized or held below the fuel injection

pump intake then it is likely that there is a fault with the internal transfer pump (i.e. not able to

draw fuel).

4. Faulty fuel injection pump - high-pressure part or inlet metering valve (IMV):

Carry out a guided fuel pressure test diagnosis with the aid of WDS (symptom "No engine start"

or "Poor driveability").

CAUTION: Do not crank the engine for more than 5 seconds. The fuel injection pump

will be damaged with long or repeated cranking and no transfer pressure.

Check the fuel pressure (with the ignition ON, engine OFF) (it should fluctuate between 4 and 10

bar maximum). If a default fuel pressure of 2000 bar is displayed then there is an electrical fault

on the fuel pressure sensor (connector, wiring etc.).

Check the fuel pressure at the moment the engine starts (target value = 300 bar 50 bar).

Check the fuel pressure at idling (target value = 250 bar 40 bar).

5. Injectors:

Perform a return quantity test using the WDS guided diagnostic. This test uses special tool

310-129 (see TSB 106/2003). If high return quantities are experienced, check a sample of fuel

from the FIP return for black metallic swarf . Go to the next step.

6. Swarf in the system:

Despite improved materials it is possible there may be swarf in the system, without the fuel

injection pump being defective. A sample of fuel should be collected from the fuel injection pump

return line. If this sample contains over 5mm diameter of black metallic swarf please refer to TSB

42/2003 for appropriate action. First run through all of the other system checks (as described

above).

P1211 (Fuel pressure higher/lower than requested)

Symptoms:

Malfunction indicator lamp (MIL) light on. Engine shut down.

Cause:

Always occurs in conjunction with P0251 (follow on fault). If P0251 is present for a

pre-determined number of engine cycles then P1211 is set and the engine is shut

down.

P2291 (Pressure lower than expected)

Symptoms:

This often arises in conjunction with P0251 and other trouble codes, but may also

appear by itself.

Poor engine performance (glow plug warning lamp flashes).

Engine cuts out (glow plug warning lamp flashes).

Engine will not start.

Causes:

Fuel metering valve stuck. Use IMV cycle test if available on this vehicle.

Fuel supply (see P0251 in this bulletin).

Fuel injection pump defective (see P0251 in this bulletin).

P2288 (Pressure higher than expected)

Symptoms:

2 of 6

14.03.2010 00:18

FordEtis - TECHNICAL SERVICE BULLETIN 46/2005

http://127.0.0.1:8888/tsb/tsbView.do?regionalNumberYear=2005&print...

This trouble code often occurs in conjunction with other trouble codes.

Engine frequently undershoots to a stop.

Engine will not start up.

Causes:

Loose contacts (corrosion) on the wiring harness connector of the fuel metering

valve, or the connector is not pushed together properly. Check wiring harness

connector to ensure it is connected correctly and that the pins are not corroded. Use

IMV cycle test (located in WDS toolbox) if available on this vehicle.

Fault with IMV wiring harness. Use wiring pinpoint checks available on WDS.

Fuel metering valve stuck. Use IMV cycle test if available on this vehicle.

Loose contact on the fuel pressure sensor wiring harness connector (see

TSB37/2003). This tends to happen more rarely.

If DTC P0191 is also set, check RPM signal is present during cranking. If not check

crank sensor.

P0200 (Shared injector actuation malfunction)

Symptoms:

Engine cuts out while driving - glow plug warning lamp flashes.

Engine judders (similar experience to misfiring) - glow plug warning lamp flashes.

Cause:

Usually faults in the ground supply or the voltage supply to the injectors.

1. Check all ground connections.

2. Often the cause is the ground connection underneath the battery (corroded attachment) (for

Mondeo 2001 (10/2001-) see TSB 44/2002).

P0201 / P0202 / P0203 / P0204 (Individual injector actuation malfunction)

Symptoms:

DTC set.

Cause:

Short circuit/open circuit on the wiring harness of the injector.

Loose contact in the wiring harness connector of the injector.

Faulty injector (interruption in the coil of the solenoid valve).

Leaking wiring harness connector (diesel or water in the connector).

1. Clear fault codes and test vehicle. If fault codes return continue with the following checks.

2. Check all injector electrical connections are properly attached.

3. Carry out WDS pinpoint checks for wiring harness continuity.

P1664 (dual-module system - injector drive module (IDM) malfunction; single-module

system - powertrain control module (PCM) malfunction)

NOTE: Ignore this trouble code if it occurs in conjunction with other trouble codes. Diagnose

the other fault codes first.

P1664 and P0251 - Ignore P1664 initially. See description of P0251 in this bulletin.

P1664 and P0180 - Ignore P1664 initially. See description of P0180 in this bulletin.

P1664 and P0191 - Ignore P1664 initially. Trouble code may have been provoked by the

3 of 6

14.03.2010 00:18

FordEtis - TECHNICAL SERVICE BULLETIN 46/2005

http://127.0.0.1:8888/tsb/tsbView.do?regionalNumberYear=2005&print...

customer, e.g. the engine was re-started too soon after engine undershooting to a stop. In this

case there would not have been enough time to dissipate the pressure quickly enough, and P0191

would have been set. Ignore initially and delete them both.

Symptoms:

P1664 and P0191 re-appear after deleting.

Long startup times.

Repeated startup attempts because the engine will not start.

Engine finally starts after several attempts and after the ignition has been OFF for a

longer period of time.

Cause:

Powertrain control module (PCM)/injector drive module (IDM) malfunction.

1. First delete the fault memory.

2. Follow the service instructions in accordance with TSB 44/2002 (ground supply / voltage

supply).

3. If P1664 is set again, initially install a new supply relay for the IDM (dual-module)/ PCM (singlemodule) and delete the fault memory.

4. If P1664 is set again, install a new IDM/PCM.

P1664 and P1665 - P1665 only occurs in addition to other trouble codes. Ignore initially and

delete them.

Symptoms:

P1664 and P1665 are still present after deleting them both.

Cause:

A problem in the ground supply (Often between the battery and the body). Check all

ground connections.

IDM/PCM power supply and ground connection.

CAN connection to the PCM.

On Mondeo 2001 (10/2000-) vehicles with the dual-module system it is possible that

the wiring harness may have been damaged in the area of the pollen filter after

installing a new windshield.

P0180 (Fuel temperature sensor circuit)

Symptoms:

P0180 usually occurs in conjunction with several other trouble codes (particularly

P1664). Initially ignore any other trouble codes.

Engine cuts out.

Rough running engine.

Irregular idling.

Glow plug warning lamp usually flashes.

Cause:

Loose contact on the wiring harness connector of the fuel temperature sensor.

Fuel temperature sensor defective.

1. Read off the value of the fuel temperature sensor using the WDS data logger when the engine is

4 of 6

14.03.2010 00:18

FordEtis - TECHNICAL SERVICE BULLETIN 46/2005

http://127.0.0.1:8888/tsb/tsbView.do?regionalNumberYear=2005&print...

switched off. The value must be realistic (e.g. it must not show -20 C when the ambient

temperature is +18 C).

2. If the displayed value is realistic, carefully move the sensor connection - if the value jumps to

+39 C (substitute value), then the problem lies with the connector.

3. If the displayed value is not realistic, carefully tap the sensor or perform a road test. If large

temperature jumps are observed (e.g. +150/-230 C or -110/+200 C), then usually the fuel

temperature sensor is defective (see TSB 38/2003).

P0191 (Fuel pressure sensor malfunction) - non-electrical fault

Symptoms:

Engine will not start - glow plug warning lamp flashes.

Cause:

In most cases this is a software fault. In the process, the system recognizes a fuel

pressure which is implausible for the given conditions.

1. Turn the ignition key to ignition ON. At this moment, using WDS data logger, the fuel pressure

should be below 90 bar.

2. If the fuel pressure is higher than 90 bar then this is a fault, as the pressure is dissipated after

the ignition is switched off.

3. Upload the latest PCM calibration using WDS.

P0190 (Fuel pressure sensor malfunction) - electrical fault

Symptoms:

Engine cuts out while driving.

Engine will not start.

Cause:

Wiring harness connector of the fuel pressure sensor.

1. Read off the fuel pressure with the ignition ON and the engine OFF using the WDS data logger.

2. If a default value of 2000 bar is displayed, repair the wiring harness connector. For additional

information, refer to TSB 37/2003.

P0340 (Camshaft position (CMP) sensor)

The following possible concern may occur without a trouble code necessarily being set in the

system.

Symptoms:

Engine will not start.

Engine cuts out while driving.

Severe misfiring. If this occurs while idling then the engine may stop as a result.

Cause:

Wiring harness to the CMP sensor (short circuit, open loop control).

Loose contact in the wiring harness connector.

CMP sensor defective.

PCM fault (single-module vehicles) or IDM fault (dual-module vehicles) - exclude all

other possibilities first.

1. An oscilloscope can be used to check that the CMP signal is present on start up.

2. Check the voltage supply to the CMP sensor (refer to the description below). For additional

5 of 6

14.03.2010 00:18

FordEtis - TECHNICAL SERVICE BULLETIN 46/2005

http://127.0.0.1:8888/tsb/tsbView.do?regionalNumberYear=2005&print...

information, refer to TSB 69/2003.

P0325 (Knock sensor fault)

It is extremely rare that the knock sensor itself is the problem, as this component is very reliable.

This may also occur without a trouble code being set.

Symptoms:

Extreme combustion noise (knocking).

Cause:

Knock sensor wiring harness.

IDM/PCM connector.

P0335 (Invalid crankshaft position (CKP) signal)

NOTE: This trouble code is set when no concordance is detected between the CKP signal and

the CMP signal.

Symptoms:

Engine cuts out while driving.

Engine will not start.

Cause:

The CKP sensor wheel is damaged or loose on the flywheel.

The CMP signal is not in order - no synchronization taking place.

The CKP sensor and/or the CKP sensor bracket are loose.

The CKP gap is incorrect.

The CKP gap was set incorrectly and has damaged the sensor.

1. Check the CKP sensor wheel to make sure it is securely attached, has no bent/damaged teeth

and there is no corrosion on the teeth.

2. Use WDS Datalogger to check the CKP signal, look for two clearly defined triggering teeth

responses within a 720 captured event .

3. Use an oscilloscope to check whether the CMP signal is present when the engine is started. If it

is not present, refer to the description for P0340 in this bulletin.

6 of 6

14.03.2010 00:18

You might also like

- TSB Ford Transit 2006.5Document5 pagesTSB Ford Transit 2006.5torrencial75% (4)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 2.5 out of 5 stars2.5/5 (2)

- VW Jetta CodesDocument4 pagesVW Jetta CodesJeremy DubsNo ratings yet

- Epic Service ManualDocument43 pagesEpic Service Manualdiego742000No ratings yet

- Ford Focus Wiring DiagramDocument1,203 pagesFord Focus Wiring Diagram0128 Nguyễn Thanh BìnhNo ratings yet

- Abrites Diagnostics For Ford Mazda User ManualDocument55 pagesAbrites Diagnostics For Ford Mazda User ManualJame Eduardo100% (2)

- DQ200issue en PDFDocument7 pagesDQ200issue en PDFIdris TalibNo ratings yet

- 2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramDocument7 pages2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramcarlosNo ratings yet

- Pajero 4WD Flashing Light Fix and TroubleshootingDocument13 pagesPajero 4WD Flashing Light Fix and TroubleshootingAren MendozaNo ratings yet

- Diagnosis Fuel SystemDocument16 pagesDiagnosis Fuel SystemCristhian HuilcapazNo ratings yet

- A4 B8 Stereo RemovalDocument7 pagesA4 B8 Stereo RemovalMickyman123No ratings yet

- AUTOMATICDocument15 pagesAUTOMATICmacciastarNo ratings yet

- Service Manual TDI Injection and Glow Plug System (8-Cyl Common Rail AKF)Document135 pagesService Manual TDI Injection and Glow Plug System (8-Cyl Common Rail AKF)toms4100% (3)

- ST810 - Advanced Diesel Technology Workbook PDFDocument119 pagesST810 - Advanced Diesel Technology Workbook PDFVASEKNo ratings yet

- Transit 2002 PDFDocument2,797 pagesTransit 2002 PDFCostel GogleazaNo ratings yet

- 02b - E70 Gasoline EnginesDocument27 pages02b - E70 Gasoline EnginesLeonard 'Leo' NgNo ratings yet

- GA8HP Unlock 3Document2 pagesGA8HP Unlock 3julio montenegro100% (1)

- Manual Transmission 5 SpeedDocument12 pagesManual Transmission 5 Speedav1135100% (1)

- Westfalia Wiring For AudiDocument38 pagesWestfalia Wiring For AudiThomas Egbert0% (2)

- Audi A4 B8 Trim Removal GuideDocument25 pagesAudi A4 B8 Trim Removal GuideIONITA CRISTIANNo ratings yet

- VDO-Siemens Common Rail - 2009Document24 pagesVDO-Siemens Common Rail - 2009Hannu Jaaskelainen80% (5)

- SSP - 351 Common Rail Fuel Injection System Fitted in The 3.0l V6 TDI Engine PDFDocument56 pagesSSP - 351 Common Rail Fuel Injection System Fitted in The 3.0l V6 TDI Engine PDFJonathan JoelNo ratings yet

- Motor 2.0 Diesel Journey 2009Document177 pagesMotor 2.0 Diesel Journey 2009Injeletro Diesel100% (1)

- PD InjectorDocument5 pagesPD InjectorTomas NoneeNo ratings yet

- TSB 18-020-10 PCM Software Sensor & DTC ImprovementsDocument7 pagesTSB 18-020-10 PCM Software Sensor & DTC ImprovementsJose ivan delgado Ugalde100% (1)

- Manual Transmàssion 6 Speed PDFDocument55 pagesManual Transmàssion 6 Speed PDFIvan Alex Escobar100% (1)

- BMW 3 (E90) (2008) : IssuesDocument4 pagesBMW 3 (E90) (2008) : Issuesachmade zakryNo ratings yet

- Interject Harry Tech Book EFISpares TipsDocument10 pagesInterject Harry Tech Book EFISpares Tipsgolden68No ratings yet

- 00 Engine, GeneralDocument205 pages00 Engine, GeneralDiego Paramo100% (1)

- SrsDocument25 pagesSrsChristian Ramos CamposNo ratings yet

- BMW E61 Tailgate Wiring Repair PDFDocument35 pagesBMW E61 Tailgate Wiring Repair PDFImre MartonNo ratings yet

- TRANSIT 2015 Engine Compartment Fuse Box PDFDocument3 pagesTRANSIT 2015 Engine Compartment Fuse Box PDFtadeuNo ratings yet

- Continuously Variable Valve TimingDocument12 pagesContinuously Variable Valve TiminggamerpipeNo ratings yet

- Ford Focus Workshop ManualDocument3,124 pagesFord Focus Workshop Manual0128 Nguyễn Thanh BìnhNo ratings yet

- Instrument Cluster Repair PDFDocument3 pagesInstrument Cluster Repair PDFROYAL100% (1)

- BMW DTC CodesDocument14 pagesBMW DTC CodesLaimis Karnyzas100% (1)

- Bosch VP44 Info & InstallationDocument4 pagesBosch VP44 Info & InstallationbenjiNo ratings yet

- BMW Automatic Trans ServiceDocument31 pagesBMW Automatic Trans ServiceJone Khang83% (6)

- Focom Pats Info en PDFDocument8 pagesFocom Pats Info en PDFCraig Waters100% (1)

- Fuel SystemDocument98 pagesFuel SystemLei Yii Villanes100% (1)

- CX-5 Textbook 4A 2012 PDFDocument237 pagesCX-5 Textbook 4A 2012 PDFDo Kiet100% (3)

- BMW E36 Cruise Control Upgrade - DIY - v.2Document16 pagesBMW E36 Cruise Control Upgrade - DIY - v.2dvggaNo ratings yet

- Embrague CitroenDocument9 pagesEmbrague CitroenJoseNo ratings yet

- SSP - 296 - d1 VW 1.4 FSI EngineDocument40 pagesSSP - 296 - d1 VW 1.4 FSI EngineGavriloae Ion75% (4)

- Technical Service Bulletin: No.46/2005 24 June 2005Document6 pagesTechnical Service Bulletin: No.46/2005 24 June 2005Nick DelafontaineNo ratings yet

- Engine Misfire, Runs Rough or Is UnstableDocument4 pagesEngine Misfire, Runs Rough or Is UnstableAdolfo Dario Saavedra0% (1)

- Acceleration Is Poor or Throttle Response Is PoorDocument6 pagesAcceleration Is Poor or Throttle Response Is Poorfalah100% (2)

- Engine Misfires, Runs Rough or Is Unstable CAT 320DDocument4 pagesEngine Misfires, Runs Rough or Is Unstable CAT 320DfalahNo ratings yet

- 3412 Fuel Pump Testing and AdjustingDocument127 pages3412 Fuel Pump Testing and Adjustingharikrishnanpd332794% (16)

- Acceleration Is Poor or Throttle Response Is PoorDocument5 pagesAcceleration Is Poor or Throttle Response Is PoorNay SoeNo ratings yet

- Land Rover Fuel Pump TestDocument3 pagesLand Rover Fuel Pump Testgaryservicerepair2013No ratings yet

- Engine Misfires, Runs Rough or Is Unstable: TroubleshootingDocument4 pagesEngine Misfires, Runs Rough or Is Unstable: Troubleshootingnay hlaing SoeNo ratings yet

- Power Is Intermittently Low or Power Cutout Is Intermittent 320DDocument4 pagesPower Is Intermittently Low or Power Cutout Is Intermittent 320DfalahNo ratings yet

- 3126 Truck Engine 7LZ00001-UP (SEBP2797 - 14) - DocumentationDocument95 pages3126 Truck Engine 7LZ00001-UP (SEBP2797 - 14) - DocumentationJorge ShashteNo ratings yet

- Chinh Kim CoDocument67 pagesChinh Kim ColeminhNo ratings yet

- Nota VWDocument5 pagesNota VWGabrielNo ratings yet

- Pinpoint Test P: Misfire/Injector Driver Circuit Operation: Output FunctionsDocument7 pagesPinpoint Test P: Misfire/Injector Driver Circuit Operation: Output FunctionsReyes FunesNo ratings yet

- Engine Misfires, Runs Rough or Is UnstableDocument4 pagesEngine Misfires, Runs Rough or Is UnstableFaresNo ratings yet

- 3306 Industrial Engine - Troubleshooting - Testing and AdjustingDocument93 pages3306 Industrial Engine - Troubleshooting - Testing and AdjustingJordy Zavaleta100% (7)

- tr2116 Iss.5.engine Power Complains Check 7 8700 5700SL 6700S Global See Tr0707iss9Document26 pagestr2116 Iss.5.engine Power Complains Check 7 8700 5700SL 6700S Global See Tr0707iss9Márton ŐriNo ratings yet

- Journal of Biosafety and Biosecurity: Research ArticleDocument4 pagesJournal of Biosafety and Biosecurity: Research ArticleDenise DeniseNo ratings yet

- PCRS Version 1.0Document182 pagesPCRS Version 1.0Hind DiraniNo ratings yet

- ControlLogix RedundancyDocument192 pagesControlLogix Redundancyl1f3b00kNo ratings yet

- WK315Document7 pagesWK315Suneela KhandavalliNo ratings yet

- Fuse LinkDocument28 pagesFuse LinkSunil JoshiNo ratings yet

- 30-99-90-1651 Foc ConduitDocument17 pages30-99-90-1651 Foc ConduitEswar ReddyNo ratings yet

- 005 - Fuel+SystemDocument92 pages005 - Fuel+Systemeduan laraNo ratings yet

- Iso 21148 2017 en PDFDocument11 pagesIso 21148 2017 en PDFRui SantosNo ratings yet

- COS10011 CWA Unit Outline-S2Document7 pagesCOS10011 CWA Unit Outline-S2Abner ogegaNo ratings yet

- Rhino Motion Controls: RMCS-1102 v2.0 Micro-Stepping Motor Driver With ENABLE (Max. 50Vdc and 5A Per Phase)Document11 pagesRhino Motion Controls: RMCS-1102 v2.0 Micro-Stepping Motor Driver With ENABLE (Max. 50Vdc and 5A Per Phase)sanjeev kumarNo ratings yet

- Quick Start Guide Xerox 7142Document32 pagesQuick Start Guide Xerox 7142Sidnei Oliveira0% (1)

- Catalago Pçs 8000 - 2009 - ImportadoDocument123 pagesCatalago Pçs 8000 - 2009 - Importadorichard100% (1)

- A ViatorDocument37 pagesA ViatorMontse Gazquez FernandezNo ratings yet

- Feasibilty Study For Grading SystemDocument5 pagesFeasibilty Study For Grading Systemanmolkainth100% (1)

- Idnet Communicating Devices Model A4090-9002 Relay Iam Features Product SelectionDocument2 pagesIdnet Communicating Devices Model A4090-9002 Relay Iam Features Product SelectionmuralyyNo ratings yet

- Image React NativeDocument13 pagesImage React NativeHéctorGarcíaGarcíaNo ratings yet

- Cisco Aironet1200 DatasheetDocument8 pagesCisco Aironet1200 DatasheetAbdirisaq MohamudNo ratings yet

- Joining Instructions ST JohnDocument2 pagesJoining Instructions ST JohnseongilNo ratings yet

- Six Sigma Green Belt ExaminationDocument6 pagesSix Sigma Green Belt ExaminationJagmohan BishtNo ratings yet

- Instruction Manual Fieldvue Dvc6200 Hw2 Digital Valve Controller en 123052Document108 pagesInstruction Manual Fieldvue Dvc6200 Hw2 Digital Valve Controller en 123052Cautao Cuahang50No ratings yet

- Vehicle Tracking System Using Gps & GSM - Acd ProjectDocument18 pagesVehicle Tracking System Using Gps & GSM - Acd ProjectRam Gopal VetukuriNo ratings yet

- Huawei SSN D12S Hardware DescriptionDocument8 pagesHuawei SSN D12S Hardware Descriptionchiting ZhangNo ratings yet

- DTMA-GSM1900M-12-AISG: Technical Characteristis Type No: 00906806Document2 pagesDTMA-GSM1900M-12-AISG: Technical Characteristis Type No: 00906806Kansiime JonanNo ratings yet

- K14A55D ToshibaDocument6 pagesK14A55D ToshibaZxdIaminxXzlovewithzxXzyouzxNo ratings yet

- FedreDocument283 pagesFedreAnonymous j5apk2AumNo ratings yet

- Technical SpecificationsDocument12 pagesTechnical SpecificationsgrenzoNo ratings yet

- Forklift Safety Manual PolicyDocument6 pagesForklift Safety Manual PolicyHIGH REACH EQUIPMENTNo ratings yet

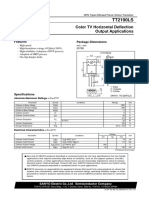

- TT2190LS: Color TV Horizontal Deflection Output ApplicationsDocument4 pagesTT2190LS: Color TV Horizontal Deflection Output ApplicationsFreddyNo ratings yet

- Itp-Ofmr - Fat PDFDocument3 pagesItp-Ofmr - Fat PDFPrabhakar SvNo ratings yet

- Template (General & Preliminaries)Document4 pagesTemplate (General & Preliminaries)Carlo Mangalindan100% (1)