Professional Documents

Culture Documents

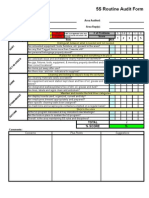

5S Audit Sheet

Uploaded by

sachinsharma31100%(1)100% found this document useful (1 vote)

128 views1 page1S & 2S audit

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1S & 2S audit

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

128 views1 page5S Audit Sheet

Uploaded by

sachinsharma311S & 2S audit

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 1

5S Checklist for the Shopfloor

Area :

S

E

I

R

I

Date :

Auditor :

YES

NO

Total NO

COMMENTS/ACTIONS

Are all of the materials (raw materials, packaging..) needed

?

Are all of the machines, boxes, benches, stands needed ?

Are all of the tools, cleaning eqpt., testing eqpt needed ?

Look for excess materials. Are they for R&D? Return to

stores?

Look for unnecessary equipment. Check the area map.

Look in lockers, drawers, cupboards for unnecessary things.

Is the standard respected? Are there unofficial or old notices

Are the noticeboards up to date with the right information ? ?

Are all items tagged? Past the expiry date? Are tags

Is the red tag area in place and the standards respected ?

available?

Are all surfaces clear of items that are not currently needed? Look on tops of machines, benches, tool trolleys.

Sort

S

E

I

T

O

N

Are signs up showing the names of machines, product being

Are the work area and its processes identified ?

made ?

Check max/min stock values - safely stacked? Check

Are all locations for materials clearly marked and respected? floor/shelf marking

Check for unlabelled material (COSHH), wrongly labelled

Are all materials clearly marked and in the right place ?

material.

Is material handling easy and safe from store to point of

Look at storing/lifting for heavy or bulky items. Too high ?

use?

Wrong size?

Are all locations for equipment clearly marked and

Have boxes/stands got clear floor locations? Tape colour

respected?

respected?

Check for unlabelled items, wrongly labelled items. Illegible

Is all equipment (boxes, stands, testing) clearly marked ?

markings?

Are they readily available, signs and instructions, easy to

Are First Aid kits, eye wash, sinks and soaps in locations ? see ?

Is all quality and data collection documentation in the right

Look for scraps of paper, out of date sheets, missing

place ?

information.

Must be properly displayed, clean, damage free and safe to

Are tools used in the area stored visible and ready for use ? use.

S

E

I

S

O

Is drainage working, are hazard sources contained, openings

Are the floors/stairs clean, free from slip, trip & fall hazards ? covered?

Are the machines clean on the outside?

Free from oil, dust and grease, product contamination.

Visual check for excessive product contamination, oil, dust,

Are the machines clean on the inside?

grease.

Check condition, interlock, emergency stop buttons easy to

Are all machine guards in place and in good condition ?

reach & visible.

Are cleaning materials within arms reach, all there, identified Check for non-standard cleaners, missing tools, wrong

?

locations

Are all rubbish & reject materials in appropriate containers ? Look for cluttered benches, check what is in the reject bins.

Look for broken bulbs, leaks, drafts, unclear switches,

Are heating & lighting right for the job being done ?

broken heaters.

Systemmatically Arrange

Shine & Service

Kaizen Institute 2006

Version 1

You might also like

- General Housekeeping Checklist: Hazard Risk ControlDocument3 pagesGeneral Housekeeping Checklist: Hazard Risk ControlJohnPaulLaggui100% (2)

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsFrom Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- 5S Score Sheet: Auditor: Nikesha Clarence Area: Shop Floor Date: 10-Feb-2012Document1 page5S Score Sheet: Auditor: Nikesha Clarence Area: Shop Floor Date: 10-Feb-2012Faith26No ratings yet

- 5s OfficeDocument10 pages5s OfficeTechie InblueNo ratings yet

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- 5S ChecklistDocument8 pages5S Checklistta3kobahokaNo ratings yet

- 5S Warehouse ChecklistDocument3 pages5S Warehouse ChecklistAudit Department100% (1)

- Stangerweb 5S Audit QuestionnaireDocument4 pagesStangerweb 5S Audit QuestionnaireambicaNo ratings yet

- 5 SDocument7 pages5 SLokesh DahiyaNo ratings yet

- 5S Audit Final VersionDocument13 pages5S Audit Final VersionMuqeet KazmiNo ratings yet

- 5S Audit ReportDocument8 pages5S Audit Reportmananshah89No ratings yet

- 5S ChecklistDocument8 pages5S ChecklistAna Auquillas AlvarezNo ratings yet

- 1st S: Sort Through/sort OutDocument8 pages1st S: Sort Through/sort OutNashwa SaadNo ratings yet

- Workplace Housekeeping - Checklist For General Inspection Floors and Other AreasDocument2 pagesWorkplace Housekeeping - Checklist For General Inspection Floors and Other Areaskanji63No ratings yet

- Seiri Audit ChecklistDocument4 pagesSeiri Audit Checklistthephaiduong100% (1)

- 5S ChecklistsDocument5 pages5S ChecklistsRheneir MoraNo ratings yet

- 03 5S Audit Spider-Chart 4 PgsDocument4 pages03 5S Audit Spider-Chart 4 PgssuryaksvidyuthNo ratings yet

- Inspector Checklist Sniff Sips Coffee ShopDocument2 pagesInspector Checklist Sniff Sips Coffee ShopPtrck MgnyNo ratings yet

- Audit Area: Stores / Goods in Name of Auditor:: Check Item Description Check Item DescriptionDocument1 pageAudit Area: Stores / Goods in Name of Auditor:: Check Item Description Check Item DescriptionrjueiNo ratings yet

- Generic 5S ChecklistDocument2 pagesGeneric 5S Checklistswamireddy100% (1)

- Facilities Housekeeping Inspection Form Department Area: - (Once Per Shop Weekly) (2 Points)Document2 pagesFacilities Housekeeping Inspection Form Department Area: - (Once Per Shop Weekly) (2 Points)Shailesh WankhadenssoNo ratings yet

- Laydown Yard ChecklistDocument6 pagesLaydown Yard Checklistjonathan cambaNo ratings yet

- 5s Audit ChecklistDocument22 pages5s Audit ChecklistJeevaAJAnanthanNo ratings yet

- Workplace Inspection ChecklistDocument10 pagesWorkplace Inspection Checklistkervin cstrNo ratings yet

- 5S Audit Sheet (2015)Document26 pages5S Audit Sheet (2015)Waqar DarNo ratings yet

- 5S Audit FormDocument2 pages5S Audit Formsigmasundar100% (1)

- 5S Audit FormDocument2 pages5S Audit FormNavnath Tamhane100% (2)

- 5S Audit FormDocument2 pages5S Audit Formmounirs719883No ratings yet

- 5s Check List MakeDocument30 pages5s Check List MakeAl Arafat Rumman100% (2)

- Safety Audit ChecklistDocument5 pagesSafety Audit ChecklistAbhishekNo ratings yet

- 6S ChecklistDocument2 pages6S Checklistabbiejune_363739No ratings yet

- 6s Audit Workshop FormDocument22 pages6s Audit Workshop FormGman0% (1)

- 5S and Safety FormsDocument4 pages5S and Safety FormsMadhan KumarNo ratings yet

- Presentation 6 S STARTER TrainingDocument96 pagesPresentation 6 S STARTER Trainingm_ramas2001No ratings yet

- 5S Audit Checklist PDFDocument4 pages5S Audit Checklist PDFAjay Krishnan100% (3)

- 5S Audit SheetsDocument5 pages5S Audit Sheetsgandee2017No ratings yet

- Kitchen Inspection ChecklistDocument8 pagesKitchen Inspection ChecklisttzryadNo ratings yet

- How To Use This Kitchen Inspection Checklist: Safetyunit@gre - Ac.uk October 2010 Page 1 of 8Document8 pagesHow To Use This Kitchen Inspection Checklist: Safetyunit@gre - Ac.uk October 2010 Page 1 of 8tzryadNo ratings yet

- 5S Safety AuditDocument9 pages5S Safety Auditmuthuswamy77No ratings yet

- PLU Building Safety Inspection ChecklistDocument5 pagesPLU Building Safety Inspection Checklistmusiomi2005No ratings yet

- Office EHS Audit ChecksheetDocument3 pagesOffice EHS Audit ChecksheetPanbarasan GanapathyNo ratings yet

- 5S Checklist ReaderDocument1 page5S Checklist ReaderarianaseriNo ratings yet

- 5 S ChecklistsDocument11 pages5 S Checklistsjahazi2No ratings yet

- 6S Audit Report No.4Document13 pages6S Audit Report No.4Rachel FloresNo ratings yet

- Building Inspection FormDocument3 pagesBuilding Inspection FormDavid tangkelangi50% (2)

- SafetyDocument12 pagesSafetydelacruzrey583No ratings yet

- 5S Audit Form PCI MasterDocument2 pages5S Audit Form PCI MasterTengku SmyNo ratings yet

- Facility Inspection ChecklistDocument9 pagesFacility Inspection ChecklistdesignselvaNo ratings yet

- 5S Audit FormDocument2 pages5S Audit FormWaqar DarNo ratings yet

- 5S Audit Scorecard Instructions: Step 1Document4 pages5S Audit Scorecard Instructions: Step 1commonthinksNo ratings yet

- Monthly Housekeeping Evaluation Checklist: 1. OfficesDocument7 pagesMonthly Housekeeping Evaluation Checklist: 1. Officesjohn haider gamolNo ratings yet

- How To Use This Kitchen Inspection ChecklistDocument7 pagesHow To Use This Kitchen Inspection Checklistmichael lester echonNo ratings yet

- 5s Audit Summary Score SheetDocument1 page5s Audit Summary Score SheetubraghuNo ratings yet

- Audit ChecklistDocument3 pagesAudit Checklistlbss22008No ratings yet

- BF Area - 5S Check ListDocument30 pagesBF Area - 5S Check ListVi KraNo ratings yet

- 5s Audit Check SheetDocument4 pages5s Audit Check SheetLAI WEI SINGNo ratings yet

- Mentor Visit Agenda: Timing What Who Where Comments Start Duration EndDocument1 pageMentor Visit Agenda: Timing What Who Where Comments Start Duration Endsachinsharma31No ratings yet

- Stoppages Study FormatDocument2 pagesStoppages Study Formatsachinsharma31No ratings yet

- Mentor Visit Agenda: Timing What Who Where Comments Start Duration EndDocument1 pageMentor Visit Agenda: Timing What Who Where Comments Start Duration Endsachinsharma31No ratings yet

- OEE SheetDocument1 pageOEE Sheetsachinsharma31No ratings yet

- OEE Monitoring Sheet SampleDocument1 pageOEE Monitoring Sheet Samplesachinsharma31No ratings yet

- OEE Monitoring Sheet SampleDocument1 pageOEE Monitoring Sheet Samplesachinsharma31No ratings yet

- PM Check ListDocument10 pagesPM Check Listsachinsharma31No ratings yet

- Efficiency OEE, Efficiency &Document3 pagesEfficiency OEE, Efficiency &sachinsharma31No ratings yet

- Daily Report Format: O.K Time With Sheets JOB Comple TE Date Time Operat OR Shift JOB SEC Tion QTY RemarksDocument2 pagesDaily Report Format: O.K Time With Sheets JOB Comple TE Date Time Operat OR Shift JOB SEC Tion QTY Remarkssachinsharma31No ratings yet

- Kra FormatDocument1 pageKra Formatsachinsharma31No ratings yet

- Format For Process Capability Study in PrintingDocument1 pageFormat For Process Capability Study in Printingsachinsharma31No ratings yet

- Format For Changeover at Sheetfed PrintingDocument12 pagesFormat For Changeover at Sheetfed Printingsachinsharma31No ratings yet

- Daily Report FormatDocument2 pagesDaily Report Formatsachinsharma31No ratings yet

- TQM & QCC Handbook Vol-2Document132 pagesTQM & QCC Handbook Vol-2xavear100% (42)

- Work Flow ChartDocument5 pagesWork Flow Chartsachinsharma31No ratings yet

- Why Why AnalysisDocument3 pagesWhy Why Analysissachinsharma31No ratings yet

- Reputed Placement Consultants of DelhiDocument5 pagesReputed Placement Consultants of Delhisachinsharma31No ratings yet

- f77 f55 User ManualDocument36 pagesf77 f55 User ManualGabi GabrielNo ratings yet

- Centum VPDocument101 pagesCentum VPgopalNo ratings yet

- Raman Spectroscopy SetupDocument13 pagesRaman Spectroscopy SetupRafael RamosNo ratings yet

- 04 Rociador Tyco K11.2 SRDocument6 pages04 Rociador Tyco K11.2 SRRuben Saucedo JacomeNo ratings yet

- Vol Damper (Smacna)Document9 pagesVol Damper (Smacna)MohamedOmar83No ratings yet

- Bhanu Brose Excursion ReportDocument6 pagesBhanu Brose Excursion ReportBhanu Pratap SinghNo ratings yet

- Chapter 14 - Storm and Sanitary Analysis PDFDocument41 pagesChapter 14 - Storm and Sanitary Analysis PDFdobridorinNo ratings yet

- 2007 Volkswagen Jetta Fuse Box Diagram (Inside and Outside) Needed PDFDocument7 pages2007 Volkswagen Jetta Fuse Box Diagram (Inside and Outside) Needed PDFGuillermo Nájera MolinaNo ratings yet

- TDG11Document100 pagesTDG11Splycho GoranNo ratings yet

- Brain Controlled Car For Disabled Using Artificial IntelligenceDocument17 pagesBrain Controlled Car For Disabled Using Artificial IntelligenceMdkhanzNo ratings yet

- Batteries and Primitive Survival Ebook 2008+ PDFDocument333 pagesBatteries and Primitive Survival Ebook 2008+ PDFOceanNo ratings yet

- Safety Inventory ExercisesDocument12 pagesSafety Inventory ExercisesParnabho KunduNo ratings yet

- Supplier Run Rate CalculatorDocument9 pagesSupplier Run Rate CalculatordcevipinNo ratings yet

- Datasheet 783Document2 pagesDatasheet 783veertulNo ratings yet

- Standards of MeasurementDocument12 pagesStandards of MeasurementShubham KheraNo ratings yet

- Refrigerator: Service ManualDocument44 pagesRefrigerator: Service ManualBetileno QuadAlexNo ratings yet

- Slum FinalDocument46 pagesSlum FinalSanghita Bhowmick83% (6)

- CH 19Document147 pagesCH 19Kathy YellaNo ratings yet

- Roofing SafetyDocument38 pagesRoofing SafetyDhârâñî KûmârNo ratings yet

- Chip Scale Atomic Magnetometer Based On SERFDocument4 pagesChip Scale Atomic Magnetometer Based On SERFluckystar83100% (2)

- Weld Fitting Flange Astm SpecsDocument1 pageWeld Fitting Flange Astm SpecsAZU-OKPONo ratings yet

- Hydrocracking Reactor Temperature Control For Increased Safety, Reliability and PerformanceDocument8 pagesHydrocracking Reactor Temperature Control For Increased Safety, Reliability and Performancekirandevi1981No ratings yet

- Module 3 Density Altitude ExperimentDocument3 pagesModule 3 Density Altitude ExperimentIvan100% (1)

- Week4 Divide and ConquerDocument15 pagesWeek4 Divide and ConquerHg0% (1)

- LOLERDocument68 pagesLOLERpraba8105100% (3)

- (4.5.0 ZULU Beta) (DUMP ALL) BTFL - Cli - 20230916 - 172153Document27 pages(4.5.0 ZULU Beta) (DUMP ALL) BTFL - Cli - 20230916 - 172153Dan MultiNo ratings yet

- Lab 3 SST 4303Document5 pagesLab 3 SST 4303Muazrul MangsorNo ratings yet

- V7.0 Function ListDocument48 pagesV7.0 Function ListInyectronix VyhNo ratings yet

- Cost BreakdownDocument241 pagesCost Breakdownbilisuma sebokaNo ratings yet

- Código BoogaDocument138 pagesCódigo BoogaJazmin SeguelNo ratings yet