Professional Documents

Culture Documents

Wall Thickness Calculation - ASME B31.8 2007 (Template)

Uploaded by

Hendra YudistiraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wall Thickness Calculation - ASME B31.8 2007 (Template)

Uploaded by

Hendra YudistiraCopyright:

Available Formats

ATTACHMENT - X

Document No. X

Wall Thickness Calculation of 36in Gas Pipeline (Location Class-3, D.F.=0.5, Corr. Allow.=1.5mm)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

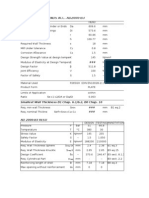

DESIGN INPUT

ASME B31.8

36

in

1.5

mm

3

0.5

Steel Coefficient of Expansion,

Modulus of Elasticity

0.0000117

2.07E+05

Pressure and Temperature Data

Design Pressure

Design Temperature (Underground)

Installation (backfill) Temp

P

Td

Ti

63.5

65

13

16

17

18

19

20

21

22

23

Weld joint factor

Temperature Derating Factor

E

T

1

1

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Next higher API wall thickness

D/t Check ( Should be < 96)

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

D

A

914

mm

per deg C

Mpa

6.50E-06 in/in/ C

3.05E+07 Psi

bar g

C

C

921.0

149.0

55.4

o

o

psi g

F

F

o

o

A. WALL THICKNESS

Grade

SMYS of Line Pipe

Wall Thickness Calculated

tmin = P x D / (2x Sx Fx E x T) + A

X60

60200

15.5

psi

mm

415 MPa

0.610 inch

15.9

58

mm

0.626 inch

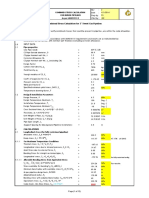

B. EQUIVALENT STRESS CHECK FOR CORRODED PIPE CONDITION

Wall thickness (t)

Hoop Stress = Sh = PD/2t

14.4

201.6

mm

MPa

B.1 Restrained Pipe (Underground)

Thermal Stress = ST = a (Ti - Td) E

Longitudinal Stress due to pressure = SP = 0.3 Sh

-125.9

60.5

MPa

MPa

-65.5

OK

MPa

267.1

241.1

267.1

MPa

MPa

MPa

Longitudinal Stress, SL

SL = SP + ST + SB + SX

S

tmin

t

0.9 x SMYS = 374 MPa

Without considering SB (Bending stress) and SX (Axial stress due to external loading):

SL = SP + ST

Longitudinal Stress check :

hence

SL 0.9 x SMYS

Equivalent Stress, SE

SE1 = | Sh - SL |

SE2 = [ Sh2 + SL2 - Sh SL ]1/2

SE = Max (SE1, SE2)

Equivalent Stress check :

0.9 x SMYS = 374 MPa

SE 0.9 x SMYS

SE1

SE2

SE

hence

OK

B.2 Unrestrained Pipe (Aboveground)

Longitudinal Stress due to pressure = SP = 0.5 Sh

100.8

MPa

Longitudinal Stress, SL

SL = SP +SB + SX

0.75 x SMYS = 312 MPa

Without considering SB (Bending stress) and SX (Axial stress due to external loading):

SL = SP

SL 0.75 x SMYS

Longitudinal Stress check :

hence

100.8

OK

MPa

C. MINIMUM BENDING RADIUS

Minimum bending radius for underground section is calculated from maximum margin of bending stress,

based on Max (SE1, SE2) = 0.9 x SMYS. Hence, bending stress SB =

-106.5 MPa

R (Minimum Bend Radius) = E D / (2 |Sb|)

889 m

D. CHECK ON THINNING DUE TO COLD BENDS: BEND RADIUS = 40 D

41

42

43

44

45

Design Code

Pipeline Size / Nominal O.D

Corrosion Allowance

Location Class

Design Factor

Inner bend radius divided by diameter, (n)

As per PD 8010-1:2004, % of Wall thinning = 50 / (n+1)

Pipe thk. before bending = cal thk/(1-thinning %)

Available thickness for bending (= Selected thk)

Adequacy Check (Pipe thk before bending < Available thk)

39.5

1.23

15.7

15.9

OK

Page 1 of 1

%

mm

mm

You might also like

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (29)

- Weldolet Branch Connection CalculationDocument3 pagesWeldolet Branch Connection Calculationsaravoot_j100% (4)

- D.G Size Calculation (22.8.12)Document1 pageD.G Size Calculation (22.8.12)Waleed Mohammed FekryNo ratings yet

- Blind flange design calculationDocument4 pagesBlind flange design calculationmukesh100% (2)

- Pipe Drafting and Design Third Edition PDFDocument475 pagesPipe Drafting and Design Third Edition PDFHendra Yudistira91% (33)

- ISO 6520 Defect Classification GuideDocument27 pagesISO 6520 Defect Classification Guidealinor_tn100% (4)

- B31G CalculatorDocument3 pagesB31G CalculatorHendra Yudistira100% (6)

- Pipe Wall Thickness Calculation ASME B31.8Document16 pagesPipe Wall Thickness Calculation ASME B31.8DikaAnindyajati100% (2)

- Thickness Calculations As Per ASME B 31.3, 31.4 and 31.8Document9 pagesThickness Calculations As Per ASME B 31.3, 31.4 and 31.8harsh_158250% (2)

- Clamp DesignDocument4 pagesClamp DesignDilip Reddy100% (1)

- Steam TurbinesDocument198 pagesSteam TurbinesHendra Yudistira100% (1)

- GE Gas TurbineDocument24 pagesGE Gas TurbineIwan Surachwanto0% (1)

- Radiography Calculations: Ir-192 Exposure Calculator (Fe)Document2 pagesRadiography Calculations: Ir-192 Exposure Calculator (Fe)Ali AlhaikNo ratings yet

- Crossing Calculation API RP1102 (TEMPLATE)Document1 pageCrossing Calculation API RP1102 (TEMPLATE)Hendra Yudistira100% (1)

- Wall THK Calculation Asme b31.4Document5 pagesWall THK Calculation Asme b31.4Dwi Hermawan100% (2)

- Pipe Wall Thickness Calculation Using ASME B31.4Document21 pagesPipe Wall Thickness Calculation Using ASME B31.4YusepSúarðiNo ratings yet

- Pipe Bend Againts Coating 3LPE AnalisisDocument25 pagesPipe Bend Againts Coating 3LPE Analisisraditia2205100% (1)

- Wall Thickness Calculation of 36in Gas PipelineDocument1 pageWall Thickness Calculation of 36in Gas PipelineLU1228100% (3)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- AS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESSDocument33 pagesAS4041 PRESSURE PIPING - REQUIRED PRESSURE DESIGN WALL THICKNESSaike_5No ratings yet

- Wall Thickness Calculation Verification under StressDocument1 pageWall Thickness Calculation Verification under StresshhgjdfNo ratings yet

- Wall THK Calculation Asme b31.4Document7 pagesWall THK Calculation Asme b31.4Luis Jose Duran100% (1)

- Calculation For Reinforced PadDocument4 pagesCalculation For Reinforced Padjsridhar_34750% (2)

- Pipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Document9 pagesPipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Oswaldo GuerraNo ratings yet

- Pipeline Wall Thickness Calculation: 3.2 Calculated Using SCH WT W/o CorrosionDocument2 pagesPipeline Wall Thickness Calculation: 3.2 Calculated Using SCH WT W/o CorrosionImmanuel SNo ratings yet

- ASME B31.3.4.8 Wall Thickness CalculatorDocument26 pagesASME B31.3.4.8 Wall Thickness Calculatoreko123No ratings yet

- Thickness Analysis ReportDocument9 pagesThickness Analysis ReportEhtisham AndrAbiNo ratings yet

- Minimum Pipe Thickness - B31.1 - PG1Document10 pagesMinimum Pipe Thickness - B31.1 - PG1ravivarmadatla2011No ratings yet

- Pipeline Wall Thickness Calculation SheetDocument4 pagesPipeline Wall Thickness Calculation SheetthehraoNo ratings yet

- Wall THK Calculation Asme B31.4Document7 pagesWall THK Calculation Asme B31.4ISRAEL PORTILLONo ratings yet

- Above Ground Piping Wall Thickness CalculationsDocument7 pagesAbove Ground Piping Wall Thickness Calculationslutfi awn100% (1)

- Wall Thickness Pipeline (Gas) B31Document25 pagesWall Thickness Pipeline (Gas) B31Rais Brian Abdurahman100% (6)

- Pipe Thickness Calculation AS Per ASME 31.3Document11 pagesPipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRNo ratings yet

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument8 pagesAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Wall Thickness 2Document18 pagesWall Thickness 2Imam Zulfir RamandhaNo ratings yet

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Document20 pages2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (2)

- Pipe Branch Connection CalculationDocument3 pagesPipe Branch Connection Calculationsaravoot_jNo ratings yet

- ASME 31 - 4 CalcDocument1 pageASME 31 - 4 CalcMarcoAlbaNo ratings yet

- Minimum Pipe Wall Thickness and MAWP SI Final ProtectedDocument11 pagesMinimum Pipe Wall Thickness and MAWP SI Final Protectedjsfscibd100% (1)

- Pipes. Wall Thickness Calculation According ASME B31.3Document86 pagesPipes. Wall Thickness Calculation According ASME B31.3Jeannie Tatiana Pérez Sánchez100% (4)

- Trunnion Calcualtion SheetDocument22 pagesTrunnion Calcualtion SheetAbhijit0% (1)

- ASME B31.8 Riser CalcDocument12 pagesASME B31.8 Riser CalcSalz EngineeringNo ratings yet

- PRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONSDocument5 pagesPRESSURE DESIGN AND REINFORCEMENT OF STRAIGHT PIPES AND BRANCH CONNECTIONSUmar Aslam0% (1)

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- Branch Reinforcement Pad Requirement CalculationDocument2 pagesBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- API 510 Bolted Flat Head ThicknessDocument11 pagesAPI 510 Bolted Flat Head ThicknessAleiser Quevedo Acuña100% (1)

- Pipe Is Under Clamping ForceDocument7 pagesPipe Is Under Clamping Forcejosediaz141No ratings yet

- SP Item DatasheetsDocument21 pagesSP Item DatasheetsSELVAMANINo ratings yet

- ASME B31 8 Riser CalcDocument12 pagesASME B31 8 Riser CalcEmmanuel LawrenceNo ratings yet

- Pipe Wall Thickness (Complete)Document40 pagesPipe Wall Thickness (Complete)Andri PutraNo ratings yet

- TBE-Pressure Vessel Standard TemplateDocument4 pagesTBE-Pressure Vessel Standard TemplateSiva baalanNo ratings yet

- Pipes. Wall Thickness Calculation According ASME B31.3Document125 pagesPipes. Wall Thickness Calculation According ASME B31.3musaveerNo ratings yet

- Design Sheet As Per ASME 31.8 2012 For 12inch TeeDocument3 pagesDesign Sheet As Per ASME 31.8 2012 For 12inch TeechethanNo ratings yet

- Mechanical Calculations for Air Receiver Pressure VesselDocument32 pagesMechanical Calculations for Air Receiver Pressure VesselAndiWSutomoNo ratings yet

- Pipe Thickness Calculation As Per ASME B31.3Document3 pagesPipe Thickness Calculation As Per ASME B31.3vipulNo ratings yet

- Brance Pipe CALDocument6 pagesBrance Pipe CALKlaikangwol AnuwarnNo ratings yet

- Pdesign: 100 Barg Line Pipe Material: API Grade X60Document64 pagesPdesign: 100 Barg Line Pipe Material: API Grade X60Luong NgoNo ratings yet

- Wall Thickness Calculation ASME B31!8!2007Document1 pageWall Thickness Calculation ASME B31!8!2007shafeeqm3086No ratings yet

- Miter B1 ADocument55 pagesMiter B1 AFarid TataNo ratings yet

- Design of anchor bolts and base plate for a fixed base columnDocument4 pagesDesign of anchor bolts and base plate for a fixed base columnSuryaSinghNo ratings yet

- 31barg CalculationDocument10 pages31barg Calculationshani5573No ratings yet

- AD2000 (31barg) CalculationDocument10 pagesAD2000 (31barg) CalculationMagdaline Matabang100% (1)

- Storage Tank Design Calculations for Hydrogen PeroxideDocument12 pagesStorage Tank Design Calculations for Hydrogen Peroxidechompink6900No ratings yet

- Weight CalculatorDocument12 pagesWeight CalculatorShafqat AfridiNo ratings yet

- SPAN Calc.Document48 pagesSPAN Calc.yoi_123No ratings yet

- Wall thickness calculation for 36-inch gas pipelineDocument1 pageWall thickness calculation for 36-inch gas pipelinetitir bagchiNo ratings yet

- Combined Stress Calc Rev. 2Document12 pagesCombined Stress Calc Rev. 2babu75% (4)

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- 05 CalDocument53 pages05 Calnatarajan RavisankarNo ratings yet

- Thermodynamic and Thermochemical Characteristics of Holmium SilicidesDocument10 pagesThermodynamic and Thermochemical Characteristics of Holmium SilicidesHendra YudistiraNo ratings yet

- The Physical Chemistry of Inorganic MaterialsDocument8 pagesThe Physical Chemistry of Inorganic MaterialsHendra YudistiraNo ratings yet

- WRC 107 2002, Local Stresses in PDFDocument78 pagesWRC 107 2002, Local Stresses in PDFHendra YudistiraNo ratings yet

- Heater Section 2Document17 pagesHeater Section 2Hendra YudistiraNo ratings yet

- Ut-Part 1Document44 pagesUt-Part 1cengizarda1979No ratings yet

- General Inspection CraneDocument12 pagesGeneral Inspection CraneHendra YudistiraNo ratings yet

- Economic FactorDocument44 pagesEconomic FactorHendra YudistiraNo ratings yet

- Heater Section 1Document50 pagesHeater Section 1Hendra YudistiraNo ratings yet

- Rigging Book CRDocument53 pagesRigging Book CRFaizal Muhaini100% (2)

- ASTM - STP 1250 - Case Studies For Fatigue Education PDFDocument224 pagesASTM - STP 1250 - Case Studies For Fatigue Education PDFHendra Yudistira100% (1)

- Fracture MechanicDocument540 pagesFracture Mechaniclightwinterday100% (3)

- Vessel support designDocument5 pagesVessel support designAzwa Onexox75% (4)

- Hot Tap ProcedureDocument21 pagesHot Tap ProcedureImanuel Sitepu100% (1)

- Form 610 - Daily Field Coating Inspection ReportDocument8 pagesForm 610 - Daily Field Coating Inspection ReportHendra Yudistira100% (1)

- Integrity Evaluation of Small Bore Connections (Branch Connections) PDFDocument9 pagesIntegrity Evaluation of Small Bore Connections (Branch Connections) PDFHendra YudistiraNo ratings yet

- Drilling CementingDocument3 pagesDrilling CementingHendra YudistiraNo ratings yet

- Fabrication - Assembly & ErectionDocument83 pagesFabrication - Assembly & ErectionRengga Andryastama100% (2)

- Pressure Relief Valve Engineering HandbookDocument93 pagesPressure Relief Valve Engineering Handbookakrouti92% (12)

- Testing of Sheet MetalDocument94 pagesTesting of Sheet MetalHendra YudistiraNo ratings yet

- Cost Engineering TerminologyDocument120 pagesCost Engineering TerminologyHendra YudistiraNo ratings yet