Professional Documents

Culture Documents

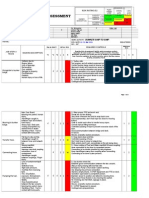

Risk Assessment No. 39 WELDING IN GENERAL Rev. 02 20.03.09

Uploaded by

Devi Ratna PratiwiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment No. 39 WELDING IN GENERAL Rev. 02 20.03.09

Uploaded by

Devi Ratna PratiwiCopyright:

Available Formats

.

RISK ASSESSMENT

PT. SWIBER BERJAYA

CHECK PPE & CONTROLS REQUIRED

Hard Hats

Safety Shoes

Safety Glasses

Hearing Protection

Cotton Gloves

Leather Gloves

Respirator

Work Vest

Safety Harness

Face Shield

Goggles

Ventilation

Fire Extinguisher

Lockout / Tag-out

Permit to Work

Stokes Basket

Life Rings

Barricades

WORK ACTIVITY:

VESSEL:

Preparation.

Welding in General.

Heavy equipment, cables and

tools.

Manual handling; back pain.

Slippery and un-tidy working

area; slip, trip and fall.

*S

*E

REGISTERED NO :- 039

INITIAL

RISK

REQUIRED CONTROLS

Describe fully all equipment, facility, and/or procedure controls applicable for each

hazard (i.e. if PPE is used as control, it must be specifically describe.) If a control can

only be verified by documentation then it must be available. All controls must be valid

in that they reduce severity, probability of both.

S: PTW System, Toolbox talk and proper PPE.

Welder to wear welding mask and leather apron in addition to other PPE.

Use crane for heavier equipment.

Inspection of equipment and cables/hoses, no open/exposed wire/leak.

M Long cables/hoses to prevent need of lifting.

Correct manual lifting technique.

Clean, dry and tidy working area/good house keeping.

Work area must be gas free.

Buddy system if working near ship side.

HAZARD DESCRIPTION

*H

Other - List

REV. DATE: 02 / 20 Mar 2009

Risk to

WHAT?

JOB STEPS / TASKS

RESIDUAL

RISK

Page 1 of 2

Wet surface; electric shock.

Difficult surface; back pain.

Fire local and adjacent spaces.

Combustible gas; fire/explosion.

Welding fumes (Iron oxide mild

steel fume, Nitrogen oxide)

Welding operation.

Welding operation.

Chipping slag.

After welding.

Arc light; eye injury.

Fumes/smoke; suffocation.

Welding spark; body injury/burn.

Flash fire or spark.

Throwing of welding waste;

pollution.

Sun heat; heat stress/stroke.

Skin cancer.

Flying particles; eye injury.

Noise; hearing loss.

Fire broke local or adjacent

spaces.

S: Stop work policy to be applied if working surface is wet.

Qualified welder. Operating instruction.

Dry work area.

Low voltage welding plant (Grounded.)

Rubber soled boots/non electricity conducting sole.

Correct posture and rest if felt pain or numbness.

Site inspection and complete PPE available for welder.

H

No bunkering or fuel transfer at the same time of welding.

H: MSDS

Welding rods

Toolbox talk

Dedicated chemical stowage area

PPE

Reporting of occupational health issues.

S: Fire watch and FFE ready at site.

Watch in adjacent spaces.

Remove combustible materials from work area.

Verify proximity of fuel oil tanks.

Communication with below deck watch.

Underside cooling as required.

Stop work policy if feeling back pain.

H

Fan to be used if no wind.

Good quality welding rod to be used.

H: Scrap not to be disposed of over board.

Use working umbrella in open space.

Use fan/blower if required.

Drink water freely.

Use sun block lotion.

S: Wear suitable goggles.

M Wear ear plug/muff.

S: Maintain fire watch until risk is over or about one hour after stop

working.

M

Run cooling water to speed up cooling process.

Close PTW only when temperature is normal.

Page 2 of 2

You might also like

- Risk Assessment for Vessel Approaching InstallationDocument2 pagesRisk Assessment for Vessel Approaching InstallationDevi Ratna PratiwiNo ratings yet

- PT. SWIBER BERJAYA CHECK PPE & CONTROLS REQUIREDDocument1 pagePT. SWIBER BERJAYA CHECK PPE & CONTROLS REQUIREDDevi Ratna Pratiwi0% (1)

- Risk Assessment No. 25 PAINTING in GENERAL Rev. 02 20.03.09Document2 pagesRisk Assessment No. 25 PAINTING in GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi89% (9)

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikNo ratings yet

- Risk Assessment No. 07 BUNKER SHIP TO SHIP Rev. 02 20.03.09Document3 pagesRisk Assessment No. 07 BUNKER SHIP TO SHIP Rev. 02 20.03.09Devi Ratna Pratiwi83% (6)

- Risk Assessment No. 41 WORKING IN MACHINERY SPACE Rev. 02 20Document3 pagesRisk Assessment No. 41 WORKING IN MACHINERY SPACE Rev. 02 20Devi Ratna Pratiwi100% (3)

- Use of Hand ToolsDocument2 pagesUse of Hand Toolsvictor100% (1)

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar KashinathNo ratings yet

- Assignment Nos. 3 - Scaffolding Risk AssessmentDocument11 pagesAssignment Nos. 3 - Scaffolding Risk AssessmentFrancis Enriquez Tan100% (1)

- Risk Assessment No. 42 WORKING OVER-SIDE Rev. 02 28.12.09Document2 pagesRisk Assessment No. 42 WORKING OVER-SIDE Rev. 02 28.12.09Devi Ratna Pratiwi80% (5)

- Risk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX BDocument5 pagesRisk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX BDevi Ratna Pratiwi100% (2)

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- 7 Hand Held Power ToolsDocument4 pages7 Hand Held Power ToolsGilmar MonteiroNo ratings yet

- Lift Accessories Lift Measure Risk Assessment Form BaseDocument6 pagesLift Accessories Lift Measure Risk Assessment Form Basebalusandeep20No ratings yet

- HIRA No. 02-Use of Access Scaffolding SBDDocument2 pagesHIRA No. 02-Use of Access Scaffolding SBDVenkadesh Periathambi25% (4)

- DR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutDocument4 pagesDR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutSachin DharneNo ratings yet

- Risk Assessment No. 06 ASCENDING & DESCENDING STAIRWAY RevDocument1 pageRisk Assessment No. 06 ASCENDING & DESCENDING STAIRWAY RevDevi Ratna Pratiwi100% (1)

- Job Hazard AssessmentDocument26 pagesJob Hazard AssessmentGeherson AbustanNo ratings yet

- Risk Assessment of Erecting Steel StructuresDocument10 pagesRisk Assessment of Erecting Steel StructuresTubagus DikaNo ratings yet

- Risk Asses 65-Piping Fabricated and Assembly - H03Document11 pagesRisk Asses 65-Piping Fabricated and Assembly - H03Rochdi BahiriNo ratings yet

- RA For High Pressure Cleaning Using HPCE 520-330Document3 pagesRA For High Pressure Cleaning Using HPCE 520-330George CristianNo ratings yet

- #15 Activity Based Risk Assessment For Painting of The Terror Club Compound and Roof Washing of T.C. BuildingsDocument14 pages#15 Activity Based Risk Assessment For Painting of The Terror Club Compound and Roof Washing of T.C. BuildingsSathish Insmile100% (1)

- Risk Assessment Construction of Lighting Pole at Site OfficeDocument9 pagesRisk Assessment Construction of Lighting Pole at Site OfficeSinaNo ratings yet

- Risk Assessment No. 46 PERSONNEL TRANSFER Rev. 02 20.03.09Document1 pageRisk Assessment No. 46 PERSONNEL TRANSFER Rev. 02 20.03.09Devi Ratna PratiwiNo ratings yet

- Risk Assessment For Working in Confined SpaceDocument1 pageRisk Assessment For Working in Confined SpaceRicardo Dalisay100% (1)

- IM-08-B HSE Wall Grinding For Finishing WorkDocument2 pagesIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisNo ratings yet

- Adverse Weather PolicyDocument10 pagesAdverse Weather Policyvlad100% (1)

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDocument3 pagesRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanNo ratings yet

- JSARA - Fire Detection System InstallationDocument13 pagesJSARA - Fire Detection System InstallationUtku Can KılıçNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- SWMS-HYD-VAYUCON-03 - Unloading and Shifting Material Through ForkliftDocument7 pagesSWMS-HYD-VAYUCON-03 - Unloading and Shifting Material Through ForkliftBodakunta Ajay VarmaNo ratings yet

- Risk Assess - 98-Installation Fuel Oil ConditioniDocument4 pagesRisk Assess - 98-Installation Fuel Oil ConditioniRochdi BahiriNo ratings yet

- Risk Assessment For Sand BlastingDocument8 pagesRisk Assessment For Sand BlastingRochdi Bahiri69% (16)

- Risk Assessment No. 24 MOORING TO WHARF - VESSELS Rev. 02 28.1Document3 pagesRisk Assessment No. 24 MOORING TO WHARF - VESSELS Rev. 02 28.1Devi Ratna Pratiwi100% (5)

- (SWMS-01) Loading, Unloading and ShiftingDocument5 pages(SWMS-01) Loading, Unloading and ShiftingPRATEEK SINGH100% (2)

- RISK ASSE 110 - Fire Fighting System - F03Document8 pagesRISK ASSE 110 - Fire Fighting System - F03Rochdi BahiriNo ratings yet

- Shifting of Materials by Double HydraDocument1 pageShifting of Materials by Double HydraShahid RazaNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- Working at Heights RiskDocument3 pagesWorking at Heights Riskmyo lwin75% (4)

- PM 01 Hira For Excavation of Boiler FoundationDocument3 pagesPM 01 Hira For Excavation of Boiler FoundationSyed Shariq Hassan100% (1)

- RA For Nitoflor FC150Document4 pagesRA For Nitoflor FC150kkhafajiNo ratings yet

- Risk Assessment & Control Register - Grease Trap CleaningDocument7 pagesRisk Assessment & Control Register - Grease Trap CleaningAbdul RahmanNo ratings yet

- EFS-SLB-SRA-006 Risk Assessment For General Waste CollectionDocument2 pagesEFS-SLB-SRA-006 Risk Assessment For General Waste Collectionmohammed ayazNo ratings yet

- Risk Assesment - Floor Chasing and ScreedingDocument3 pagesRisk Assesment - Floor Chasing and Screedingirfan vpNo ratings yet

- GIS-RA-4061E-002 Risk Assessment For Lifting (Rev.00)Document6 pagesGIS-RA-4061E-002 Risk Assessment For Lifting (Rev.00)Ajas AjuNo ratings yet

- Safety Alert 260 - Unsafe Cradle Installation and UsageDocument2 pagesSafety Alert 260 - Unsafe Cradle Installation and UsageAbdulKatherNo ratings yet

- STC5 Risk Management and Safe Work ProcedureDocument36 pagesSTC5 Risk Management and Safe Work ProcedureDenise Isebella LeeNo ratings yet

- Risk Assess Plastering 2006 Tcm17 26368Document2 pagesRisk Assess Plastering 2006 Tcm17 26368Anonymous QGHbz92uNo ratings yet

- Risk Assessment of Fire Pipe Flange T ConnectionDocument5 pagesRisk Assessment of Fire Pipe Flange T Connectionimran aliNo ratings yet

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Document5 pagesEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- Risk Assessment For Repair of ManholeDocument5 pagesRisk Assessment For Repair of Manholeflmm09No ratings yet

- JSA-Construction Right of WayDocument3 pagesJSA-Construction Right of Wayfrancis_e_tan100% (5)

- Task Risk Assessment For RadiographyDocument5 pagesTask Risk Assessment For RadiographySanjeev Nair81% (21)

- Risk Assessment For Earthing Work-R1Document3 pagesRisk Assessment For Earthing Work-R1Azhar Mushtaq75% (4)

- JSA - Suface Preparationand Brush PaintingDocument5 pagesJSA - Suface Preparationand Brush PaintingAzad pravesh khanNo ratings yet

- Water Tank Base Construction Hazard Identification and Risk ControlDocument5 pagesWater Tank Base Construction Hazard Identification and Risk Controlramod100% (2)

- Risk Assessment No 25 PAINTING in GENERAL Rev 02 20 03 09Document2 pagesRisk Assessment No 25 PAINTING in GENERAL Rev 02 20 03 09sizwe0% (1)

- How Chin Engineering: Job Safety AnalysisDocument5 pagesHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdNo ratings yet

- Hot Work Safety TrainingDocument36 pagesHot Work Safety Trainingarnold arayataNo ratings yet

- BTEC Assignment - Unit 23Document11 pagesBTEC Assignment - Unit 23Muthu Rajan100% (1)

- MV.OPS ANDRA MASTER'S STANDING ORDERSDocument2 pagesMV.OPS ANDRA MASTER'S STANDING ORDERSDevi Ratna Pratiwi100% (3)

- Risk Assessment No. 08 BUNKERING IN GENERAL Rev. 02 20.03.09Document2 pagesRisk Assessment No. 08 BUNKERING IN GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi91% (11)

- Daftar Pustaka AkdrDocument1 pageDaftar Pustaka AkdrDevi Ratna PratiwiNo ratings yet

- LSA-FFA INVENTORIES FOR AUGUST 2013Document1 pageLSA-FFA INVENTORIES FOR AUGUST 2013Devi Ratna Pratiwi100% (1)

- Risk Assessment No. 06 ASCENDING & DESCENDING STAIRWAY RevDocument1 pageRisk Assessment No. 06 ASCENDING & DESCENDING STAIRWAY RevDevi Ratna Pratiwi100% (1)

- Towing ArragementDocument1 pageTowing ArragementDevi Ratna PratiwiNo ratings yet

- Towing Arrangement Batam to Laem Cabang Voy #01Document2 pagesTowing Arrangement Batam to Laem Cabang Voy #01Devi Ratna Pratiwi67% (3)

- Contoh Soal Marlin TestDocument7 pagesContoh Soal Marlin TestDevi Ratna Pratiwi79% (14)

- BEAUFORT SCALE - PhotoDocument2 pagesBEAUFORT SCALE - PhotoDevi Ratna PratiwiNo ratings yet

- Risk Assessment No. 08 BUNKERING IN GENERAL Rev. 02 20.03.09Document2 pagesRisk Assessment No. 08 BUNKERING IN GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi91% (11)

- Towing Arrangement BDocument2 pagesTowing Arrangement BDevi Ratna PratiwiNo ratings yet

- Towing Arrangement CDocument2 pagesTowing Arrangement CDevi Ratna PratiwiNo ratings yet

- Towing Arrangement ADocument2 pagesTowing Arrangement ADevi Ratna Pratiwi83% (6)

- Risk assessment for anchor handling vessel PT. SWIBER BERJAYADocument3 pagesRisk assessment for anchor handling vessel PT. SWIBER BERJAYADevi Ratna PratiwiNo ratings yet

- Risk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Document5 pagesRisk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Devi Ratna Pratiwi78% (9)

- MASTER CABLE (Panduan)Document1 pageMASTER CABLE (Panduan)Devi Ratna PratiwiNo ratings yet

- QSA-319 Oil Spill DrillDocument1 pageQSA-319 Oil Spill DrillDevi Ratna PratiwiNo ratings yet

- PT PERTAMINA ULLAGE REPORTDocument1 pagePT PERTAMINA ULLAGE REPORTDevi Ratna PratiwiNo ratings yet

- STOP TEMPORARY (Panduan)Document1 pageSTOP TEMPORARY (Panduan)Devi Ratna PratiwiNo ratings yet

- Risk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX BDocument5 pagesRisk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX BDevi Ratna Pratiwi100% (2)

- Risk Assessment No. 03 ANCHOR HANDLING, RETRIEVING, SUIT CASDocument2 pagesRisk Assessment No. 03 ANCHOR HANDLING, RETRIEVING, SUIT CASDevi Ratna Pratiwi80% (5)

- Risk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Document5 pagesRisk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Devi Ratna Pratiwi78% (9)

- OFF HIRE CERTIFICATE (Panduan)Document1 pageOFF HIRE CERTIFICATE (Panduan)Devi Ratna PratiwiNo ratings yet

- LOG ABSTRACT (Panduan)Document1 pageLOG ABSTRACT (Panduan)Devi Ratna Pratiwi100% (1)

- NOTICE OF SEALING (Panduan)Document1 pageNOTICE OF SEALING (Panduan)Devi Ratna PratiwiNo ratings yet

- MV.OPS ANDRA MASTER'S STANDING ORDERSDocument2 pagesMV.OPS ANDRA MASTER'S STANDING ORDERSDevi Ratna Pratiwi100% (3)

- QSA-319 Abandon ShipDocument1 pageQSA-319 Abandon ShipDevi Ratna PratiwiNo ratings yet

- QSA-319 Fire DrillDocument1 pageQSA-319 Fire DrillDevi Ratna PratiwiNo ratings yet

- QSA-319 Oil Spill DrillDocument1 pageQSA-319 Oil Spill DrillDevi Ratna PratiwiNo ratings yet

- Din en 12517 - 2006Document17 pagesDin en 12517 - 2006marcelogf74No ratings yet

- Anil Deswal 139Document139 pagesAnil Deswal 139harsh yadavNo ratings yet

- Chirag Sharma: Education SkillsDocument1 pageChirag Sharma: Education SkillsShivam MangalNo ratings yet

- Tapco Catalog 6th EditionDocument108 pagesTapco Catalog 6th EditionchinhvuvanNo ratings yet

- Chemical Engineering Basics MCQ Practice TestDocument10 pagesChemical Engineering Basics MCQ Practice TestAmir RajputtNo ratings yet

- Audi q7 Service TrainingDocument7 pagesAudi q7 Service Trainingsara100% (46)

- Rice & Dal Mill Machinery PDFDocument9 pagesRice & Dal Mill Machinery PDFSHASHI SHEKARNo ratings yet

- Practical Exam Instructions: Canadian Welding BureauDocument4 pagesPractical Exam Instructions: Canadian Welding BureauRajesh KunaNo ratings yet

- Housekeeping NC II CGDocument19 pagesHousekeeping NC II CGPaolo IcangNo ratings yet

- Ador WeldDocument130 pagesAdor Weldjignesh sutariyaNo ratings yet

- GeKa Katalog PDFDocument514 pagesGeKa Katalog PDFElshan FeyzullayevNo ratings yet

- Process - 14 Arc Welding - MODULE 14Document52 pagesProcess - 14 Arc Welding - MODULE 14sskiitbNo ratings yet

- A1033-10 (2015) Standard Practice For Quantitative Measurement and Reporting of Hypoeutectoid Carbon and Low-Alloy Steel Phase TransformationsDocument14 pagesA1033-10 (2015) Standard Practice For Quantitative Measurement and Reporting of Hypoeutectoid Carbon and Low-Alloy Steel Phase Transformationstjt4779No ratings yet

- Low alloy steel electrode for high strength weldingDocument1 pageLow alloy steel electrode for high strength weldingsatnamNo ratings yet

- PSK GET 9th v2Document827 pagesPSK GET 9th v2Luis PozoNo ratings yet

- 钢材中英文对照Document48 pages钢材中英文对照He Yun QingNo ratings yet

- Position of Welds ComparisonDocument3 pagesPosition of Welds ComparisonYuvaraj SathishNo ratings yet

- Welding Consumables 544Document16 pagesWelding Consumables 544Sathiya SeelanNo ratings yet

- UPP Installation Manual - V7a - WebDocument124 pagesUPP Installation Manual - V7a - WebFranco TorrealbaNo ratings yet

- Consider Penetration When Determining Fillet Weld SizeDocument3 pagesConsider Penetration When Determining Fillet Weld SizecanakyuzNo ratings yet

- Btech Computer Science and Engg Semester I To Vi Semester Vii and Viii Old Sys CbcegsDocument132 pagesBtech Computer Science and Engg Semester I To Vi Semester Vii and Viii Old Sys CbcegsJasmine SinghNo ratings yet

- Iso Code PDFDocument37 pagesIso Code PDFJP WayNo ratings yet

- Brief Description: Application Note - Industries & MarketDocument2 pagesBrief Description: Application Note - Industries & MarketJose Oliveros ArdilaNo ratings yet

- Chimney NotesDocument3 pagesChimney NotesmonojitdeyNo ratings yet

- Busbar TightnessDocument11 pagesBusbar Tightnesssanjeev267No ratings yet

- Amitabha Ghosh, Asok Kumar Mallik - Manufacturing Science-East-West Press PVT LTD (2010)Document514 pagesAmitabha Ghosh, Asok Kumar Mallik - Manufacturing Science-East-West Press PVT LTD (2010)Israel HerreraNo ratings yet

- Workshop Practice-I ES - ME - 292 Manual MainDocument55 pagesWorkshop Practice-I ES - ME - 292 Manual MainKunal KumarNo ratings yet

- Bunnings CatalogueDocument24 pagesBunnings Cataloguethomas.mammenNo ratings yet

- Tender Document For CraneDocument10 pagesTender Document For Craneamechmar5935No ratings yet

- Astm A803-12Document7 pagesAstm A803-12Артем ТитовNo ratings yet