Professional Documents

Culture Documents

Engine Top Bracing PDF

Uploaded by

rajishrrrOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Top Bracing PDF

Uploaded by

rajishrrrCopyright:

Available Formats

Main Engine Top Bracing

INSTRUCTION MANUAL

for

MAIN ENGINE TOP BRACING

Hydraulically Operated Main Engine Top Bracing

with Manifold Block

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

CONTENTS

1. GENERAL .. 2

2. SPECIFICATION ..... 3

3. SCOPE OF SUPPLY .... 3

3.1 When the compressive load force is lower than 10,050 kg

3.2 When the compressive load force is higher than 10,050 kg

3.3 When the compressive load force is lower than the self-returning force of the H.T.B

4. INSTALLATION ... 4

4.1 Before Starting the installation work

4.2 Preparation (Flange welding)

4.3 Installation of hydraulic cylinder

4.4 Install piping between the hydraulic cylinder and the manifold block

4.5 Oil filling & air bleeding

5. ROUTINE CHECK DURING NORMAL USE .... 7

5.1 Pressure in the air chamber

5.2 Pressure in the low-pressure chamber

5.3 Pressure in the high-pressure chamber

5.4 Position of the main piston

5.5 Position of the air piston

6. MAINTENANCE ... 8

6.1 Dismantling .

6.2 Disassembling

6.3 Re-assembling

6.4 Re-installation

7. TROUBLE SHOOTING ...... 9

7.1 Rattling Noise around the bearing support

7.2 External oil leakage along the surface of piston rod

7.3 Internal oil leakage into the air chamber

7.4 Front reference line marked on the piston rod is near the position indicator

8. APPENDIX ..10~13

8.1 General Assembly

8.2 Spare parts & special tool list

8.3 E.T.B dimension

8.4 Alignment Tolerance Range for Installation

8.5 Installation environment

8.6 Piping diagragm (for two E.T.B.)

8.7 Piping diagragm (for four E.T.B.)

TBHA 001

TBHA 002

TBHA 003

TBHA 004

TBHA 005

TBHA 007

TBHA 045

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

Page: 2

1. GENERAL

As the output power of the ship engine becomes larger the height of the engine becomes

higher accompanied by greater rocking movement of the engine body. This movement

causes heavy vibration and necessitates the use of engine top bracing to reduce or

prevent the vibration from being transmitted to the hull side.

BYs engine top bracing (hereinafter ETB) is consisted of several parts such as cylinder

(ID 300mm), main piston, air piston, piston rod (OD 210mm), relief valve, by-pass valve,

bearing support, spherical bearing and etc.. Small-sized air piston is designed to be

placed in the main piston rod which is utilized as the air piston cylinder. This kind of

differential type piston assembly enables a small and compact structure with cheaper

product cost. The spherical bearing on both sides protect the piston assembly from being

exposed to the vertical force caused by the external power source. This will prevent the

unbalanced wear of the cylinder and reduces the necessity for frequent maintenance.

The BYs ETB is to be installed on the upper starboard side of engine in single or in pairs.

It is operated both hydraulically and pneumatically with self-return mechanism. During the

operation, basically two types of function spring function and damper function are to

be exercised to reduce or dampen the vibration depending on the magnitude of frequency

and vibration.

Spring function is displayed when the compressive force from the engine is not so large

enough for the relief valve to be opened. Under this condition the ETB reduces the engine

vibration in the same way as a spring does against an external compressive force. In

contrast to spring function, damper function is displayed when the compressive force from

the engine is large enough to make the relief valve open. Under this condition a portion of

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

Page: 3

the oil in the high pressure oil chamber is forced to be squeezed into the low pressure oil

chamber through the open port in the relief valve, thus creating damping effect as a result

of reactive force.

By-pass valve is to be used to select the function of the ETB: in case it is closed, both the

spring function and damper function can be attained, but in case it is kept open only the

damper function is possible.

2. SPECIFICATION

Hydraulic

Cylinder

1. Type

2. Dimension, mm

3. Repulsive force per cylinder

under air supply pressure of

6~8 bar

4. Max. expected dynamic load

5. Installation

6. Valve Block Components

Accessories

1. Manifold Block

2. Manifold Block Components

3. Oil type

4. Oil volume/ 1 Cylinder

5. Weight

6. Max. allowable ambient temp.

7. Allowable installation offsets

HY 300

Head end diameter: 300

Rod end diameter: 210

Piston travel length: 20

Volume of gas accumulator: 2.5 liter

2100 kgf for 6 bar

2400 kgf for 7 bar

2800 kgf for 8 bar

5,000 kgf

28 Stud bolts, Nut M1665L

One(1) Relief Valve

One(1) Bypass Valve

One(1) per two(2) or four(4) ETB

Air regulator with press gage

Check valve (on the air supply line)

Manifold header with press gage

(for oil supply and air bleeding)

Block valves

Standard hydraulic oil

(ISO VG 32)

3.3 liters

Approx. 100 kg

Approx. 75C

10mm (normal)

3. SCOPE of SUPPLY

Hydraulic cylinder with built-in valve block assembly

Manifold block with fittings and rubber hoses.

Spare parts (O-rings, wear rings, piston seals)

Special tools (hand pump and a pair of hook wrench)

e Piping material except flexible hoses is to be supplied by shipyard.

e Fitting & valves to be connected to hydraulic cylinder & manifold block are included in

the scope of supply.

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

Page: 4

4. INSTALLATION

4.1 Before starting the installation work

It is recommended to read this manual before starting to install the ETB. Review the relevant

drawings and check the parts if they comply with the specification. Also check if there is any

missing part.

4.2 Preparation (Flange Welding)

WELDING FLANGE

ADJUST BOLT

ADJUSTABLE LENGTH : 20mm

LIFTING LUG

65010

INSTALLATION JIG

1) Disconnect both of the welding-flanges from the ETB and fit them in the installation jig.

2) Measure the distance between the hull-side beam and gallery (engine-side) beam.

The distance should be within 6505mm. In case the distance is too short it is

recommended to cut the gallery beam to meet the required distance. But, on the contrary,

if the distance is too long it is recommended to apply an adjustable plate to the gallery

beam.

4) After having set the required distance, lift and fix the installation jig temporarily inbetween

the hull-side and gallery beams using the adjust bolts.

5) Check the alignment of the horizontal axis line if it is within the tolerance range. I f

acceptable, weld the welding flange.

6) Remove the installation jig

7) Weld inside corner of the flange

8) Remove welding slugs and do the painting.

4.3 Install the hydraulic cylinder

Lift the hydraulic cylinder and tighten the mounting bolts.

4.4 Install piping btwn the hydraulic cylinder and the manifold block

- It is of utmost importance to ensure these piping line be free of any leakage for the safe and

reliable performance of the whole system.

- See piping diagram (TBHA 007 or TBHA 045) for correct piping.

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

Page: 5

e Be sure to use flexible piping or rubber hoses to avoid premature rupture caused by heavy

vibration.

4.5 Oil Filling & Air Bleeding

(Refer to the piping diagram TBHA 007 or TBHA 045)

4.5.1 PREPARATION

1) Hand pump:

Fill the hand pump with oil (*) and connect the hand pump hose to the oil supply nozzle

on the manifold block.

(*)Depending on the situation, it may be necessary to fill several times during the air

purge operation since the oil chamber in the hand pump is not large.

2) Line-up:

Check if the bypass valve in the valve block is open, and all of the block valves on the

manifold headers are closed.

3) Position of the main piston:

Check if the position indicator (the edge of piston rod cover) meet the center line (if not,

adjust accurately by turning the bearing support with hook wrench supplied by BY and fix

it with lock nut after completion of adjustment.)

4) Drainage panel:

Put a oil drainage panel below the ETB to prevent oil spillage over the floor.

4.5.2 AIR BLEEDING

LINE 25

AIR SUPPLY

NOTE 1.

LINE NUMBERING

AIR BLEED

VALVE

OIL SUPPLY

WITH HANDPUMP

OIL SHUT OFF V/V

A : TOP BRACING NO.

B : KIND OF LINE

1 ~ OIL SUPPLY LINE

2 ~ HIGH PRESSURE CHAMBER LINE

3 ~ LOW PRESSURE CHAMBER LINE

5 ~ AIR SUPPLY LINE

LINE 21

LINE 11

LINE 23

LINE 12

LINE 22

LINE 13

A B

NOTE 2.

HIGH PRESSURE

CHAMBER LINE

SYMBOL

LOW PRESSURE

CHAMBER LINE

25

15

LINE 15

(AIR SUPPLY LINE)

FLEXIBLE HOSE

23 22 13 12

21 11

NOTE 3.

COPPER TUBE (O.D8*I.D6*t1) :YARD SUPPLY

FLEXIBLE HOSE (=500L) : MAKER SUPPLY

BREARING

SUPPORT

LOCK NUT

POSITION INDICATOR

VALVE BLOCK

OIL SUPPLY LINE

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

Page: 6

1) Air filling to the air chamber:

Turn the knob at the air regulator clockwise (line #15,) and fill the air to

a. 4.0 bar in case the normal operating pressure (*1) in the air chamber is 6 bar

b. 4.5 bar in case the normal operating pressure (*1) in the air chamber is 7 bar

c. 5.0 bar in case the normal operating pressure (*1) in the air chamber is 8 bar

After air has been filled up to proper pressure among the three cases above, block the air

supply line by turning the knob at the air regulator counterclockwise (*2) or simply closing

the main stop valve on the air supply line.

(*1) This pressure is the same as the air supply pressure since the pressure in the air

chamber is normally maintained at the same air supply pressure level available in

the ship.

(*2): The reason for air filling is to keep the volume of low pressure oil chamber to the

minimum during this stage, thus to facilitate air purging operation.)

2) Line-up:

Open the air bleed valve on the air bleed manifold header, block valve on the line to and

from the high-pressure chamber (line #11, 12) and main oil block valve at the oil supply

manifold header.

Confirm if the bypass valve in the valve block assembly is opened.

3) Air purging in the high pressure oil chamber:

Start air purging supplying oil with hand pump. Oil will now fill the cylinder and the air

trapped both in the piping and oil chamber will be purged through the bleed valve. When

oil overflows with no sign of entrainment of air bubbles, the high-pressure chamber is

regarded as fully bled.

When air purging is finished, stop hand pump and close block valve on the line from the

high-pressure chamber (line #12).

4) Air purging in the low pressure oil chamber

Open the block valve on the line out of the low-pressure chamber (line #13), and start air

purging supplying oil to the low pressure chamber with hand pump. Oil will now fill the

cylinder and the air trapped inside the low pressure oil chamber will be purged out of the

system through the bleed valve. When oil runs out with no sign of entrainment of air

bubbles, the air in the low -pressure chamber is regarded as fully bled.

When air purging is finished, stop hand pump and close both the air bleed valve and the

block valve on the line out of the low pressure oil chamber (line #13).

4.5.3 OIL CHAMBER PRESSURE and BYPASS V/V SETTING

1) Oil chamber pressure setting

With the outlet block valves of both the high and low pressure oil chambers closed and the

bypass valve in the valve block assembly open, continue pumping until the pressure in the

oil chambers reach the final set pressure (6 or 7 or 8 bar) which matches the air chamber

pressure described in 4.5.2 1) above (*1).

(*1): The reason for oil chamber pressure setting is to put the air piston in proper (neutral)

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

Page: 7

position (*2) for safe and stable performance of the ETB.

(*2): This can be easily checked with the New Type ETB which has an indicating

cap with inner indicating bar nailed into the body of the air piston. If the bar

is positioned in the blue division line 20% range, it is regarded as normal.

If the bar is positioned out of this range, adjustment can be made by simply

supplying (in case the bar is in the negative side) or releasing (in case the bar is

in the positive side) the oil as required.

2) Line-up:

After the oil pressurization has been finished, close the block valves on the line to the lowpressure chamber (line #11) and oil supply line to the manifold header.

3) Setting of bypass valve opening

Fully close the bypass valve (*).

(*) The degree of opening is based on the cumulated experiences. Depending on the

specific conditions of the engine, this can be adjusted by the user to the optimum.

5. ROUTINE CHECK AFTER INSTALLATION

5.1 Air supply pressure (air chamber pressure)

Check the pressure in the pressure gage of the air regulator on the air supply line. This

should be the same as the pressure in the air chamber.

5.2 Pressure in the high-pressure oil chamber

Open the block valve on the line out of the high-pressure chamber (line #12) and check

the pressure using the pressure gauge on the manifold block. Close the block valve after

check has been finished (*).

(*): If wanted, one block valve may be kept open for convenience.

5.3 Position of the main piston

Check if the position indicator (the edge of the piston rod cover) meets the center

reference line marked on the outside surface of the piston rod.

If the piston rod is found to have moved inside (the edge of the piston rod cover

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

Page: 8

approaching the front reference line marked on the piston rod), it is suspected that the oil

in the oil chambers is leaking.

5.4 Position of the air piston

a. ETB without The Indicating Bar :

It is difficult to directly confirm the right position of the air piston with the existing type of

ETB. In case the procedure 4.5.2.1) & 4.5.3 1) are followed strictly the air piston is

believed to be kept in neutral position.

b. ETB with The Indicating Bar :

Check if the indicating bar is positioned within the normal position range (blue division

line) 20%. If the bar is positioned out of this range, adjustment can be made by

simply supplying (in case the bar is in the negative side) or releasing (in case the bar is

in the positive side) the oil as required.

6. MAINTENANCE

6.1 Dismantling

1) Secure a strong hoist wire to the lifting lugs on the ETB body.

Put the oil spillage panel ready under the ETB body

2) Stop air supply by turning the knob on the air regulator counterclockwise and disconnect

the air line from the cylinder (air chamber).

3) Close the block valve on the line to the oil chambers (line # 11) and disconnect the oil

lines from top of the cylinder (line # 12,13).

4) Loosen the adjustment nut to give slack, and remove the ETB to safe place.

(ETB weigh approximately 100kg and may be slippery because of oil on the surface.

Special care must be taken to prevent E.T.B. from being dropped on the floor by mistake.

6.2 Disassembling

1) Oil draining out of the low pressure oil chamber:

Connect air supply tube to the air inlet port and set the pressure at approx. 2 bar.

This will make the air chamber expand, squeezing the oil in the low pressure oil chamber

out of the cylinder.

Vent the air pressure completely after oil has been drained.

2) Pulling out the main piston & piston rod assembly

- Open the front cover-plate (piston rod side) of the cylinder by unscrewing the bolts.

- Pull out the main piston ( or let it slide out by turning the cylinder upside-down )

Be careful the sliding surfaces dont get scratched.

- Open the rear cover-plate, if needed.

3) Pulling out the air piston

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

Page: 9

- Separate the main piston and the piston rod by unscrewing the bolts installed through the

main piston wall.

- Pull the air piston out of the piston rod by slightly pressurizing (*) the air chamber with air.

(*): Care must be taken not to increase abruptly to avoid air piston being puffed out of the

piston rod like a blind bullet.

4) Replace the seals

Replace all of the seals and O-rings with spare parts.

5) Check all of the super-finish surfaces

Check for any damage or severe wear. If the surfaces look damaged, the damaged part

should be either repaired (lapped) or replaced.

6.3 Re-assembling

1)

2)

3)

4)

5)

6)

Insert the air piston into the rod.

Check if the check valve is clean and the ball is in place.

Re-assemble the piston rod and main piston.

Fit the main piston & piston rod assembly into the front cover plate

Fit the main piston & piston rod assembly into the cylinder.

Tighten the cover plates.

e Lubricate well before inserting the piston into the cylinder. Care should be taken no seals

be cut or damaged during this step.

6.4 Re-installation

Reinstall carefully according to 4. INSTALLATION procedure in this manual.

7. TROUBLE SHOOTING

7.1 Rattling Noise around the bearing support

1) Possible cause: Insufficient oil charge before service

Excessive oil loss from the oil chambers or

Abnormally low pressure in the air chamber.

2) Diagnosis: Check if air pressure in the air chamber is normal.

Check if the position of the main piston is normal.

3) Remedy: In case of heavy oil loss, overhaul the ETB assembly for replacement of the

seals including O-rings.

In case of insufficient oil charge, make up to normal level.

In case of air pressure loss, locate the leaky point and fix it.

7.2 External oil leakage along the surface of piston rod

1) Possible cause: Worn out piston seal or

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

Page: 10

2) Remedy:

Scratches on the piston rod surface.

Overhaul the ETB assembly for replacement of the seals or repair of the

scratches on the surface of piston rod.

7.3 Internal oil leakage into the air chamber

1) Possible cause: Worn out piston seal.

2) Diagnosis: If oil in the low pressure oil chamber can leak into the air chamber the reverse

can be possible. In this case the repulsive force by the air chamber will be

deteriorated or paralyzed. Open the block valve on the line #13, and crackopen the air bleed valve on the manifold header to confirm if any sign of air

bubble is found.

2) Remedy: Overhaul the ETB assembly for replacement of air piston seal.

7.4 Front reference line marked on the piston rod is near the position

indicator

1) Possible cause: Worn out piston seal or

Scratches on the piston rod surface.

2) Remedy: Overhaul the ETB assembly for replacement of the seals or repair of the

scratches on the surface of piston rod.

8. APPENDIX (DRAWINGS)

8.1 General Assembly

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

Page: 11

8.2 Spare Parts & Tool List

8.3 ETB Dimension

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

Page: 12

8.4 Tolerance Range for Installation

8.5 Installation Environment

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

Main Engine Top Bracing

Page: 13

8.6 Piping Diagram (for two ETB)

8.7 Piping Diagram (for four ETB)

-The End

BY Controls, Inc. 850-2, Cheongcheon-Ri, Chillye-Myon, Kimhae-si, Kyungnam, 621-884, Korea

Phone : +82-55-345-6110 Fax :+82-55-345-6115 E-mail : by@bycontrols.com URL: http://www.bycontrols.com

You might also like

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- VIT Fuel PumpDocument16 pagesVIT Fuel PumpAbhishek Singh Chauhan50% (2)

- G50me-B9 5Document375 pagesG50me-B9 5Neeraj RajpalNo ratings yet

- S80mec8 PDFDocument361 pagesS80mec8 PDFRodrigoEhNo ratings yet

- HITACHI-MAN B&W Stroke Sensor AdjustmentDocument2 pagesHITACHI-MAN B&W Stroke Sensor Adjustmentg arvNo ratings yet

- Scrape Down Analysis-Abhijit Ghosh PDFDocument4 pagesScrape Down Analysis-Abhijit Ghosh PDFabhijit_11No ratings yet

- Tie BoltsDocument31 pagesTie BoltsMuhammad Nasim AbbasNo ratings yet

- Cross Head Removal For Man B WDocument13 pagesCross Head Removal For Man B WMOHAN100% (1)

- ALPHA Commissioning ManualDocument43 pagesALPHA Commissioning Manualgmegoulis_772534693100% (1)

- Stuffing BoxDocument2 pagesStuffing BoxMeghali Borle67% (3)

- ORBDocument14 pagesORBRommelNo ratings yet

- Starting Air Distributor: Plate 90703-0086Document2 pagesStarting Air Distributor: Plate 90703-0086Roshan RamachandranNo ratings yet

- Man B&W Serv LTR Sl09-509-Sb-jDocument7 pagesMan B&W Serv LTR Sl09-509-Sb-jafsal999No ratings yet

- Important QuestionsDocument82 pagesImportant Questionssams shuvoNo ratings yet

- CC Pump Manual-Full (Original)Document109 pagesCC Pump Manual-Full (Original)friendbce100% (1)

- Marine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionFrom EverandMarine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- Man B&W: Starting Air DistributorDocument14 pagesMan B&W: Starting Air DistributorRajesh Sharma100% (1)

- Procedure For Cross Head Bearing Removal of Marine EngineDocument6 pagesProcedure For Cross Head Bearing Removal of Marine EngineVenkatarama KrishnanNo ratings yet

- E-021 Auxiliary Engine Performance.04Document2 pagesE-021 Auxiliary Engine Performance.04Rizky Sapugungdo100% (1)

- Stuffing BoxDocument6 pagesStuffing BoxrajishrrrNo ratings yet

- Puncture ValveDocument1 pagePuncture ValveAnkit DedhiyaNo ratings yet

- Yanmar Auxiliary Engine Overhaul PDFDocument7 pagesYanmar Auxiliary Engine Overhaul PDFRani NoumanNo ratings yet

- Vit and Super VitDocument6 pagesVit and Super VitRavindar Anandan0% (1)

- The Airguard Seal PDFDocument3 pagesThe Airguard Seal PDFrajishrrrNo ratings yet

- How A Rotocap WorksDocument6 pagesHow A Rotocap WorksBharatiyulam83% (6)

- Copt Manual PDFDocument79 pagesCopt Manual PDFSriram RamaswamiNo ratings yet

- Recent MMD QuestionsDocument49 pagesRecent MMD QuestionsAkash Nair100% (1)

- Ce Handing OverDocument10 pagesCe Handing OverAkhilvjohnNo ratings yet

- MSC Carina Delivery 6 June 2013: Main Engine MAN 6S60ME-C 8.1 AuxiliariesDocument10 pagesMSC Carina Delivery 6 June 2013: Main Engine MAN 6S60ME-C 8.1 AuxiliariesПетрNo ratings yet

- 16 NZ Series Hydraulic Governor Model NZ61 - NZ115 3Document48 pages16 NZ Series Hydraulic Governor Model NZ61 - NZ115 3Frank1No ratings yet

- MEO Class I OralsDocument2 pagesMEO Class I OralsGurvindarNo ratings yet

- Alpha Lubricator Manual-Check TimingDocument1 pageAlpha Lubricator Manual-Check TimingRaviNo ratings yet

- Connecting Rod: Ident No.: 0741673-1Document15 pagesConnecting Rod: Ident No.: 0741673-1Şansal DikmenerNo ratings yet

- Computer Controlled Engine SystemsDocument3 pagesComputer Controlled Engine Systemssevero97100% (1)

- Starting - Reversing Problems in Marine EnginesDocument6 pagesStarting - Reversing Problems in Marine EnginesTarek AzizNo ratings yet

- Me 2006-01Document32 pagesMe 2006-01VLADNo ratings yet

- Slide Fuel ValvesDocument2 pagesSlide Fuel ValvesSpasoje100% (1)

- MC Engines Service Experience: Cylinder Condition, Design Updates, and Reliability ImprovementsDocument12 pagesMC Engines Service Experience: Cylinder Condition, Design Updates, and Reliability ImprovementsHarpreet Singh100% (1)

- Slide Fuel Valves Reduce EmissionsDocument5 pagesSlide Fuel Valves Reduce EmissionsParthiban NagarajanNo ratings yet

- Cleaning FIVA ValvesDocument5 pagesCleaning FIVA ValvesValeriy DomashenkoNo ratings yet

- 728 Marine Engineering Interview Questions Answers GuideDocument6 pages728 Marine Engineering Interview Questions Answers Guidepandavadra rajesh100% (1)

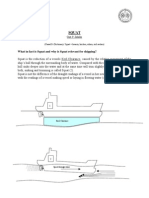

- Squat: What in Fact Is Squat and Why Is Squat Relevant For Shipping?Document8 pagesSquat: What in Fact Is Squat and Why Is Squat Relevant For Shipping?Abhay Kinra100% (2)

- Centrifugal Pumps Instruction ManualDocument20 pagesCentrifugal Pumps Instruction ManualYaman Yalçın100% (1)

- SN183Document18 pagesSN183papaki2No ratings yet

- MAN B&W Diesel A/S: Licence LetterDocument3 pagesMAN B&W Diesel A/S: Licence Letterbhaswath2000No ratings yet

- MAN B&W Diesel A/S: Service LetterDocument2 pagesMAN B&W Diesel A/S: Service Letterflorin100% (1)

- Exhst VV Puncture VVDocument4 pagesExhst VV Puncture VVrakeshbiswa100% (1)

- Guidelines - CE 2EDocument14 pagesGuidelines - CE 2ESUNILNo ratings yet

- MSC Carina Delivery 6 June 2013: Main Engine MAN 6S60ME-C 8.1Document5 pagesMSC Carina Delivery 6 June 2013: Main Engine MAN 6S60ME-C 8.1ПетрNo ratings yet

- Man B&W 6S60MC 702Document6 pagesMan B&W 6S60MC 702Ishan Bhatnagar100% (1)

- Main Fuel Pump Overhauling Procedure Step-by-StepDocument5 pagesMain Fuel Pump Overhauling Procedure Step-by-StepAnoop Vijayakumar100% (1)

- Int Eng Prospects MAN BWDocument19 pagesInt Eng Prospects MAN BWWsm HNNo ratings yet

- Royal Belgian Institute of Marine Engineers Basic Ship Propulsion PrinciplesDocument4 pagesRoyal Belgian Institute of Marine Engineers Basic Ship Propulsion Principlespapaki2100% (1)

- V70808 0001Document18 pagesV70808 0001maronnamNo ratings yet

- 701Document35 pages701tmtt44100% (1)

- What Are The Steering Gear Motor SafetiesDocument2 pagesWhat Are The Steering Gear Motor SafetiesRachitNo ratings yet

- Engine Top Bracing Installation and OperationDocument6 pagesEngine Top Bracing Installation and OperationSREEJUHARI100% (1)

- Some Test About RuddersDocument2 pagesSome Test About RuddersVaibhav DesaiNo ratings yet

- ME Trouble Shooting - V70320-0005Document9 pagesME Trouble Shooting - V70320-0005bkans crerercNo ratings yet

- 12596Document2 pages12596call_manishNo ratings yet

- 12596Document2 pages12596call_manishNo ratings yet

- 12596Document2 pages12596call_manishNo ratings yet

- 12596Document2 pages12596call_manishNo ratings yet

- Calendar 2014Document1 pageCalendar 2014Frank OchochoqueNo ratings yet

- Page 9 Print On Plain Paper: Follower Pin Follower Arm PinDocument4 pagesPage 9 Print On Plain Paper: Follower Pin Follower Arm PinRiadh Fantar100% (1)

- Calendar 2014Document1 pageCalendar 2014Frank OchochoqueNo ratings yet

- Calendar 2014Document1 pageCalendar 2014Frank OchochoqueNo ratings yet