Professional Documents

Culture Documents

190f02 Speed d8r Kma

Uploaded by

Ed CalheCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

190f02 Speed d8r Kma

Uploaded by

Ed CalheCopyright:

Available Formats

D8R Series II Track-Type Tractor 6YZ00001-UP (MACHINE) POWERED BY 34...

Pgina 1 de 6

Shutdown SIS

Previous Screen

Product: TRACK-TYPE TRACTOR

Model: D8R II TRACK-TYPE TRACTOR 6YZ

Configuration: D8R Series II Track-Type Tractor 6YZ00001-UP (MACHINE) POWERED BY 3406E Engine

Troubleshooting

561N, 572R and 572R Series II Pipelayers and D10R, D11R, D5M, D5N, D6M, D6N,

D6R, D6R Series II, D7R, D7R Series II and D8R Series II Track-Type Tractors

Power Train Electronic Control System

Media Number -SENR8367-18

Publication Date -01/01/2012

Date Updated -20/01/2012

i01785990

MID 113 - CID 0190 - FMI 02

SMCS - 1907-038

Conditions Which Generate This Code:

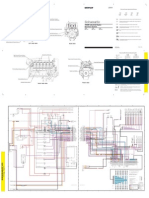

Illustration 1

g00600204

Schematic of the Engine Speed Sensor

This diagnostic code is for the engine speed sensor.

This diagnostic code is recorded when the ECM reads the signal from the engine speed sensor and

the ECM determines that the signal is erratic, intermittent or incorrect. This is determined when

https://127.0.0.1:446/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/siswe... 03/12/2014

D8R Series II Track-Type Tractor 6YZ00001-UP (MACHINE) POWERED BY 34... Pgina 2 de 6

the ECM compares the signal from the engine speed sensor to the signal from the torque converter

output speed sensor. A diagnostic code is recorded when the signal from the engine speed sensor

is below the dropout value and the engine speed is above low idle. This problem prevents the

ECM from calculating the ratio of the torque converter.

Note: The engine must be running. The engine speed signal must be received from the torque

converter output speed sensor in order for the ECM to display this diagnostic code as being

present.

Test Step 1. CHECK THE RESISTANCE OF THE SENSOR.

A. Turn the key start switch to the OFF position.

B. Disconnect the machine harness from the speed sensor.

C. Measure the resistance between the two contacts of the connector for the speed sensor.

Expected Result:

The resistance measurement should be between 110 ohms and 200 ohms.

Results:

OK - The resistance measurement is between 110 ohms and 200 ohms. The speed sensor

has not failed. Proceed to Test Step 2.

NOT OK - The resistance measurement is not between 110 ohms and 200 ohms.

Repair: The speed sensor has failed. Replace the sensor. Adjust the speed sensor properly

when the sensor is being installed. See Testing and Adjusting, "Speed Sensor - Adjust".

Verify that the new sensor corrects the problem.

Stop.

Test Step 2. CHECK THE RETURN CIRCUIT.

A. The machine harness remains disconnected from the sensor.

B. Turn the key start switch to the OFF position.

C. At the machine harness connector for the sensor, measure the resistance between contact 1

(G939-PK) and frame ground.

Expected Result:

The resistance should measure 20 ohms or less.

Results:

OK - The resistance measures 20 ohms or less. The return circuit is correct. Proceed to Test

Step 3.

NOT OK - The resistance does not measure 20 ohms or less.

Repair: The return circuit (G939-PK) in the machine harness has excessive resistance

(open). Repair the machine harness or replace the machine harness.

https://127.0.0.1:446/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/siswe... 03/12/2014

D8R Series II Track-Type Tractor 6YZ00001-UP (MACHINE) POWERED BY 34... Pgina 3 de 6

Stop.

Test Step 3. CHECK THE SIGNAL CIRCUIT FOR AN OPEN IN THE MACHINE

HARNESS.

A. At the machine harness connector for the speed sensor, place a jumper between the two

contacts.

B. Disconnect the machine harness connectors J1 and J2 from the ECM.

C. At the machine harness connectors J1 and J2, measure the resistance from J2-38 (sensor

signal) to J1-15 (the return circuit) and to J1-16 (the return circuit).

Expected Result:

There should be less than 5.0 ohms resistance.

Results:

OK - There is less than 5.0 ohms resistance. The signal circuit in the machine harness is

correct. Proceed to Test Step 4.

NOT OK - There is not less than 5.0 ohms resistance.

Repair: The signal circuit (450-YL) is open in the machine harness. Repair the machine

harness or replace the machine harness.

Stop.

Test Step 4. CHECK THE SIGNAL CIRCUIT FOR A SHORT.

A. If a jumper was used in a previous step, remove the jumper.

B. Reconnect the machine harness to the speed sensor.

C. At the harness connector J1 and harness connector J2, measure the resistance between J2-38

(450-YL) and all sources of positive voltage and ground. The possible sources of positive

voltage are contacts J1-1, J1-4, J1-6, J1-8, J1-10, J1-11, J1-12, J1-17, J1-18, J1-40, J2-1, J22, J2-7, J2-8, J2-13, J2-19, and J2-37. The possible sources of ground are contact J1-2,

contact J1-5, contact J1-7, contact J1-15, contact J1-16, contact J2-3, and frame ground.

Expected Result:

Each resistance should be greater than 5000 ohms.

Results:

OK - Each resistance is greater than 5000 ohms. The machine harness is correct. Proceed to

Test Step 5.

NOT OK - Each resistance is not greater than 5000 ohms.

Repair: There is a short in the machine harness. The short is between the signal circuit (450

-YL) and the circuit that has a low resistance measurement. Repair the machine harness or

replace the machine harness.

https://127.0.0.1:446/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/siswe... 03/12/2014

D8R Series II Track-Type Tractor 6YZ00001-UP (MACHINE) POWERED BY 34... Pgina 4 de 6

Stop.

Test Step 5. CHECK IF THE DIAGNOSTIC CODE IS STILL ACTIVE.

A. Clean the contacts of the harness connectors.

B. Reconnect all harness connectors.

C. Turn the key start switch to the ON position.

D. Start the engine and run the engine at low idle.

E. Enter service mode of the Caterpillar Monitoring System. Put the CID 0190 FMI 02

diagnostic code on hold.

F. Observe the status of the diagnostic code indicator.

Expected Result:

The diagnostic code indicator shows "SERV CODE".

Results:

YES - The diagnostic code indicator shows "SERV CODE". Proceed to Test Step 6.

NO - The diagnostic code indicator does not show "SERV CODE".

Repair: The diagnostic code is NOT present. The problem does not exist at this time. The

initial problem was probably caused by a poor electrical connection or a short at one of the

harness connectors that was disconnected and reconnected. Resume normal machine

operation.

Stop.

Test Step 6. CHECK THE ADJUSTMENT OF THE SENSOR.

A. Check the adjustment of the speed sensor. See Testing and Adjusting, "Speed Sensor Adjust".

B. Clean the contacts of the harness connectors.

C. Reconnect all harness connectors.

D. Turn the key start switch to the ON position.

E. Start the engine and run the engine at low idle.

F. Enter service mode of the Caterpillar Monitoring System. Put the CID 0190 FMI 02

diagnostic code on hold.

G. Observe the status of the diagnostic code indicator.

Expected Result:

The diagnostic code indicator shows "SERV CODE".

https://127.0.0.1:446/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/siswe... 03/12/2014

D8R Series II Track-Type Tractor 6YZ00001-UP (MACHINE) POWERED BY 34... Pgina 5 de 6

Results:

YES - The diagnostic code indicator shows "SERV CODE".

Repair: Replace the speed sensor.

Proceed to Test Step 7.

NO - The diagnostic code indicator does not show "SERV CODE".

Repair: The diagnostic code is NOT present. Adjustment of the speed sensor corrected the

failure.

Stop.

Test Step 7. CHECK IF THE DIAGNOSTIC CODE IS STILL ACTIVE.

A. Remove connector J1 and connector J2 from the ECM. Inspect the contacts and clean the

contacts of the harness connectors.

B. Reconnect all harness connectors.

C. Turn the key start switch to the ON position.

D. Enter service mode of the Caterpillar Monitoring System. Put the CID 0190 FMI 02

diagnostic code on hold.

E. Operate the machine.

F. Determine if CID 0190 FMI 02 is present.

Expected Result:

CID 0190 FMI 02 is present.

Results:

YES - CID 0190 FMI 02 is present.

Repair: Exit this procedure and perform the diagnostic code procedure again. If the

problem persists, the ECM may have failed. Prior to replacing an ECM, always contact your

dealership's Technical Communicator for possible consultation with Caterpillar. This

consultation may greatly reduce repair time. See the Testing and Adjusting, "Electronic

Control Module (ECM) - Replace".

Stop.

NO - CID 0190 FMI 02 is not present.

Repair: The problem does not exist at this time. The new speed sensor corrected the

problem. Resume normal machine operation.

Stop.

Wed Dec 3 15:30:13 EST 2014

https://127.0.0.1:446/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/siswe... 03/12/2014

D8R Series II Track-Type Tractor 6YZ00001-UP (MACHINE) POWERED BY 34... Pgina 6 de 6

Copyright 1993 - 2014 Caterpillar Inc.

All Rights Reserved.

Private Network For SIS Licensees.

https://127.0.0.1:446/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/siswe... 03/12/2014

You might also like

- 3500B Industrial Engine Electrical System: Left Side View Rear ViewDocument2 pages3500B Industrial Engine Electrical System: Left Side View Rear ViewEd Calhe0% (1)

- Whitepaper Fuel SystemsDocument8 pagesWhitepaper Fuel SystemsQaiser Iqbal100% (4)

- WOMA Technical Data All Pumps en MedidasDocument11 pagesWOMA Technical Data All Pumps en MedidasEd CalheNo ratings yet

- CompetitorsDocument4 pagesCompetitorsEd CalheNo ratings yet

- JCB JS EXCAVATOR HAMMERS GUIDEDocument1 pageJCB JS EXCAVATOR HAMMERS GUIDEEd CalheNo ratings yet

- Brant AgitatorDocument68 pagesBrant AgitatorEd CalheNo ratings yet

- Calibrating Pressure GaugesDocument4 pagesCalibrating Pressure GaugesRonny AndalasNo ratings yet

- CompetitorsDocument4 pagesCompetitorsEd CalheNo ratings yet

- Volvo Prosis 2013 VMDocument2 pagesVolvo Prosis 2013 VMEd CalheNo ratings yet

- WarrenCATDynoReport2 3508Document11 pagesWarrenCATDynoReport2 3508Ed CalheNo ratings yet

- Datasheet 2494Document1 pageDatasheet 2494Ed CalheNo ratings yet

- 3406Document2 pages3406Ed CalheNo ratings yet

- 3 Way Direct Acting Solenoid Valve SV83Document4 pages3 Way Direct Acting Solenoid Valve SV83Ed CalheNo ratings yet

- System Operation Mechanical Cat 3306 SN EpsDocument37 pagesSystem Operation Mechanical Cat 3306 SN EpsEd Calhe94% (18)

- IADC Dull Bit Grading Chart GuideDocument1 pageIADC Dull Bit Grading Chart GuideanarkasisNo ratings yet

- Westrom Cameron PartsDocument22 pagesWestrom Cameron PartsEd CalheNo ratings yet

- !rex Roller To Part Book TableDocument1 page!rex Roller To Part Book TableEd Calhe0% (1)

- Testing and Adjusting Cat 3412 SN 3fzDocument21 pagesTesting and Adjusting Cat 3412 SN 3fzEd Calhe100% (11)

- Oteco Shear Pin Relief Pressure SettingsDocument1 pageOteco Shear Pin Relief Pressure SettingsEd Calhe100% (1)

- Grooy D9Awiñg'S: Cam LineDocument1 pageGrooy D9Awiñg'S: Cam LineEd CalheNo ratings yet

- Item No. Part No. Name of Part Material No. Reqd DescriptionDocument3 pagesItem No. Part No. Name of Part Material No. Reqd DescriptionEd CalheNo ratings yet

- 261 267Document7 pages261 267Ed CalheNo ratings yet

- Request for Equipment Repair PartsDocument1 pageRequest for Equipment Repair PartsEd Calhe100% (1)

- Melco Type F and FC Manual Valve PartsDocument4 pagesMelco Type F and FC Manual Valve PartsEd CalheNo ratings yet

- Power Swivel Torque ReactionDocument6 pagesPower Swivel Torque ReactionEd CalheNo ratings yet

- Cylinder Injector Readings ReportDocument9 pagesCylinder Injector Readings ReportEd CalheNo ratings yet

- Top Driven Bowen BarcoDocument65 pagesTop Driven Bowen BarcoingcalderonNo ratings yet

- Strippers JU y JU HDocument5 pagesStrippers JU y JU HEd CalheNo ratings yet

- KG Act 3121269Document24 pagesKG Act 3121269Gustavo KemeñyNo ratings yet

- Item No. Part No. Name of Part Material No. Reqd DescriptionDocument3 pagesItem No. Part No. Name of Part Material No. Reqd DescriptionEd CalheNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ofdm PDFDocument5 pagesOfdm PDFnikitajanu100% (1)

- Dual Synchronous, Step-Down Controller With 5-V and 3.3-V LdosDocument31 pagesDual Synchronous, Step-Down Controller With 5-V and 3.3-V Ldosamrat rudiNo ratings yet

- Pipeline Locator VLoc Series 2 BrochureDocument6 pagesPipeline Locator VLoc Series 2 Brochuresashikant31No ratings yet

- Dynatel 965DSPDocument6 pagesDynatel 965DSPCatalin PancescuNo ratings yet

- Sx440 Avr Newage StamfordDocument4 pagesSx440 Avr Newage Stamfordabuzer1981No ratings yet

- IA08 Proximity Sensors Stainless Steel Housing Extended RangeDocument2 pagesIA08 Proximity Sensors Stainless Steel Housing Extended RangeAlin PetcuNo ratings yet

- Acl-03-04 - Exp-01-C PR PDFDocument6 pagesAcl-03-04 - Exp-01-C PR PDFDESMALANILS48No ratings yet

- HTTP Freecircuitdiagram - Com 2009-05-09 Dynamic-compressor-self-powered-circuit-DesignDocument4 pagesHTTP Freecircuitdiagram - Com 2009-05-09 Dynamic-compressor-self-powered-circuit-Designmahmud ibrahimNo ratings yet

- Sharlene Katz, David Schwartz and James FlynnDocument10 pagesSharlene Katz, David Schwartz and James FlynnJuan Jose PerezNo ratings yet

- EC6801 Wireless Communication PDFDocument22 pagesEC6801 Wireless Communication PDFmenakadevieceNo ratings yet

- Manual 7 PDFDocument16 pagesManual 7 PDFosair012345No ratings yet

- ESD Lab Manual PDFDocument67 pagesESD Lab Manual PDFAnonymous mg0FcO1xjNo ratings yet

- TE-6420 Standard I/O Module Technical SpecificationsDocument4 pagesTE-6420 Standard I/O Module Technical Specificationse.vicente.caballeroNo ratings yet

- Adjust headlight beam position automatically with LWRDocument4 pagesAdjust headlight beam position automatically with LWRSalisburNo ratings yet

- Phillips Manual Servicio Mc-m570Document74 pagesPhillips Manual Servicio Mc-m570José Manuel SalvatierraNo ratings yet

- Ericsson LTE TrainingDocument53 pagesEricsson LTE Trainingbybj88% (8)

- VREG and LCD ChecksDocument53 pagesVREG and LCD ChecksYe Yint AungNo ratings yet

- R&E Smoke DetectorsDocument2 pagesR&E Smoke DetectorsDario Darius100% (2)

- E5566 - MX6021 Sell Sheet R01Document2 pagesE5566 - MX6021 Sell Sheet R01Demo MxNo ratings yet

- Standard Cell LibraryDocument46 pagesStandard Cell LibraryAjay G BellamNo ratings yet

- TetraDocument14 pagesTetraEden AikaNo ratings yet

- Dfa OfficialsDocument46 pagesDfa OfficialsPierre BoNo ratings yet

- Program a remote control to operate devicesDocument2 pagesProgram a remote control to operate devicesstelianlazaroiuNo ratings yet

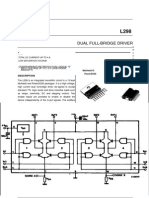

- Datasheet l298Document27 pagesDatasheet l298TikaaDantSNo ratings yet

- Brushless DC Motor ReportDocument2 pagesBrushless DC Motor ReportAnonymous 7Q1NIANo ratings yet

- Eltex - FD SensorsDocument2 pagesEltex - FD Sensorssaad naveedNo ratings yet

- Artica FreeDocument20 pagesArtica FreeClapaucius_IKEA-cheatNo ratings yet

- Fromato de Archivos ComtradeDocument4 pagesFromato de Archivos ComtrademarcospowerNo ratings yet

- DRamDocument16 pagesDRamshastryNo ratings yet