Professional Documents

Culture Documents

Deep Drawing

Uploaded by

alexmonse2014Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Deep Drawing

Uploaded by

alexmonse2014Copyright:

Available Formats

Tooling Technology

TOOLING BY DESIGN

PETER ULINTZ

Deep-Drawing GuidelinesCups Part 1

ne of the most complex metalforming operations is the deepdrawing process. In most sheetmetal-forming operations the finished

part is stretched or squeezed into a

desired shape. This is particularly true

for bending, flanging, extruding,

embossing and coining. But in deep

drawing the objective is to force the

sheetmetal to flow into a die cavity to

produce the required shape with minimal stretching and thinning of the

material.

Deep drawing can be defined as a

metalforming process in which a part is

produced from a flat sheetmetal blank

by the action of a punch force onto the

blank. The blank is pulled (drawn) into

a die cavity, which causes the flange of

the blank to compress in the circumferential direction while material flow is

controlled by a restraining force pro-

O

Peter Ulintz is Advanced Product

Engineering Manager for Anchor

Manufacturing Group, Inc., Cleveland, OH. Having worked in the

metalforming industry since 1978,

his background includes tool and

die making, tool engineering, engineering management, advanced

process planning and product

development. Ulintz has been

speaking at PMA seminars,

symposiums and roundtables

since 1996, focusing on tool and

die technology, deep-draw stamping, metalforming simulation and

vided by a blankholder.

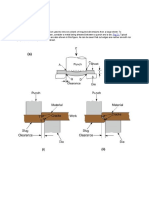

Fig. 1 illustrates the basic components in a typical draw-tool arrangement. These components include: the

blankholder and related pressure system,

a draw punch, a die cavity and a sheetmetal blank. Each of these components

contains important features critical to

the success of the drawing operation.

The draw punch applies the required

force onto the sheetmetal blank in order

to cause the material to flow into the die

cavity. The critical features of the draw

punch include the punch face and

punch-nose radius (Rpn). The punchnose radius cannot be too small as it will

try to pierce or cut the blank rather

than force the material to bend around

the radius. The minimum punch-nose

radius depends on material type and

thickness. Limitations have been established through years of empirical testing

metalforming problem solving. His

published technical works include

a computer-assisted deep-drawing

method and metalforming-simula-

Die face

tion case studies.

Die

cavity

Peter Ulintz

pete.ulintz@toolingbydesign.com

Rd

www.toolingbydesign.com

Blankholder

Blank

thickness (t)

Blankholder

Rpn

Punch face

Punch

Blankholder

pressure system

Fig. 1Draw-tool nomenclature.

52

METALFORMING / FEBRUARY 2007

www.metalformingmagazine.com

Punch radius

16t

16t

Minimum

acceptable

14t

14t

Draw Radius as a Multiple of Material Thickness

Punch Radius as a Multiple of Material Thickness

Middle of

acceptable range

12t

10t

Good

8t

6t

4t

Bad

2t

0t

0.025

0.050 0.075 0.100

Material Thickness (t) in.

0.125

Fig. 2Minimum punch-nose radii as a function of material

thickness.

and field study. Fig. 2, the result of such

testing with low-carbon steels, identifies

minimum punch-nose radii related to

the material thickness of the blank. This

ratio of radius (r) to material thickness (t) is commonly referred to as the

r/t ratio.

It is equally important to understand that as the punch-nose radius is

increased the blank will tend to stretch

on the punch face rather than draw-in

the blank edge. A large radius, especially one that is highly polished,

reduces the amount of friction on the

punch-face surface. Reducing friction

here allows the material to stretch more

easily across the punch, the path of least

resistance, instead of drawing-in the

blank edge.

When a large punch radius is

required it often is helpful to leave the

punch face rough. This increases the

coefficient of friction over the punchface surface and discourages material

flow, thus helping to pull in the blank

flange in toward the die cavity. Avoiding

lubrication between the punch face and

the blank surface also will help retard

material flow. Remember, the objective is

www.metalformingmagazine.com

Maximum

acceptable

12t

10t

Wrinkling

8t

Op

tim

um

ran

ge

6t

4t

2t

0t

Splitting

0.025

0.050

0.075

0.100

Material Thickness (t) in.

0.125

to cause the blank

edge to flow toward Fig. 3Optimizing the draw radius.

the die cavity, not to

stretch the blank over the punch face.

galling. On the other hand, an excessive

The die radius (Rd) and die-face

die radius causes the blank to wrinkle in

surface are probably the most influenthe unsupported region between the

tial features in a draw tool that uses a

punch face and the die face. When the

flat blankholder. The flat blankholder

blank wrinkles, the engineered clearance

distinction is made because some draw

between the punch and die cavity is

tools, with complex product geomereduced by the wrinkle height and

try, often have blankholders that are not

material flow is impeded and fractures

flat but have curvature that wraps the

in the stamping result.

blank prior to forming. In these tools

It is apparent that there must be

the blankholder geometry is extremely

some range of die radii to select from

critical and highly engineered with fully

that will work; not too small and not too

developed surfaces to ensure that the

big. The die radius, similar to the punch

blank wrap does not impede material

radius, depends on the r/t ratio. The

flow after the die closes. But in cup

graph in Fig. 3 helps select die radii

drawing, flat blankholders are nearly

when deep drawing low-carbon steels.

always used.

Finally, attention to detail in the dieIf the draw radius is too small the

design and tool-build process should

part may split as the material deforms.

reflect the importance of the draw-die

This is due to the high restraining forces

radius. The die radius must be absolutecaused by bending and unbending of

ly smooth, highly polished in the directhe sheetmetal over a tight radius.

tion of material flow, and blend perDrawing over a tight radius also profectly into the die wall.

duces a tremendous amount of heat.

Next month, well discuss drawThis can lead to microscopic welding of

reduction ratios and blankholder forces.

MF

the sheetmetal to the tools, known as

METALFORMING / FEBRUARY 2007

53

You might also like

- The Sheet Metal Deep DrawnDocument3 pagesThe Sheet Metal Deep DrawnjoaopedrosousaNo ratings yet

- Key Design Principles For Successful Deep DrawingDocument93 pagesKey Design Principles For Successful Deep Drawingshahzad afzal100% (5)

- Deep DrawingDocument29 pagesDeep DrawingRafael Jose Perez Pizarro100% (1)

- Deep Draw Technology 02Document40 pagesDeep Draw Technology 02joseprf6180No ratings yet

- Deep Drawing Is One of The Most Crucial and Widely Used Practices of Metal Forming. It IsDocument1 pageDeep Drawing Is One of The Most Crucial and Widely Used Practices of Metal Forming. It IsgauravNo ratings yet

- Heater DetailsDocument35 pagesHeater DetailsPushkar Pandit100% (1)

- Deep Drawing - ProjectDocument112 pagesDeep Drawing - ProjectideepujNo ratings yet

- Isostatic PressingDocument4 pagesIsostatic PressingBelma HasanovicNo ratings yet

- Chapter 2: Casting Processes: Proses TuanganDocument76 pagesChapter 2: Casting Processes: Proses TuanganhizanorhudaNo ratings yet

- Deep Drawing: Benefits and Industrial ApplicationsDocument3 pagesDeep Drawing: Benefits and Industrial ApplicationsChandru NatarajanNo ratings yet

- TALAT Lecture 3704: Deep DrawingDocument15 pagesTALAT Lecture 3704: Deep DrawingCORE MaterialsNo ratings yet

- Automation in Sheet Metal Tig Welding Process: A Case StudyDocument6 pagesAutomation in Sheet Metal Tig Welding Process: A Case StudyseventhsensegroupNo ratings yet

- Deep Drawn StampingDocument12 pagesDeep Drawn StampingJahazielNo ratings yet

- Getting Started: in This Hands-On Scenario You Will Experiment How To Quickly Position A Part in An AssemblyDocument34 pagesGetting Started: in This Hands-On Scenario You Will Experiment How To Quickly Position A Part in An Assemblyady1001No ratings yet

- Appendix A - Tolerances For Impression DieDocument21 pagesAppendix A - Tolerances For Impression Diekkozak99No ratings yet

- Die Design ParametersDocument3 pagesDie Design ParameterspunkhunkNo ratings yet

- Tool Engineering and Design Design of SiDocument23 pagesTool Engineering and Design Design of Simulugeta assefaNo ratings yet

- SHEARINGDocument6 pagesSHEARINGanmol6237No ratings yet

- Deep Drawing Process PDFDocument34 pagesDeep Drawing Process PDFCADCAM CAENo ratings yet

- Plastic Metal Forming of Metals and PowdersDocument20 pagesPlastic Metal Forming of Metals and Powdersيوسف عادل حسانينNo ratings yet

- Mini Review On Desiging of Press Tools For Sheet Metal PartsDocument11 pagesMini Review On Desiging of Press Tools For Sheet Metal Partsdhananjaya_eeeNo ratings yet

- MP SheetMetal PDFDocument48 pagesMP SheetMetal PDFNhan LeNo ratings yet

- Deep DryingDocument83 pagesDeep DryingYasir HussainNo ratings yet

- Ultrasonic Welding PDFDocument43 pagesUltrasonic Welding PDFsanmiteNo ratings yet

- Generalitati Mold DesignDocument9 pagesGeneralitati Mold DesignStefan VladNo ratings yet

- Sheet Metal Forming 2015Document84 pagesSheet Metal Forming 2015bmsschlotterbeck100% (2)

- Stretch Forming JomyDocument33 pagesStretch Forming JomyJoNo ratings yet

- Metal Forming & RollingDocument14 pagesMetal Forming & RollingAmmarNo ratings yet

- Deep Drawing Literature ReviewDocument37 pagesDeep Drawing Literature ReviewS T100% (3)

- Sheet Metal-Cup DrawingDocument25 pagesSheet Metal-Cup DrawingCADTDD100% (1)

- Dies1 2Document23 pagesDies1 2Ajay BabuNo ratings yet

- Mechanical ForgingDocument17 pagesMechanical Forgingjjonesche2100% (1)

- DFM CH 3Document44 pagesDFM CH 3Trâp A NâtïøñNo ratings yet

- Sheet Metal WorkingDocument23 pagesSheet Metal WorkingSujit MishraNo ratings yet

- Deep DrawingDocument4 pagesDeep DrawingSsk RogueNo ratings yet

- Fit Tolerance For Plastic PartsDocument16 pagesFit Tolerance For Plastic PartsA_JANNESNo ratings yet

- Basic Concepts of Sequence Design For Cold Forging Parts.Document3 pagesBasic Concepts of Sequence Design For Cold Forging Parts.david2404No ratings yet

- Horizontal High Temperature Vacuum Chamber Furnace - Schmetz, PDFDocument8 pagesHorizontal High Temperature Vacuum Chamber Furnace - Schmetz, PDFEmanuelValenciaHenao100% (1)

- 156 180Document181 pages156 180Kurnia Adi WibowoNo ratings yet

- EIN 3390 Chap 17 Sheet-Forming Processes Part 1 Spring 2012Document50 pagesEIN 3390 Chap 17 Sheet-Forming Processes Part 1 Spring 2012sudharsans88No ratings yet

- MFG Tooling - 09 Progressive Dies PDFDocument16 pagesMFG Tooling - 09 Progressive Dies PDFNhan LeNo ratings yet

- Sheet Metal Form Vinay 1226927986919169 9Document83 pagesSheet Metal Form Vinay 1226927986919169 9Nhan LeNo ratings yet

- Steel Characteristics and Their Link To Chip Breaking and Tool Wear in Metal CuttingDocument86 pagesSteel Characteristics and Their Link To Chip Breaking and Tool Wear in Metal CuttingOtoniel Reyes Galay100% (1)

- 2000 09 JIMT Cost Estimation Injection MoldingDocument11 pages2000 09 JIMT Cost Estimation Injection MoldingVictor Villouta LunaNo ratings yet

- NPTEL - Vacuum TechnologyDocument38 pagesNPTEL - Vacuum Technologyавдей александрNo ratings yet

- Sheet Metal BendingDocument30 pagesSheet Metal BendingZen P MonachanNo ratings yet

- Forging Rolling DefectsDocument14 pagesForging Rolling DefectsRavichandran GNo ratings yet

- Die and Punch AssemblyDocument14 pagesDie and Punch AssemblyPiyal ChakrabortyNo ratings yet

- Ch21 Fundamentals of Cutting2Document70 pagesCh21 Fundamentals of Cutting2manojc68No ratings yet

- Report of Battery ModelDocument13 pagesReport of Battery ModelvbvirulkarNo ratings yet

- Cutting Tool FundamentalsDocument25 pagesCutting Tool FundamentalssatenawuNo ratings yet

- TB Grinding EnglishDocument20 pagesTB Grinding EnglishVk PrabakranNo ratings yet

- Mould TechnologyDocument5 pagesMould TechnologyAkshay SarodeNo ratings yet

- Sheet Metal FormingDocument25 pagesSheet Metal Formingankushkapoor2003No ratings yet

- Deep DrawingDocument11 pagesDeep DrawingJayditya KumarNo ratings yet

- Module 7 Sheet Metal-Forming Lecture 1Document9 pagesModule 7 Sheet Metal-Forming Lecture 1ettypasewangNo ratings yet

- Presentation On Sheet Metal DesignDocument27 pagesPresentation On Sheet Metal Designniloy_67No ratings yet

- WrinklingDocument2 pagesWrinklinga c s reddyNo ratings yet

- Drawing and Stretching of MetalsDocument16 pagesDrawing and Stretching of MetalsNavdeep Singh DhakaNo ratings yet

- Sheet Metal OperationDocument2 pagesSheet Metal OperationNageswar ReddyNo ratings yet

- Google Chrome Keyboard ShortcutsDocument2 pagesGoogle Chrome Keyboard ShortcutsMaRkY A1r0E1s6No ratings yet

- Infoblox Datasheet Bloxone DdiDocument3 pagesInfoblox Datasheet Bloxone DdiSudhakar AruchamyNo ratings yet

- Design of Low Power Sram Cell With Improved Stability: Javed Akhtar AnsariDocument54 pagesDesign of Low Power Sram Cell With Improved Stability: Javed Akhtar AnsariSunil KumarNo ratings yet

- 1par Regular (New)Document8 pages1par Regular (New)Daw Aye NweNo ratings yet

- HIAB14000XGDocument267 pagesHIAB14000XGMigueNo ratings yet

- NMA 5V, 12V & 15V Series: Isolated 1W Dual Output DC/DC ConvertersDocument6 pagesNMA 5V, 12V & 15V Series: Isolated 1W Dual Output DC/DC ConvertersJoel Eljo Enciso SaraviaNo ratings yet

- Design and Development of CNC Writing and Drawing MachineDocument6 pagesDesign and Development of CNC Writing and Drawing MachineVIVA-TECH IJRINo ratings yet

- Syllabus Booklet ElectronicsDocument15 pagesSyllabus Booklet ElectronicsZuraizNawazNo ratings yet

- Warehouse ProjectDocument21 pagesWarehouse Projectpakshaheen75% (4)

- Manual de Partes JCB JS200L PDFDocument99 pagesManual de Partes JCB JS200L PDFAdolfo Martinez89% (18)

- CV Alexandru PaturanDocument1 pageCV Alexandru PaturanAlexreferatNo ratings yet

- DIO 1000 SprcificationsDocument2 pagesDIO 1000 SprcificationsJosue Rios NavaNo ratings yet

- Vantage: Installation and Operating InstructionsDocument2 pagesVantage: Installation and Operating InstructionsAngel Quijano ArmengolNo ratings yet

- Installation Instructions MODELS TS-2T, TS-3T, TS-4T, TS-5T: Rear View of PlateDocument2 pagesInstallation Instructions MODELS TS-2T, TS-3T, TS-4T, TS-5T: Rear View of PlateXavier TamashiiNo ratings yet

- Brochure South DL202Document2 pagesBrochure South DL202jimmyNo ratings yet

- T2265 PDFDocument0 pagesT2265 PDFMerlin PokamNo ratings yet

- Major Department Code Course Title Prerequisites Trimester Course Description: Credit Hours (Hour/week) L Contact Hours (Hour/week) WDocument7 pagesMajor Department Code Course Title Prerequisites Trimester Course Description: Credit Hours (Hour/week) L Contact Hours (Hour/week) Wyash1239No ratings yet

- Datbook Book High Performance HornsDocument5 pagesDatbook Book High Performance HornsSandoval JhonNo ratings yet

- Security MindsetDocument3 pagesSecurity MindsetcykablyatNo ratings yet

- Product CodeDocument20 pagesProduct CodeHEnajeNo ratings yet

- Generic PapersizesDocument3 pagesGeneric PapersizesConarch StudioNo ratings yet

- Application Note - Solaredge Inverter Support of Voltage SourcesDocument6 pagesApplication Note - Solaredge Inverter Support of Voltage Sourcesanhthong3kNo ratings yet

- Computer Organization and Assembly Language: Laboratory ManualDocument25 pagesComputer Organization and Assembly Language: Laboratory ManualMohd ShahNo ratings yet

- As 2118.6-1995 Automatic Fire Sprinkler Systems Combined Sprinkler and HydrantDocument7 pagesAs 2118.6-1995 Automatic Fire Sprinkler Systems Combined Sprinkler and HydrantSAI Global - APACNo ratings yet

- Hill David. - English for Information Technology. Level 2 (транскрипты к аудиозаписям)Document17 pagesHill David. - English for Information Technology. Level 2 (транскрипты к аудиозаписям)Ghada HamilaNo ratings yet

- Research On Soft Start Up of VSC Hvdc2Document153 pagesResearch On Soft Start Up of VSC Hvdc2Dante FilhoNo ratings yet

- 009lab Practice - Rendering 1 & 2Document1 page009lab Practice - Rendering 1 & 2iimsheungNo ratings yet

- MS Word 2. ExcelDocument13 pagesMS Word 2. ExcelKunjal PalNo ratings yet

- Manish SeminarDocument13 pagesManish SeminarIshu RajNo ratings yet

- Semiconductor KIA78R05API KIA78R15API: Technical DataDocument8 pagesSemiconductor KIA78R05API KIA78R15API: Technical DataCesar Enrique MalesNo ratings yet