Professional Documents

Culture Documents

g3520c Im Natural Gas For 1966

Uploaded by

Pankaj KambleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

g3520c Im Natural Gas For 1966

Uploaded by

Pankaj KambleCopyright:

Available Formats

GAS GENERATOR SET

Natural Gas Continuous

(Island Mode Operation)

1966 ekW 2458 kVA 50 Hz

1500 rpm 400 Volts

Image shown may not reflect actual package

Caterpillar is leading the power generation

market place with power solutions engineered

to deliver unmatched performance, reliability,

durability and cost-effectiveness.

BENEFITS

EMISSIONS

Meets most worldwide emissions requirements down

to 250 mg/NM3 Nox level without after-treatment.

FULL RANGE OF ATTACHMENTS

Wide range of bolt-on system expansion

attachments, factory designed and tested

WORLDWIDE PRODUCT SUPPORT

Caterpillar dealers have over 1,600 dealer branch

stores operating in 200 countries.

Comprehensive post-sales support including

maintenance and repair agreements that a re-tailored

to your specific equipment application.

High skilled technicians are trained to service every

aspect of your electric power generation system.

The Cat SOSsm Service monitors and tracks internal

engine component condition providing the capability to

maximize product performance and minimizing

owning and operating costs.

CAT G3520C GAS ENGINE

Robust high speed block design provides

prolonged life and lower owning and

operating costs.

Designed for maximum performance on

low pressure pipeline natural gas

Simple open chamber combustion system

for reliability and fuel flexibility

Leading edge technology in ignition system

and air/fuel ratio control for lower emission

and engine efficiency.

One electronic control module handles all

engine functions: ignition, governing,

air/fuel ratio control and engine protection

Island Mode feature improves engines

capability to handle electrical loading and

unloading.

CAT SR4B GENERATOR

Designed to match performance and

output characteristics of Caterpillar gas

engines

Industry leading mechanical and electrical

design

High efficiency

CAT EMCP II+ CONTROL PANEL

Simple user friendly interface and navigation.

Digital monitoring, metering and protection

setting.

Fully-featured power metering and protective

relaying.

Remote control and monitor capability options

LEHE8968-00

Continuous 2458 kVA 50 Hz 1500 RPM 400V

Factory Installed Standard & Optional Equipment

System

Standard

Gas Engine Control Fuel/air ratio control;

Module (GECM)

Start/stop logic: gas purge cycle, staged shutdown;

Optional

Engine Protection System: detonation sensitive timing,

high exhaust temperature shutdown;

Governor: Transient richening and turbo bypass control;

Ignition.

Island Mode Feature -- addiitonal engine control module ,

new software and engine sensores

Air Inlet

Two element, single-stage air cleaner with enclosure and

Air cleaner with precleaner; Mounting stand

service indicator

Control Panel

EMCP II+

Local alarm module; Remote annuciator;

Kilowatt transducer

Communications Module (PL1000T, PL1000E)

(ship loose for LV & MV, installed in wall mounted EMCP for HV) Synchronizing module; Engine failure relay

Cooling

Engine driven water pumps for jacket water and aftercooler;

Exhaust

Remote radiator for JW and SCAC circuits,

Jacket water and SCAC thermostats;

level switch included but not wired,

ANSI/DN customer flange connections for JW inlet and outlet

coolant level drain line with valves, fan with guard;

Cat flanges on SCAC circuit

Inlet/Outlet connections.

Dry exhaust manifolds, insulated and shielded;

Flange; Exhaust expander; Elbow; Flexible fitting;

Center section cooled turbocharger with Cat flanged outlet;

Muffler and spark-arresting muffler with companion

Individual exhaust port and turbocharger outlet wired to

flanges.

Integrated Temperature Sensing Module (ITSM) with GECM

providing alarms and shutdowns.

Fuel

Electronic fuel metering valve;

Fuel filter;

Throttle plate, 24V DC actuator, controlled by GECM;

Gas pressure regulator;

Fuel system is sized for 31.5 to 47.2 MJ/NM3 (800 to 1200

Gas shutoff valve, 24V, ETR (Energized-To-Run)

Btu/cu ft) dry pipeline natural gas with pressure of 10.2 to 34.5

kPa (1.5 to 5 psi) to the engine fuel control valve.

Generator

SR4B generator, includes:

Medium and high voltage generators and attachments;

Caterpillar's Digital Voltage Regulator (CDVR) with 3-phase

Low voltage extension box; Cable access box;

sensing and KVAR/PF control; Reactive droop;

Air filter for generator; Bearing temperature detectors;

Bus bar connections; Winding temperature detectors;

Manual voltage control; European bus bar.

Anti-condensation space heater.

Governing

Electronic speed governor as part of GECM;

Woodward load sharing module

Electronically-controlled 24V DC actuator connected to

throttle shaft.

Ignition

Electronic Ignition System controlled by GECM;

Individual cylinder Detonation Sensitive Timing (DST)

Lubrication

Lubricating oil; Gear type lube oil pump; Oil filter, filler and dipstick Oil level regualtor; Prelube pump;

Integral lube oil cooler; Oil drain valve; Crankcase breather.

Mounting

Positive crankcase ventilation system

330 mm structural steel base (for low and medium voltage units);

Spring-type anti-vibration mounts (shipped loose)

Starting / Charging 24V starting motors; Battery with cables and rack (shipped loose) Charging alternator; Battery charger;

Battery disconnect switch;

Oversized battery; Lacket water heater;

60A, 24V charging alternator (standard on 60Hz 1800rpm only)

General

LEHE8968-00

Paint -- Caterpillar Yellow except rails & radiators;

Crankcase explosion relief valve;

Damper guard.

Engine barring group;

Operation and Maintenance Manuals; Parts Book.

EEC D.O.I and other certifications

Continuous 2458 kVA 50 Hz 1500 RPM 400V

SPECIFICATIONS

CAT GAS ENGINE

CAT EMCPII+ CONTROL PANAL

* Power by 24 volts DC

G3520C SCAC 4-stroke-cycle watercooled gas engine

Number of Cylinders ------------------------------------------V20

* NEMA 12, IP44 dust-proof enclosure

Bore --- mm (in) ------------------------------------------------170 (6.7)

* Lockable hinged door

Stroke --- mm (in) ----------------------------------------------190 (7.5)

* Single-location customer connection

Displacement --- L (cu in) -----------------------------------86.3 (5266)

* Auto start/stop control switch

Compression Ratio -------------------------------------------11.3:1

* Voltage adjustment potentiomenter

Aspiration -------------------- Turbocharged Separate Circuit Aftercooled

* True RMS AC metering, 3 phase

Cooling Type ---- Two stage aftercooler, JW + O/C + A/C 1 combined

* Pruge cycle and staged shutdown logic

Fuel System ------------------------------------------------------ Low Pressure

* Digital indication for:

Governor Type ------------------------------------------ Electronic (ADEM TM III)

RPM

Operating hours

CAT SR4B GENERATOR

Oil pressure

Frame size -------------------------------------------------------828

Coolant temperature

Excitation ------------------------------------------------------ Permanent Magnet

DC voltage

Pitch ---------------------------------------------------------------0.7778

L-L volts, L-N volts, phase amps, Hz,

Number of poles -----------------------------------------------4

ekW, kVA, kVAR, kWhr, %kW, pf

Number of bearings ------------------------------------------2

System diagnostic codes

Number of leads -----------------------------------------------6

* Shutdown with indicating lights;

Insulation --------------------------------------------------------Class H

Low oil pressure

IP rating ------------------------------------------------------------ Drip proof IP22

High coolant temperature

Alignment --------------------------------------------------------Pilot shaft

High oil temperature

Overspeed capability -- % of rated ------------------------125%

Overspeed

Waveform deviation line to line, no load ------------------ less than 2.0%

Overcrank

Paralleling kit droop transformer --------------------------Standard

Emergency stop

Voltage regulator -----------------------------------------------CDVR

High inlet air temperature (for TA engine only)

Voltage regulation ---------------------------------------------+/- 0.5%

Detonation sensitive timing (for LE engine only)

Telephone Influence Factor (TIF) --------------------------less than 50

* Programmable protective relaying functions:

Total Harmonic Distortion (THD) --------------------------- less than 3.0%

Under / Over voltage

Under / Over frequency

Consult your Caterpillar dealer for available voltage

Overcurrent

Reverse power

* Spare indicator LEDs

* Spare alarm/shutdown inputs

Materials and specifications are subject to change without notice.

The International System of Units (SI) is used in this publication.

LEHE8968-00

Continuous 2458 kVA 50 Hz 1500 RPM 400V

TECHNICAL DATA

G3520C Gas Generator Set (Island Mode)

Emission level (NOx)

mg/N.M3

Aftercooler SCAC (Stage 2)

Deg C

DM 8636

DM 8637

500

250

54

54

Package Performance (1)

Power Rating @ 0.8 pf (w/ 2 water pumps and w/o fan)

ekW Continuous

1966

1966

Power Rating @ 0.8 pf (w/ 2 water pumps and w/o fan)

kVA Continuous

2458

2458

Power Rating @ 1.0 pf (w/ 2 water pumps and w/o fan)

ekW Continuous

1986

1986

Electric Efficiency @ 1.0 pf (ISO 3046/1)

40.4

39.5

bkW

2035

2035

100% load w/o fan

NM3/hr

498

509

75% load w/o fan

NM3/hr

385

394

50% load w/o fan

NM3/hr

271

277

1250

950

(2)

Mechanical Power (w/ 2 water pumps and w/o fan)

Fuel Consumption (3)

Altitude Capability (4)

At 25 Deg C (77 Deg F) ambient, above sea level

Cooling System

Ambient air temperature

Jacket water temperature ( Maximum outlet )

Deg C

25

25

Deg C

99

99

Exhaust System

Combustion air inlet flow rate

NM3/min

143

148

Exhaust stack gas temperature

Deg C

472

471

Exhaust gas flow rate

NM3/min

152

157

Exhaust flange size ( internal diameter )

mm

360

360

Heat rejection to jacket water and oil cooler and AC - Stag kW

1030

1074

Heat rejection to AC - Stage 2

kW

175

180

Heat rejection to exhaust (LHV to 25 Deg C)

kW

1629

1689

Heat rejection to exhaust (LHV to 120 Deg C)

kW

1259

1295

Heat rejection to atmosphere from engine

kW

138

138

Heat rejection to atmosphere from generator

kW

69

69

828

828

Heat Rejection (5)

Generator

Frame

Temperature rise

Deg C

105

105

Motor starting capability @ 30% voltage dip (6)

skVA

4557

4557

541

541

Lubrication System

Standard sump refill with filter change

Emissions (7)

NOx @ 5% O2 (dry)

mg/N.M3

500

250

CO @ 5% O2 (dry)

mg/N.M3

1076

974

THC @ 5% O2 (dry)

mg/N.M3

2331

2548

NMHC @ 5% O2 (dry)

mg/N.M3

350

383

9.4

9.7

Exhaust O2 (dry)

LEHE8968-00

Continuous 2458 kVA 50 Hz 1500 RPM 400V

CONDITIONS AND DEFINITIONS

DEFINITIONS AND CONDITIONS

(1) Continuous --- Maximum output available for an unlimited time

Ratings are based on pipeline natural gas having a Low Heat Value

(LHV) of 35.6 MJ/NM3 (905 Btu/ft3) and 80 Caterpillar Methane Number.

For values in excess of altitude, ambient temperature, inlet/exhaust restriction,

or different from the conditions listed, contact your local Caterpillar dealer.

(2) Efficiency of standard generator is used. For higher efficiency generators, contact

your local Caterpillar dealer.

(3) Ratings and fuel consumption are based on ISO3046/1 standard reference conditions of

25 deg C (77 deg F) of ambient temperature and 100 kPa (29.61 in Hg) of total barometic

pressure, 30% relative humidity with 0, +5% fuel tolerance.

(4) Altitude capability is based on 2.5 kPa air filter and 5.0 kPa exhaust stack restrictions.

(5) Heat Rejection --- Values based on nominal data with fuel tolerence of +/-2.5% and

2.5 kPa inlet and 5.0 kPa exhaust restrictions.

(6) Assume synchronous driver

(7) Emissions data measurements are consistent with those described in EPA CFR

40 Part 89 Subpart D & E and ISO8178-1 for measuring HC, CO, PM, NOx. Data shown

is based on steady state engine operating conditions of 25 deg C (77 deg F), 96.28 kPa

(28.43 in Hg) and fuel having a LHV of 35.6 MJ/NM3 (905 Btu/cu ft) and 80 Caterpillar

Methane Number at 101.60 kPa (30.00 in Hg) absolute and 0 deg C (32 deg F).

Emission darta shown is subject to instrumentation, measurement, facility, and engine

fuel system adjustment.

LEHE8968-00

Continuous 2458 kVA 50 Hz 1500 RPM 400V

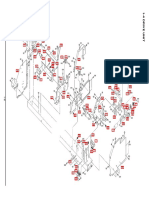

DIMENSIONS

Package Dimensions

Length

Width

Height

Approx. Shipping Weight

6316.0 mm

1827.5 mm

2254.0 mm

18 350 kg

248.66 in

71.95 in

88.74 in

40 437 lb

Note: Do not use for installation design.

See general dimension drawings

for detail ( Drawing # 326-8028 ).

Performance Number: DM8636, DM8637

Feature Code: 520GE59

Generator Arrangement: 144-1830

Information contained in this publication may be considered confidential. Discretion is recommended when distributing.

Materials and specifications are subject to change without notice. CAT, CATERPILLAR, their respective logos,

Caterpillar Yellow and the POWER EDGE trade dress, as well as corporate and product identity used herein,

are trademarks of Caterpillar and may not be used without permission.

http://www.cat-electricpower.com/

U.S. Sourced

LEHE8968-00 (09/08)

LEHE8968-00

2008 Caterpillar

All Rights Reserved.

Printed in U.S.A.

You might also like

- AURTTC103 Assessment 1 Written Knowledge Questions V3Document28 pagesAURTTC103 Assessment 1 Written Knowledge Questions V3RomanaIjazNo ratings yet

- GS02 directional proportional solenoid valve specifications and performance dataDocument2 pagesGS02 directional proportional solenoid valve specifications and performance dataAdal VeraNo ratings yet

- Hydraulic Diagram For Liebherr 544Document12 pagesHydraulic Diagram For Liebherr 544Liebherr100% (1)

- Service Manual: RP5500, RP6500 E, and RP7500 E Portable GeneratorsDocument126 pagesService Manual: RP5500, RP6500 E, and RP7500 E Portable GeneratorsMouh ElobeyNo ratings yet

- WoodWard Egcp 2Document4 pagesWoodWard Egcp 2Julian Pompy Buitrago Carrascal100% (1)

- RMG 324 20 en 2012 09Document11 pagesRMG 324 20 en 2012 09Candiano PopescuNo ratings yet

- FEPA Gas-over-oil ActuatorsDocument4 pagesFEPA Gas-over-oil Actuatorstoader56No ratings yet

- Slam Shut Off FlowgridDocument16 pagesSlam Shut Off FlowgridmateuNo ratings yet

- 399ADocument24 pages399ADana Mera100% (2)

- HP Regulators v2Document9 pagesHP Regulators v2Danny SánchezNo ratings yet

- FloBoss™ S600+ Flow Computer Instruction Manual PDFDocument152 pagesFloBoss™ S600+ Flow Computer Instruction Manual PDFSibabrata ChoudhuryNo ratings yet

- Pressure-Operated Valves Series 290-390-298-398Document8 pagesPressure-Operated Valves Series 290-390-298-398Nelson AlvarezNo ratings yet

- HUBA 691 Pressure TransmitterDocument4 pagesHUBA 691 Pressure TransmitterkuraimundNo ratings yet

- Solenoid Operated Valves: Nuclear Power GenerationDocument12 pagesSolenoid Operated Valves: Nuclear Power GenerationVeerabhadra BujurkeNo ratings yet

- 8155 PPI Chapter Explains Programmable Peripheral InterfaceDocument12 pages8155 PPI Chapter Explains Programmable Peripheral InterfacebelihuNo ratings yet

- Manual Regulators Man Slamshut 2-4inchDocument20 pagesManual Regulators Man Slamshut 2-4inchDelfin Rosanieto TapiaNo ratings yet

- Easy-to-Use Paralleling Controller for Gen-SetsDocument6 pagesEasy-to-Use Paralleling Controller for Gen-SetsThao Nguyen XuanNo ratings yet

- Dse7210 20 DiagramDocument3 pagesDse7210 20 DiagramErmanNo ratings yet

- IC 8155 InformationDocument13 pagesIC 8155 InformationKajol PhadtareNo ratings yet

- Documents - MX Grinnellfirepanel PDFDocument8 pagesDocuments - MX Grinnellfirepanel PDFcchristt2584No ratings yet

- FloBoss IO ModulesDocument5 pagesFloBoss IO ModulesAdeel HassanNo ratings yet

- Intro Process Xmitters (Suresh)Document33 pagesIntro Process Xmitters (Suresh)sreeyukthaNo ratings yet

- EZR Installation ManualDocument40 pagesEZR Installation ManualRoberto Aldayuz HerediaNo ratings yet

- G3516H Spec - 400vDocument3 pagesG3516H Spec - 400vAbstruse RonNo ratings yet

- G761 CDS6673 D Moog Trubleshooting ManualDocument4 pagesG761 CDS6673 D Moog Trubleshooting ManualRamesh BabuNo ratings yet

- 8255 - SeminarDocument28 pages8255 - SeminarJKNo ratings yet

- TIB-723-GB-0613 AP 2way Valves With Electric Actuator English PDFDocument67 pagesTIB-723-GB-0613 AP 2way Valves With Electric Actuator English PDFnguyenvanhai19031981No ratings yet

- 67Document10 pages67johnnylim456No ratings yet

- F 0077 e 55Document6 pagesF 0077 e 55Bùi Cảnh TrungNo ratings yet

- ML434 V12 D758Document40 pagesML434 V12 D758darkchess76No ratings yet

- Solar Centaur 40 DSDocument2 pagesSolar Centaur 40 DSabuahnfNo ratings yet

- Type Ezr EstancoDocument40 pagesType Ezr EstancoJuan JuanNo ratings yet

- G3516B-1300 KW PDFDocument6 pagesG3516B-1300 KW PDFgerrzen64No ratings yet

- N67 TE2F: 1/ GeneralDocument3 pagesN67 TE2F: 1/ General林哲弘100% (1)

- Why 4-20 Ma Signal Is Used in Industrial Instrumentation?: Google ChromeDocument2 pagesWhy 4-20 Ma Signal Is Used in Industrial Instrumentation?: Google Chromemunro_85No ratings yet

- Altronic EPC-110/120 Air-Fuel Controller Operating ManualDocument55 pagesAltronic EPC-110/120 Air-Fuel Controller Operating Manualfrancis_mouille_iiNo ratings yet

- Per EmcDocument802 pagesPer Emcapi-3709675No ratings yet

- FCDocument46 pagesFCJcRodriguezNo ratings yet

- Omni Flow Computer ManualDocument57 pagesOmni Flow Computer ManualRifki AsfariNo ratings yet

- D12 MH Volvo Penta Inboard Diesel Engine Technical SpecsDocument4 pagesD12 MH Volvo Penta Inboard Diesel Engine Technical Specszulu800% (1)

- Anexo 2. D103605X012 DVC6200 Instruction Manual PDFDocument104 pagesAnexo 2. D103605X012 DVC6200 Instruction Manual PDFJairo andres Guarnizo SuarezNo ratings yet

- Directional Valves WebinarDocument18 pagesDirectional Valves WebinarhaggNo ratings yet

- Getting The Best Measurement From Your Turbine Meters: M.SC., P.EngDocument6 pagesGetting The Best Measurement From Your Turbine Meters: M.SC., P.Engwaheed100% (1)

- Marine Galley PDFDocument218 pagesMarine Galley PDFclodNo ratings yet

- Device Summary EnglishDocument14 pagesDevice Summary Englishكاظم محمدNo ratings yet

- Section 3 Gas Turbines Start SystemsDocument14 pagesSection 3 Gas Turbines Start SystemsPodeh AspriyantoNo ratings yet

- Sailor RE-2100Document186 pagesSailor RE-2100Fernando SuarezNo ratings yet

- L5794gsi (E) pb7058-0905Document2 pagesL5794gsi (E) pb7058-0905ikatparNo ratings yet

- Adjust Axial Bently Nevada ProbesDocument3 pagesAdjust Axial Bently Nevada Probesmic-grNo ratings yet

- GSM Controlled Automatic Irrigation System Using 8051 Microcontroller OriginalDocument13 pagesGSM Controlled Automatic Irrigation System Using 8051 Microcontroller Originalamism24No ratings yet

- Speed ControlDocument38 pagesSpeed ControlewfsdNo ratings yet

- Proinert® Cylinder Completer Kit - Ig-541Document2 pagesProinert® Cylinder Completer Kit - Ig-541Марко НакићNo ratings yet

- SECTION 5.35: Exhaust SystemDocument30 pagesSECTION 5.35: Exhaust SystemLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Altronic DD20 Annunciator and TachmotersDocument31 pagesAltronic DD20 Annunciator and TachmotersVladimirNo ratings yet

- PLC & HMI Training Program at Government Polytechnic, PuneDocument4 pagesPLC & HMI Training Program at Government Polytechnic, PunemanisegarNo ratings yet

- TX2/RX2 Remote Controller With Five Functions: FeaturesDocument8 pagesTX2/RX2 Remote Controller With Five Functions: FeaturesRambo333No ratings yet

- RE50214 Nivometer PDFDocument16 pagesRE50214 Nivometer PDFCaspar Heerkens100% (1)

- Air Compressor (V Type)Document19 pagesAir Compressor (V Type)Anindya ChakrabortyNo ratings yet

- Gas EngineDocument6 pagesGas EngineMRizwanSadiq313No ratings yet

- G3520 Lehe2832 02 PDFDocument6 pagesG3520 Lehe2832 02 PDFCostas Aggelidis100% (1)

- G3508 - 600kvaDocument7 pagesG3508 - 600kvaJim Patrick ChombaNo ratings yet

- g3520c Natural Gas For 1950Document6 pagesg3520c Natural Gas For 1950Shahzad AliNo ratings yet

- G3516 (975 Ekw 1218 kVA)Document7 pagesG3516 (975 Ekw 1218 kVA)Antwon CharlesNo ratings yet

- RAABTA - Ik Vaari Aa Chords and Lyrics - ChordZoneDocument2 pagesRAABTA - Ik Vaari Aa Chords and Lyrics - ChordZonePankaj KambleNo ratings yet

- RedBus Ticket TK4584488458 BNG To Mum 7th MarchDocument2 pagesRedBus Ticket TK4584488458 BNG To Mum 7th MarchPankaj KambleNo ratings yet

- 3 TMF Crack InitiationDocument8 pages3 TMF Crack InitiationPankaj KambleNo ratings yet

- Process Plant Piping OverviewDocument133 pagesProcess Plant Piping Overviewskdalalsin100% (8)

- Reconditioning Gas Turbine Components Quality Control Assessment MethodDocument8 pagesReconditioning Gas Turbine Components Quality Control Assessment MethodPankaj KambleNo ratings yet

- Brochure Engine 51-60GDocument7 pagesBrochure Engine 51-60GAnonymous 0irJN2UINo ratings yet

- Reconditioning Gas Turbine Components Cleaning BrazingDocument4 pagesReconditioning Gas Turbine Components Cleaning BrazingPankaj KambleNo ratings yet

- Planning DetailsDocument4 pagesPlanning DetailsPankaj KambleNo ratings yet

- Saarang TicketsDocument3 pagesSaarang TicketsPankaj KambleNo ratings yet

- Non Destructive Testing of Rotors From The BoreDocument2 pagesNon Destructive Testing of Rotors From The BorePankaj KambleNo ratings yet

- Ts EnglishDocument24 pagesTs EnglishPankaj KambleNo ratings yet

- TSI Rotostat Profile Latest1Document39 pagesTSI Rotostat Profile Latest1Pankaj KambleNo ratings yet

- 5160DF PowerDocument7 pages5160DF PowerPankaj Kamble100% (1)

- Gas Power PlantsDocument9 pagesGas Power PlantsPankaj KambleNo ratings yet

- 3544G PowerDocument13 pages3544G PowerPankaj KambleNo ratings yet

- 4860 PowerDocument7 pages4860 PowerPankaj KambleNo ratings yet

- SFGLD560Document2 pagesSFGLD560Pankaj KambleNo ratings yet

- 4860TS PowerDocument7 pages4860TS PowerPankaj KambleNo ratings yet

- SFGLD480Document2 pagesSFGLD480Pankaj KambleNo ratings yet

- SFGLD240Document2 pagesSFGLD240Pankaj KambleNo ratings yet

- Datasheet of MWM-DeUTZ Gas Generator EM-1250NDocument1 pageDatasheet of MWM-DeUTZ Gas Generator EM-1250NPankaj KambleNo ratings yet

- SFGLD180Document2 pagesSFGLD180Pankaj KambleNo ratings yet

- Natural Gas Generator 58Document4 pagesNatural Gas Generator 58Pankaj KambleNo ratings yet

- SFGLD360Document2 pagesSFGLD360Pankaj KambleNo ratings yet

- Ettes Power Biomass Gas Generator SetsDocument1 pageEttes Power Biomass Gas Generator SetsPankaj KambleNo ratings yet

- LEXE0839 00 - 1 UDocument2 pagesLEXE0839 00 - 1 UPankaj KambleNo ratings yet

- GU GasEnginesDocument2 pagesGU GasEnginesPankaj KambleNo ratings yet

- MWM DEUTZ Natural Gas Generator 63Document1 pageMWM DEUTZ Natural Gas Generator 63Pankaj KambleNo ratings yet

- EP 4page BrochureREV2013Document2 pagesEP 4page BrochureREV2013Pankaj KambleNo ratings yet

- Lexe7582 05Document44 pagesLexe7582 05Pankaj KambleNo ratings yet

- Operating & Maintenance manual-RM-290AC'J'Document33 pagesOperating & Maintenance manual-RM-290AC'J'faqdaniNo ratings yet

- Aerzen Usa TB Series Turbo Brochure PDFDocument4 pagesAerzen Usa TB Series Turbo Brochure PDFherrerafaridNo ratings yet

- Universal MotorDocument4 pagesUniversal MotorarunNo ratings yet

- Marinediesel Duramax 300 HP 500 HPDocument2 pagesMarinediesel Duramax 300 HP 500 HPMaurizio BernasconiNo ratings yet

- Roland XC-540 Drive UnitDocument2 pagesRoland XC-540 Drive Unitigino biaginiNo ratings yet

- Tractor Design and TestingDocument235 pagesTractor Design and TestingCristian-Nicolae Spulber100% (1)

- Quo GCMDocument11 pagesQuo GCMcost_engineerNo ratings yet

- Carrier 40mphaq12xa3 Article 2478185340526029 en SMDocument48 pagesCarrier 40mphaq12xa3 Article 2478185340526029 en SMWilliam TayNo ratings yet

- Troubleshooting Rub Marks in A Centrifugal PumpDocument4 pagesTroubleshooting Rub Marks in A Centrifugal Pumpابو المعالي الهمامNo ratings yet

- 04-Coupling 304 Motor-Gear PDFDocument12 pages04-Coupling 304 Motor-Gear PDFManuel Díaz VilloutaNo ratings yet

- Propeller Equipment: Installation DrawingsDocument36 pagesPropeller Equipment: Installation DrawingsSergei KurpishNo ratings yet

- Operator Parts IdentificationDocument3 pagesOperator Parts IdentificationRodolfo Franco RFNo ratings yet

- Air Cylinder: Female Rod End Available As Standard Rod End Styles Suitable For The Application Can Be SelectedDocument96 pagesAir Cylinder: Female Rod End Available As Standard Rod End Styles Suitable For The Application Can Be SelectedDobos LászlóNo ratings yet

- Sonnax Planet Rebuild KitsDocument4 pagesSonnax Planet Rebuild Kitsacmemail583No ratings yet

- QSK45C HTC2500Document137 pagesQSK45C HTC2500Nova kurniawan 34No ratings yet

- Hvac - Centralized AC SystemDocument21 pagesHvac - Centralized AC SystemVala Vraj M.No ratings yet

- Installation and Maintenance Instructions: Resilient Seat Butterfly ValvesDocument12 pagesInstallation and Maintenance Instructions: Resilient Seat Butterfly ValvesBhargav PatelNo ratings yet

- C100 Spare Parts Catalogue-R1Document19 pagesC100 Spare Parts Catalogue-R1cengiz karahanNo ratings yet

- Manual Del Motor Aeronautico LycomingDocument80 pagesManual Del Motor Aeronautico LycomingWalter Gutierrez100% (2)

- MBE4000 Serv ManDocument587 pagesMBE4000 Serv ManRicardo Diaz95% (19)

- BAIC SENOVA X25 CatalogueDocument3 pagesBAIC SENOVA X25 Cataloguecifer.xiongNo ratings yet

- DL550 - Specification Sheet - 20160502Document27 pagesDL550 - Specification Sheet - 20160502AbdelrahmanNo ratings yet

- Internal Combustion Engine Testing RequirementsDocument2 pagesInternal Combustion Engine Testing RequirementsokaNo ratings yet

- Parking Brake System: SectionDocument10 pagesParking Brake System: SectionPiyapong SaerimNo ratings yet

- Air Conditioning TechnicianDocument3 pagesAir Conditioning Technicianaungmyothant7792No ratings yet

- Wave SpringsDocument8 pagesWave SpringsHenrique SouzaNo ratings yet

- Reciprocating Compressors Capacity Control MethodsDocument8 pagesReciprocating Compressors Capacity Control MethodsChem.EnggNo ratings yet