Professional Documents

Culture Documents

Subminiature Models Capable of Large-Capacity Load of 7A: Ultra Subminiature Basic Switch

Uploaded by

Luthie SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Subminiature Models Capable of Large-Capacity Load of 7A: Ultra Subminiature Basic Switch

Uploaded by

Luthie SinghCopyright:

Available Formats

J

Ultra Subminiature Basic Switch

Subminiature Models

Capable of Large-capacity

load of 7A

Snap-action switch allows large-capacity

switching (7A at 250 VAC) in spite of its small

size.

Particularly suitable as control switches for

applications where there are restrictions on

installation space and weight.

RoHS Compliant

Model Number Legend

Contact Form

SPDT

1

J-7- @

1. Actuator

None : Pin plunger

V : Short hinge lever

V22 : Short hinge roller lever

V2 : Hinge roller lever

V3 : Hinge lever

COM

Contact Specifications

V4 : Long hinge lever

Specification

Contact

List of Models

Actuator

NO NC

Material

Rivet

Silver alloy + Gold plated

Gap (standard value)

Model

0.35 mm

Minimum applicable load (reference value)

5 VDC 1 mA

Pin plunger

J-7

Short hinge lever

J-7-V

Short hinge roller lever

J-7-V22

Hinge roller lever

J-7-V2

Hinge lever

J-7-V3

Note. The above rating values apply under the following test conditions.

(1) Ambient temperature: 202C

(2) Ambient humidity: 655%

(3) Operating frequency: 30 operations/min

Long Hinge Lever

J-7-V4

Approved Safety Standards

Note. Consult your OMRON sales representative for specific models with safety

standard approvals.

Ratings

Rated voltage

Resistive load

125 VAC

250 VAC

7A

7A

Consult your OMRON sales representative for specific

models with safety standard approvals.

UL (UL508)/CSA (CSA C22.2 No.55)

Rated voltage

Model

125 VAC

250 VAC

J-7

7A

7A

Subminiature Basic Switch

Characteristics

Permissible operating speed

Permissible operating

frequency

0.05 mm to 1 m/s (for pin plunger models)

Mechanical

400 operations/min max.

Electrical

30 operations/min max.

Insulation resistance

100 m min. (at 500 VDC with insulation tester)

Contact resistance (initial value)

Dielectric strength

Vibration resistance *1

Shock resistance *1

Durability *2

15 m max.

Between terminals of the same polarity

600 VAC 50/60 Hz for 1 min

Between current-carrying metal parts and ground

1,500 VAC 50/60 Hz for 1 min

Between each terminals and non-current-carrying metal parts

1,500 VAC 50/60 Hz for 1 min

Malfunction

10 to 55 Hz, 1.5 mm double amplitude

Durability

1,000 m/s2 max.

Malfunction

200 m/s2 max. (pin plunger models)

Mechanical

10,000,000 operations min. (60 operations/min)

Electrical

50,000 operations min. (30 operations/min)

Degree of protection

IEC IP40

Ambient operating temperature

-10C to +80C (at ambient humidity of 60% max.)

(with no icing or condensation)

Ambient operating humidity

85% max. (for +5C to +35C)

Weight

Approx. 1 g (pin plunger models)

Note. The data given above are initial values.

*1. For the pin plunger models, the above values apply for use at the free position, operating position, and total travel position. For the lever models, they apply for

the total travel position. Close or open circuit of the contact is shorter than 1 ms.

*2. For testing conditions, consult your OMRON sales representative.

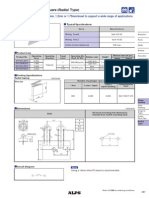

Dimensions (Unit: mm) and Operating Characteristics

Pin Plunger

J-7

3.5 dia.

1.5 dia.

PT

Operating Characteristics

R0.8

OP

8.9

2.3

2.35+0.05

-0.025

3.95

4.80.05

12.7

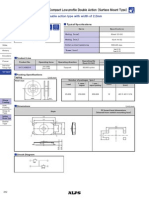

Short Hinge Lever

J-7-V

5.1

0.05

2.5+0.05

-0.025 dia.

J-7

OF

RF

Max.

Min.

1.37 N {140 gf}

0.27 N {28 gf}

Pretravel

Overtravel

Movement Differential

PT

OT

MD

Max.

Min.

Max.

0.6 mm

0.1 mm

0.15 mm

Operating Position

OP

8.10.3 mm

1 dia.

1.5 dia.

2.35+0.05

-0.025 dia.

5.10.1

9.3

R12.70.4

PT

A t=0.3*

9.150.4 8

6.6

2.3

2.35+0.05

-0.025

2.3

5.1

* Stainless-steel lever

t=0.3*

PT

R220.4

Max.

Min.

0.49 N {50 gf}

0.09 N {9 g}

Pretravel

Overtravel

Movement Differential

PT

OT

MD

Max.

Min.

Max.

1.7 mm

0.35 mm

0.5 mm

Operating Position

OP

9.150.4 8

6.6

2.3

2.3

OP

5.1

0.05

2.5+0.05

-0.025 dia.

3.95

4.80.05

12.7

14.7

8.31.2 mm

5.10.1

Operating Characteristics

2.35+0.05

-0.025

J-7-V

OF

RF

1.5 dia.

2.35+0.05

-0.025 dia.

4.80.05

12.7

14.7

9.3

Models

Operating Force

Releasing Force

1 dia.

3.95

Hinge Lever

J-7-V3

Operating Characteristics

OP

+0.05

2.5-0.025

-0.025 dia.

2.35+0.05

-0.025

1 dia.

1.5 dia.

dia.

* Stainless-steel lever

Note 1. Unless otherwise specified, a tolerance of 0.2 mm applies to all dimensions.

Note 2. The operating characteristics are for operation in the A direction ( ).

Models

Operating Force

Releasing Force

5.10.1

Models

J-7-V3

Operating Force

Releasing Force

OF

RF

Max.

Min.

0.29 N {30 gf}

0.05 N {5 gf}

Pretravel

Overtravel

Movement Differential

PT

OT

MD

Max.

Min.

Max.

2.9 mm

0.5 mm

0.7 mm

Operating Position

OP

8.31.9 mm

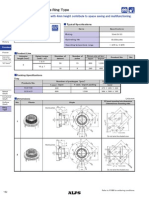

Subminiature Basic Switch

Long Hinge Lever

J-7-V4

t=0.3*

9.3

PT

9.150.4 8

6.6

2.3

2.35+0.05

-0.025

Operating Force

Releasing Force

OP

5.1

Operating Position

2.35+0.05

-0.025 dia.

OP

8.32.9 mm

PT

4.8x2.2* dia.

Models

Operating

Characteristics

Operating Force

Releasing Force

OP

OF

RF

Max.

Min.

Pretravel

PT Max.

Overtravel

OT Min.

Movement Differential MD Max.

9.150.4 8

8.9

2.3

Operating Position

2.8

0.05

2.5+0.05

-0.025 dia.

4.80.05

12.7

14.7

4.5 mm

0.8 mm

1.2 mm

1.5 dia.

* Stainless-steel lever

3.95

J-7-V4

0.20 N {20 gf}

0.03 N {3 gf}

5.10.1

R11.50.4

2.35+0.05

-0.025

Max.

Min.

1 dia.

4.80.05

12.7

14.7

9.3

OF

RF

Pretravel

PT Max.

Overtravel

OT Min.

Movement Differential MD Max.

0.05

2.5+0.05

-0.025 dia.

3.95

Short Hinge Roller Lever

J-7-V22

Models

Operating

Characteristics

2.3

R33.80.4

OP

J-7-V22

0.54 N {55 gf}

0.05 N {5 gf}

1.6 mm

0.25 mm

0.4 mm

14.71 mm

1 dia.

2.35+0.05

-0.025 dia.

1.5 dia.

5.10.1

* Stainless-steel lever

Stainless-steel roller

Hinge Roller Lever

J-7-V2

PT

4.8x2.2* dia.

R20.50.4

9.3

Operating Force

Releasing Force

OP

9.150.4 8

4.80.05

Max.

Min.

Operating Position

OP

J-7-V2

0.33 N {33 gf}

0.03 N {3 gf}

2.7 mm

0.45 mm

0.7 mm

14.71.9 mm

5.1

0.05

2.5+0.05

-0.025

0.025 dia.

3.95

OF

RF

Pretravel

PT Max.

Overtravel

OT Min.

Movement Differential MD Max.

6.6

2.3

2.35+0.05

-0.025

Models

Operating

Characteristics

1 dia.

1.5 dia.

2.35+0.05

-0.025 dia.

12.7

14.7

5.10.1

* Stainless-steel lever

Stainless-steel roller

Note 1. Unless otherwise specified, a tolerance of 0.2 mm applies to all dimensions.

Note 2. The operating characteristics are for operation in the A direction ( ).

Precautions

Please refer to "Common Precautions" for correct use.

Caution

Soldering

Terminal connection

When soldering, make sure that the temperature of the

soldering iron tip is not higher than 280C, and complete the

soldering within 3 seconds. Leave it for 1 minute without

applying any external force to the terminal after the soldering.

Soldering at an excessively high temperature or soldering for

more than 3 s may deteriorate the characteristics of the

Switch.

Correct Use

Mounting

Use M2.3 mounting screw with plane washers or spring washers

to securely mount the Switch. Tighten the screws to a torque of

0.2 to 0.29 Nm {2 to 3 kgfcm}.

Subminiature Basic Switch

Application examples provided in this document are for reference only. In actual applications, confirm equipment functions and safety before using the product.

Consult your OMRON representative before using the product under conditions which are not described in the manual or applying the product to nuclear control systems, railroad

systems, aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems or equipment that may have a serious

influence on lives and property if used improperly. Make sure that the ratings and performance characteristics of the product provide a margin of safety for the system or

equipment, and be sure to provide the system or equipment with double safety mechanisms.

Note: Do not use this document to operate the Unit.

OMRON Corporation

ELECTRONIC AND MECHANICAL COMPONENTS COMPANY

Contact: www.omron.com/ecb

Cat. No.B033-E1-04

0812(0207)(O)

You might also like

- Ordering Information: Sealed Snap Action SwitchDocument6 pagesOrdering Information: Sealed Snap Action SwitchG Sandeep KumarNo ratings yet

- Quick-Connect Terminals Simplify Wiring and Reduce Production StepsDocument5 pagesQuick-Connect Terminals Simplify Wiring and Reduce Production StepsStephen GreeneNo ratings yet

- DPDT Basic Switch For Two Independent Circuit ControlDocument5 pagesDPDT Basic Switch For Two Independent Circuit ControlShubham GuptaNo ratings yet

- Special Purpose Basic SwitchDocument5 pagesSpecial Purpose Basic Switchng_viet_cuong_groupNo ratings yet

- For Normal/reverse Rotation Motor Control: Automotive PCB Relay (Dual H-Bridge)Document3 pagesFor Normal/reverse Rotation Motor Control: Automotive PCB Relay (Dual H-Bridge)balescu_florentinaNo ratings yet

- Model Number Structure: High-Temperature Basic SwitchDocument4 pagesModel Number Structure: High-Temperature Basic Switchblackbeast8No ratings yet

- Model Number Structure: Enclosed SwitchDocument10 pagesModel Number Structure: Enclosed SwitchJavierNo ratings yet

- En g8nbDocument3 pagesEn g8nbAnonymous 3hUDn2No ratings yet

- Economical, Miniature Limit Switch Boasting Rigid ConstructionDocument5 pagesEconomical, Miniature Limit Switch Boasting Rigid ConstructionRajeev Saini100% (1)

- G70R-SOC08: Space-Saving and Labor-Saving 8-Point Output BlockDocument6 pagesG70R-SOC08: Space-Saving and Labor-Saving 8-Point Output Blockkasim leeNo ratings yet

- 18mm Size Insulated Shaft Type: Absolute Type Achieving High Water Resistance and Heavy TorqueDocument4 pages18mm Size Insulated Shaft Type: Absolute Type Achieving High Water Resistance and Heavy TorqueshyhuNo ratings yet

- 12mm Size Insulated Shaft TypeDocument5 pages12mm Size Insulated Shaft TypeshyhuNo ratings yet

- Sealed Ultra Subminiature Basic Switch D2JWDocument5 pagesSealed Ultra Subminiature Basic Switch D2JWMuhamad PriyatnaNo ratings yet

- 10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignDocument3 pages10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignshyhuNo ratings yet

- Sealed Basic Switch For Vehicles D2FW-GDocument4 pagesSealed Basic Switch For Vehicles D2FW-GMuhamad PriyatnaNo ratings yet

- Omron Z-15GW2-Omron PDFDocument18 pagesOmron Z-15GW2-Omron PDFCorne WolfaardtNo ratings yet

- Series 065 Slide Switch: Data Sheet Data SheetDocument2 pagesSeries 065 Slide Switch: Data Sheet Data Sheetdabhianand13No ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- LC4341-11 Datasheet, Pinout, Application Circuits SINGLE DIGIT DISPLAY LEDDocument6 pagesLC4341-11 Datasheet, Pinout, Application Circuits SINGLE DIGIT DISPLAY LEDordenador90No ratings yet

- 10mm Square Water-Proof (Snap-In Type)Document5 pages10mm Square Water-Proof (Snap-In Type)shyhuNo ratings yet

- BCH Electric Ltd-Limit Switch-CatalogueDocument6 pagesBCH Electric Ltd-Limit Switch-CataloguesachmayaNo ratings yet

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDocument3 pages7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuNo ratings yet

- G5Q PCB Relay: Ordering InformationDocument4 pagesG5Q PCB Relay: Ordering InformationLAU_CBrNo ratings yet

- List of Varieties: Detector Slide Push RotaryDocument5 pagesList of Varieties: Detector Slide Push RotaryshyhuNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Document3 pagesHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuNo ratings yet

- Omron Master GuideDocument14 pagesOmron Master GuidemasakpNo ratings yet

- 1.2 (H) MM, Single-Side Recoil TypeDocument4 pages1.2 (H) MM, Single-Side Recoil TypeshyhuNo ratings yet

- Safety Limit Switch: Model Number StructureDocument16 pagesSafety Limit Switch: Model Number StructureEgoitz Arruti BarrenetxeaNo ratings yet

- SKEGDocument4 pagesSKEGshyhuNo ratings yet

- E MCGBDocument7 pagesE MCGBSamiul IslamNo ratings yet

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocument3 pages4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNo ratings yet

- 0.6mm Low-Profile, Double Action TypeDocument3 pages0.6mm Low-Profile, Double Action TypeshyhuNo ratings yet

- Notes: Cam Operated Rotary Switches Cam Operated Rotary SwitchesDocument16 pagesNotes: Cam Operated Rotary Switches Cam Operated Rotary Switchesatanumaster1987No ratings yet

- 6.1 × 3.7mm Compact High-Speed Mounting (Surface Mount Type)Document3 pages6.1 × 3.7mm Compact High-Speed Mounting (Surface Mount Type)shyhuNo ratings yet

- Doosan Ac Servo Motor Driver Maintenance Manual Dasd - RH Series PDFDocument49 pagesDoosan Ac Servo Motor Driver Maintenance Manual Dasd - RH Series PDFvasiliy vasilievichNo ratings yet

- 21mm Size Ring Type: Ring Encoder With 4mm Height Contribute To Space Saving and MultifunctioningDocument4 pages21mm Size Ring Type: Ring Encoder With 4mm Height Contribute To Space Saving and MultifunctioningshyhuNo ratings yet

- LX5000Document6 pagesLX5000senthilrsenthilNo ratings yet

- Low-Torque Basic Switch D2MCDocument5 pagesLow-Torque Basic Switch D2MCMuhamad PriyatnaNo ratings yet

- Miniature Basic Switch SS-PDocument6 pagesMiniature Basic Switch SS-PMuhamad PriyatnaNo ratings yet

- Differential Pressure SwitchDocument4 pagesDifferential Pressure Switchakamalapuri388No ratings yet

- Ultra-Miniature, Highly SensitiveDocument4 pagesUltra-Miniature, Highly SensitivemariotexmNo ratings yet

- 45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignDocument3 pages45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignshyhuNo ratings yet

- 6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeDocument5 pages6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeshyhuNo ratings yet

- Sapm 01 PDocument10 pagesSapm 01 PAna MirelaNo ratings yet

- 35mm Size Ring Type: A Low-Profile Unit With 4.5mm Height and Good Operation FeelDocument3 pages35mm Size Ring Type: A Low-Profile Unit With 4.5mm Height and Good Operation FeelshyhuNo ratings yet

- 12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingDocument4 pages12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingshyhuNo ratings yet

- List of Varieties: Top Push Side PushDocument5 pagesList of Varieties: Top Push Side PushshyhuNo ratings yet

- 28mm Size Ring Type: A Low-Profile Unit With 4mm Height and Good Operation FeelDocument3 pages28mm Size Ring Type: A Low-Profile Unit With 4mm Height and Good Operation FeelshyhuNo ratings yet

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- Ordering Information: Snap Action SwitchDocument10 pagesOrdering Information: Snap Action Switchconti51No ratings yet

- Technical Data Sheet CM24G-..: Type OverviewDocument4 pagesTechnical Data Sheet CM24G-..: Type OverviewAnh GiàNo ratings yet

- Model Number Structure: General-Purpose Limit SwitchDocument9 pagesModel Number Structure: General-Purpose Limit SwitchHung LeNo ratings yet

- FS90R-V2.0 SpecsDocument2 pagesFS90R-V2.0 SpecsLêĐìnhDanhNo ratings yet

- HL-500 General-Purpose Limit SwitchDocument9 pagesHL-500 General-Purpose Limit SwitchMuhamad PriyatnaNo ratings yet

- G9EB-1-B-AQ: Capable of Interrupting High-Voltage, High-Current LoadsDocument2 pagesG9EB-1-B-AQ: Capable of Interrupting High-Voltage, High-Current LoadsNandam SrinivasNo ratings yet

- lm285 1.2 NDocument23 pageslm285 1.2 NrrebollarNo ratings yet

- Quiet Middle-Stroke (Surface Mount Type) : Switch With 0.7mm Stroke Achieving Both Quiet Operation and An Excellent FeelDocument3 pagesQuiet Middle-Stroke (Surface Mount Type) : Switch With 0.7mm Stroke Achieving Both Quiet Operation and An Excellent FeelshyhuNo ratings yet

- 3SE53220SB21 Datasheet enDocument7 pages3SE53220SB21 Datasheet enothello999No ratings yet

- Quarterly ONE 226 9Document4 pagesQuarterly ONE 226 9Luthie SinghNo ratings yet

- Fluid Resuscitation: Kristan Staudenmayer, MD Stanford University, Stanford, CADocument15 pagesFluid Resuscitation: Kristan Staudenmayer, MD Stanford University, Stanford, CALuthie SinghNo ratings yet

- Qbase Paediatrics 3 Mcqs For The Part B MRCPCH: More InformationDocument2 pagesQbase Paediatrics 3 Mcqs For The Part B MRCPCH: More InformationLuthie SinghNo ratings yet

- 2002 Kelly 660 7Document9 pages2002 Kelly 660 7Luthie SinghNo ratings yet

- Pediatrics - Dr. Adnan - Lecture 1 - Diarrhea: Definition and SignificanceDocument3 pagesPediatrics - Dr. Adnan - Lecture 1 - Diarrhea: Definition and SignificanceLuthie SinghNo ratings yet

- Risksfactor PDFDocument50 pagesRisksfactor PDFLuthie SinghNo ratings yet

- Lecture Notes On Political Economy: Allan Drazen Fall 2005Document13 pagesLecture Notes On Political Economy: Allan Drazen Fall 2005Luthie SinghNo ratings yet

- Notes Clinicalreview PDFDocument8 pagesNotes Clinicalreview PDFLuthie SinghNo ratings yet

- Nebraska: Must Inform EMS AlsoDocument12 pagesNebraska: Must Inform EMS AlsoLuthie SinghNo ratings yet

- The Perl Archive Toolkit Using PAR To Package and Deploy Perl ApplicationsDocument8 pagesThe Perl Archive Toolkit Using PAR To Package and Deploy Perl ApplicationsLuthie SinghNo ratings yet

- Jazz ClubDocument0 pagesJazz ClubLuthie Singh100% (1)

- Path MCQ 2003-2005 RecallsDocument91 pagesPath MCQ 2003-2005 RecallsLuthie Singh100% (1)

- MCQDocument40 pagesMCQLuthie Singh100% (2)

- SPICE Macro Model For IC ResistorDocument10 pagesSPICE Macro Model For IC ResistorSharath_Patil_7623No ratings yet

- Correntes Parasitas - TrilhosDocument10 pagesCorrentes Parasitas - TrilhosHenrique RobertoNo ratings yet

- Grundig Classic 960 MANUALDocument15 pagesGrundig Classic 960 MANUALjuanp1020No ratings yet

- LM117 Voltage RegulatorDocument26 pagesLM117 Voltage Regulatore_bahamondesNo ratings yet

- Hfe Hitachi Sr-503 603 Service en FRDocument28 pagesHfe Hitachi Sr-503 603 Service en FRVladimirNo ratings yet

- Module 2 - Part III - UpdatedDocument38 pagesModule 2 - Part III - UpdatedDhriti NayyarNo ratings yet

- Short Circuit Analysis Lecture NotesDocument107 pagesShort Circuit Analysis Lecture NotesSankar MuthuswamyNo ratings yet

- Laboratory 7Document4 pagesLaboratory 7Priyamdas123No ratings yet

- Ofc LedDocument6 pagesOfc LedVignesh DevanNo ratings yet

- DDRDocument9 pagesDDRnivinNo ratings yet

- Wide Band RF TransformersDocument13 pagesWide Band RF Transformerskbdstl1No ratings yet

- Peltier Device Experiments PDFDocument4 pagesPeltier Device Experiments PDFTravisNo ratings yet

- Гусеничный экскаватор Hidromek HMK 370 LC HDDocument2 pagesГусеничный экскаватор Hidromek HMK 370 LC HDdicon100% (1)

- Tutorial StellaDocument19 pagesTutorial StellaCaioGomesNo ratings yet

- Sega Master System II Service Manual April, 1991Document26 pagesSega Master System II Service Manual April, 1991Giuseppe TomarchioNo ratings yet

- An Autonomous Flight Safety SystemDocument12 pagesAn Autonomous Flight Safety SystemWoofyNo ratings yet

- Abs EdgeDocument39 pagesAbs Edgecorporacion corprosinfro100% (3)

- DUO Castellini PDFDocument148 pagesDUO Castellini PDFKhaled MAMMAR KOUADRI100% (1)

- EPAK TVRO Manual PDFDocument32 pagesEPAK TVRO Manual PDFChandan NaikNo ratings yet

- Parker Moduflex MicroDocument12 pagesParker Moduflex MicroEdison FerreiraNo ratings yet

- Support ProfessionalDocument2 pagesSupport ProfessionalscriNo ratings yet

- Voice Over IP (VoIP)Document54 pagesVoice Over IP (VoIP)Peter R. Egli100% (1)

- Protocol Efficiency and HDLCDocument31 pagesProtocol Efficiency and HDLCBijoy04No ratings yet

- PG 3 ZYBO - SCHDocument13 pagesPG 3 ZYBO - SCHanuptonemeNo ratings yet

- Ps Electricity and Magnetism HandoutDocument5 pagesPs Electricity and Magnetism HandoutMarcus 'stulla' AllisonNo ratings yet

- Design, Matlab/Simulink Modeling of Novel 5-Level & 7-Level Multi-Level Inverter TopologiesDocument6 pagesDesign, Matlab/Simulink Modeling of Novel 5-Level & 7-Level Multi-Level Inverter Topologiesdipendra prasad yadav.No ratings yet

- Three Improvements To The Reduceron: Matthew Naylor and Colin Runciman University of YorkDocument50 pagesThree Improvements To The Reduceron: Matthew Naylor and Colin Runciman University of YorkaldeghaidyNo ratings yet

- Strategy - Apple Inc - Project PPT (Recovered)Document16 pagesStrategy - Apple Inc - Project PPT (Recovered)Jayesh GoswamiNo ratings yet

- Areva Ieee MnitDocument37 pagesAreva Ieee Mnitsmilehood99No ratings yet