Professional Documents

Culture Documents

Pigging Operation

Uploaded by

prasad5034Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pigging Operation

Uploaded by

prasad5034Copyright:

Available Formats

The name pig was originally applied to Go-Devil scrapers which were

devices driven through the pipeline by the flowing fluid trailing springloaded

rakes to scrape wax off the internal walls. The rakes made a

characteristic loud

squealing noise, hence the name "pig" which is now used to describe any

device made to pass through a pipeline driven by the pipeline fluid.

A large variety of pigs has now evolved, some of which are illustrated in

Fig.l. They typically perform the following functions:separation of

products

cleaning out deposits and debris

gauging the internal bore

location of obstructions

meter loop calibration

liquids' removal

gas removal

pipe geometry measurements

internal inspection

coating of internal bore

corrosion inhibition

improving flow efficiency

PIGGING DURING OPERATION

If pigging is required during operation, then the pipeline must be designed

with permanent pig traps, especially when the product is hazardous. As was

mentioned above, it is far better to avoid pigging if possible, but for some

operations it is the safest and most economical solution. Typical applications

for pigging in operational lines are illustrated in Fig.3, and include separation

of products, flow improvement, corrosion inhibition, meter proving and

inspection.

Separation of products

Some applications demand that a pipeline carries a number of different

products at various times. It is basically a matter of economics and operational

flexibility as to whether a single line with batches of products in series is to

be preferred to numerous exclusive lines where the products can flow in

parallel.

As with flooding and dewatering, a batching pig provides an efficient

interface between products, minimizing cross contamination. To ensure that

Pipeline Pigging Technology

1

SEPARATION

OF PRODUCTS

PIGGING DURING OPERATION

1

1

IMPROVING FLOW

EFFICIENCY

1

CORROSION

INHIBITION

1

METER

PROVING

Multiproduct lines

Dewatering

Removal of sand and Batching with

wax from oil lines inhibitor

Clearance of dirt and Water drop-out

condensate from gas removal

lines

Fig.3. Pigging during operation.

Calibration of

flow meters

no mixing takes place, a train of two or three batching pigs could be launched

with the new product in between.

Wax removal

Some crude oils have a tendency to form wax as they cool. The wax

crystallizes onto the pipe wall reducing the diameter and making the surface

rough. Both effects reduce the flow efficiency of the pipeline such that more

pumping energy must be expended to transport the same volume of oil.

A variety of cleaning and scraping pigs is available to remove the wax; most

work on the principle of having a by-pass flow through the body of the pig,

over the brushes or scrapers, and out to the front. This flow washes tne wax

away in front of the pig. The action of the pig also polishes wax remaining on

the pipe wall, leaving it smooth with a low hydraulic resistance.

There are alternatives to pigging for this application. For example, it is

possible to add pour-point depressants to inhibit wax formation, or it is

possible to add flow improvers which reduce turbulence and increase the

hydraulic efficiency of the pipeline. For a given pipeline, the choice will

depend on the reduction in pumping costs against the cost of pigging or

chemical injection, if indeed there is a net gain. Regular pigging does,

10

Why pig a pipeline?

however, have the advantage that it proves the line is clear and there is no wax

build up which might cause problems for a line which is only pigged

occasionally.

Line cleaning

Similar arguments about improving pumping efficiency apply to any

products prone to depositing solids on the pipe wall. Gas line efficiencies can

be improved by removing dust or using a smooth epoxy-painted internal

surface.

Condensate clearance

In gas lines, conditions can occur where liquids condense and collect on

the bottom of the pipeline. They can be swept up by the gas to arrive at the

terminal in the occasional large slug, causing problems with the process

facilities. Slug catchers which are basically large separators are used to absorb

these fluctuations. However, it is normal to limit the potential size of the

condensate slugs by regular sphering, and thus reduce the size of the slug

catcher required.

Corrosion inhibition

Inhibitors are used to prevent the product attacking and corroding the

pipeline steel. In some cases, particularly in liquid lines, small quantities of

inhibitor are added to the flow. However, in other cases it is necessary for the

inhibitor to coat the whole inside surface of the pipe at regular intervals. This

is accomplished by retaining a slug of inhibitor between two batching pigs.

This method also ensures that the top of the pipe is coated.

Meter proving

In order to calibrate flowmeters during operation, a pig is used to displace

a precisely-known volume of fluid from a prover loop past the flowmeter.

Normally a tightly-fitting sphere is used for this purpose, and the run is

repeated until consistent results are obtained.

11

You might also like

- Torque Coverter Case StudiesDocument2 pagesTorque Coverter Case Studiesprasad5034100% (1)

- Comp and Tur 3Document27 pagesComp and Tur 3prasad5034No ratings yet

- Heavy Duty GT: MaintenanceDocument79 pagesHeavy Duty GT: Maintenanceprasad5034100% (5)

- FBC BoilersDocument8 pagesFBC Boilerssk3146No ratings yet

- Gas Turbine Compressor Wash System ModificationDocument13 pagesGas Turbine Compressor Wash System Modificationprasad5034No ratings yet

- Inlet Casing - IGV: GT Inlet Air Flow 165 m3/s IGV Minimum Angle 32 Deg Maximum 84deg Number of Vanes:64Document6 pagesInlet Casing - IGV: GT Inlet Air Flow 165 m3/s IGV Minimum Angle 32 Deg Maximum 84deg Number of Vanes:64prasad5034No ratings yet

- Generator CourseDocument61 pagesGenerator Courseprasad5034No ratings yet

- Boe DRWG Paper 2007Document3 pagesBoe DRWG Paper 2007prasad5034No ratings yet

- Gas Turbine Inle and CompressorDocument23 pagesGas Turbine Inle and Compressorprasad5034100% (1)

- Inlet Casing - IGV: GT Inlet Air Flow 165 m3/s IGV Minimum Angle 32 Deg Maximum 84deg Number of Vanes:64Document6 pagesInlet Casing - IGV: GT Inlet Air Flow 165 m3/s IGV Minimum Angle 32 Deg Maximum 84deg Number of Vanes:64prasad5034No ratings yet

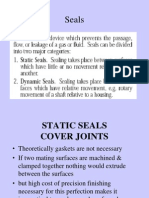

- SealsDocument52 pagesSealsprasad5034No ratings yet

- TurbineDocument19 pagesTurbineprasad5034No ratings yet

- Gov SchemeDocument3 pagesGov Schemeprasad5034No ratings yet

- Boiler Start UpDocument16 pagesBoiler Start Upprasad503467% (3)

- Mark V Control 2Document30 pagesMark V Control 2prasad5034No ratings yet

- Mark VDocument162 pagesMark Vprasad503467% (3)

- Gas Cycles Otto, Diesel, Dual CyclesDocument43 pagesGas Cycles Otto, Diesel, Dual Cyclesprasad5034100% (1)

- To Avoid Over Speed This Relay Is Necessary When MHG Is in Service But Kept in Operation When EHG ControlsDocument11 pagesTo Avoid Over Speed This Relay Is Necessary When MHG Is in Service But Kept in Operation When EHG Controlsprasad5034No ratings yet

- Refrigerant Air DryerDocument2 pagesRefrigerant Air Dryerprasad5034No ratings yet

- Combustion 6FADocument30 pagesCombustion 6FAprasad5034100% (5)

- Gen DesignDocument24 pagesGen Designprasad5034No ratings yet

- Mark V Control 2Document30 pagesMark V Control 2prasad5034No ratings yet

- Transformation Training Material Format-DR-SERDocument34 pagesTransformation Training Material Format-DR-SERprasad5034No ratings yet

- Boiler Start UpDocument16 pagesBoiler Start Upprasad503467% (3)

- Woodward Turbine ControlDocument17 pagesWoodward Turbine Controlprasad5034100% (1)

- Heavy Duty GT: MaintenanceDocument79 pagesHeavy Duty GT: Maintenanceprasad5034100% (5)

- Pigging OperationDocument3 pagesPigging Operationprasad5034No ratings yet

- Gas Turbine Maintenence AspectsDocument38 pagesGas Turbine Maintenence Aspectsprasad5034100% (1)

- Gas Turbine Axial Flow Compressor Stalling PreventionDocument27 pagesGas Turbine Axial Flow Compressor Stalling Preventionprasad5034No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Specific Lube Oil Consumption SLOC: Edition 01 Description Page 1Document2 pagesSpecific Lube Oil Consumption SLOC: Edition 01 Description Page 1Atanasio Perez100% (1)

- Diagrama de Interconexion XL 200 PDFDocument9 pagesDiagrama de Interconexion XL 200 PDFjoseNo ratings yet

- Dsd-060 Earthquake Shutdown Unit: DescriptionDocument2 pagesDsd-060 Earthquake Shutdown Unit: Descriptionmuhammad arifNo ratings yet

- Notification 1 2017 For CGST Rate ScheduleDocument74 pagesNotification 1 2017 For CGST Rate ScheduleIti CglNo ratings yet

- LM1117Document20 pagesLM1117Shahril RizalNo ratings yet

- Induction Material MoPnGDocument60 pagesInduction Material MoPnGRaghvendra UpadhyaNo ratings yet

- Rotak: Downloaded From Manuals Search EngineDocument18 pagesRotak: Downloaded From Manuals Search EngineOvidiu BrinzanNo ratings yet

- FP2 FP3 CRP 49691A Sanitary PumpDocument6 pagesFP2 FP3 CRP 49691A Sanitary PumpetmvmartNo ratings yet

- EBARA Company ProfileDocument11 pagesEBARA Company ProfileMohamed IbrahimNo ratings yet

- Improved procedures for separating crystals from the meltDocument10 pagesImproved procedures for separating crystals from the meltAna Mariel VenturaNo ratings yet

- Dealer price list AKDocument1 pageDealer price list AKKunal TanwarNo ratings yet

- AQA QMS Pvt. LTD.: S No Company Name Membership NoDocument11 pagesAQA QMS Pvt. LTD.: S No Company Name Membership NoDevasyrucNo ratings yet

- Design and Implementation of IOT Based Monitoring System For Solar TreeDocument26 pagesDesign and Implementation of IOT Based Monitoring System For Solar TreeDhanraj GuptaNo ratings yet

- Flow of Lubricating Greases in Centralized Lubricating SystemsDocument8 pagesFlow of Lubricating Greases in Centralized Lubricating SystemsFelipe LeiteNo ratings yet

- Flowserve Oil and Gas Upstream and Pipeline PDFDocument20 pagesFlowserve Oil and Gas Upstream and Pipeline PDFmesplamaxNo ratings yet

- Physics Chap 3 F5 !!!!!!!!!!!Document46 pagesPhysics Chap 3 F5 !!!!!!!!!!!Ethan Dharshen100% (1)

- Renewable RevolutionDocument52 pagesRenewable RevolutionDaisyNo ratings yet

- Saacke Steam Pressure Atomizer PDFDocument2 pagesSaacke Steam Pressure Atomizer PDFKhaled SaadnehNo ratings yet

- Instr 12205 Elements Transmitters Transducers DisplacersDocument103 pagesInstr 12205 Elements Transmitters Transducers DisplacersKumar SomasundaramNo ratings yet

- Mike Busch on Engines What Every Aircraft Owner Needs to Know About the Design Operation Condition Monitoring Maintenance and Troubleshooting of Piston Aircraft Engines 1nbsped 1718608950 9781718608955 CompressDocument509 pagesMike Busch on Engines What Every Aircraft Owner Needs to Know About the Design Operation Condition Monitoring Maintenance and Troubleshooting of Piston Aircraft Engines 1nbsped 1718608950 9781718608955 CompressHugo HernandNo ratings yet

- Diesel Engine Power Plant GuideDocument51 pagesDiesel Engine Power Plant GuideShashank ShastriNo ratings yet

- Syllabus: Certificate in Subsea EngineeringDocument6 pagesSyllabus: Certificate in Subsea EngineeringJerome LIKIBINo ratings yet

- Aoc 712sa+Service+ManualDocument50 pagesAoc 712sa+Service+ManualGiovanny Gregorio Gonzalez SanchezNo ratings yet

- Power Generating Floor PDFDocument3 pagesPower Generating Floor PDFMeghjit MazumderNo ratings yet

- Optimized Skid Design For Compress Sor PackagesDocument5 pagesOptimized Skid Design For Compress Sor Packagessantosh kumarNo ratings yet

- 64 Meeting January 7-8, 2013Document42 pages64 Meeting January 7-8, 2013ymadhukumarNo ratings yet

- 2004-01-0403 - Design and Analysis of Fuel Tank Baffles To Reduce The Noise Generated From Fuel Sloshing PDFDocument14 pages2004-01-0403 - Design and Analysis of Fuel Tank Baffles To Reduce The Noise Generated From Fuel Sloshing PDFCaio PaimNo ratings yet

- StandardsDocument76 pagesStandardsSohaib ZafarNo ratings yet

- Error Codes Special Modes: Yes Yes YesDocument2 pagesError Codes Special Modes: Yes Yes YesJorge SaavedraNo ratings yet

- GEA PHE NT enDocument2 pagesGEA PHE NT enVLASTAR100% (2)