Professional Documents

Culture Documents

Fault Current Limiters Report On The Activities of CIGRE WG A3.10

Uploaded by

Kelvin Pantaleon RiofrioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fault Current Limiters Report On The Activities of CIGRE WG A3.10

Uploaded by

Kelvin Pantaleon RiofrioCopyright:

Available Formats

Fault Current Limiters

Report on the Activities of CIGRE WG A3.10

by CIGRE Working Group 13.10 (*)

Abstract

the market.

A CIGRE Working Group (WG 13.10) was established

in 1996 with the task to prepare a specification for fault

current limiters. As a result of this work a report entitled

"Functional Specification for a Fault Current Limiter"

was published in 2001 [1]. The Working Group then

continued its investigations on fault current limiters with

a special focus on the topics "System Demands" [2],

"State of the Art" [3] and "Testing" [4]. The original

scope was the application of fault current limiters in

distribution networks (1 kV < Ur 36 (40.5) kV) and

sub-transmission networks (52 kV Ur 145 kV).

Contributions related to fault current limiter applications

in transmission networks (with Ur up to 420 kV) have

however also been taken into account.

The present report gives an introduction to the problem

of fault current limitation and an overview of the work

carried out by the Working Group on this subject.

The members also undertook to assemble a bibliography

on proposed solutions for the current limiting problem

[1]. This showed that there has been considerable

interest in the subject for almost forty years but with a

few exceptions, there has been relatively little progress

in developing suitable devices and bringing them to

___________

(*) Members:

H. Schmitt, Convenor (Germany), J. Amon (Brazil), D.

Braun (Switzerland), F. X. Camescasse (France), M.

Collet (France), G. C. Damstra (The Netherlands), H.

Fukagawa (Japan), F. Gil Garcia (France), K.-H.

Hartung (Germany), J. Kida (Japan), M. Saravolac

(France)

Keywords: Power System - Short-Circuit Current Current Limiter

1.

Fault Current Limitation

Faults in electrical power systems are inevitable. Apart

from the damages in the vicinity of the fault - e.g. due to

the effects of an electric arc - the fault currents flowing

from the sources to the location of the fault lead to high

dynamical and thermal stresses being imposed on

equipment like overhead lines, cables, transformers and

switchgear. The circuit-breakers further have to be

capable of (selectively) interrupting the currents

associated with such faults.

A growth in the generation of electrical energy and an

increased interconnection of the networks lead to higher

fault currents. Especially, the continuous growth in the

generation of electrical energy has the consequence that

networks approach or even exceed their limits with

respect to the short-circuit current withstand capability.

Therefore there is a considerable interest in devices

which are capable of limiting fault currents. A fault

current limiter can limit a fault current passing trough it

within the first half cycle. The use of fault current

limiters allows equipment to remain in service even if

the prospective fault current exceeds its rated peak and

short-time withstand current and in case of circuitbreakers also its rated short-circuit making and breaking

current. Replacement of equipment can be avoided or at

least shifted to a later date. In case of newly planned

networks fault current limiters allow the use of

equipment with lower ratings which renders possible

considerable cost savings.

to cause a zero or negative rate-of-rise of the current.

This can be achieved by inserting a voltage or an

impedance of a high enough value into the circuit. Such

an action requires the use of non-linear elements and

leads to currents of the shape i2 or i3, respectively,

depending on whether the current is only limited (i2) or

limited and also interrupted (i3). Associated with this

current limitation is the generation of an overvoltage

which is proportional to the superimposed di/dt.

Figure 1a) shows a simple equivalent circuit for

discussing the problems associated with fault current

limitation in power systems [5]. Independent of the load

current flowing prior to the fault, the short-circuit

current starts with a certain rate-of-rise depending on

the parameters of the circuit (source voltage U0 and

source impedance ZS) and on the angle of initiation of

the fault. When no limiting action takes place a fault

current of shape i1 in Figure 1b) will flow (prospective

short-circuit current). This current will be interrupted by

a conventional circuit-breaker at t3.

2.

Description of the Limiting Behaviour of Fault

Current Limiters

In the following characteristics and relations describing

the limiting behaviour of fault current limiters are

defined. These characteristics and relations cover the

behaviour of existing fault current limiting devices (e.g.

fault current limiting reactors, high-voltage current

limiting fuses, IS-limiters) as well as fault current

limiting devices which are still under development (e.g.

superconducting fault current limiters, solid-state fault

current limiters). The following definitions apply:

Normal operation (for denominations see Figure 2):

Peak value of rated current (Ir) - 1

Limitation (for denominations see Figure 2):

Minimum initiating current (min) - 2

Maximum limited current (max) - 3

Peak short-circuit current (p) - 4

Peak value of follow current (fol) - 5

a)

b)

Figure 1: Fault current limitation

a) Equivalent circuit representing a fault

condition

b) Typical current waveforms due to a fault

The simplest way to limit the short-circuit current would

be the use of a source impedance ZS of an appropriate

high value. The drawback of this solution is that it

obviously also influences the system during normal

operation, i.e. it results in considerable voltage drops at

high load currents.

In order to be able to limit the first peak 1 of the shortcircuit current i1 it is necessary for the fault current

limiting device to operate within the time interval t1 and

Figure 2: Definitions related to fault current limiters

(see text)

a) Fault current limiting device with current

limitation only

b) Fault current limiting device with current

limitation and interruption

The performance characteristics of a fault current

limiter can then be described using the relations given

below:

0: follow current ratio (ratio of peak value of the

follow current (5) to the peak value of the rated

current (1)), also referred to as stationary current

limiting ratio s

1: peak current limiting ratio (ratio of maximum

limited current (3) to the peak short-circuit current

(4))

2: current limiting ratio (ratio of peak value of the

follow current (5) to the peak short-circuit current

(4))

ta: action time (time required from fault initiation at

t = 0 to maximum limited current (3))

td: fault duration (time defined from fault initiation at

t = 0 to fault current interruption)

tr: recovery time (time between current interruption

and return of the fault current limiter to its initial

operation state at low impedance)

Reduction of voltage sags and flicker due to the

lower total source impedance

Reduction of harmonics due to the lower total

source impedance

Higher system availability due to the parallel

connection of the feeding generators and

transformers

Higher loads possible in a sub-system (higher than

the ratings of the feeding generators and

transformers in that sub-system)

Even loading of the of feeding transformers due to

their parallel connection

In addition to the above the following relations are also

useful for describing the performance characteristics of

a fault current limiter [6]:

d: dynamic current limiting ratio (ratio of maximum

limited current (3) to the peak value of the rated

current (1))

l: limiting ratio (ratio of maximum limited current

(3) to the peak value of the follow current (5))

i: initiating ratio (ratio of minimum initiating current

(2) to the peak value of the rated current (1))

3.

Application of Fault Current Limiters

3.1 Installation of Fault Current Limiters

Fault current limiters can in principle be installed in bus

ties/couplings (Figure 3), in incoming feeders (Figure 4)

or in outgoing feeders (Figure 5).

Note: circuit-breakers, disconnectors, etc. are not shown

Figure 3: Installation of a fault current limiter in a bus

tie/coupling (example)

A fault current limiter in a bus tie/coupling limits the

contribution of a sub-system to the total short-circuit

current of the system.

The advantages of the use of a fault current limiter in a

bus tie/coupling (refer to Figure 3) are:

Reduction of the short-circuit current of the system

(compared to the short-circuit current with closed

tie circuit-breaker)

Note: circuit-breakers, disconnectors, etc. are not shown

Figure 4: Installation of fault current limiters in

incoming feeders (example)

A fault current limiter in an incoming feeder limits on

the one side the contribution of this feeder to the total

short-circuit current of the system and on the other side

the contribution of the remaining system to the shortcircuit current in that particular feeder.

The advantages of the use of a fault current limiter in an

incoming feeder (refer to Figure 4) are:

Reduction of the short-circuit current of the system

Reduction of voltage sags and flicker due to the

lower total source impedance

Reduction of harmonics due to the lower total

source impedance

Higher system availability due to the parallel

connection of the feeding generators and

transformers

Even loading of the of feeding transformers due to

their parallel connection

A fault current limiter in an outgoing feeder limits

contribution of the system to the short-circuit current in

that particular feeder.

The advantages of the use of a fault current limiter in an

outgoing feeder (refer to Figure 5) are:

Reduction of the short-circuit current in the

particular feeder

Reduction of voltage sags and flicker due to the

lower total source impedance

Reduction of harmonics due to the lower total

source impedance

a trip is required

Effect of a trip of the fault current limiter when no

trip is required

Failure mode of the fault current limiter in case of

an internal fault

Maintenance requirements of the fault current

limiter

Feeder

15%

Incoming Transformer

18%

Note: circuit-breakers, disconnectors, etc. are not shown

Figure 5: Installation of fault current limiters in

outgoing feeders (example)

The results of an inquiry carried out by the Working

Group regarding the preferred locations for installing

fault current limiters are shown in Figure 6. From this

survey follows that the majority of fault current limiters

will be installed in bus ties (52 %) and incoming feeders

(33 %).

3.2 System-Device Interactions

When a fault current limiter is installed in a system

there will be interactions between the fault current

limiter and the system. A list of some of the items which

have to be taken into consideration when applying fault

current limiters is presented.

3.2.1 Effects of a Fault Current Limiter on the

System

3.2.1.1 Effects on Protection Schemes

Relay settings

Selectivity

Protection blinding (especially in the case of

directional protection)

Compatibility with downstream fuses

3.2.1.2 Effects on Independent Power Producer

Installations

Generator stability

Generator decoupling protection

3.2.1.3 Effects on Conventional Switchgear

Transient recovery voltage of downstream circuitbreakers

3.2.1.4 Effects on System Reliability

Reliability of the fault current limiter

Effect of a no-trip of the fault current limiter when

Incoming Generator

15%

Bus Tie

52%

Figure 6: Preferred locations for installing fault current

limiters

3.2.2 Effects of the System on a Fault Current

Limiter

3.2.2.1 Undesirable Tripping of Fault Current Limiter

Transient currents due to single-phase-to-earth

faults in ungrounded cable networks

Inrush currents due to transformer energisation

Inrush currents due to capacitor bank switching

Starting currents of motors

3.2.2.2 Ability of Fault Current Limiter to Withstand

Short-Circuit Currents

In case of fault current limiters with current limitation

only the fault current limiter has to be able to withstand

the short-circuit current as long as required by the

protection scheme applied (i.e. if applicable also during

several reclosing cycles)

3.3 Requirements for Fault Current Limiters

The requirements imposed on a fault current limiter can

be summarised as follows:

Low impedance during normal operation (low

voltage drop across the device)

Low losses

Adequate current limiting performance

Compatibility with existing or planned protection

schemes

No deterioration of the limiting behaviour during

the useful life

High reliability

Low maintenance requirements

No risk for personnel

Low impact on the environment

The Working Group specifically also investigated the

requirements regarding the permissible number of

limiting operations and the duty cycle. The results are

indicated in Figure 7.

Apart from the above mentioned requirements the

acquisition cost and operation and maintenance costs of

course play an important role when a decision regarding

the installation of a fault current limiter is made. The

Working Group carried out an inquiry about the price

customers are ready to pay for a fault current limiting

device (Figure 8). For comparison purposes the results

of two earlier surveys [7, 8] are also indicated.

Rated voltage

Rated insulation level

Rated frequency

Rated current and overload capability

Rated current limiting performance (initiating

current, limited current, follow current, action time,

fault

duration,

recovery

time,

switching

overvoltage)

100.0%

CIGRE

EPRI

90.0%

80.0%

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

<1

1-3

100.0%

5 - 10

a)

CIGRE

90.0%

3-5

EPRI

80.0%

75.0%

70.0%

60.0%

4.76 to 38 kV

69 to 145 kV

50.0%

245 to 362 kV

40.0%

50.0%

30.0%

20.0%

10.0%

25.0%

0.0%

<5

5 - 10

10 - 20

20 - 30

30 - 50

> 50

a)

0.0%

1

100.0%

CIGRE

EPRI

90.0%

10

b)

80.0%

Figure 8: Worth of a fault current limiter to a customer

(price unit: price of a conventional circuitbreaker)

a) Inquiries of CIGRE WG 13.10 and of

EPRI [7]

b) Inquiry of AEIC [8] (demand vs. price)

70.0%

60.0%

50.0%

40.0%

30.0%

20.0%

10.0%

0.0%

O

OCO

OCOCO

OCOCOCO

b)

Figure 7: Requirements regarding the permissible

number of operation and the duty cycle of a

fault current limiter based on inquiries of

CIGRE WG 13.10 and of EPRI [7]

a) Permissible number of operations

b) Duty cycle

3.4 Specifications for Fault Current Limiters

A specification for a fault current limiter must contain

the following basic information:

If the required current limiting performance is specified

as ratio of the short-circuit current with fault current

limiter operation to the short-circuit current without

fault current limiter operation it should be clearly

indicated whether this ratio refers to the short-circuit

current at the fault location or the short-circuit current

flowing trough the fault current limiter.

In case of fault current limiters which introduce a

resistance into the circuit the fault current limiter not

only limits the fault current but also shifts its phase

which leads to an additional current limiting effect when

a limited and an unlimited fault current sum up to a total

short-circuit current

Also the following items need to be addressed in a

specification:

Installation (indoor or outdoor)

Service conditions (normal or special)

Requirements regarding dimensions and weight

Three-phase or single-phase device

Device with or without integrated series switches or

disconnectors

Requirements

regarding

the

supervision

(monitoring) of the device

Etc.

4.

limitation may nevertheless be an attractive by-product

of such applications.

Splitting of grids

Splitting of busbars

Introduction of higher

voltage levels

Transformers with

increased short-circuit

impedance

Fault current limiting

reactors

State of the Art of Fault Current Limiters

Only fault current limiters for the application in

medium-voltage networks (1 kV < Ur 36 (40.5) kV)

and in high-voltage networks (Ur 52 kV) are

considered. Fault current limiters for the applications in

low-voltage networks (Ur < 1 kV) are not dealt with.

High-voltage current

limiting fuses

Is-Limiters

Novel approaches:

SCFCL

PTC-resistors

Liquid metal FCL

Solid-state FCL

FCL using EM-forces

Hybrid FCL

A comparison of the current limiting performance and

other pertinent features (e.g. losses) of the different

current limiting devices is outside the scope of this

overview.

A distinction is made between passive and active fault

current limiting measures (Figure 9) [5]. Passive

measures make use of an already initially high source

impedance both at normal and at fault conditions

whereas active measures bring about a fast increase of

the source impedance at fault conditions only.

Active fault current limiters can be further characterised

as follows:

self-triggered or external triggered

with current limitation only or with current

limitation and interruption

resetable or non-resetable (parts of the fault current

limiter need to be replaced after an operation)

It should be noted that instead of using fault current

limiters the problems associated with increased fault

current levels can also be coped with measures like:

Uprating of existing switchgear and other

equipment

Changes in network topology, e.g. splitting of grids

or splitting of busbars

Introduction of higher voltage levels

Use of complex control strategies like sequential

tripping

Etc.

These measures are not dealt with any further. Also not

covered are measures like to use of FACTS-devices

with fault current limitation (for instance a thyristor

controlled series compensator with fault current

limitation (e.g. Kayenta, U.S.A. [9])) or DC-links as

such measures are hardly being installed for the purpose

of limiting fault currents in the first place. Fault current

Figure 9: Overview of fault current limiting measures

[5]

4.1 State of the Art

Table 1 gives an overview of fault current limiting

devices which are (or have been) commercially

available.

4.2 Novel Approaches

In Table 2 an overview of fault current limiting devices

which are still in a research or development state is

given. Prototypes of such devices may already have

been installed in power systems. Only active measures

are considered.

Many different types of fault current limiters have been

proposed over the years. No pretension is made to give

a complete coverage of all these devices.

Although many investigations have been carried out in

the past and are currently being carried out the state of

the art in the field of fault current limiting devices are

conventional solutions like fault current limiting

reactors, high-voltage current limiting fuses,

pyrotechnic fault current limiters, etc. For the time

being, none of the novel approaches led to an

economically acceptable solution for a fault current

limiter for medium-voltage or high-voltage networks.

5.

Testing of Fault Current Limiters

Standards with rules for the testing are presently only

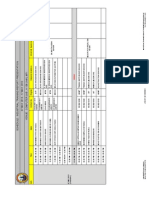

Table 1: State of the art

Type

Fault current limiting reactor

Transformer with increased shortcircuit impedance

High-voltage current limiting fuse

Pyrotechnic fault current limiter

(Is-Limiter)

Resonance link ("Kalkner"Kupplung)

Passive/

Active

Passive

Passive

Triggering

Method

---------

Active

Active

Self-triggered

External triggerd

Active

Self-tiggered

Passive/

Active

Active

Triggering

Method

Self-triggered

Active

Self-triggered

Active

Characteristics

Current

Interruption

---------

Voltage Level

Lit.

Resetable

Hybrid

---------

---------

MV, HV

MV, HV

Yes

Yes

No

No

No

Yes

MV

MV

[10]

[11]

No

Yes

No

MV, HV

[12, 13]

Resetable

Hybrid

Voltage Level

(Prototypes)

Lit.

Yes

No

MV

[14, 15]

No

Yes

No

MV

[16]

Self-triggered

No

Yes

No

MV

[17]

Active

External triggerd

Yes

No

MV

[18]

Active

Self-triggered

Yes 3)

Yes 4)

No

MV

[19]

Active

Active

Active

Self-triggered

External triggerd

External triggerd

No

Yes

Yes

Yes

Yes

Yes

No

No

No

----MV

MV

[20]

Active

External triggerd

Yes

Yes

Yes

MV

Active

External triggerd

Yes

Yes

MV

Active

External triggerd

No

Yes

No

-----

Table 2: Novel approaches

Type

Superconducting fault current

limiter: Resistive type

Superconducting fault current

limiter: Shielded iron core type

Superconducting fault current

limiter: Saturated iron core type

Superconducting fault current

limiter: "Current controller" type

Fault current limiter based on

PTC-resistors 2)

Liquid metal fault current limiters

Current limiting solid-state switch

Solid-state fault current limiter

with current limiting impedance

Solid-state fault current limiter

based on hybrid principle

Current limiter based on high arcvoltage

Resonance link with switching

device (vacuum, solid-state)

Characteristics

Current

Interruption

No

[21, 22]

Notes:

1

) depending on the layout of the device

2

) PTC: positive temperature coefficient

3

) with integrated series switch

4

) numbers of operation is limited

available for fault current limiting reactors (IEC 60289

[23]) and for high-voltage current limiting fuses (IEC

60282-1 [24]). Rules for the testing of other types of

fault current limiters need to be established in the future.

In this section some basic considerations about the tests

to be carried out are given. It is understood that for

different types of fault current limiters different test

procedures will apply.

5.1 Dielectric Tests

Dielectric tests as described in IEC 60694 [25] have to

be performed with the fault current limiter in closed

position between phase and ground and between the

phases. The test voltages should be chosen in

accordance with Tables 1 and 2 of IEC 60694.

If a fault current limiter (or the combination of a fault

current limiter and a series switch) can have an open

position the dielectric performance in this position has

also to be verified, independent of the nature of the gap

(e.g. solid-state switch, mechanical switch). The voltage

imposed on an open circuit-breaker in a grid coupling

could serve as a basis for determining the test voltages

in this case. Additionally, the long term performance

shall be investigated, especially in the case of semiconductors.

5.2 Temperature-Rise Tests

Temperature-rise tests including the measurement of the

resistance of the main current path have to be performed

in accordance with IEC 60694 [25]. The test current

shall be equal to the rated current of the fault current

limiter. The temperature rise of the contacts and other

parts should be within the limits specified in Table 3 of

IEC 60694. The admissible temperature rise of nonaccessible parts such as contacts in vacuum interrupters,

silicon wafers in semiconductor devices or super-

conducting materials will have to be considered

separately.

appropriate number of limiting operations shall be

carried out.

If a fault current limiting device has an overload

capability this shall also be verified by tests.

5.6 Electromagnetic Compatibility (EMC) Tests

5.3 Short-Time Withstand Current Tests

In case of self-triggered fault current limiters (e.g.

superconducting fault current limiters) the prospective

short-circuit current shall be applied to the device. The

purpose of the test is to verify the current limiting

performance (i.e. the initiating current, the limited

current and the follow current).

External triggered fault current limiters can be divided

in two sub-groups:

Devices which are capable of withstanding the

prospective short-circuit current of the system (e.g.

pyrotechnic fault current limiters): These devices

shall be subjected to a peak and short-time

withstand current test with the prospective shortcircuit current without any limiting operation. The

operation of the triggering device shall be tested

separately to verify the trigger levels required in

accordance with the ratings of the system.

Devices which are not capable of withstanding the

prospective short-circuit current of the system (e.g.

solid-state fault current limiters): These devices

shall be subjected to a peak and short-time

withstand current test with the prospective shortcircuit current with the triggering device operative.

This test will therefore at the same time serve to

verify current limiting performance.

5.4 Short-Circuit Making and Breaking Tests

These tests apply to fault current limiting devices with

current interruption. The short-circuit current breaking

tests shall be carried out at the rated voltage of the fault

current limiter. The source impedance of the test circuit

shall be chosen so that the required prospective shortcircuit current flows in the circuit. Tests at different

fault initiation angles are to be performed in order to

verify that the fault current limiter is capable of

interrupting both symmetrical and asymmetrical

currents. The transient recovery voltage of the test

circuit shall be defined taking into account the network

condition prevailing at the location where the fault

current limiter will be installed.

When a fault current limiter can be used for closing a

circuit, short-circuit current making tests need also to be

carried out.

5.5 Endurance Tests

In case of fault current limiters suitable for more than

one limiting operation an endurance test with an

Electromagnetic compatibility tests shall be carried out

in accordance IEC 60694 [25]. Depending on the type

of fault current limiter and triggering device it may be

advisable to supplement the tests described in IEC

60694 by additional EMC-tests.

6.

Outlook

The management of power systems in countries in all

parts of the world is changing nowadays and there is a

strong tendency towards separating generation from

transmission. In this deregulated environment the

utilities responsible for operating the networks are

losing control over the siting and scheduling of

generation. The connection of independent power

producers to transmission, sub-transmission and

distribution networks causes an increase of short-circuit

currents not included in previous long-term planning

forecasts. A consequence of this development is that in

certain part of the networks the short-circuit currents

approach or even exceed the limiting values.

The problem of excessive short-circuit currents has

therefore become an import issue for the operators of

power systems and there are clear indications for a

growing interest in devices which are capable of

limiting fault currents.

Literature

[1] CIGRE WG 13.10: Functional Specification for a

Fault Current Limiter. ELECTRA (2001)

194, pp. 22-29. Note: the complete report together

with the bibliography can be downloaded from the

web site of CIGRE (http://www.cigre.org)

[2] CIGRE WG 13.10: Fault Current Limiters System Demands (Final Draft). Document 1302(SC) 06 IWD.

[3] CIGRE WG 13.10: Fault Current Limiters - State

of the Art (Final Draft). Document 13-02

(SC) 08 IWD.

[4] CIGRE WG 13.10: Fault Current Limiters Testing (Final Draft). Document 13-02 (SC) 07

IWD.

[5] Steurer, M.; Frhlich, K.: Current Limiters - State

of the Art. Fourth Workshop and Conference on

EHV Technology, Bangalore, 1998.

[6] Noe, M.: Supraleitende Strombegrenzer als

neuartige Betriebsmittel in Elektroenergiesystemen. Dissertation Universitt Hannover,

1998.

[7] Slade, P.G.; Voshall, R.E.; Wu, J.L.; Stacey, E.J.;

Stubler, W.F.; Talvacchio, J.: Study of FaultCurrent-Limiting Techniques. EPRI-Report EL6903, 1990.

[8] Barkan, P.: Effects of Reduced Fault Duration

upon Power-System Components. EPRI-Report

EL-2772, 1982.

[9] Johnson, R.K.; Torgerson, D.R.; Renz, K.;

Thumm, G.; Weiss, S.: Thyristor Control Gives

Flexibility in Series Compensated Transmission.

Power Technology International, 1993.

[10] Wright, A.; Newbery, P.G.: Electric Fuses. The

Institution of Electrical Engineers, 1995.

[11] Dreimann, E.; Grafe, V.; Hartung, K.H.:

Schutzeinrichtungen zur Begrenzung von

Kurzschlusstrmen. ETZ, 115(1994)9, pp. 492494.

[12] Kalkner, B.: Die Begrenzungskupplung, ein

Beitrag zum Kurzschlussproblem des

Verbundbetriebes. ETZ, 87(1966)19, pp. 681-685.

[13] GEC Switchgear Ltd.: Short Circuit Limiting

Couplings. Publication 1491-3, 1975.

[14] Witzmann, R.; Schmidt, W.; Volkmar, R.:

Resistive HTSL-Strombegrenzer. Energietechnik

fr die Zukunft, Internationaler ETG-Kongress

2001, Nrnberg. ETG Fachberichte Band 85,

VDE-Verlag, 2001.

[15] Lakner, M.; Paul, W.; Chen, M.; Rhyner, J.;

Braun, D.: Supraleitende Strombegrenzer Stand der Entwicklung. Energietechnik fr die

Zukunft, Internationaler ETG-Kongress

2001, Nrnberg. ETG-Fachberichte Band 85,

VDE-Verlag, 2001.

[16] Paul, W.; Lakner, M.; Rhyner, J.; Unternhrer, P.;

Baumann, T.; Chen, M. Widenhorn, L.; Guerig,

A.: Test of a 1.2 MVA High-Tc Superconducting

Fault Current Limiter. Supercond. Sci. Technol.

10(1997), pp. 914-918.

[17] Raju, B.P.; Bartram, T.C.: Fault Current Limiter

with Superconducting DC Bias. IEE Proceedings,

129 (1982), pp. 166-171.

[18] Leung, W.; et. al.: Design and Development of a

15 kV, 20 kA HTS Fault Current Limiter. IEEE

Transactions on Applied Superconductivity,

10(2000)1, pp. 832-835.

[19] Strmpler, R.; Skindhoj, J.; Glatz-Reichenbach, J.;

Kuhlefelt, J.H.W.; Perdoncin, F.: Novel Medium

Voltage Fault Current Limiter Based on Polymer

PTC Resistors. IEEE Transactions on Power

Delivery, 14(1999)2, pp. 425-430.

[20] Krtzschmar, A.; Berger, F.; Terhoeven, P.; Rolle,

S.: Liquid Metal Current Limiters.

Proceedings

of the 20th International Conference on Electric

Contacts, Stockholm, 2000, pp. 167172.

[21] Fukagawa, H; Matsumura, T.; Ohkuma, T.;

Sugimoto; S.; Genji, T.; Uezono, H.: Current

State and Future Plans of Fault Current Limiting

Technology in Japan. CIGRE 2000 Session,

Report 13-208, Paris, 2000.

[22] Steurer, M.: Ein hybrides Schaltsystem fr

Mittelspannung zur strombegrenzenden

Kurzschlussunterbrechung. Dissertation ETH

Zrich, 2001.

[23] IEC Publication 60289: Reactors.

[24] IEC Publication 60282-1: High-Voltage Fuses Part 1: Current-Limiting Fuses.

[25] IEC Publication 60694: Common Specifications

for High-Voltage Switchgear and Controlgear

Standards.

You might also like

- Fault Current Limiters Report On The Activities of CIGRE WG A3.10Document9 pagesFault Current Limiters Report On The Activities of CIGRE WG A3.10Sameer MalikNo ratings yet

- PEC006Document7 pagesPEC006Ravi Kiran BNo ratings yet

- Automated Fault Clearance Using Fault Current Limiter in Primary Distribution SystemDocument6 pagesAutomated Fault Clearance Using Fault Current Limiter in Primary Distribution SystemIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- 998 1175581 Harmonic Mitigation SolutionDocument10 pages998 1175581 Harmonic Mitigation SolutionSing-Yew LAMNo ratings yet

- The Effect of DC Offset On Current-Operated RelaysDocument5 pagesThe Effect of DC Offset On Current-Operated Relayseubis_machado4370No ratings yet

- ESBI White Paper Delayed Zero Crossings Following Short Circuit PDFDocument6 pagesESBI White Paper Delayed Zero Crossings Following Short Circuit PDFbgojkovic13No ratings yet

- Comparision PDFDocument5 pagesComparision PDFWESTAREAOPERATIONNo ratings yet

- Understanding of Harmonics in Power Distribution System: Instructor: Dr. Adel. M. SharafDocument29 pagesUnderstanding of Harmonics in Power Distribution System: Instructor: Dr. Adel. M. SharafkgskgmNo ratings yet

- Transformer Inrush Currents and Protection 2603 003 A00Document4 pagesTransformer Inrush Currents and Protection 2603 003 A00Joshi DhvanitNo ratings yet

- Designing Harmonics Filters For Adjustable Speed DrivesDocument6 pagesDesigning Harmonics Filters For Adjustable Speed DrivesRolando AvalosNo ratings yet

- Nterharmonics in Ower Ystems: IEEE Interharmonic Task Force, Cigré 36.05/CIRED 2 CC02 Voltage Quality Working GroupDocument9 pagesNterharmonics in Ower Ystems: IEEE Interharmonic Task Force, Cigré 36.05/CIRED 2 CC02 Voltage Quality Working Groupjeeva_ebookNo ratings yet

- Novel Method For Power Quality Improvement Using Active Power FilterDocument6 pagesNovel Method For Power Quality Improvement Using Active Power Filtersurendiran123No ratings yet

- Voltage Analysis of Distribution Systems With DFIG Wind TurbinesDocument6 pagesVoltage Analysis of Distribution Systems With DFIG Wind TurbinesNirneya GuptaNo ratings yet

- Computation of Transformer Losses Under The Effects of Non-Sinusoidal CurrentsDocument14 pagesComputation of Transformer Losses Under The Effects of Non-Sinusoidal CurrentsAnonymous IlrQK9HuNo ratings yet

- Effects Voltage Sags Industry ApplicationsDocument8 pagesEffects Voltage Sags Industry ApplicationsSJS68No ratings yet

- Module IV Fault Analysis & Short Circuit CalculationsDocument14 pagesModule IV Fault Analysis & Short Circuit Calculationsbobby4u143No ratings yet

- Dstatcom Project ReportDocument43 pagesDstatcom Project ReportMahendar Mahe100% (3)

- Ger 3983B PDFDocument23 pagesGer 3983B PDFerec87No ratings yet

- 948-955 IJER - 2016 - 1201 Mona CDocument7 pages948-955 IJER - 2016 - 1201 Mona CInnovative Research PublicationsNo ratings yet

- Paper Final CorregidoDocument6 pagesPaper Final CorregidoJuan David MartinezNo ratings yet

- Analysis and Control of DSTATCOM For A Line Voltage RegulationDocument6 pagesAnalysis and Control of DSTATCOM For A Line Voltage RegulationSeema P DiwanNo ratings yet

- Local Media5941271462837301265Document65 pagesLocal Media5941271462837301265jason mr.perfect11No ratings yet

- Symmetrical Faults On 3 Phase SystemDocument10 pagesSymmetrical Faults On 3 Phase Systemprincess doctoleroNo ratings yet

- Symmetrical Fault Analysis in Power SystemsDocument14 pagesSymmetrical Fault Analysis in Power Systemsstudents answerNo ratings yet

- Chapter Three: Fault Study, Analysis and Short Circuit CalculationsDocument23 pagesChapter Three: Fault Study, Analysis and Short Circuit Calculationsmuaz_aminu1422No ratings yet

- A Lecture On Current LimiterDocument25 pagesA Lecture On Current LimiterLavanya VallbhareddyNo ratings yet

- Vacuum Contactor Switching Phenomena PDFDocument9 pagesVacuum Contactor Switching Phenomena PDFjulianvillajosNo ratings yet

- COBEP 2005 paper on capacitive compensation in distribution gridsDocument5 pagesCOBEP 2005 paper on capacitive compensation in distribution gridsserban_elNo ratings yet

- HERICDocument7 pagesHERICMinh NhậtNo ratings yet

- Using A Six Fault Zone Approach For Predictive Maintenance On MotorsDocument12 pagesUsing A Six Fault Zone Approach For Predictive Maintenance On Motorsho-faNo ratings yet

- VSD Line ReactorDocument3 pagesVSD Line ReactorAhmed El SebaiiNo ratings yet

- System Neutral Resistance GroundingDocument7 pagesSystem Neutral Resistance GroundingadhyarthaNo ratings yet

- Measurement System For Transformer Inrush Current Higher Harmonics DeterminationDocument6 pagesMeasurement System For Transformer Inrush Current Higher Harmonics DeterminationnmulyonoNo ratings yet

- A Case Study of FerroresonanceDocument36 pagesA Case Study of Ferroresonancefreddy riveraNo ratings yet

- The Application of IEEE-1547 To Small, Residential-Style Wind TurbinesDocument9 pagesThe Application of IEEE-1547 To Small, Residential-Style Wind TurbinesAbhijitKshirsagarNo ratings yet

- Comparison of Volt and Curr SourceDocument6 pagesComparison of Volt and Curr Sourcessp303No ratings yet

- Simulation and Implementation of DVR For Voltage Sag CompensationDocument5 pagesSimulation and Implementation of DVR For Voltage Sag Compensationjcrodriguez83No ratings yet

- Mariusz MalinowskiDocument128 pagesMariusz Malinowskiahmadusman123No ratings yet

- Power Quality Issues and SolutionsDocument26 pagesPower Quality Issues and SolutionsAbhishek Dasari100% (2)

- File Name StamperDocument35 pagesFile Name StampersohaibazamNo ratings yet

- Calculation For Short Circuit Current Calculation Using IEC / IEEE StandardDocument11 pagesCalculation For Short Circuit Current Calculation Using IEC / IEEE StandardibmmoizNo ratings yet

- American International University - Bangladesh (Aiub) : Power System Analysis (Section: B)Document5 pagesAmerican International University - Bangladesh (Aiub) : Power System Analysis (Section: B)M. K. RashedinNo ratings yet

- Investigation of Harmonic Current Source Effects On Distribution and Transmission Lines Capacity and Losses: Case StudyDocument5 pagesInvestigation of Harmonic Current Source Effects On Distribution and Transmission Lines Capacity and Losses: Case Studyawan_krNo ratings yet

- Operational Characteristics of A Filtering Rectifier Transformer For Industrial Power SystemsDocument12 pagesOperational Characteristics of A Filtering Rectifier Transformer For Industrial Power SystemsStedroy RoacheNo ratings yet

- Transformer FaultsDocument11 pagesTransformer FaultsMusembiNo ratings yet

- Ijaret: ©iaemeDocument14 pagesIjaret: ©iaemeIAEME PublicationNo ratings yet

- Reduction of Current Harmonic Distortion in Three-Phase Grid-Connected Photovoltaic Inverters Via Resonant Current ControlDocument9 pagesReduction of Current Harmonic Distortion in Three-Phase Grid-Connected Photovoltaic Inverters Via Resonant Current ControlRam KumarNo ratings yet

- VFD Harmonic MitigationDocument17 pagesVFD Harmonic Mitigationbirmaduu100% (1)

- Transient Stability Improvement of SMIB With Unified Power Flow ControllerDocument78 pagesTransient Stability Improvement of SMIB With Unified Power Flow ControllerRagesh OdungattuNo ratings yet

- Wcecs2009 - pp545-549 Computer LoadsDocument5 pagesWcecs2009 - pp545-549 Computer LoadsYogesh MsdNo ratings yet

- Voltage collapse causes and mitigation techniquesDocument3 pagesVoltage collapse causes and mitigation techniquesNik Mohd Fazli HasifieNo ratings yet

- Comparison of Isolated and Transformer-less PV Inverter TopologiesDocument5 pagesComparison of Isolated and Transformer-less PV Inverter TopologiesmfkashifNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 3: Switching Power SuppliesFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 3: Switching Power SuppliesNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Battery Charger CKT Using SCRDocument20 pagesBattery Charger CKT Using SCRSai Shashank AkulaNo ratings yet

- UniKL MFI Industrial Training Report Presentation Schedule May 2013Document45 pagesUniKL MFI Industrial Training Report Presentation Schedule May 2013Syahmi Azhar100% (1)

- Juhil Zalavadiya: A-65, Charitra Appt. Phase-II, Simandhar City, Trimandir, Adalaj, Gandhinagar Mo: 98259-30639 MailDocument1 pageJuhil Zalavadiya: A-65, Charitra Appt. Phase-II, Simandhar City, Trimandir, Adalaj, Gandhinagar Mo: 98259-30639 MailJuhil ZalavadiyaNo ratings yet

- Discover how EDDY Pumps increase uptime and productivity for industrial processesDocument3 pagesDiscover how EDDY Pumps increase uptime and productivity for industrial processesSekson JunsukplukNo ratings yet

- Distribution PolicyDocument93 pagesDistribution PolicysdmaityNo ratings yet

- Manual Tta - Asco EmersonDocument20 pagesManual Tta - Asco EmersonDennis Walter Ramos TafurNo ratings yet

- A 'Dashboard' for Assessing India's Multi-Dimensional Energy SectorDocument9 pagesA 'Dashboard' for Assessing India's Multi-Dimensional Energy SectorRachita MisraNo ratings yet

- Motor Management and Condition AssessmentDocument4 pagesMotor Management and Condition AssessmentEngr Irfan AkhtarNo ratings yet

- Morgan Advanced Materials Carbon Brushes for Power GenerationDocument4 pagesMorgan Advanced Materials Carbon Brushes for Power GenerationnguyenkuongNo ratings yet

- PF Correction - RickOrman - EFC2016 PDFDocument82 pagesPF Correction - RickOrman - EFC2016 PDFjitendra jhaNo ratings yet

- Refrigerant Suction Recovery UnitDocument4 pagesRefrigerant Suction Recovery UnitOmair FarooqNo ratings yet

- Megaflo Brochure 70lDocument20 pagesMegaflo Brochure 70lSanimouse MousesaniNo ratings yet

- Caustic Soda Market in South Africa 2016-2021 Review - Sample PagesDocument23 pagesCaustic Soda Market in South Africa 2016-2021 Review - Sample PagesShumani Pharamela100% (2)

- Inspection and Test Plan For Fire Tube BoilerDocument4 pagesInspection and Test Plan For Fire Tube BoilerJayaram MV100% (1)

- Fire Water Make Up PumpDocument7 pagesFire Water Make Up PumpAlvin SmithNo ratings yet

- Thermochemistry DPPDocument6 pagesThermochemistry DPPTanisha SubudhiNo ratings yet

- Kadapa PDFDocument20 pagesKadapa PDFMadhavi KurraNo ratings yet

- Eee-503 Elements of Power System 2013-14Document3 pagesEee-503 Elements of Power System 2013-14Devesh RaiNo ratings yet

- Detergent Powder AcknowledgementDocument6 pagesDetergent Powder AcknowledgementAbhayThakurNo ratings yet

- Consultancy For Recycle PSF, Flakes, POY, Washing LineDocument3 pagesConsultancy For Recycle PSF, Flakes, POY, Washing LineMK YogiNo ratings yet

- Module 8 - WESM RulesDocument29 pagesModule 8 - WESM RulesPao CastillonNo ratings yet

- Case Study of Absolute TowerDocument0 pagesCase Study of Absolute TowerSadia HusainNo ratings yet

- Terramax PDFDocument20 pagesTerramax PDFfebriNo ratings yet

- Material Balances Design Project Production of A Drying Oil: Chemical ReactionDocument39 pagesMaterial Balances Design Project Production of A Drying Oil: Chemical ReactionmoheedNo ratings yet

- Philippines Biofuels Policy and OutlookDocument14 pagesPhilippines Biofuels Policy and OutlookByron VergaraNo ratings yet

- Canadian Solar Datasheet CS6P P 270enDocument2 pagesCanadian Solar Datasheet CS6P P 270enDanny Ricce EnriqueNo ratings yet

- ONGC Executive J T Mahavar Google SearchDocument2 pagesONGC Executive J T Mahavar Google SearchPerfectionistSushantNo ratings yet

- Indian Exhibitors ListDocument104 pagesIndian Exhibitors Listadnan editsproNo ratings yet

- Guide To LEED Certification - Commercial - U.SDocument14 pagesGuide To LEED Certification - Commercial - U.SEler GhatNo ratings yet

- MBA ThesisDocument162 pagesMBA ThesisCarlos TorresNo ratings yet