Professional Documents

Culture Documents

Mme

Uploaded by

AmyRapaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mme

Uploaded by

AmyRapaCopyright:

Available Formats

The recrystallisation process is of utmost importance to obtain finest ductility in a material.

In

fact, annealing, is commonly used in the industry so that after recrystallisation occurs, the

material would be adequate for its purpose.

Firstly, recrystallisation anneal (or annealing process) is carried out during most of the

fabrication procedures that require cold working such as sheet and plate forming as well as wire

and deep drawing. During the mentioned processes, a point is reached where one cannot avoid

cracks and damages in the material. Provided this, further cold working would not be possible as

it causes the materials ductility to decline, whilst shifting its yield strength to higher levels. [3]

Thereupon, recrystallisation takes place so as to decrease the material's yield strength and boosts

its ductility. Being ductile, the material could undergo further cold working so that it is

transformed into the desired final product including electricity wires, hospital equipment and

kitchen appliances. Besides, rolled sheets also find their use in roofing of buildings along with

the construction of dams and bridges. [2]

Furthermore, continuous recrystallisation coupled with deformation, is carried out to refine the

deep drawing features of aluminium sheets so that these can be easily turned into beverage cans

or used in the automobile industry for the assembly of several vehicle parts.

Moreover, it is noticeable that recrystallisation is predominant in aluminium and its alloys. After

undergoing recrystallisation, these alloys, including Magnalium and Hiduminium are used for

pistons, bulkheads, ribs and fuselage in an aircraft. [5]

Likewise, steel obtains maximum softness following recrystallisation, as the latter removes

internal strain and stresses in the metal. As a result, being more workable yet still strong, steel is

the perfect choice of material to be used in the landing gear of an aircraft as well as in fasteners

such as rivets, screws and bolts. [1] Additionally, recrystallisation makes steel as the preferred

metal for the skin of certain high speed aircraft. This is because, steel being stronger than

aluminium, yet with improved ductility, can withstand higher temperatures. [4]

Finally, recrystallisation does not only help in manipulating the characteristics and original

internal structure of the material, but market wise, it increases the companies' profits as a result

of reducing their costs. This is because, companies are opting for cheaper materials, knowing

they can obtain the same properties of a more expensive one, through recrystallisation.

References:

1. "What kinds of materials are used to make aircraft?". Retrieved November, 2014

Available: https://howthingsfly.si.edu/structures-materials/materials

2. A , "Apex International". RetrievedNovember , 2014 Available: http://www.apexinternational.org/sheets-coils.html

3. Pfeifer, M , "Annealing to Increase Metal Ductility". Retrieved November , 2014

Available: http://www.imetllc.com/annealing-to-increase-metal-ductility/

4. , K , "Heat treating of aluminum and aluminum alloys". Retrieved November , 2014

Available: http://www.keytometals.com/page.aspx?ID=CheckArticle&site=ktn&NM=7

5. "Aircraft Materials, Processes and Hardware". Retrieved November , 2014 Available:

http://www.faa.gov/regulations_policies/handbooks_manuals/aircraft/amt_handbook/med

ia/faa-8083-30_ch05.pdf

You might also like

- Count Rhythms With Notes and Rests 2Document3 pagesCount Rhythms With Notes and Rests 2AmyRapaNo ratings yet

- Count Rhythms Notes GuideDocument2 pagesCount Rhythms Notes GuideAmyRapaNo ratings yet

- All Rhythm Worksheets in One FileDocument28 pagesAll Rhythm Worksheets in One FileAmyRapa100% (1)

- Music Theory Worksheet 17 Sharps PDFDocument1 pageMusic Theory Worksheet 17 Sharps PDFNoreen Ann Flynn0% (2)

- Grade 1 NotesDocument5 pagesGrade 1 NotesAmyRapaNo ratings yet

- Theory Worksheet Major Scale Notation PDFDocument1 pageTheory Worksheet Major Scale Notation PDFRonan SharkeyNo ratings yet

- Count Rhythms Notes RestsDocument2 pagesCount Rhythms Notes RestsAmyRapaNo ratings yet

- Major Scale PDFDocument1 pageMajor Scale PDFGeraldNo ratings yet

- Music Theory Worksheet 18 Whole Half Stepsv2 PDFDocument1 pageMusic Theory Worksheet 18 Whole Half Stepsv2 PDFJelenaGutić67% (3)

- Music Theory Worksheet 8 Grand Staff PDFDocument1 pageMusic Theory Worksheet 8 Grand Staff PDFTeganMillerNo ratings yet

- Music Theory Worksheet 12 Eighth Notes PDFDocument1 pageMusic Theory Worksheet 12 Eighth Notes PDFAmyRapa100% (1)

- Music Theory Worksheet 13 Eighth Rests PDFDocument1 pageMusic Theory Worksheet 13 Eighth Rests PDFAmyRapaNo ratings yet

- Music Theory Worksheet 9 Ledger LinesDocument1 pageMusic Theory Worksheet 9 Ledger LinesKaty-Gianina Strugaru83% (6)

- Music Theory Worksheet 14 Dotted Quarter Notes PDFDocument1 pageMusic Theory Worksheet 14 Dotted Quarter Notes PDFTeganMiller0% (1)

- Music Theory Worksheet 20 Natural Minor ScaleDocument1 pageMusic Theory Worksheet 20 Natural Minor ScaleTeganMiller100% (1)

- Music Theory Worksheet 21 Harmonic Minor ScaleDocument1 pageMusic Theory Worksheet 21 Harmonic Minor ScaleTeganMillerNo ratings yet

- Part SongsDocument2 pagesPart SongsAmyRapaNo ratings yet

- Health and Safety Manual Company TemplateDocument55 pagesHealth and Safety Manual Company Templatepandu_chemengNo ratings yet

- Rehearsal 4Document2 pagesRehearsal 4AmyRapaNo ratings yet

- Play This Song With The Regular Shapes of The Chords Given in This SongDocument2 pagesPlay This Song With The Regular Shapes of The Chords Given in This Songdankor 04No ratings yet

- Beautiful in WhiteDocument3 pagesBeautiful in WhiteAmyRapaNo ratings yet

- Happy Xmas (War Is Over)Document2 pagesHappy Xmas (War Is Over)AmyRapaNo ratings yet

- Musical Knowledge ParametersDocument2 pagesMusical Knowledge Parameterssrinivas_gajulNo ratings yet

- Rehearsal 1 PDFDocument2 pagesRehearsal 1 PDFAmyRapaNo ratings yet

- Kings of Leon - Sex On FireDocument3 pagesKings of Leon - Sex On FireAmyRapaNo ratings yet

- Autumn Leaves: C F B EDocument1 pageAutumn Leaves: C F B EAmyRapaNo ratings yet

- Amy Rapa 2/16/2018: Designed by Checked by Approved by Date DateDocument1 pageAmy Rapa 2/16/2018: Designed by Checked by Approved by Date DateAmyRapaNo ratings yet

- 1st MarchDocument6 pages1st MarchAmyRapaNo ratings yet

- Consent Form Xewkija Forms 2 3Document1 pageConsent Form Xewkija Forms 2 3AmyRapaNo ratings yet

- Drying Technology: An International JournalDocument3 pagesDrying Technology: An International JournalAmyRapaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Beginner's Guide To Centrifugal Compressor Design and SimulationDocument17 pagesBeginner's Guide To Centrifugal Compressor Design and Simulationvijay_jvNo ratings yet

- Fall Magazine Aug 4Document27 pagesFall Magazine Aug 4Ed GoncalvesNo ratings yet

- IPCC Waste ModelDocument103 pagesIPCC Waste ModelEndah Sri PraptianiNo ratings yet

- Courts uphold possession rights of farmers over disputed landDocument36 pagesCourts uphold possession rights of farmers over disputed landJan Aguilar EstefaniNo ratings yet

- AAP 851 Vamp 30 Repair Manual 195212 OCRDocument210 pagesAAP 851 Vamp 30 Repair Manual 195212 OCRNicholasNo ratings yet

- The Lean Journey at BoeingDocument9 pagesThe Lean Journey at Boeingoscar100% (1)

- BRC Order of Prayer PDFDocument20 pagesBRC Order of Prayer PDFMaryvincoNo ratings yet

- Application Engineering BulletinDocument11 pagesApplication Engineering BulletinCesar G.No ratings yet

- Fractal Music, Hypercards & More Mathematical Recreations From Scientific American Magazine - Martin Gardner - EnglishDocument334 pagesFractal Music, Hypercards & More Mathematical Recreations From Scientific American Magazine - Martin Gardner - EnglishValaki Aki100% (5)

- Cutting Tools and Essentials GuideDocument6 pagesCutting Tools and Essentials GuideCaleb ArbouetNo ratings yet

- Hydraulic HammerDocument153 pagesHydraulic Hammerk2rnoir100% (1)

- MFB Filter Center Frequency CalculationDocument4 pagesMFB Filter Center Frequency Calculationdoctorsur7No ratings yet

- Rounded Scoodie Bobwilson123 PDFDocument3 pagesRounded Scoodie Bobwilson123 PDFStefania MoldoveanuNo ratings yet

- ExChEL Group Study Session 13 - Day 1 ExaminationDocument15 pagesExChEL Group Study Session 13 - Day 1 ExaminationRochelle Louise SampagaNo ratings yet

- Anodize AluminiumDocument200 pagesAnodize AluminiumYunus LorrNo ratings yet

- Catalog 08 PDFDocument216 pagesCatalog 08 PDFไอ้หนุ่ม ร้อยแรง100% (1)

- Weather ProjectDocument4 pagesWeather Projectapi-271953090No ratings yet

- Autolift 3000 User ManualDocument16 pagesAutolift 3000 User ManualAntonioPalloneNo ratings yet

- Advr 440 Manual enDocument5 pagesAdvr 440 Manual enBrianHazeNo ratings yet

- Friction From Meriam PDF 161228121738 PDFDocument62 pagesFriction From Meriam PDF 161228121738 PDFTHEOPHILUS ATO FLETCHERNo ratings yet

- 07 - SELinuxDocument46 pages07 - SELinuxridaNo ratings yet

- Warman Mcu 350 Masbate Philippines Case Study DuplicateDocument2 pagesWarman Mcu 350 Masbate Philippines Case Study DuplicateBJ AbelaNo ratings yet

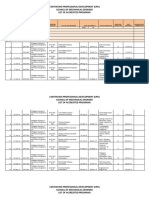

- CPDprogram MECHENG-91018Document43 pagesCPDprogram MECHENG-91018PRC Board100% (1)

- EWD-H-KXJ3 Elevator Load Weighing GuideDocument10 pagesEWD-H-KXJ3 Elevator Load Weighing GuideKang RohendyNo ratings yet

- Hydraulic Guidelines Bridge Design ProjectsDocument15 pagesHydraulic Guidelines Bridge Design ProjectsUmmi Ummi Ummi0% (1)

- Self HRMDocument372 pagesSelf HRMSaad NazeerNo ratings yet

- Nylosolv Additiv A ENDocument1 pageNylosolv Additiv A ENMohammed Abdul HaleemNo ratings yet

- Bridge Bearings 2014Document167 pagesBridge Bearings 2014ErDKushwaha100% (1)

- Switching TrainningDocument107 pagesSwitching TrainningchinthasreenivasaraoNo ratings yet

- Discretization of The Markov Regime Switching AR (1) Process: Yan Liu Wuhan UniversityDocument13 pagesDiscretization of The Markov Regime Switching AR (1) Process: Yan Liu Wuhan UniversityAbinash MishraNo ratings yet