Professional Documents

Culture Documents

Low Voltage and High Voltage Cable Testin1

Uploaded by

Himdad TahirOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Low Voltage and High Voltage Cable Testin1

Uploaded by

Himdad TahirCopyright:

Available Formats

Low Voltage and High Voltage Cable Testing

LOW VOLTAGE XLPE DISTRIBUTION CABLES:

Insulation Resistance:

Cables shall be tested for insulation resistance with an insulation tester (i.e. Megger) at 1000 Volts for 1 minute.

The minimum insulation resistance to earth or between phases shall be 100 meg-ohms.

The instrument used for this measurement shall have a minimum resolution of 10 meg-ohms on the 0 to 500

meg-ohm range.

At the conclusion of LV insulation resistance testing, the neutrals must be connected to the earth stakes.

Phasing Test:

The correct phasing of all LV circuits shall be checked at all positions where the LV cables are terminated into

fuse bases and where any LV cable is run from point to point.

This test shall be performed with an instrument designed for the purpose. Mains frequency voltage of 240 Volts is

not acceptable for this test.

The neutral conductor shall be connected to the earth stake for this test.

Continuity Test (resistance of bolted connections):

For loop LV systems, a continuity test shall be carried out on each LV circuit to ensure that all bolted connections

are complete and adequate. The test shall be carried out as follows:

(1)

(2) Undertake a continuity test at every point where there is a service provision or open point. In a fused service

At the transformer firmly bond all 4 conductors together

pillar the bottom row of fuses bases must be the point at which the test is undertaken as that is the furthest extent

of the network.

The difference between the readings of each phase conductor and the neutral for each individual test shall not be

greater than 10% of each other. Any difference greater than this may indicate a loose or dirty connection and will

require further investigation.

The instrument used for this measurement should have a resolution to the second decimal point in the 0 to 5 ohm

range.

A typical instrument would be the earth Megger type and taking into account the resistance values of the test

leads.

Earth Resistance Test:

In any overhead or underground network the earth resistance at any point along the length of a LV feeder is to

have a maximum resistance of 10 ohms prior to connection to the existing network.

In any overhead or underground network the overall resistance to earth Shall be less than 1 ohm prior to

connection to the existing network.

11 KV AND 33 KV XLPE CABLES CABLE:

Phasing Test

The correct phasing of all HV circuits shall be checked at all positions where the HV cables have been

terminated.

This test shall be performed with an instrument designed for the purpose. 240 Volt mains frequency is not

acceptable for the performance of this test. The test may be conducted on either the wire screens or the

aluminum conductors.

Where the test is performed on the wire screens, they shall be disconnected from earth.

Outer Sheath Insulation Resistance (Screen wire test)

The purpose of the test is to determine soundness of the outer polyethylene sheath against water ingress,

mechanical damage and termite attack.

Values below 0.5 meg-ohms (500 k) can indicate sheath damage. Values between 1.0 and 10 meg-ohms may

not indicate damage in a single location. Fault finding can often be very difficult. In new cables, values of greater

than 100 mega ohms are required.

The integrity of the outer sheath shall be checked after cables have been buried by an insulation tester (Megger)

at 1000 Volts.

The test shall be conducted for 1 minute between each wire screen and earth after the cable has been jointed

and terminations installed.

For cables after repairs, the resistance must not be less than 10 meg-ohms.

Where HV cable circuits are cut and joined to new circuits, sheath testing must be carried out on the existing old

circuit prior to joining to the new cable.

HV test on XLPE cables already in service or previously energized

Except for New Cables, Testing at Voltage greater than 5.0KV is not permitted

Studies carried out on DC high voltage testing of XLPE cables now conclude that;

DC testing above 5kV of field aged XLPE cables generally increases water tree growth and reduces service life.

5kV is not considered a High Voltage DC Test. The test voltages for tests on XLPE cables is now limited to 5kV

after in service repairs and 10kV for new installations.

A 5kV Megger is suitable for a 5kV test on cables after repairs.

The changes to this section will also make it possible for a repaired cable to be tested by repair crews and made

available for immediate return to service.

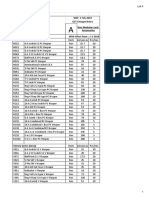

Application

Test Voltage

Criteria

After repairs Sheath

1kV Megger 1 minute

10 meg-ohms min.

After repairs Insulation

5kV Megger 1 minute

1000 meg-ohms min.

After repairs Insulation

5kV DC 1 minute

5.0 A (micro-amps) max.

HV test on new XLPE cable:

Prior to the performance of this test, the screen wires must be connected to the permanent earth position.

The cable shall be tested at the test voltage and the pass criteria shall be in accordance with the following table:

Application

Test Voltage

Criteria

New cables Sheath

1kV Megger 1 minute

100 meg-ohms min.

New cables Insulation

10kV DC 15 minute

1.0 A (micro-amps) max

New cables Insulation

10kV DC 15 minute

1000 meg-ohms min.

If further repair works are undertaken, and they require additional joints to be installed, the complete HV testing

procedure shall be repeated.

Alternative HV Test Requirement on Insulation for 11kV Cables

Where it is not practical to conduct a high voltage test, the test requirements for insulation (core to screen wire)

may be limited to testing for the condition of safe to energize. The following list of circumstances and conditions

must be met as a minimum requirement:

The cable circuit voltage shall be 11kV,

The circuit outage duration shall be not more than 48 hours,

The work shall involve extending or repairs to existing circuits,

The insulation test shall be applied for 1 minute between each

phase core and screen with a 1000 Volt minimum insulation tester (Megger),

Typically the test result should be in the order of 1000 meg-ohms.

PAPER INSULATED CABLES

Tests on LV Cables

An insulation resistance test shall be conducted with a 1000 Volt megger. Test results as low as 10 meg-ohms on

old cable circuits are common and therefore considered safe to energies.

Test on 11kV and 33kV Cables between Cores and Earth

For three core belted cables, the test on any core shall be conducted between the core and lead sheath with the

remaining two cores connected to earth.

The test voltages and pass criteria shall be in accordance with the table below.

Application

Test Voltage

Criteria

11kV new cables

5kV Megger 1 minute

100 meg-ohms.

11kV after repairs

5kV Megger 1 minute

100 meg-ohms.

33kV no TFs connected

5kV Megger 1 minute

1000 meg-ohms.

33kV with TFs connected

5kV Megger 1 minute

15 meg-ohms.

66kV XLPE CABLES

Core to Sheath Test after Repairs:

After repairs have been carried out, the 66kV XLPE cable shall be energized at power frequency for 24 hours

without load. DC testing is not permitted.

The cable sheath link box/cross bonding system shall be put into its normal condition.

Outer Sheath Integrity Test:

An insulation resistance test between the metallic sheath and earth shall be conducted. The anti-termite barrier

must be connected to the metallic sheath and the insulation test performed to earth.

The test voltage applied for 1 minute shall be 5kV DC applied with either a high voltage test set or insulation

resistance tester (Megger).

References:

ETSA TECHNICAL STANDARD

You might also like

- GE Circuit BreakersDocument6 pagesGE Circuit BreakerstowiwaNo ratings yet

- Cable TerminationDocument2 pagesCable Terminationapandey070273No ratings yet

- DG BusductDocument16 pagesDG BusductanandpurushothamanNo ratings yet

- EHVHV Underground Cable Sheath Earthing Part 12Document5 pagesEHVHV Underground Cable Sheath Earthing Part 12rajfab100% (1)

- Selection of Cables/ConductorsDocument37 pagesSelection of Cables/ConductorsshuwingNo ratings yet

- Interleaved Bus Bar Explanation PDFDocument4 pagesInterleaved Bus Bar Explanation PDFVikram Singh100% (2)

- HIPOT Testing (Dielectric Strength Test)Document5 pagesHIPOT Testing (Dielectric Strength Test)Wathik AbmNo ratings yet

- Cable SizingDocument25 pagesCable Sizing54045114100% (1)

- Voltage Drop Calculation For XLPEDocument1 pageVoltage Drop Calculation For XLPEedwin fernandezNo ratings yet

- Technical Specification of Lattice Steel PolesDocument9 pagesTechnical Specification of Lattice Steel PolesCalinB.ACNo ratings yet

- Cable Etap 01 18 2IN1 PDFDocument77 pagesCable Etap 01 18 2IN1 PDFMichael BesaNo ratings yet

- A Review of Polarization Index and IEEE Standard 43-2000Document5 pagesA Review of Polarization Index and IEEE Standard 43-2000vasanth11kvNo ratings yet

- Busbar Arrangement (BUSBAR SCHEME) PDFDocument7 pagesBusbar Arrangement (BUSBAR SCHEME) PDFRaditya Ghani100% (1)

- Calculation of Voltage Drop and Cable Size For Motor / Elect - LoadDocument33 pagesCalculation of Voltage Drop and Cable Size For Motor / Elect - LoadpraveshkafleNo ratings yet

- CBCT AbbDocument272 pagesCBCT AbbAnonymous rWZ2WNh4No ratings yet

- Simplified Method For Short Circuit CalculationsDocument4 pagesSimplified Method For Short Circuit Calculationshaiob100% (1)

- Heatshrink Joints PDFDocument24 pagesHeatshrink Joints PDFMonish KrishnaNo ratings yet

- Battery Sizing: From Open ElectricalDocument11 pagesBattery Sizing: From Open ElectricalBADRI VENKATESHNo ratings yet

- RE - 5 - Phase Discontinuity Protection Function DI (CUB3Low)Document14 pagesRE - 5 - Phase Discontinuity Protection Function DI (CUB3Low)rajeshNo ratings yet

- Harmonics & There Filters 1Document41 pagesHarmonics & There Filters 1Talha MehmoodNo ratings yet

- Different IEC Standards For Solar WorksDocument2 pagesDifferent IEC Standards For Solar Worksfurqan343No ratings yet

- Reduced Series ReactorDocument10 pagesReduced Series ReactorclicknagpalNo ratings yet

- Cable JointsDocument2 pagesCable Jointsneha061089No ratings yet

- Abstract of IS 694-1554-11892Document2 pagesAbstract of IS 694-1554-11892Jignesh ParmarNo ratings yet

- Busduct FormatDocument5 pagesBusduct FormatAjish Rajan TNo ratings yet

- Substation Equipment Failure Report October 14 To August 15Document95 pagesSubstation Equipment Failure Report October 14 To August 15Yogendra SwarnkarNo ratings yet

- As 4398.1-1996 (R2010) Insulators - Ceramic or Glass - Station Post For Indoor and Outdoor Use - Voltages GREDocument8 pagesAs 4398.1-1996 (R2010) Insulators - Ceramic or Glass - Station Post For Indoor and Outdoor Use - Voltages GRESAI Global - APACNo ratings yet

- Electrical Test After Site Installation 62067 IEC-2011Document5 pagesElectrical Test After Site Installation 62067 IEC-2011waqas_a_shaikh4348No ratings yet

- Study and Analysis On 33Kv Transmission Line Loss Calculation of Pabna Pbs-2Document10 pagesStudy and Analysis On 33Kv Transmission Line Loss Calculation of Pabna Pbs-2mv_mallikNo ratings yet

- BUS BAR Sizing CalculationDocument2 pagesBUS BAR Sizing Calculationmohan babuNo ratings yet

- Cable Impedance Calculations - Open ElectricalDocument4 pagesCable Impedance Calculations - Open Electricaludayakumart100% (1)

- HV Cable Sheath EarthingDocument15 pagesHV Cable Sheath EarthingjuliancansenNo ratings yet

- Conductors Damage Curves CablesDocument4 pagesConductors Damage Curves Cablesnegrin100% (1)

- Arc Control in Circuit Breakers: Low Contact Velocity 2nd EditionFrom EverandArc Control in Circuit Breakers: Low Contact Velocity 2nd EditionNo ratings yet

- Theory Fault CalcDocument11 pagesTheory Fault CalcSureshraja9977No ratings yet

- 11kv CablesDocument46 pages11kv CablesS.k. RathNo ratings yet

- Cable Fault DetectionDocument15 pagesCable Fault DetectionVarun Thakur100% (1)

- Paper On Water Tree Resistant XLPEDocument4 pagesPaper On Water Tree Resistant XLPEMahadi HassanNo ratings yet

- 8.I-11 KV Xlpe CablesDocument5 pages8.I-11 KV Xlpe CablesAnkur SinhaNo ratings yet

- P64x EN AP A11Document92 pagesP64x EN AP A11Sakthi Krishnan0% (1)

- Measurement of Insulation Resistance (IR) - Part 2 - EEP PDFDocument16 pagesMeasurement of Insulation Resistance (IR) - Part 2 - EEP PDFHeri SulaimanNo ratings yet

- Technical Note: Trip-Circuit Supervision (TCS)Document30 pagesTechnical Note: Trip-Circuit Supervision (TCS)feromagnetizamNo ratings yet

- Earthing Protection SpecificationDocument5 pagesEarthing Protection SpecificationNi ReNo ratings yet

- Uniformity RatiosDocument27 pagesUniformity RatiosApurve Pratap SinghNo ratings yet

- HV Test of PanelsDocument5 pagesHV Test of PanelsSumit SawaiNo ratings yet

- Joints and Terminations of Polymeric Cables For Working Voltages From 6.6 KV Up To and Including 33 KV - Performance Requirements and Type TestsDocument14 pagesJoints and Terminations of Polymeric Cables For Working Voltages From 6.6 KV Up To and Including 33 KV - Performance Requirements and Type TestsPrashant TrivediNo ratings yet

- Operacion Recloser RoclwillDocument54 pagesOperacion Recloser RoclwillChristian Vasquez MedranoNo ratings yet

- Idoc - Pub - Iec 60228 Conductors of Insluated Cablespdf PDFDocument52 pagesIdoc - Pub - Iec 60228 Conductors of Insluated Cablespdf PDFShashank SaxenaNo ratings yet

- 5-Power & Control Cables PDFDocument11 pages5-Power & Control Cables PDFAnonymous ufMAGXcskMNo ratings yet

- Fire Resistant 08Document36 pagesFire Resistant 08mehdi227No ratings yet

- Sizing of Power Cables For Circuit Breaker Controlled Feeders (Part 3) - EEP PDFDocument21 pagesSizing of Power Cables For Circuit Breaker Controlled Feeders (Part 3) - EEP PDFNatarajan ViswanathanNo ratings yet

- LT & HT Cable SpecificationDocument5 pagesLT & HT Cable SpecificationMohammed Irshad50% (2)

- Megger-Insulation Test ValuesDocument4 pagesMegger-Insulation Test ValuesJoeDabid100% (1)

- Low Voltage and High Voltage Cable Testing 1700529056Document4 pagesLow Voltage and High Voltage Cable Testing 1700529056prabhakaran jaganathanNo ratings yet

- Xlpe Cable Commissioning Test Procedure Following Iec StandardDocument5 pagesXlpe Cable Commissioning Test Procedure Following Iec StandardAkd Deshmukh100% (2)

- Cable TestingDocument29 pagesCable TestingRakesh Kumar100% (4)

- Test On 110kV Power Cable After InstallationDocument9 pagesTest On 110kV Power Cable After InstallationKate Catherine RamosNo ratings yet

- Electrical Power Transmission 4Document7 pagesElectrical Power Transmission 4FaisalSoNo ratings yet

- IR Insulation Resistance ValuesDocument11 pagesIR Insulation Resistance ValuesBenabidNo ratings yet

- Etap Validation Cases and Comparison Results: Load FlowDocument66 pagesEtap Validation Cases and Comparison Results: Load FlowK.RamachandranNo ratings yet

- Application Guide Over-Current Protection TutorialDocument37 pagesApplication Guide Over-Current Protection Tutorialluhusapa-1No ratings yet

- Tutorial Digsilent InglesDocument18 pagesTutorial Digsilent InglesHenry MichaelNo ratings yet

- Police Office Station - BOQ - UNOPS - AfghanistanDocument6 pagesPolice Office Station - BOQ - UNOPS - AfghanistanHimdad TahirNo ratings yet

- Suruhanjaya Tenaga - Guidelines For Wiring ResidentialDocument55 pagesSuruhanjaya Tenaga - Guidelines For Wiring Residentialkingcloud7100% (24)

- Normal Earth-Earth Fault Current &csa TableDocument37 pagesNormal Earth-Earth Fault Current &csa TableAbraham JyothimonNo ratings yet

- 100 Words Kids Need To Read PDFDocument92 pages100 Words Kids Need To Read PDFHimdad Tahir0% (1)

- Pcm600 en ManualDocument12 pagesPcm600 en ManualRobert RocafuerteNo ratings yet

- ECP 11-0209 Interlocks Test Form: 1 General DataDocument3 pagesECP 11-0209 Interlocks Test Form: 1 General DataHimdad TahirNo ratings yet

- CewePrometer User Manual (Cewe) BGX501-856-R02Document80 pagesCewePrometer User Manual (Cewe) BGX501-856-R02Himdad Tahir100% (1)

- Normal Earth-Earth Fault Current &csa TableDocument37 pagesNormal Earth-Earth Fault Current &csa TableAbraham JyothimonNo ratings yet

- Constant of 132 KV and 400 KV Over Head Lines PDFDocument1 pageConstant of 132 KV and 400 KV Over Head Lines PDFHimdad TahirNo ratings yet

- Abb Fast Switching Apfc RelayDocument2 pagesAbb Fast Switching Apfc RelayParashar PathakNo ratings yet

- Principles of MV SWG Testing 01: Visual InspectionDocument7 pagesPrinciples of MV SWG Testing 01: Visual InspectionAhmed Mohsen HandoussaNo ratings yet

- Incremental Encoders: Solid Shaft With EURO Flange B10 25... 5000 Pulses Per RevolutionDocument4 pagesIncremental Encoders: Solid Shaft With EURO Flange B10 25... 5000 Pulses Per RevolutionSaraNo ratings yet

- S2C-H6-11R - Auxiliary ContactDocument3 pagesS2C-H6-11R - Auxiliary ContactJulian PinedaNo ratings yet

- Compact NS - 630A - 30783Document3 pagesCompact NS - 630A - 30783R TNo ratings yet

- Half Wave & Full Wave RectifiersDocument19 pagesHalf Wave & Full Wave RectifiersRNKNo ratings yet

- Table 4d4aDocument2 pagesTable 4d4aZunnur ZamzamNo ratings yet

- 12 Class Physics Investigatory Project On TransformersdocxDocument12 pages12 Class Physics Investigatory Project On TransformersdocxHritik ChouhanNo ratings yet

- DT92xx MultimeterDocument5 pagesDT92xx Multimeterhammouche_soufianeNo ratings yet

- 1977 Wiring DiagramsDocument11 pages1977 Wiring Diagramspete112No ratings yet

- Service and Installation SYNAPSIS RADARDocument422 pagesService and Installation SYNAPSIS RADARElectrifying GuyNo ratings yet

- AWA0000C1Document34 pagesAWA0000C1AB-S ELECTRO MECHANICAL INDUSTRIAL AUTOMATIONNo ratings yet

- Technical Manual FOR Compact HF SSB N2161: S.P. Radio A/S Aalborg DenmarkDocument29 pagesTechnical Manual FOR Compact HF SSB N2161: S.P. Radio A/S Aalborg DenmarkEstetNo ratings yet

- Transistor CharacteristicsDocument25 pagesTransistor Characteristicsmanish100% (1)

- PC-3000RL ManualDocument4 pagesPC-3000RL Manualmartynas.bNo ratings yet

- Agente Limpio & Diluvio 4010ESDocument8 pagesAgente Limpio & Diluvio 4010ESData Clean Sac ChisanNo ratings yet

- MCBDocument6 pagesMCBvicky gosaviNo ratings yet

- 2500 CryptoDocument14 pages2500 CryptoinsulatedNo ratings yet

- Integrated CircuitsDocument204 pagesIntegrated CircuitsvipinNo ratings yet

- GX Series: Installation, Operation, & Maintenance InstructionsDocument36 pagesGX Series: Installation, Operation, & Maintenance Instructionsy149487No ratings yet

- EE6004Document58 pagesEE6004Anonymous DAjfj9HIBmNo ratings yet

- BVCDocument4 pagesBVCD SNo ratings yet

- Hosper List - Feb 2019 - ADocument4 pagesHosper List - Feb 2019 - ANikhil GoelNo ratings yet

- EIN 01 Questions 20 November 10Document22 pagesEIN 01 Questions 20 November 10Aleihs AyadneNo ratings yet

- DPT 2Document15 pagesDPT 2shadman souravNo ratings yet

- Push - Pull Converter - 4 - Wavforms - Voltage - StressDocument18 pagesPush - Pull Converter - 4 - Wavforms - Voltage - StressEngr Fahimuddin QureshiNo ratings yet

- of PDP Dec-21Document28 pagesof PDP Dec-21BHUVANESH MNo ratings yet

- Dry Type TrafoDocument2 pagesDry Type Trafok_arindam1No ratings yet

- 800ma Low Dropout Positive Regulator: Features DescriptionDocument12 pages800ma Low Dropout Positive Regulator: Features DescriptionmarcianocalviNo ratings yet

- Trapatt, ImpattDocument9 pagesTrapatt, ImpattVasavi MagadapalliNo ratings yet