Professional Documents

Culture Documents

160.47-PW6 Solid State Starter

Uploaded by

Awo Orumila GiraldolegraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

160.47-PW6 Solid State Starter

Uploaded by

Awo Orumila GiraldolegraCopyright:

Available Formats

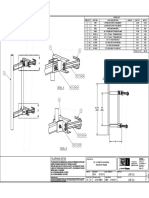

FORM 160.

47-PW6

ELEMENTARY DIAGRAM (Contd)

Supersedes: 160.47-PW6 (1197)

Transient Overvoltage dv/dt rate of rise protection for the

SDCs is furnished by a snubber resistor capacitor (R-C)

network. It prevents false firing of the SCRs and reduces the

repetitive peak transient voltage (from incoming power line).

Out-Of-Phase Re-energization Protection (Power Fault)

Incoming power line momentary interruption (one electrical

cycle duration detected) circuitry to shut down the starter and

unit. Disconnects starter within 3-1/2 electrical cycles. Autoreset, restarting unit automatically once fault has cleared.

Prevents abnormally high inrush currents, (resulting in high

transient motor shaft torque) that can be produced in the motor

when it is re-energized soon after a power interruption.

POWER FAULT indicator is lit and maintained until reset.

Locked Rotor Protection If the motor is stalled and will

not come up to speed, a timer (see below) will shut down the

starter and unit after approximately 40 seconds.

105% Motor Current Light Indicates the compressor-motor current has exceeded 105% full load amps and the 40

second overload timer has started. If for any reason, the compressor motor does not come up to speed, timer will shut

down the starter and unit after approximately 40 seconds.

This provides an incomplete start sequence function.

Out-of-Lock Light Indicates excessive input line-to-line voltage distortion and initiates system shutdown.

LD02613

Starter Fault Light Indicates the compressor-motor current

has exceeded 150% of starting current and the one second

overload timer has started; timer shuts down the starter and

unit.

Undervoltage Safety Prevents start-up or causes shutdown

if the input line-to-line voltage (any phase) drops below 80%

of the nominal line voltage. Safety is reset when input voltage

rises to 88% of nominal line voltage. Displayed on

MicroComputer Control Center readout.

Phase Current Unbalance Causes system shutdown if the

percent current unbalance exceeds 30% while operating at

or above 80% FLA. Displayed on MicroComputer Control

Center readout.

Fusing Starter 3-phase control circuit fuse holders with 500

volt dual element fuses for 200 thru 460 volts or 600 volt single

element fuses for 575 volts. Protection for gate driver/voltmeter transformer and control transformer.

Interlocks A panel shutdown relay provides positive shutdown of the unit on any starter safety control shutdown; any

unit safety or operating control shutdown, through the YORK

Control Center, will stop the starter via starter control signal.

All interlocks between the YORK Control Center and starter

are furnished completely factory wired.

NOTE: Indicating lights and reset button are on the logic

board inside the MicroComputer Control Center.

PRODUCT DRAWING

YORK INTERNATIONAL CORPORATION

P.O. Box 1592, York, PA 17405

CONTRACTOR _______________________

ORDER NO. __________________________

YORK CONTRACT NO. _________________

YORK ORDER NO. ____________________

REFERENCE

DATE ________

WIRING DIAGRAM

YORK SOLID STATE STARTER

MILLENNIUM YS (STYLE C & D) ROTARY SCREW CHILLER

WITH MICROCOMPUTER CONTROL CENTER

PURCHASER ____________________________________________

JOB NAME _______________________________________________

LOCATION _______________________________________________

ENGINEER ______________________________________________

APPROVAL

NOTES:

CONTROL POWER SUPPLY

1. Field Wiring to be in accordance with the current edition of

the National Electric Code as well as all other applicable

codes and specifications.

1.5 KVA 115 volt, control power transformer (on side of

starter) with 15 amp secondary fuse (located within Solid State

Starter). Provides control power for starter, YORK Control

Center and starter cooling pump power; completely factory

installed and wired.

2. Numbers along the left side of the elementary diagram are

line identification numbers. The numbers along the right

side indicate the line number location of relay contacts. An

underlined contact location signifies a normally closed contact.

Main power connection points are indicated by numbers

within a hexagon, i.e. L2

Enclosure NEMA I, ventilated; hinged door with lock and

key latch; for indoor location.

Disconnect Switch Optional unit mounted factory wired disconnects available for SSS-7L, SSS-14L and SSS-26L models.

Numbers adjacent to circuit lines are the circuit identification numbers.

Cooling System Water cooled; unit mounted, factory wired,

inherently protected, 115V, 1/22 HP pump; unit mounted,

cleanable heat exchanger.

PROTECTIVE DEVICES AND

SERVICE INDICATORS (LED TYPE)

Mounting Unit mounted on the compressor-motor at the

factory. Starter factory wired to YORK Control Center, and

compressor-motor and cooling pump motor.

Meters

Ammeter Simultaneous 3-phase, digital readout via Micro Computer Control Center. Three current transformers

provide isolated sensing. Accuracy is typically 3% of full

scale. Scales: 7L 0-750A, 14L 0-1500A, 26L 0-2800A,

33L 0-3500A.

Voltmeter Simultaneous 3-phase, digital readout via Micro Computer Control Center. 3-phase potential transformer

provides isolated sensing. Accuracy is typically 3% of full

scale. Scales: 0-300V for 200-240V starters, 0-700V for

380-600V starters.

Elapsed Time Meter Digital readout of elapsed running

time (0 - 65,535 hours resetable) via MicroComputer Control Center.

Component terminal markings are indicated by numbers

within a circle, i.e. 2

9. Starter approximate overall dimensions are:

7L/14L 34" wide x 21-1/2" high x 11" deep; weight is

approx. 194 lbs. with transformer.

26L/33L 35" wide x 25-1/2" high x 12" deep; weight is

approx. 294 lbs. with transformer. See Notes

7 & 8.

10. The starter will not apply power to the compressor-motor

if the ambient air temperature is higher than 110F. The

starter cooling pump will begin to run when the compressor-motor is started, and continue to run while the compressor-motor is operating. When the compressor-motor is de-energized, the cooling pump will continue to run

until the SCR temperature is reduced to 110F.

Motor Overcurrent Protection Three-leg sensing solid

state current overloads with indicating light and reset button.

Ambient temperature compensated protection system provides compressor-motor overcurrent protection at 105% full

load current and at 150% of Start current setting. Overload light indicates overcurrent condition has stopped the

starter and unit.

5. The three-phase solid state motor overload protection system provides compressor-motor overcurrent protection at

105% Full Load Amps.

11. The short circuit withstand capacity, as tested per U.L.

Standard 508 (13th Edition), Para. 31 at 480 volts, in

RMS (Root Mean Square equals .707 x peak current),

symmetrical current are: SSS-7L, 18,000 amps; SSS14L, 30,000 amps; SSS-26L and SSS-33L, 42,000

amps. The short circuit withstand capacity of the YORK

Solid State Starter with optional disconnect switch, as

tested per U.L. standard 508 (13th Edition), Para. 31

at: 200-480 volts see above. CSA approved for 600

volts SSS-7L, 18,000 amps; SSS-14L, 22,000

amps; SSS-26L, 25,000 amps. Disconnect switch not

available for SSS-33L.

6. See YORK Control Center Wiring Diagram Product Drawing, Form 160.47-PW2 for Style C and Form 160.47-PW12

for Style D Units.

12. The allowable voltage* range for application of the starter

is the same as the compressor motor:

Phase Rotation & Loss Protection circuit and indicator light.

Monitors phase rotation and detects a loss of phase. This

protects the motor from running backwards and from starting

if single phasing is detected (or fuse is blown).

7. See Field Connection Wiring Diagram, Product Drawing,

Form 160.47-PW4 for details on the following items: main

power transformer sizing; power factor correction capacitors (if applied) wiring location; power wiring ampacity; line

side lug sizes; branch circuit overcurrent protection device(s) (fuse/breaker) sizing; power and control wiring harnesses that require field connection (at extra cost) on units

shipped knocked down (see Note 13).

4. Terminals L1, L2 & L3 are the main power input terminals

and are field connected (see Note 7). Terminals T1, T2 &

T3 are the compressor motor load power terminals and

are factory connected.

High Temperature SCR heat sink high temperature safety

protection system with three thermistors (one per phase). High

Temp indicating light and reset button. Shuts down the starter

and unit, if temperature exceeds safe operating levels. Inhibits start-up until temperature falls to an acceptable level.

Proud Sponsor

of the 1998

U.S. Olympic Team

36USC380

P.O. Box 1592, York, Pennsylvania USA 17405-1592

Copyright by York International Corporation 1998

YORK INTERNATIONAL

DATE ________

CHILLER MODEL NO.

YS _________________________

NUMBER OF UNITS ____________

SOLID STATE STARTER, MODEL NO. SSS _____ L _____

MOTOR/STARTER POWER ________ VOLTS, 3-PHASE, ________ HERTZ

OPTIONAL FACTORY INSTALLED DISCONNECT SWITCH __________ AMPS

Terminal Lugs Pressure type (solderless), bolted connector, tin plated aluminum lugs for incoming 3-phase power line

(copper conductors only) connections and system grounding.

Type Starting Reduced voltage; soft start; controlled inrush

maintains the motor current at a constant level throughout

the acceleration period, using six silicon controlled rectifiers.

CONSTRUCTION

DATE ________

JOB DATA:

3. Terminal board connection points are indicated by numbers within a square, i.e. 1TB

15

SOLID STATE STARTER

Form 160.47-PW6 (798)

Form 160.47-PW6 (798)

Supersedes: 160.47-PW6 (1197)

Subject to change without notice. Printed in USA

ALL RIGHTS RESERVED

8. Starter incoming power wiring location, Model YS Full Load

Amps (FLA), Locked Rotor Amps (LRA), inrush amps, and

unit dimensions with YORK Solid State Starter are per Product Drawing, Form 160.47-PA1.

FREQ.

HZ.

RATED

VOLTAGE

NAMEPLATE

MOTOR VOLTAGE

60

60

60

60

50

50

50

200

230

460

575

380

400

415

200 or 208

230 or 240

460 or 480

575 or 600

380

380

415

EXTREME OPER. VOLT.

LOWEST

HIGHEST

180

207

414

518

342

360

374

220

254

508

635

402

423

440

*See Form 160.47-PW4, Note 19, for main power transformer voltage drop.

FORM 160.47-PW6

CONNECTION DIAGRAM

REF. 035-08230-000 REV. C

13. The YORK Solid State Starter is C.S.A. certified (all 60

Hz models) and U.L. approved (all 60 Hz models, except

575 volts 58) when factory applied to YS units. Model

YS units shipped knocked-down will not have C.S.A. or

U.L. label.

LD02599

14. A 3-phase undervoltage safety control (80% dropout voltage, 88% pickup voltage) is furnished as a standard part

of the YORK Control Center.

15. If semi-conductor fuses (branch circuit) are furnished (by

others) instead of time delay type (by others) SCR max.

I2t (non-repetitive surge rating at 60 Hz half wave) for

fuse coordination: 7L, 295,000 (amp)2 sec; 14L, 661,000

(amp)2 sec; 26L, 3,370,000 (amp)2 sec.; 33L, 6,845,000

(amp)2 sec.

(See notes 2 and 3)

(See notes 3 and 4)

>

Capacitors, snubber, 0.5MF, 500VAC

3-phase transformer fuses / oil pump motor fuses

Control supply transformer primary fuses

Control supply transformer secondary fuse

Trigger and water pump control fuse

Semiconductor controlled rectifiers

Snubber resistor see Table 1

Resistor, voltage divider 510K ohms, 1/2W

Heatsink thermistor temperature sensors

Trigger control transformer

Feedback current transformers

1.5 KVA control power transformer

Terminal block, factory wiring

Jack, J1-18

Plug, P1 . . . etc.

ELEMENTARY DIAGRAM

LD02612

LEGEND

1C-6C

1FU-3FU

4FU-5FU

6FU

7FU

Q1-Q6

RES1-3

RES4-9

1RT-3RT

1T

2T-4T

5T

1TB, 2TB

>______

_______

FORM 160.47-PW6

LD02598

YORK INTERNATIONAL

YORK INTERNATIONAL

YORK INTERNATIONAL

FORM 160.47-PW6

CONNECTION DIAGRAM

REF. 035-08230-000 REV. C

13. The YORK Solid State Starter is C.S.A. certified (all 60

Hz models) and U.L. approved (all 60 Hz models, except

575 volts 58) when factory applied to YS units. Model

YS units shipped knocked-down will not have C.S.A. or

U.L. label.

LD02599

14. A 3-phase undervoltage safety control (80% dropout voltage, 88% pickup voltage) is furnished as a standard part

of the YORK Control Center.

15. If semi-conductor fuses (branch circuit) are furnished (by

others) instead of time delay type (by others) SCR max.

I2t (non-repetitive surge rating at 60 Hz half wave) for

fuse coordination: 7L, 295,000 (amp)2 sec; 14L, 661,000

(amp)2 sec; 26L, 3,370,000 (amp)2 sec.; 33L, 6,845,000

(amp)2 sec.

(See notes 2 and 3)

(See notes 3 and 4)

>

Capacitors, snubber, 0.5MF, 500VAC

3-phase transformer fuses / oil pump motor fuses

Control supply transformer primary fuses

Control supply transformer secondary fuse

Trigger and water pump control fuse

Semiconductor controlled rectifiers

Snubber resistor see Table 1

Resistor, voltage divider 510K ohms, 1/2W

Heatsink thermistor temperature sensors

Trigger control transformer

Feedback current transformers

1.5 KVA control power transformer

Terminal block, factory wiring

Jack, J1-18

Plug, P1 . . . etc.

ELEMENTARY DIAGRAM

LD02612

LEGEND

1C-6C

1FU-3FU

4FU-5FU

6FU

7FU

Q1-Q6

RES1-3

RES4-9

1RT-3RT

1T

2T-4T

5T

1TB, 2TB

>______

_______

FORM 160.47-PW6

LD02598

YORK INTERNATIONAL

YORK INTERNATIONAL

YORK INTERNATIONAL

FORM 160.47-PW6

CONNECTION DIAGRAM

REF. 035-08230-000 REV. C

13. The YORK Solid State Starter is C.S.A. certified (all 60

Hz models) and U.L. approved (all 60 Hz models, except

575 volts 58) when factory applied to YS units. Model

YS units shipped knocked-down will not have C.S.A. or

U.L. label.

LD02599

14. A 3-phase undervoltage safety control (80% dropout voltage, 88% pickup voltage) is furnished as a standard part

of the YORK Control Center.

15. If semi-conductor fuses (branch circuit) are furnished (by

others) instead of time delay type (by others) SCR max.

I2t (non-repetitive surge rating at 60 Hz half wave) for

fuse coordination: 7L, 295,000 (amp)2 sec; 14L, 661,000

(amp)2 sec; 26L, 3,370,000 (amp)2 sec.; 33L, 6,845,000

(amp)2 sec.

(See notes 2 and 3)

(See notes 3 and 4)

>

Capacitors, snubber, 0.5MF, 500VAC

3-phase transformer fuses / oil pump motor fuses

Control supply transformer primary fuses

Control supply transformer secondary fuse

Trigger and water pump control fuse

Semiconductor controlled rectifiers

Snubber resistor see Table 1

Resistor, voltage divider 510K ohms, 1/2W

Heatsink thermistor temperature sensors

Trigger control transformer

Feedback current transformers

1.5 KVA control power transformer

Terminal block, factory wiring

Jack, J1-18

Plug, P1 . . . etc.

ELEMENTARY DIAGRAM

LD02612

LEGEND

1C-6C

1FU-3FU

4FU-5FU

6FU

7FU

Q1-Q6

RES1-3

RES4-9

1RT-3RT

1T

2T-4T

5T

1TB, 2TB

>______

_______

FORM 160.47-PW6

LD02598

YORK INTERNATIONAL

YORK INTERNATIONAL

YORK INTERNATIONAL

FORM 160.47-PW6

ELEMENTARY DIAGRAM (Contd)

Supersedes: 160.47-PW6 (1197)

Transient Overvoltage dv/dt rate of rise protection for the

SDCs is furnished by a snubber resistor capacitor (R-C)

network. It prevents false firing of the SCRs and reduces the

repetitive peak transient voltage (from incoming power line).

Out-Of-Phase Re-energization Protection (Power Fault)

Incoming power line momentary interruption (one electrical

cycle duration detected) circuitry to shut down the starter and

unit. Disconnects starter within 3-1/2 electrical cycles. Autoreset, restarting unit automatically once fault has cleared.

Prevents abnormally high inrush currents, (resulting in high

transient motor shaft torque) that can be produced in the motor

when it is re-energized soon after a power interruption.

POWER FAULT indicator is lit and maintained until reset.

Locked Rotor Protection If the motor is stalled and will

not come up to speed, a timer (see below) will shut down the

starter and unit after approximately 40 seconds.

105% Motor Current Light Indicates the compressor-motor current has exceeded 105% full load amps and the 40

second overload timer has started. If for any reason, the compressor motor does not come up to speed, timer will shut

down the starter and unit after approximately 40 seconds.

This provides an incomplete start sequence function.

Out-of-Lock Light Indicates excessive input line-to-line voltage distortion and initiates system shutdown.

LD02613

Starter Fault Light Indicates the compressor-motor current

has exceeded 150% of starting current and the one second

overload timer has started; timer shuts down the starter and

unit.

Undervoltage Safety Prevents start-up or causes shutdown

if the input line-to-line voltage (any phase) drops below 80%

of the nominal line voltage. Safety is reset when input voltage

rises to 88% of nominal line voltage. Displayed on

MicroComputer Control Center readout.

Phase Current Unbalance Causes system shutdown if the

percent current unbalance exceeds 30% while operating at

or above 80% FLA. Displayed on MicroComputer Control

Center readout.

Fusing Starter 3-phase control circuit fuse holders with 500

volt dual element fuses for 200 thru 460 volts or 600 volt single

element fuses for 575 volts. Protection for gate driver/voltmeter transformer and control transformer.

Interlocks A panel shutdown relay provides positive shutdown of the unit on any starter safety control shutdown; any

unit safety or operating control shutdown, through the YORK

Control Center, will stop the starter via starter control signal.

All interlocks between the YORK Control Center and starter

are furnished completely factory wired.

NOTE: Indicating lights and reset button are on the logic

board inside the MicroComputer Control Center.

PRODUCT DRAWING

YORK INTERNATIONAL CORPORATION

P.O. Box 1592, York, PA 17405

CONTRACTOR _______________________

ORDER NO. __________________________

YORK CONTRACT NO. _________________

YORK ORDER NO. ____________________

REFERENCE

DATE ________

WIRING DIAGRAM

YORK SOLID STATE STARTER

MILLENNIUM YS (STYLE C & D) ROTARY SCREW CHILLER

WITH MICROCOMPUTER CONTROL CENTER

PURCHASER ____________________________________________

JOB NAME _______________________________________________

LOCATION _______________________________________________

ENGINEER ______________________________________________

APPROVAL

NOTES:

CONTROL POWER SUPPLY

1. Field Wiring to be in accordance with the current edition of

the National Electric Code as well as all other applicable

codes and specifications.

1.5 KVA 115 volt, control power transformer (on side of

starter) with 15 amp secondary fuse (located within Solid State

Starter). Provides control power for starter, YORK Control

Center and starter cooling pump power; completely factory

installed and wired.

2. Numbers along the left side of the elementary diagram are

line identification numbers. The numbers along the right

side indicate the line number location of relay contacts. An

underlined contact location signifies a normally closed contact.

Main power connection points are indicated by numbers

within a hexagon, i.e. L2

Enclosure NEMA I, ventilated; hinged door with lock and

key latch; for indoor location.

Disconnect Switch Optional unit mounted factory wired disconnects available for SSS-7L, SSS-14L and SSS-26L models.

Numbers adjacent to circuit lines are the circuit identification numbers.

Cooling System Water cooled; unit mounted, factory wired,

inherently protected, 115V, 1/22 HP pump; unit mounted,

cleanable heat exchanger.

PROTECTIVE DEVICES AND

SERVICE INDICATORS (LED TYPE)

Mounting Unit mounted on the compressor-motor at the

factory. Starter factory wired to YORK Control Center, and

compressor-motor and cooling pump motor.

Meters

Ammeter Simultaneous 3-phase, digital readout via Micro Computer Control Center. Three current transformers

provide isolated sensing. Accuracy is typically 3% of full

scale. Scales: 7L 0-750A, 14L 0-1500A, 26L 0-2800A,

33L 0-3500A.

Voltmeter Simultaneous 3-phase, digital readout via Micro Computer Control Center. 3-phase potential transformer

provides isolated sensing. Accuracy is typically 3% of full

scale. Scales: 0-300V for 200-240V starters, 0-700V for

380-600V starters.

Elapsed Time Meter Digital readout of elapsed running

time (0 - 65,535 hours resetable) via MicroComputer Control Center.

Component terminal markings are indicated by numbers

within a circle, i.e. 2

9. Starter approximate overall dimensions are:

7L/14L 34" wide x 21-1/2" high x 11" deep; weight is

approx. 194 lbs. with transformer.

26L/33L 35" wide x 25-1/2" high x 12" deep; weight is

approx. 294 lbs. with transformer. See Notes

7 & 8.

10. The starter will not apply power to the compressor-motor

if the ambient air temperature is higher than 110F. The

starter cooling pump will begin to run when the compressor-motor is started, and continue to run while the compressor-motor is operating. When the compressor-motor is de-energized, the cooling pump will continue to run

until the SCR temperature is reduced to 110F.

Motor Overcurrent Protection Three-leg sensing solid

state current overloads with indicating light and reset button.

Ambient temperature compensated protection system provides compressor-motor overcurrent protection at 105% full

load current and at 150% of Start current setting. Overload light indicates overcurrent condition has stopped the

starter and unit.

5. The three-phase solid state motor overload protection system provides compressor-motor overcurrent protection at

105% Full Load Amps.

11. The short circuit withstand capacity, as tested per U.L.

Standard 508 (13th Edition), Para. 31 at 480 volts, in

RMS (Root Mean Square equals .707 x peak current),

symmetrical current are: SSS-7L, 18,000 amps; SSS14L, 30,000 amps; SSS-26L and SSS-33L, 42,000

amps. The short circuit withstand capacity of the YORK

Solid State Starter with optional disconnect switch, as

tested per U.L. standard 508 (13th Edition), Para. 31

at: 200-480 volts see above. CSA approved for 600

volts SSS-7L, 18,000 amps; SSS-14L, 22,000

amps; SSS-26L, 25,000 amps. Disconnect switch not

available for SSS-33L.

6. See YORK Control Center Wiring Diagram Product Drawing, Form 160.47-PW2 for Style C and Form 160.47-PW12

for Style D Units.

12. The allowable voltage* range for application of the starter

is the same as the compressor motor:

Phase Rotation & Loss Protection circuit and indicator light.

Monitors phase rotation and detects a loss of phase. This

protects the motor from running backwards and from starting

if single phasing is detected (or fuse is blown).

7. See Field Connection Wiring Diagram, Product Drawing,

Form 160.47-PW4 for details on the following items: main

power transformer sizing; power factor correction capacitors (if applied) wiring location; power wiring ampacity; line

side lug sizes; branch circuit overcurrent protection device(s) (fuse/breaker) sizing; power and control wiring harnesses that require field connection (at extra cost) on units

shipped knocked down (see Note 13).

4. Terminals L1, L2 & L3 are the main power input terminals

and are field connected (see Note 7). Terminals T1, T2 &

T3 are the compressor motor load power terminals and

are factory connected.

High Temperature SCR heat sink high temperature safety

protection system with three thermistors (one per phase). High

Temp indicating light and reset button. Shuts down the starter

and unit, if temperature exceeds safe operating levels. Inhibits start-up until temperature falls to an acceptable level.

Proud Sponsor

of the 1998

U.S. Olympic Team

36USC380

P.O. Box 1592, York, Pennsylvania USA 17405-1592

Copyright by York International Corporation 1998

YORK INTERNATIONAL

DATE ________

CHILLER MODEL NO.

YS _________________________

NUMBER OF UNITS ____________

SOLID STATE STARTER, MODEL NO. SSS _____ L _____

MOTOR/STARTER POWER ________ VOLTS, 3-PHASE, ________ HERTZ

OPTIONAL FACTORY INSTALLED DISCONNECT SWITCH __________ AMPS

Terminal Lugs Pressure type (solderless), bolted connector, tin plated aluminum lugs for incoming 3-phase power line

(copper conductors only) connections and system grounding.

Type Starting Reduced voltage; soft start; controlled inrush

maintains the motor current at a constant level throughout

the acceleration period, using six silicon controlled rectifiers.

CONSTRUCTION

DATE ________

JOB DATA:

3. Terminal board connection points are indicated by numbers within a square, i.e. 1TB

15

SOLID STATE STARTER

Form 160.47-PW6 (798)

Form 160.47-PW6 (798)

Supersedes: 160.47-PW6 (1197)

Subject to change without notice. Printed in USA

ALL RIGHTS RESERVED

8. Starter incoming power wiring location, Model YS Full Load

Amps (FLA), Locked Rotor Amps (LRA), inrush amps, and

unit dimensions with YORK Solid State Starter are per Product Drawing, Form 160.47-PA1.

FREQ.

HZ.

RATED

VOLTAGE

NAMEPLATE

MOTOR VOLTAGE

60

60

60

60

50

50

50

200

230

460

575

380

400

415

200 or 208

230 or 240

460 or 480

575 or 600

380

380

415

EXTREME OPER. VOLT.

LOWEST

HIGHEST

180

207

414

518

342

360

374

220

254

508

635

402

423

440

*See Form 160.47-PW4, Note 19, for main power transformer voltage drop.

FORM 160.47-PW6

ELEMENTARY DIAGRAM (Contd)

Supersedes: 160.47-PW6 (1197)

Transient Overvoltage dv/dt rate of rise protection for the

SDCs is furnished by a snubber resistor capacitor (R-C)

network. It prevents false firing of the SCRs and reduces the

repetitive peak transient voltage (from incoming power line).

Out-Of-Phase Re-energization Protection (Power Fault)

Incoming power line momentary interruption (one electrical

cycle duration detected) circuitry to shut down the starter and

unit. Disconnects starter within 3-1/2 electrical cycles. Autoreset, restarting unit automatically once fault has cleared.

Prevents abnormally high inrush currents, (resulting in high

transient motor shaft torque) that can be produced in the motor

when it is re-energized soon after a power interruption.

POWER FAULT indicator is lit and maintained until reset.

Locked Rotor Protection If the motor is stalled and will

not come up to speed, a timer (see below) will shut down the

starter and unit after approximately 40 seconds.

105% Motor Current Light Indicates the compressor-motor current has exceeded 105% full load amps and the 40

second overload timer has started. If for any reason, the compressor motor does not come up to speed, timer will shut

down the starter and unit after approximately 40 seconds.

This provides an incomplete start sequence function.

Out-of-Lock Light Indicates excessive input line-to-line voltage distortion and initiates system shutdown.

LD02613

Starter Fault Light Indicates the compressor-motor current

has exceeded 150% of starting current and the one second

overload timer has started; timer shuts down the starter and

unit.

Undervoltage Safety Prevents start-up or causes shutdown

if the input line-to-line voltage (any phase) drops below 80%

of the nominal line voltage. Safety is reset when input voltage

rises to 88% of nominal line voltage. Displayed on

MicroComputer Control Center readout.

Phase Current Unbalance Causes system shutdown if the

percent current unbalance exceeds 30% while operating at

or above 80% FLA. Displayed on MicroComputer Control

Center readout.

Fusing Starter 3-phase control circuit fuse holders with 500

volt dual element fuses for 200 thru 460 volts or 600 volt single

element fuses for 575 volts. Protection for gate driver/voltmeter transformer and control transformer.

Interlocks A panel shutdown relay provides positive shutdown of the unit on any starter safety control shutdown; any

unit safety or operating control shutdown, through the YORK

Control Center, will stop the starter via starter control signal.

All interlocks between the YORK Control Center and starter

are furnished completely factory wired.

NOTE: Indicating lights and reset button are on the logic

board inside the MicroComputer Control Center.

PRODUCT DRAWING

YORK INTERNATIONAL CORPORATION

P.O. Box 1592, York, PA 17405

CONTRACTOR _______________________

ORDER NO. __________________________

YORK CONTRACT NO. _________________

YORK ORDER NO. ____________________

REFERENCE

DATE ________

WIRING DIAGRAM

YORK SOLID STATE STARTER

MILLENNIUM YS (STYLE C & D) ROTARY SCREW CHILLER

WITH MICROCOMPUTER CONTROL CENTER

PURCHASER ____________________________________________

JOB NAME _______________________________________________

LOCATION _______________________________________________

ENGINEER ______________________________________________

APPROVAL

NOTES:

CONTROL POWER SUPPLY

1. Field Wiring to be in accordance with the current edition of

the National Electric Code as well as all other applicable

codes and specifications.

1.5 KVA 115 volt, control power transformer (on side of

starter) with 15 amp secondary fuse (located within Solid State

Starter). Provides control power for starter, YORK Control

Center and starter cooling pump power; completely factory

installed and wired.

2. Numbers along the left side of the elementary diagram are

line identification numbers. The numbers along the right

side indicate the line number location of relay contacts. An

underlined contact location signifies a normally closed contact.

Main power connection points are indicated by numbers

within a hexagon, i.e. L2

Enclosure NEMA I, ventilated; hinged door with lock and

key latch; for indoor location.

Disconnect Switch Optional unit mounted factory wired disconnects available for SSS-7L, SSS-14L and SSS-26L models.

Numbers adjacent to circuit lines are the circuit identification numbers.

Cooling System Water cooled; unit mounted, factory wired,

inherently protected, 115V, 1/22 HP pump; unit mounted,

cleanable heat exchanger.

PROTECTIVE DEVICES AND

SERVICE INDICATORS (LED TYPE)

Mounting Unit mounted on the compressor-motor at the

factory. Starter factory wired to YORK Control Center, and

compressor-motor and cooling pump motor.

Meters

Ammeter Simultaneous 3-phase, digital readout via Micro Computer Control Center. Three current transformers

provide isolated sensing. Accuracy is typically 3% of full

scale. Scales: 7L 0-750A, 14L 0-1500A, 26L 0-2800A,

33L 0-3500A.

Voltmeter Simultaneous 3-phase, digital readout via Micro Computer Control Center. 3-phase potential transformer

provides isolated sensing. Accuracy is typically 3% of full

scale. Scales: 0-300V for 200-240V starters, 0-700V for

380-600V starters.

Elapsed Time Meter Digital readout of elapsed running

time (0 - 65,535 hours resetable) via MicroComputer Control Center.

Component terminal markings are indicated by numbers

within a circle, i.e. 2

9. Starter approximate overall dimensions are:

7L/14L 34" wide x 21-1/2" high x 11" deep; weight is

approx. 194 lbs. with transformer.

26L/33L 35" wide x 25-1/2" high x 12" deep; weight is

approx. 294 lbs. with transformer. See Notes

7 & 8.

10. The starter will not apply power to the compressor-motor

if the ambient air temperature is higher than 110F. The

starter cooling pump will begin to run when the compressor-motor is started, and continue to run while the compressor-motor is operating. When the compressor-motor is de-energized, the cooling pump will continue to run

until the SCR temperature is reduced to 110F.

Motor Overcurrent Protection Three-leg sensing solid

state current overloads with indicating light and reset button.

Ambient temperature compensated protection system provides compressor-motor overcurrent protection at 105% full

load current and at 150% of Start current setting. Overload light indicates overcurrent condition has stopped the

starter and unit.

5. The three-phase solid state motor overload protection system provides compressor-motor overcurrent protection at

105% Full Load Amps.

11. The short circuit withstand capacity, as tested per U.L.

Standard 508 (13th Edition), Para. 31 at 480 volts, in

RMS (Root Mean Square equals .707 x peak current),

symmetrical current are: SSS-7L, 18,000 amps; SSS14L, 30,000 amps; SSS-26L and SSS-33L, 42,000

amps. The short circuit withstand capacity of the YORK

Solid State Starter with optional disconnect switch, as

tested per U.L. standard 508 (13th Edition), Para. 31

at: 200-480 volts see above. CSA approved for 600

volts SSS-7L, 18,000 amps; SSS-14L, 22,000

amps; SSS-26L, 25,000 amps. Disconnect switch not

available for SSS-33L.

6. See YORK Control Center Wiring Diagram Product Drawing, Form 160.47-PW2 for Style C and Form 160.47-PW12

for Style D Units.

12. The allowable voltage* range for application of the starter

is the same as the compressor motor:

Phase Rotation & Loss Protection circuit and indicator light.

Monitors phase rotation and detects a loss of phase. This

protects the motor from running backwards and from starting

if single phasing is detected (or fuse is blown).

7. See Field Connection Wiring Diagram, Product Drawing,

Form 160.47-PW4 for details on the following items: main

power transformer sizing; power factor correction capacitors (if applied) wiring location; power wiring ampacity; line

side lug sizes; branch circuit overcurrent protection device(s) (fuse/breaker) sizing; power and control wiring harnesses that require field connection (at extra cost) on units

shipped knocked down (see Note 13).

4. Terminals L1, L2 & L3 are the main power input terminals

and are field connected (see Note 7). Terminals T1, T2 &

T3 are the compressor motor load power terminals and

are factory connected.

High Temperature SCR heat sink high temperature safety

protection system with three thermistors (one per phase). High

Temp indicating light and reset button. Shuts down the starter

and unit, if temperature exceeds safe operating levels. Inhibits start-up until temperature falls to an acceptable level.

P.O. Box 1592, York, Pennsylvania USA 17405-1592

Copyright by York International Corporation 1998

YORK INTERNATIONAL

DATE ________

CHILLER MODEL NO.

YS _________________________

NUMBER OF UNITS ____________

SOLID STATE STARTER, MODEL NO. SSS _____ L _____

MOTOR/STARTER POWER ________ VOLTS, 3-PHASE, ________ HERTZ

OPTIONAL FACTORY INSTALLED DISCONNECT SWITCH __________ AMPS

Terminal Lugs Pressure type (solderless), bolted connector, tin plated aluminum lugs for incoming 3-phase power line

(copper conductors only) connections and system grounding.

Type Starting Reduced voltage; soft start; controlled inrush

maintains the motor current at a constant level throughout

the acceleration period, using six silicon controlled rectifiers.

CONSTRUCTION

DATE ________

JOB DATA:

3. Terminal board connection points are indicated by numbers within a square, i.e. 1TB

15

SOLID STATE STARTER

Form 160.47-PW6 (798)

Form 160.47-PW6 (798)

Supersedes: 160.47-PW6 (1197)

Subject to change without notice. Printed in USA

ALL RIGHTS RESERVED

8. Starter incoming power wiring location, Model YS Full Load

Amps (FLA), Locked Rotor Amps (LRA), inrush amps, and

unit dimensions with YORK Solid State Starter are per Product Drawing, Form 160.47-PA1.

FREQ.

HZ.

RATED

VOLTAGE

NAMEPLATE

MOTOR VOLTAGE

60

60

60

60

50

50

50

200

230

460

575

380

400

415

200 or 208

230 or 240

460 or 480

575 or 600

380

380

415

EXTREME OPER. VOLT.

LOWEST

HIGHEST

180

207

414

518

342

360

374

220

254

508

635

402

423

440

*See Form 160.47-PW4, Note 19, for main power transformer voltage drop.

You might also like

- Technician TestDocument2 pagesTechnician TestAwo Orumila GiraldolegraNo ratings yet

- Intro To IfaDocument133 pagesIntro To IfaIfalase Fagbenro95% (154)

- Steps For Android Phones. 1. Enter On The Setting AppDocument2 pagesSteps For Android Phones. 1. Enter On The Setting AppAwo Orumila GiraldolegraNo ratings yet

- Ogunda Meji 3Document15 pagesOgunda Meji 3Awo Orumila Giraldolegra100% (1)

- Synopsis The Readings: Ogunda MejiDocument26 pagesSynopsis The Readings: Ogunda MejiAwo Orumila Giraldolegra89% (9)

- Customers 2Document63 pagesCustomers 2Awo Orumila GiraldolegraNo ratings yet

- Filter Size Quantity Unit #: 24x24x1 1 17x22x1 1 19 1/2x23 1/2x1 1 16x25x2 4 20x20x1 1Document74 pagesFilter Size Quantity Unit #: 24x24x1 1 17x22x1 1 19 1/2x23 1/2x1 1 16x25x2 4 20x20x1 1Awo Orumila GiraldolegraNo ratings yet

- Ogunda Meji 2Document28 pagesOgunda Meji 2Awo Orumila GiraldolegraNo ratings yet

- Carrier 30g Ecologic Chillers Series 1,2Document100 pagesCarrier 30g Ecologic Chillers Series 1,2pkumar68No ratings yet

- 160.81-RP3 5-07 YR Style A, B and C Graphic Control CenterDocument12 pages160.81-RP3 5-07 YR Style A, B and C Graphic Control CenterAwo Orumila GiraldolegraNo ratings yet

- Horizontal Centrifugal PumpsDocument22 pagesHorizontal Centrifugal PumpsDenstar Ricardo SilalahiNo ratings yet

- Cooling Tower FundamentalsDocument117 pagesCooling Tower FundamentalspadzicNo ratings yet

- Model YS Rotary Screw Liquid Chillers Design Level E: FORM 160.80-EG1Document56 pagesModel YS Rotary Screw Liquid Chillers Design Level E: FORM 160.80-EG1Awo Orumila GiraldolegraNo ratings yet

- Ogunda Meji 2Document28 pagesOgunda Meji 2Awo Orumila GiraldolegraNo ratings yet

- FirmasDocument3 pagesFirmasAwo Orumila GiraldolegraNo ratings yet

- 160.80-RP1 10-99 YS Style E 100 To 675 TonsDocument20 pages160.80-RP1 10-99 YS Style E 100 To 675 TonsAwo Orumila GiraldolegraNo ratings yet

- H0015 EXPEDITED Fax Appbirth CertDocument3 pagesH0015 EXPEDITED Fax Appbirth CertAwo Orumila GiraldolegraNo ratings yet

- H0015 EXPEDITED Fax Appbirth CertDocument3 pagesH0015 EXPEDITED Fax Appbirth CertAwo Orumila GiraldolegraNo ratings yet

- 160.81-RP3 5-07 YR Style A, B and C Graphic Control CenterDocument12 pages160.81-RP3 5-07 YR Style A, B and C Graphic Control CenterAwo Orumila GiraldolegraNo ratings yet

- 160.49-PW14york Solid State StarterDocument4 pages160.49-PW14york Solid State StarterAwo Orumila Giraldolegra0% (1)

- 30g, H-8t Carrier ChillerDocument122 pages30g, H-8t Carrier ChillerAwo Orumila Giraldolegra100% (1)

- Basic Obi Abata DivinationDocument20 pagesBasic Obi Abata DivinationWilliam Litwaitis100% (20)

- Giraldo Legra ResumeDocument2 pagesGiraldo Legra ResumeAwo Orumila GiraldolegraNo ratings yet

- Type AH Pumps IOMDocument8 pagesType AH Pumps IOMAwo Orumila GiraldolegraNo ratings yet

- Model YS Rotary Screw Liquid Chillers Design Level E: FORM 160.80-EG1Document56 pagesModel YS Rotary Screw Liquid Chillers Design Level E: FORM 160.80-EG1Awo Orumila GiraldolegraNo ratings yet

- 30g, H-8t Carrier ChillerDocument122 pages30g, H-8t Carrier ChillerAwo Orumila Giraldolegra100% (1)

- H0015 EXPEDITED Fax Appbirth CertDocument3 pagesH0015 EXPEDITED Fax Appbirth CertAwo Orumila GiraldolegraNo ratings yet

- H0015 EXPEDITED Fax Appbirth CertDocument3 pagesH0015 EXPEDITED Fax Appbirth CertAwo Orumila GiraldolegraNo ratings yet

- Giraldo Legra ResumeDocument2 pagesGiraldo Legra ResumeAwo Orumila GiraldolegraNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ASENWARE Conventional Fire AlarmDocument14 pagesASENWARE Conventional Fire AlarmjsaromatocNo ratings yet

- Electrical Connectors Catalog Sheet Asco en 7414680Document2 pagesElectrical Connectors Catalog Sheet Asco en 7414680ChangHuiChuanNo ratings yet

- INVOICEDocument266 pagesINVOICEggac16312916No ratings yet

- PRR 10 User GuideDocument162 pagesPRR 10 User GuideJose SanchezNo ratings yet

- Curve Set (In) AMP: CT Ratio 250:1Document5 pagesCurve Set (In) AMP: CT Ratio 250:1Mahesh MirajkarNo ratings yet

- Hoppeck BattDocument6 pagesHoppeck BattMohammad Abo AliNo ratings yet

- CR Family Hardware Installation GuideDocument31 pagesCR Family Hardware Installation GuideDavid LimbNo ratings yet

- Diag Elect Kenr3518kenr3518 01Document2 pagesDiag Elect Kenr3518kenr3518 01julio cesar100% (1)

- En 4800xpcspec01Document2 pagesEn 4800xpcspec01Luisfer FloresNo ratings yet

- 2018-12-14 Battery-Box Pro 13.8 User Manual EN V4.0 PDFDocument23 pages2018-12-14 Battery-Box Pro 13.8 User Manual EN V4.0 PDFnevkatNo ratings yet

- IP 252 Closed-loop control module and COMREG supplementDocument430 pagesIP 252 Closed-loop control module and COMREG supplementJoseph OakdenNo ratings yet

- LG Studio Works 500E - G - N Cb553h (Chassis Ca120)Document33 pagesLG Studio Works 500E - G - N Cb553h (Chassis Ca120)Technician66No ratings yet

- Parts list for 24Document1 pageParts list for 24Ragnar RokiNo ratings yet

- Motorola Driver LogDocument9 pagesMotorola Driver LogYolaine Maria Delgado GonzalesNo ratings yet

- Vp Electronics Winter Training - Inverters Basics, Types, Applications & PWM TechnologyDocument25 pagesVp Electronics Winter Training - Inverters Basics, Types, Applications & PWM TechnologyLenowahira DillemanowaryNo ratings yet

- Engine Cooling System and Servicin1Document37 pagesEngine Cooling System and Servicin1Emmanuel KutaniNo ratings yet

- Xj900 60hz Technical Data SheetDocument2 pagesXj900 60hz Technical Data SheetArmando BarrancoNo ratings yet

- Nissei ASB 12M v2 BrochureDocument6 pagesNissei ASB 12M v2 BrochureDawn UnderNo ratings yet

- Hi-Scan 6040-2is: Dual-View X-Ray Inspection For Hand LuggageDocument2 pagesHi-Scan 6040-2is: Dual-View X-Ray Inspection For Hand LuggageLinssen KongNo ratings yet

- Magic Motion Remote Control Owner's ManualDocument5 pagesMagic Motion Remote Control Owner's Manualparkhouse2No ratings yet

- Dlro-H200 DsDocument6 pagesDlro-H200 DsAriel Martinez NNo ratings yet

- Technical Manual: ARMY TM 9-2320-280-24P-2 AIR FORCE TO 36A12-1A-3044-2 MARINE CORPS TM 2320-24P/8A Volume No. 2Document969 pagesTechnical Manual: ARMY TM 9-2320-280-24P-2 AIR FORCE TO 36A12-1A-3044-2 MARINE CORPS TM 2320-24P/8A Volume No. 2papirichyNo ratings yet

- Schiavi Enc Met Page042Document1 pageSchiavi Enc Met Page042Adel AdelNo ratings yet

- Hopper Heater System Brochure 11745 10Document4 pagesHopper Heater System Brochure 11745 10Trong Hung NguyenNo ratings yet

- Boletin Precission BCLADocument4 pagesBoletin Precission BCLALalo Barajas GarciaNo ratings yet

- Ogd V210 MG75C702Document40 pagesOgd V210 MG75C702Nemanja NisevicNo ratings yet

- Aemzp0fa Eps dc0 Pot Enc IngpdfDocument31 pagesAemzp0fa Eps dc0 Pot Enc Ingpdfhüseyin100% (2)

- Electric Vehicle TypesDocument20 pagesElectric Vehicle TypesjjjjNo ratings yet

- G531GW r16 - CompressedDocument103 pagesG531GW r16 - Compressedakhmadmukhsin1986No ratings yet

- Catalogue LMD-2435MD 2735MDDocument4 pagesCatalogue LMD-2435MD 2735MDCHANNEL VNo ratings yet