Professional Documents

Culture Documents

Mechatronics Bolton Sample

Uploaded by

Athith DOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechatronics Bolton Sample

Uploaded by

Athith DCopyright:

Available Formats

the elcments of conrol sl stems which Jre rcsponsi

a

ble for transforming thc ourput ofr microprocessor or cotrtrol system into

Acturtion systems .rc

onrr"llinc.^riononan'achinc"r derin. I hu.. t"r.\Jmfh semishr hd\e

cl(r,i;l

uutpur lrDm rhe (unrroller shich h.s ro be Datr'lormcd tnro a

linc.r motion to molc a lord- Anorher cxample might be where an clccffical

ourDur fron, rhr conrruller hJr ro be r.usformud inro u ac,ion shich

conirol' rhe amuunr of bquid pa"inS alonF a pipe.

In this chrpter t'luict powir systems, mrnelv Pneumatic and hvdraulic

re din16sed. Pneumdr ics is rhc r(rm u5eJ $hen com"cruauun s\5rms.

8

h\drauli.s then I liqu'd. rJ pn all) oil' ln

u\

J

and

rir

is

Dres'ed

r)

'haprer

Jcrua

.'echanital acr u,r"r s\.rems e disru'\ed Jnd tn Chapr(r elec!nl

Jn

tion systcms.

Pneunatic signals e olten used to cotrtrol6nal control elments, elen when

the cotrtrol s!:stm is otherwisc electri.al. This is bc@use such signals cm be

used to .cru;t large \alts ard other high-powcr control devices and so

mo\'e significant loads. The maitr drarvback sith pncum ic sv*cms is, howevcr. th; compressiulirr- of air Illdriulic s-vstcms ca. bc used for evcn higher

uru conrrul deric* bur c.e mor< e.pen,i'. rhan pnrumrtir .r*tcms and

ir.-. ." 1",".,1s as"n.'"red sifi utl leals $h,(h Jo nor o. (!r wirh air lenls'

The atnospheric pressure rarics with both loetion and time but in pneu

matics is gcnciilly taken to be 10j Pa, such a pressute hcing termed I bar'

::t;gi:L:

Hydraulic aystems

With . hydraulic system, plcssurised oil is providcd bv

clectric notor. Thc purnp pumps oil fron

pump driven bv-an

sump through 1notr return valrc

7,2

PNEUMA'TIC AND HYDRAUL]C

SYSIFMS

151

Frsrrc 7.1 (a) Hldraulic poqer

supp\', (b) a.luDulator

md an accumulard ro the slstem! from lvh;ch it rerurns to rhe sunp_

figur( 7.1(.r)illusrrJe\rhurrrJnCemenr. { prej\urc reliefrat\c is inctu,lc;,

rhis b.rng ro r(h i:c rhe pr.

'",* lt ir ""*,lo,e " *te le\et. rJrc non-r(rurn

r"lve is to prvcnt the oil bcnrg bac[ drien

ro the pump mil th. *rcumutator

is to smooth out any short term fluctuarions in the output oit pressure_

Esscntially thc accumulator is iusr a container in which thtoil is h;ld utulcr

prcssure against an exLerDal force, Figurc 7. I (b) showing rhe most commo y

used form lvhich is $s pressurised and involves gas within a btadder in thc

chamber containing the hydrauiic fluid; an oider typc involved a spring

loaded piston. lfthc oil pressurc rises rien the bldder comacts, incieasis

the volume the oil cu occupy ud so reduccs the pressurc. Ifthe oil pr.ssure

falls, the bladder cxpands to reduce the yolune occupicd br rhe oil and so

incrcases its prcssure.

_ ComTonlt u-d h)draulk rump, are rh. ger. plmp,t e \rn( pump rnd

rlrpi.ron pump. lhegearpumpconr,r.otrso.to{ me.hingtsur;heets

which rotate in opposire dircctions (Fisuc 7.2(a)). F-tuid is foi;d throush

thc pump as it bccomes trapped betwecn the rotating gear teeth and tlc

housing and su n rJn'ferr.,l rrom rhe inr,.r po,I ru o. dn, hr

u(d rhe our

I(r pofl. Such pumr\ Jre \r.lrh used. being lns ror md robu{ Thc\ gen

erdl) oFrrre Jr prc*ure, bclus Jbou, t5 \4pJ rnd ar 2{00 rohrion" ner

mmurc.Them.\imum flos upd(i,\ i.rbour 0.5 m'lmm. o$e\er, hit:se

occlrs tJetween thc teeth and thc casing and berween thc intertocking teerh,

and this limits thc ef6c;ency. The vane pump has spring-to lc.l stiding

vmes stotred itra driven rotor (Figu.e 7.2(b))_ As tne rotor rorares. the nnei

loliow the contours of rhe casing. Tbis results in fluid becomins trarued bc

twccn successivc vanes and thc cdsing ind trdnsportcd round from tjre inlct

port to oudet porr. The lcaka8e is less than wirh thc gear pumD. pistor

pumps u.ed m h!draulicsun riLe J numbrr^rtor m\ r\ irh rhe radialpisron

i cylinder block rotares round tbe stario.a;y cm

and rhis cruses hullow pi.ron'. $ irh sp, inE ri ru.n, ru mo\e in an.J oui. The

result is that fluid is dra$n in from rhe inlet port md transported roud tor

eiection from the dischatge port. The axial piston p*p o.isu." 7.2(c)

pump (Fjgure 7.2(c)),

ha' pstons shirh mure rri.rll) rarherrhrnraJiar\ Th,

rnr"n"r.rrnged

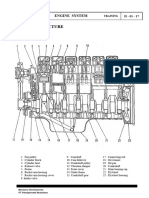

CHAPTER

1,52

PNEUiIAIIC ANO HYORAULIC ACTUATION SYSTEI'IS

t1

is

(b)

FiguE

7.2

(a) Gcar pumA (b)

Chxnbs lills siih Irid .n

dnsl n, onpcnc ou'ld

6n

,qL

(d)

line

pumD, (c)

ui

rdial piston pumE (d) dial piston pmp Nith swsh

plate.

ly in a rotating cllinder blocl and made ro move b] contict with the

'llis phte is at m ansle to the drive shaft and thus as the shft

swash plate.

rot

es they move the pisrons so thrt air is sucked in s'hen a piston is opposite

the inlet port and expelled when it is opposite the discharge port. Piston

pumps have a high efficiencl and can be used rt higher hydriulic pressures

than gear or vme pumps.

722.

Pneumatic systems

a pneumatic power supply (Figure 7.3) an electric motor drives u air

compressor The air inlet to the compressor is likel) to be filrered ud via a

sjlencer to redu.e the mise level. A plessure relief !rl!e providcs protcctiotr

againsr the pressure itr th. syst.m risins above a safe level. Sjnce the air com

pressor in.reases thc tcmpcrature of thc ait there is likely ro be a cooling sys

tem and to remore contimination md watcr from the r;r a filter with a watcr

rrap An a; receircr in rciscs thc volum ofair i. the system ind smoothcs

out my short rerm pressurc lluctuations.

Commonly used air compressors are ones in which succcssirc ldumes

ofair are isolned rnd then compressed- figu.e 7.4(a) shows thc basic form

With

7,2

PNEUMATIC AND HYDRAUL C SYSTEMS

tiexre

7.3

Pncumdtic power

E$rc

7,4

G) Sinsle a.tins, single stase! veriical, rcciprocatins compressor, (b)

roltJ,

153

vme

.lmprssor,

(c)

sc.es

of a sinsle acting, single-stage, vcrrical, ieciprocatins compressor. On thc

dr int*c stroke, the descerding piston causes air to be sucked into the

chamber through the spring-loadcd inlet \alve and whcn the pisron st ts ro

rise again, the trapped air forces thc inlet valve to closc md so becomcs

comprcssed. When the .ir pressue has risen sulEcient\,, the spring loaded

oudct mlve opens and the trrypcd air flows into the compressd-air system.

Aiicr the piston has reachcd th top dad centre it then begins to descend

md the cycle repeats itselii Such a compressor is termed sinsleactinA

bucause one pul,e ol au r{ produced per pi,r^n .rroke. doubtHctint

comprcssors are designcd to produce pulses of air on both rhe up and down

strokcs of the pisron. It is also tcrmed single-stage because the compressor

goes dircctly from atmospheric prcssure to rhe required pressLrre in a single

operation. For the pioduction of compressed air at more rhan r few b s,

two or morc stages ffe generally used. Normally two srages are uscd for

9,2

MECHANICALSWITCHES

193

Relays

Relays arc elecrricall. operatcd sw;rches in whjch changing a current in one

cleclric circun switcles a currcnt on or off i. inother ciraun. For rhe rctav

.hosn In r,gu,e o.llar. *hrn rhere i. r currenr rhrough rhr.ntenoid ut rhe

relal a magnetic ficld is produced which atbacts rhe ;on mature. moves

rhe Dush rod..nd \o.]o,e, rl,e no,malt) nlten (\rr.rir(h ronr-(rs JnJ

olren\ th( nnrmdlv Llosed (NC) s$

F{ur.9.r

i(h iuntu.c

(a)A rclay and

Rehys are ofren uscd in control s_vstems. Thc output from r controller is

relativciy shall currcnt and so it is often used in coniunction with , rran

.isror ru \sirch on rhc currenr rhroush fie rela\ .uhnnid anJ h(nr u\e rh(

rehJ to sxitch on the much larger currcnt needed ro slitch on or offd final

coftection clemenr suchas an elecrric heiter in a rempcraiure conrrol system

or a motor Figure 9.1(b) shows rhe tlpc of circuir that might bc used.

BecaLrse .claF are inductaD.es, they c?D senerllle a b..t rolrage whcn rhe

energising current is switched offor whcn thejr inpur slvirches trom a high

to low signal. As . rLsulr, damage catr occur in rhc connectins cir.un. T.J

a

olucome rhis problcn,

diode is onnecled across the rela!. Whcn the back

(.m.1 n.(ur.. rh( Lliode (onduLr",nd sho s ir uur. Such dio.tr i. rermea .

"

fiee-wheelins or flyback diode.

As an illustration of rhe wals rela,! crn bc nsed in contlot sysrem$

Fiflre 9.2 shows how two relays might be used to conrot rh opcrarion of

pneumatic lihes whi.h in rum cotrtrol the movcmcnr of pistons in th.ee

('hndcr.

C.

BuJ (..The.equrnrt ,,loperrrion rr:

I ['hen the st.ur swirch

2

3

is closed, current is applied ro ihe A and ts soie

noids and results in both A and B cxtctrdiDg, i.e A+ and B+.

lhc limit slvitches a+ and b+ de then closed; th a+ closurc resuhs

in a current flowing through relay coil I rvhich the. closes its conrmrs

and so supplies .urrerr ro the C soleno;d and rcsulrs in it c\rendjng,

i.c. C+.

Its dtension causes limir ssitch c+ to close ud so current to swirch the

A ud B control !d!es xnd hencc rchacrion oa cylinders A md B, i.e. A

mdB

Closing limit s*itch a passes r currcnt through rctay coil 2i its contxcrs

clo\( and Jllos a (Lrrcnr lo\.rl\e( and.tlinJrr(',nrer,rcr.r(.('

You might also like

- AE Mech 2012 PDFDocument22 pagesAE Mech 2012 PDFAthith DNo ratings yet

- TTD CalenderDocument14 pagesTTD CalenderAthith DNo ratings yet

- STEM DrillingDocument1 pageSTEM DrillingAthith DNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument26 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentAthith DNo ratings yet

- Detailed Product Description: Multi-Color Tooth Brush Mould Maker China Is Specialized in Multi-Color InjectionDocument1 pageDetailed Product Description: Multi-Color Tooth Brush Mould Maker China Is Specialized in Multi-Color InjectionAthith DNo ratings yet

- AE Mech 2013Document18 pagesAE Mech 2013Athith DNo ratings yet

- Panchayat RajDocument318 pagesPanchayat RajMohan Raj50% (2)

- Notification PDFDocument1 pageNotification PDFAthith DNo ratings yet

- Civil Engineering FundamentalsDocument12 pagesCivil Engineering FundamentalsAthith D100% (1)

- AsdDocument1 pageAsdAthith DNo ratings yet

- AE Mech 2013Document18 pagesAE Mech 2013Athith DNo ratings yet

- GP Mains 99 Mech EnggDocument28 pagesGP Mains 99 Mech EnggVeeresh S YNo ratings yet

- Acoustic EmissionDocument39 pagesAcoustic EmissionAthith DNo ratings yet

- Notch Chapter 7Document132 pagesNotch Chapter 7mre2006No ratings yet

- List Doc Veri Publ 8may FN AnDocument3 pagesList Doc Veri Publ 8may FN AnAthith DNo ratings yet

- Advance Machine Design Data Hand BookDocument55 pagesAdvance Machine Design Data Hand BookAthith DNo ratings yet

- Stress InvariantsDocument6 pagesStress InvariantsAthith DNo ratings yet

- Linear Static Analysis of A Plate With Hole: Department of Mechanical Engineering Toyohashi University of TechnologyDocument25 pagesLinear Static Analysis of A Plate With Hole: Department of Mechanical Engineering Toyohashi University of Technologysamaero4No ratings yet

- WanDocument2 pagesWanAthith DNo ratings yet

- Plate With HoleDocument15 pagesPlate With HoleAthith DNo ratings yet

- Plate With HoleDocument15 pagesPlate With HoleAthith DNo ratings yet

- Smart Grid Mesh Network Security Using Dynamic Key Distribution With Merkle Tree 4-Way HandshakingDocument9 pagesSmart Grid Mesh Network Security Using Dynamic Key Distribution With Merkle Tree 4-Way HandshakingAthith DNo ratings yet

- KPCL Engineer Nov 2014Document11 pagesKPCL Engineer Nov 2014Madan Doijode100% (1)

- M.tech Machine SyllabusDocument41 pagesM.tech Machine SyllabusSyed Faiz Quadri0% (1)

- Infinite Plate With Circular Hole Series SolutionDocument8 pagesInfinite Plate With Circular Hole Series SolutionAthith DNo ratings yet

- Isotropic Linear Elastic Stress ConcentrationDocument19 pagesIsotropic Linear Elastic Stress ConcentrationIoan-Lucian StanNo ratings yet

- P GovindasamyDocument15 pagesP GovindasamyAthith DNo ratings yet

- Infinite Plate With Circular Hole Series SolutionDocument8 pagesInfinite Plate With Circular Hole Series SolutionAthith DNo ratings yet

- MECHATRONICSDocument8 pagesMECHATRONICSAthith DNo ratings yet

- Plane Stress BracketDocument24 pagesPlane Stress BracketDevendra BangarNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fossil-Fuel Power Plant Engineering Services ProfileDocument34 pagesFossil-Fuel Power Plant Engineering Services ProfileMathivanan AnbazhaganNo ratings yet

- The Understated Benefits of Trolley Assisted HaulageDocument49 pagesThe Understated Benefits of Trolley Assisted HaulagewalterloliNo ratings yet

- Shimpo Circulute 3000 CatalogDocument35 pagesShimpo Circulute 3000 CatalogElectromateNo ratings yet

- Cummins C40 D6Document4 pagesCummins C40 D6Carlos AngaritaNo ratings yet

- Lecture 3 Air CyclesDocument32 pagesLecture 3 Air CyclesMemo KhalidNo ratings yet

- Aux Power OptimisationDocument18 pagesAux Power Optimisationjp mishraNo ratings yet

- Omm PC2000-8 Ten00430-03Document515 pagesOmm PC2000-8 Ten00430-03Ahmad HisyamNo ratings yet

- Diagrama Hidraulico 962g CaterpillarDocument4 pagesDiagrama Hidraulico 962g CaterpillarRonald Gareca Rueda100% (1)

- 02 EngineDocument17 pages02 EngineSantosa NagoyaNo ratings yet

- Global Oil and Gas IndustryDocument23 pagesGlobal Oil and Gas IndustryYash Agarwal100% (1)

- Car Smells and NoisesDocument7 pagesCar Smells and NoisesBob GrobmyerNo ratings yet

- Low, Medium & High Expansion Foam: Types, Uses & RegulationsDocument11 pagesLow, Medium & High Expansion Foam: Types, Uses & RegulationsRaven Lee PalerNo ratings yet

- Iqcm Annex 1 Product SpecsDocument19 pagesIqcm Annex 1 Product Specssonn1729No ratings yet

- FT Motor Volvo TAD750GEDocument2 pagesFT Motor Volvo TAD750GEYael Reinoso AriasNo ratings yet

- Chevron Pascagoula RefineryDocument39 pagesChevron Pascagoula RefineryRay Francisdeo RomeyNo ratings yet

- Environment Friendly Products Catalog - Guardian EnvironmentalDocument17 pagesEnvironment Friendly Products Catalog - Guardian EnvironmentalGuardian Environmental TechnologiesNo ratings yet

- COAL-Rank, Grade and TypeDocument83 pagesCOAL-Rank, Grade and TypeLolen Nokcha Jamir78% (9)

- Automatic Gear ShifterDocument30 pagesAutomatic Gear ShifterNithinNo ratings yet

- 12 - Horizontal Well CompletionDocument21 pages12 - Horizontal Well CompletionMaximiliano GonzalezNo ratings yet

- Rule of Thumbs For MudDocument2 pagesRule of Thumbs For MudUsama Bin Sabir67% (3)

- A Report On Types of Combustion ChamberDocument7 pagesA Report On Types of Combustion ChamberSandip LekhakNo ratings yet

- AirChainHoist 3-20ton JDN ProfiNewStyleDocument68 pagesAirChainHoist 3-20ton JDN ProfiNewStyleAdrian CantaragiuNo ratings yet

- Ford Scorpio Engine ManualDocument4 pagesFord Scorpio Engine Manualkristy100% (48)

- Simbolos para IsométricosDocument4 pagesSimbolos para IsométricosBraulio Gonzalez100% (1)

- 4 Performance of A Centrifugal FanDocument7 pages4 Performance of A Centrifugal Fanfinix33No ratings yet

- 2ZZ Engine DevelopmentDocument9 pages2ZZ Engine Developmentdavid_garlock100% (1)

- P0172 and P0175Document5 pagesP0172 and P0175Pedro Daniel Chujo Paucara100% (1)

- REZEL Saudi Arabia Introduction 20170724jth PDFDocument27 pagesREZEL Saudi Arabia Introduction 20170724jth PDFAnonymous 5o9BbzArNo ratings yet

- 2011 AEBIOM Annual Statistical ReportDocument108 pages2011 AEBIOM Annual Statistical ReportJohan HaatajaNo ratings yet

- Combustion Instability Vortex SheddingDocument16 pagesCombustion Instability Vortex Sheddingflowh_No ratings yet