Professional Documents

Culture Documents

Section 802-Aggregates For Asphaltic Concrete: 802.1 General Description

Uploaded by

Prinsipe MoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 802-Aggregates For Asphaltic Concrete: 802.1 General Description

Uploaded by

Prinsipe MoCopyright:

Available Formats

Section 802Aggregates for Asphaltic Concrete

802.1 General Description

This section includes the requirements for fine and coarse aggregates used in asphaltic concrete.

802.1.01 Definitions

Fine Aggregate: All aggregate passing a No. 8 (2.36 mm) sieve

Coarse Aggregate: All aggregate retained on a No. 8 (2.36 mm) sieve

802.1.02 Related References

A. Standard Specifications

Section 800Coarse Aggregate

Section 828Hot Mix Asphaltic Concrete Mixtures

B. Referenced Documents

AASHTO T 27

AASHTO T 96

ASTM C 295

GDT 63

GDT 76

802.2 Materials

802.2.01 Fine Aggregate for Asphaltic Concrete

A. Requirements

Use the appropriate type, group, class, and grade of fine aggregate.

1.

Types

Use fine aggregate made of sharp, strong, angular material meeting the required performance characteristics when

combined into a mixture.

a. Ensure that the aggregate meets the following requirements:

Does not contain any deleterious substances.

Natural sand is free of organic matter, roots, or twigs.

Aggregate is manufactured from Class A or B crushed stone, gravel, slag, or synthetic aggregate that meets

the requirements of Section 800.

2.

3.

A combination of natural and manufactured sands meets the requirements in Subsection 802.2.01.A.3 and

Subsection 802.2.01.A.4 after being combined.

b. Do not use crushed alluvial gravel as virgin aggregate in any mixture.

Groups

Fine aggregate groups include:

a. Group ILimestone, dolomite, marble, or combination thereof

b. Group IIGravel, slag, granitic and gneissic rocks, quartzite, natural sand, or a combination thereof

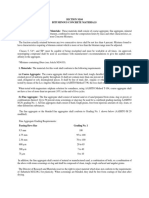

Sand Equivalent

Use these sand equivalent values:

Material

Group I

Sand Equivalent Value

At least 28

Page 1

Section 802Aggregates for Asphaltic Concrete

Group II

At least 40

Natural sand

At least 25

Blended sand*

Natural sand at least 20; combined blend at least 25

*Blended natural sands or natural sand blended with stone screenings that meet the Group I or Group II sand

equivalent limits.

4.

Mica

a. Use fine aggregate with no more than 35 percent free mica in asphaltic concrete surface mixes.

b. When approved by the Engineer, use fine aggregate with more than 35 percent mica if blended with natural

sand or sand manufactured from Group II aggregates. Ensure the blend has no more than 35 percent free mica

and meets all other requirements of this Section, Section 800 and Section 828.

5. Aggregate for Stone Matrix Asphalt

Manufactured screenings will be considered as fine aggregate and shall contain no more than 20 percent by weight

coarser than a No. 4 (4.75 mm) sieve.

B. Fabrication

General Provisions 101 through 150.

C.

Acceptance

Test the fine aggregate as follows:

Test

Method

Aggregate gradation

AASHTO T 27

Sand equivalent

Mica content

GDT 63

GDT 76 or ASTM C 295

D. Materials Warranty

General Provisions 101 through 150.

802.2.02 Coarse Aggregate for Asphaltic Concrete

A. Requirements

1.

Types

Ensure coarse aggregate meets the following requirements:

Class A or B crushed stone, gravel, slag, or synthetic aggregate as in Subsection 800.2.

Have uniform quality throughout without any deleterious substances.

Meet the required performance characteristics when combined into a mixture.

NOTE: Do not use alluvial gravel as virgin aggregate.

2.

Groups

Coarse aggregate shall be one of either group below as specified in the composition Table in Subsection 828.2.A.2:

Group ILimestone, dolomite, marble, or combination thereof

3.

Group IIGravel, slag, granite and gneissic rocks, quartzite, or combination thereof

Aggregate for Stone Matrix Asphalt

Use coarse aggregate that meets requirements of this Section and Section 800 except as follows:

Use Class A aggregate only with percent wear of each individual size not to exceed 45 percent based on the B

grading of AASHTO T 96

Use aggregate which contains no more than 20 percent flat and elongated pieces (length greater than three

times the average thickness) for that portion of the blend of all aggregate retained on the No. 4 (4.75 mm)

sieve.

Page 2

Section 802Aggregates for Asphaltic Concrete

B. Fabrication

General Provisions 101 through 150.

C. Acceptance

Test as follows:

Test

Coarse Aggregate

Method

Subsection 800.2.01.C

D. Materials Warranty

General Provisions 101 through 150.

Page 3

You might also like

- Material ControlDocument3 pagesMaterial ControlChe ElleNo ratings yet

- Section M.04 Bituminous Concrete MaterialsDocument6 pagesSection M.04 Bituminous Concrete MaterialsMohak NagraniNo ratings yet

- Dense Bituminous Macadam-DbmDocument14 pagesDense Bituminous Macadam-DbmCheng Engi50% (2)

- Annex 4.1 - Technical Specifications - Civil WorksDocument6 pagesAnnex 4.1 - Technical Specifications - Civil WorksMW ALSABRINo ratings yet

- Vol-II Concrete Work PDFDocument23 pagesVol-II Concrete Work PDFsam_bhopNo ratings yet

- Specification Bituminous Concrete (Asphaltic Concrete) Road PavementDocument18 pagesSpecification Bituminous Concrete (Asphaltic Concrete) Road PavementharivennelaNo ratings yet

- Asphalt Concrete PavingDocument10 pagesAsphalt Concrete Pavingsethu1091No ratings yet

- Porous Asphalt Specifications PDFDocument8 pagesPorous Asphalt Specifications PDFMatei PopaNo ratings yet

- M 80-87 (2003) Coarse Aggregate For PCCDocument5 pagesM 80-87 (2003) Coarse Aggregate For PCCWalticoZegarraHerrera100% (1)

- Technical SpecificationDocument83 pagesTechnical SpecificationTATATAHERNo ratings yet

- 703 Aggregate PDFDocument5 pages703 Aggregate PDFdrNo ratings yet

- DBM 507Document7 pagesDBM 507Mark Moni Mary ManoNo ratings yet

- Install Precast Tile BlocksDocument4 pagesInstall Precast Tile BlocksAbdullah AboodiNo ratings yet

- RAFT Foundation FDocument30 pagesRAFT Foundation F10bcl016100% (3)

- 346 Portland Cement Concrete. (REV 1-8-02) (FA 1-10-02) (7-02)Document72 pages346 Portland Cement Concrete. (REV 1-8-02) (FA 1-10-02) (7-02)Jb SantosNo ratings yet

- Concrete SpecificationDocument17 pagesConcrete SpecificationthakrarhitsNo ratings yet

- Standard Specification For Aggregate For Masonry MortarDocument3 pagesStandard Specification For Aggregate For Masonry MortarAlbertto GuardadoNo ratings yet

- CIVIL WORKS MANUALDocument159 pagesCIVIL WORKS MANUALrcdk2No ratings yet

- Paver BlockDocument16 pagesPaver BlockRavinder Singh100% (1)

- 5-1 Bituminous Road MaterialDocument28 pages5-1 Bituminous Road MaterialBulero BororoNo ratings yet

- 02515Document5 pages02515uddinnadeemNo ratings yet

- Aggregate Base Course Specifications for Runway ConstructionDocument10 pagesAggregate Base Course Specifications for Runway ConstructionSalahuddin MNo ratings yet

- Asphalt PavingDocument14 pagesAsphalt Pavingmido_20067581No ratings yet

- S 2400 Hot Mix Asphalt ConcreteDocument8 pagesS 2400 Hot Mix Asphalt ConcreteChaudary Azhar SaleemNo ratings yet

- Aggregate For Masonry Mortar: Aashto Designation M 45-89 (Astm Designation: C 144-84)Document2 pagesAggregate For Masonry Mortar: Aashto Designation M 45-89 (Astm Designation: C 144-84)Ba Lestari Wijanarko100% (2)

- ASSTHODocument4 pagesASSTHOpalmuchiNo ratings yet

- ASPHALT MIX DESIGNDocument34 pagesASPHALT MIX DESIGNinam.emadi2No ratings yet

- Asphalt Concrete Wearing Course RequirementsDocument29 pagesAsphalt Concrete Wearing Course RequirementsTj TalhaNo ratings yet

- IRC 95-1987: Specification for Semi-Dense Bituminous ConcreteDocument13 pagesIRC 95-1987: Specification for Semi-Dense Bituminous Concretearunmani2679100% (2)

- H Proc Notices Notices 030 K Notice Doc 28521 682090824 PDFDocument14 pagesH Proc Notices Notices 030 K Notice Doc 28521 682090824 PDFŞăźàdă MùhămmãdNo ratings yet

- Bituminous Surface TreatmentDocument7 pagesBituminous Surface TreatmentSenol KarakayaliNo ratings yet

- AST 05:2000 Sample PreparationDocument7 pagesAST 05:2000 Sample Preparationतिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- Item 311Document64 pagesItem 311Jansen WongNo ratings yet

- M 6-03 Fine Aggregate For PCC PDFDocument6 pagesM 6-03 Fine Aggregate For PCC PDFWalticoZegarraHerrera100% (1)

- Proposed School Aggregate Base CourseDocument4 pagesProposed School Aggregate Base CoursePonz MadianoNo ratings yet

- Es-2730-Hot Mix Asph Conc PaveDocument7 pagesEs-2730-Hot Mix Asph Conc Paveraghav abudhabiNo ratings yet

- CGBM Revised NoteDocument10 pagesCGBM Revised NoteSunil Bose100% (1)

- Australian Manufactured Sand GuidelineDocument2 pagesAustralian Manufactured Sand GuidelineahmadiahreadymixlabNo ratings yet

- ISSA Microsurfacing A143-2010Document16 pagesISSA Microsurfacing A143-2010Roger Molero PachecoNo ratings yet

- IRS Guidelins HPCDocument12 pagesIRS Guidelins HPCsaritasohamNo ratings yet

- Standard Specifications For Transportation Materials and Methods of Sampling and Testing - Print WindowDocument13 pagesStandard Specifications For Transportation Materials and Methods of Sampling and Testing - Print WindowrajibchattarajNo ratings yet

- Sand Asphalt Base Course 2260Document4 pagesSand Asphalt Base Course 2260Tinh HuynhNo ratings yet

- Porous HMA SpecDocument8 pagesPorous HMA SpecMalikAbdulAzizNo ratings yet

- Item P 304 Cement Treated Base CourseDocument13 pagesItem P 304 Cement Treated Base CoursePRIYANKA B A100% (1)

- T Proc Notices Notices 040 K Notice Doc 35762 449071606Document5 pagesT Proc Notices Notices 040 K Notice Doc 35762 449071606jaafar abdullahNo ratings yet

- Section 812 - Crushed Rock For Pavement Base and Subbase: 812.01 DescriptionDocument13 pagesSection 812 - Crushed Rock For Pavement Base and Subbase: 812.01 Descriptionrvim0002No ratings yet

- P-208 - Aggregae Base CourseDocument9 pagesP-208 - Aggregae Base CourseDavid Alonso Quintero HenaoNo ratings yet

- Specification 901: Concrete - General WorksDocument16 pagesSpecification 901: Concrete - General WorksminurajpereraNo ratings yet

- Material For Rigid PavementDocument11 pagesMaterial For Rigid PavementNinie AzrinNo ratings yet

- APP129Document10 pagesAPP129Gary LoNo ratings yet

- Bitumen Prime Will Be Medium Curing Cutback Bitermen Grade MC30 Conforming To The LatestDocument17 pagesBitumen Prime Will Be Medium Curing Cutback Bitermen Grade MC30 Conforming To The LatestAurelius GoraNo ratings yet

- 1195 Specification For Bitumen Mastic For FlooringDocument14 pages1195 Specification For Bitumen Mastic For FlooringRakesh RanjanNo ratings yet

- Bitexco Financial Tower Exterior Stone PavingDocument8 pagesBitexco Financial Tower Exterior Stone Pavinghuumanhcdn8No ratings yet

- Technical Specifications of Roads - Part3Document19 pagesTechnical Specifications of Roads - Part3citizenkanegNo ratings yet

- A143Document16 pagesA143Luis Jorge Nahle OrtizNo ratings yet

- Patch Work Specification - MSSDocument5 pagesPatch Work Specification - MSSJignesh P KoratNo ratings yet

- R 5-03 Selection & Use of Emulsified Asphalts PDFDocument5 pagesR 5-03 Selection & Use of Emulsified Asphalts PDFWalticoZegarraHerreraNo ratings yet

- Elastomers and Rubber Compounding MaterialsFrom EverandElastomers and Rubber Compounding MaterialsI FrantaRating: 4.5 out of 5 stars4.5/5 (3)

- Ceramic Matrix Composites: Materials, Modeling and TechnologyFrom EverandCeramic Matrix Composites: Materials, Modeling and TechnologyNo ratings yet

- EvolutionDocument8 pagesEvolutionrenjanmicianoNo ratings yet

- Cnidarian Ctenophora ProjectsDocument2 pagesCnidarian Ctenophora Projectsapi-195601294No ratings yet

- Geotechnical Properties of Dublin Boulder ClayDocument18 pagesGeotechnical Properties of Dublin Boulder ClayBLPgalwayNo ratings yet

- GMT Science Book 2018 PDFDocument206 pagesGMT Science Book 2018 PDFmilaninterNo ratings yet

- IgneousrocksDocument20 pagesIgneousrocksapi-289539870No ratings yet

- STS-125 SM4 Media GuideDocument133 pagesSTS-125 SM4 Media GuideBob AndrepontNo ratings yet

- Mars and The Beehive 3Document1 pageMars and The Beehive 3pvideoNo ratings yet

- Memberletter: Inding Uccess in The Oroscope NCGR at UacDocument28 pagesMemberletter: Inding Uccess in The Oroscope NCGR at Uacaries25th3100% (1)

- 1939 - Hammer - Terrain Corrections For Gravimeter StationsDocument11 pages1939 - Hammer - Terrain Corrections For Gravimeter Stationslinapgeo09100% (1)

- D5777 Guide For Using The Seismic Refraction PDFDocument13 pagesD5777 Guide For Using The Seismic Refraction PDFsergio rochs100% (1)

- Dhaha OromooDocument2 pagesDhaha OromooWubie Nega50% (2)

- Recreation (Concept and Importance)Document4 pagesRecreation (Concept and Importance)PRINTDESK by Dan100% (3)

- TESIS Montse SanahujaDocument317 pagesTESIS Montse SanahujadiaconalNo ratings yet

- Galileos Astronomical DiscoveryDocument14 pagesGalileos Astronomical DiscoveryAlyssa De Guzman100% (1)

- Grade 10 First Period Physics NotesDocument20 pagesGrade 10 First Period Physics NotesAlphonso Tulay100% (2)

- Remote Sensing Analysis Identifies Geothermal Prospect in Parakasak AreaDocument10 pagesRemote Sensing Analysis Identifies Geothermal Prospect in Parakasak AreaIndah NovitasariNo ratings yet

- Chapter 8 - GravitationDocument14 pagesChapter 8 - Gravitationspt007No ratings yet

- Residual Strength of Clay in LandslidesDocument16 pagesResidual Strength of Clay in Landslidessanpaz75No ratings yet

- BIRD WATCHING COURSE OBJECTIVESDocument4 pagesBIRD WATCHING COURSE OBJECTIVESPradeep MundeNo ratings yet

- Nature of Political ScienceDocument19 pagesNature of Political ScienceSachin YadavNo ratings yet

- Ocellus Lucanus On The Nature of The UniverseDocument120 pagesOcellus Lucanus On The Nature of The UniverseRomek PanNo ratings yet

- Residential Street PatternDocument8 pagesResidential Street PatternsakitkaplaxNo ratings yet

- DS13-15 Foundation GroutingDocument175 pagesDS13-15 Foundation GroutingMarijoNo ratings yet

- Lecture 5 Seismic VelocitesDocument9 pagesLecture 5 Seismic VelocitesEzzadin BabanNo ratings yet

- Terang-1 Well Geological SummaryDocument10 pagesTerang-1 Well Geological SummaryNaufal Natsir MNo ratings yet

- Herschel 400 2 Log BookDocument29 pagesHerschel 400 2 Log BookEveraldo FaustinoNo ratings yet

- Contoh Soal TOEFLDocument4 pagesContoh Soal TOEFLjiluNo ratings yet

- Skeleton 1 PDFDocument5 pagesSkeleton 1 PDFmuslizaNo ratings yet

- Sifu Downhole Camera Fact SheetDocument1 pageSifu Downhole Camera Fact SheetTùng NguyễnNo ratings yet

- Presentation of Parallel Universe To My Ma'm Dr. Ayesha GCUFDocument22 pagesPresentation of Parallel Universe To My Ma'm Dr. Ayesha GCUFmuzammalsafdar0% (1)