Professional Documents

Culture Documents

Lab 09 - Synchronous Motorg

Uploaded by

dev2191Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lab 09 - Synchronous Motorg

Uploaded by

dev2191Copyright:

Available Formats

ELEN3441FundamentalsofPowerEngineering

Lab#9

Spring2008

Lab 9: Synchronous motor.

Objective: to examine the design of a 3-phase synchronous motor; to learn how to connect it; to

obtain its starting characteristic; to determine the full-load characteristic of a synchronous motor;

to determine its pull-off characteristic.

Equipment: Power Supply, DAI, Synchronous motor (8241), Electrodynamometer (8960),

Tachometer, Timing belt.

Theory:

The synchronous motor has the special property of maintaining a constant running speed under all

conditions of load up to full load. This constant running speed can be maintained even under variable

line voltage conditions. It is, therefore, a useful motor in applications where the running speed

must be accurately known and unvarying. It should be noted that, if a synchronous motor is severely

overloaded, its operation (speed) will suddenly lose its synchronous properties and the motor will

come to a halt. The synchronous speed of the motor used in this experiment is 1800 rpm.

The synchronous motor gets its name from the term synchronous speed, which is the natural speed

of the rotating magnetic field of the stator. As you have learned, this natural speed of rotation is

controlled strictly by the number of pole pairs and the frequency of the applied power.

Like the induction motor, the synchronous motor makes use of the rotating magnetic field. Unlike

the induction motor, however, the torque developed does not depend on the induction currents in the

rotor. Briefly, the principle of operation of the synchronous motor is as follows: a multiphase

source of AC is applied to the stator windings and a rotating magnetic field is produced. A direct

current is applied to the rotor windings and a fixed magnetic field is produced. The motor is

constructed such that these two magnetic fields react upon each other causing the rotor to rotate at

the same speed as the rotating magnetic field. If a load is applied to the rotor shaft, the rotor will

momentarily fall behind the rotating field but will continue to rotate at the same synchronous

speed.

The falling behind is analogous to the rotor being tied to the rotating field with a rubber band.

Heavier loads will cause stretching of the band so the rotor position lags the stator field but the rotor

continues at the same speed. If the load is made too large, the rotor will pull out of synchronism

with the rotating field and, as a result, will no longer rotate at the same speed. The motor is then

said to be overloaded.

The synchronous motor is not a self-starting motor. The rotor is heavy and, from a dead stop, it is

not possible to bring the rotor into magnetic lock with the rotating magnetic field. For this reason,

all synchronous motors have some kind of starting device. A simple starter is another motor

which brings the rotor up to approximately 90 percent of its synchronous speed. The starting

motor is then disconnected and the rotor locks in step with the rotating field. The more commonly

used starting method is to have the rotor include a squirrel cage induction winding. This induction

winding brings the rotor almost to its synchronous speed as an induction motor. The squirrel cage

is also useful even after the motor has attained synchronous speed, because it tends to dampen rotor

oscillations caused by sudden changes in loading. Your synchronous motor/generator module contains

Page|1

ELEN3441FundamentalsofPowerEngineering

Lab#9

Spring2008

a squirrel cage type rotor.

The positive reactive power is needed to create the magnetic field in an alternating current motor.

This reactive power has the disadvantage of producing a low power factor. Low power factors are

undesirable for several reasons. Generators, transformers, and supply circuits are limited in ratings

by their current carrying capacities. This means that the load that they can deliver is directly

proportional to the power factor of the loads that they supply. For example, a system can deliver

only 70 percent of the load at 0. 7 power factor that it can deliver at unity power factor.

The synchronous motor requires considerable reactive power when it operates at no load without

any dc excitation to the rotor. It acts like a 3-phase inductance load on the power line. When the

rotor is excited, it will produce some of the magnetism in the motor with the result that the stator has

to supply less, and the reactive power drawn from the power line decreases. If the rotor is excited

until it produces all the magnetism, the power line will only have to supply real power to the stator,

and the power factor will be unity. As far as the power line is concerned, the synchronous motor

now looks like a three-phase resistance load.

If the rotor is excited still further, tending to create more magnetism than the motor needs, then the

power line starts supplying negative reactive power to the stator in its attempt to keep the total flux

constant. But negative reactive power corresponds to a capacitor, and the synchronous motor now

looks like a 3-phase capacitance load to the power line.

At no load, the synchronous motor has the property of acting like a variable inductor/variable

capacitor, the value of reactance (XL or Xc) being determined by the amount of DC current flowing

in the rotor. It is also possible to vary motors power factor under full load conditions.

A synchronous motor when used on the same power system with induction motors improves the

overall system power factor.

The power output (in horsepower) of the motor delivered to the load is defined as follows:

Pout ,hp =

1.4 rpm TNm

10 000

(09-1)

where rpm is the motor speed in revolutions per minute, TNm is its torque in Newton-meters. Keep

in mind that one horsepower equals approximately to 746 W. The reactive power [var] can be

computed as:

Q = S 2 P2

(09-2)

where S is the apparent power [VA], P is the real power [W] consumed by the motor. The

efficiency of the motor is:

efficiency =

Pout ,W

P

100 %

(09-3)

where Pout,W is the output power delivered to the load in Watts. The motor losses, therefore, are

Page|2

ELEN3441FundamentalsofPowerEngineering

Lab#9

Spring2008

estimated as:

Losses = P Pout ,W

(09-4)

Experiment:

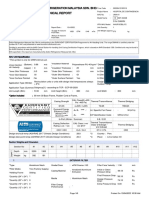

1) Examine the front face of the synchronous motor module (Figure 09-1). Note the three

separate windings connected to the terminals 1 and 4, 2 and 5, 3 and 6. These windings are

identical and located in the stator a stationary part of the motor. 3-phase power source will

be connected to these windings. The winding on the rotor is connected through a 150

rheostat and a toggle switch to the terminals 7 and 8. This winding will carry a DC current.

Figure 09-1

2) Couple the motor with the dynamometer with the timing belt. Connect the synchronous

motor to the power source as indicated in Figure 09-2.

Page|3

ELEN3441FundamentalsofPowerEngineering

Lab#9

Spring2008

Figure 09-2

Connect the dynamometer to the fixed low voltage AC source by the grey cable. Using thin

red wires, connect the torque and speed outputs of the dynamometer to the T and N

terminals of the DAI; connect ground terminals of dynamometer and DAI. Set the

MODE switch of the dynamometer to the DYN position and the dynamometer load

control switch to the MAN position. Set the dynamometer control knob to its utmost

counter-clockwise position for minimum load to the motor. Do not apply power at this time!

3) The motor is supplied with the DC current only when switch S is closed. Make sure that the

switch is open (OFF) at this time (down position). Turn ON the PS. The motor should start

running immediately. Record the values of three stator currents to a Data table.

4) Close the switch S and adjust the rheostat control for minimum stator currents as indicated by

the meters. Record the values of three (minimum) stator currents to your Data table. Increase

the rotor DC excitation by adjusting the rheostat for minimum resistance (utmost clockwise

position of the knob). Record the values of three stator currents to your Data table. Reduce

the DC excitation until the stator currents are at their minimum values. Note and record the

scale position of the rheostat control knob (i.e. 10 oclock, 2 oclock etc.). This is the correct

position of the rheostat. Do not change it.

5) Turn OFF the PS and open the switch S. Note: the switch must be closed ONLY when the

motor is running! Interchange any two of the AC connection leads at the motor stator

terminals (1, 2, or 3). Turn ON the PS and note whether the direction of rotation has changed.

Turn OFF the PS and return the connection leads to their initial positions. Turn ON the PS

and verify that the rotor is rotating in the clockwise direction.

6) Turn ON the PS and close the switch S on the motor. Motor should start running. Make sure

that the rheostat is in its correct position as determined in Part 4. Increase the load on the

motor to 0.2 Nm. (the dynamometer braking action) by varying the control knob on the

Page|4

ELEN3441FundamentalsofPowerEngineering

Lab#9

Spring2008

dynamometer. Control the load either by the dynamometer indicator or using the

corresponding LabVolt meter. Record the values of three stator currents and the motor speed

as measured by the dynamometer to your Data table. Repeat the same measurements, while

recording values of currents and motor speed to the data table, for loads of 0.4, 0.6, 0.8, 1.0,

1.2, and 1.4 Nm. Do not keep your motor running overloaded (under the loads greater than

1.0 Nm.) longer than it is necessary to take a measurement since the normal load for the

motor is 1.0 Nm.

7) Modify your circuit as indicated in Figure 09-3. Set the dynamometer to the no-load

position.

Figure 09-3

With the variable DC output voltage control knob on PS at zero, turn ON the PS. Close the

switch S. Observe the value of the stator current. Carefully adjust the rotor DC voltage to 120

V. Record stator current I1 and rotor voltage E2 to the Data table. Repeat measurements for

rotor voltages 100, 75, 50, 25, and 0 V while recording stator current and rotor voltage to

your Data table. Turn OFF the PS.

8) Modify your circuit as indicated in Figure 09-4 while keeping dynamometer connections

unchanged.

Page|5

ELEN3441FundamentalsofPowerEngineering

Lab#9

Spring2008

Figure 09-4

Note that the synchronous motor is wired in its normal starting configuration (as a 3-phase

squirrel cage induction motor). Set the dynamometer control knob at its utmost clockwise

position to provide a maximum starting load for the motor. Close the switch S. Open a new

data table to record the values of voltages E1, E2, current I1, and the load torque as indicated

by the dynamometer. Turn ON the PS and quickly measure (and record to the Data table)

values of E1, E2, I1, and the developed starting torque. Turn OFF the PS.

9) With your circuit unchanged, turn ON the PS and reduce the torque to 1.4 Nm. Record the

values of E1, E2, I1, and the torque to your Data table. Repeat the same measurements for the

load values of 1.2, 1.0, 0.8, 0.6, 0.4, 0.2, and 0 Nm. Note: the torque of 0 Nm. would be

obtained if the motor and the dynamometer were uncoupled. Since we keep the motor and the

dynamometer coupled, a small load will still be applied to the motor.

10) Modify your circuit as indicated in Figure 09-5 while keeping the motor coupled with the

dynamometer.

Page|6

ELEN3441FundamentalsofPowerEngineering

Lab#9

Spring2008

Figure 09-5

In your Metering window, set the following meters: E1 (AC), I1 (AC), I2 (DC), apparent AC

power S1 between E1 and I1 [VA]. Also set the two additional programmable meters: A to

measure a real AC power P1 between E1 and I1 in W and B to measure the power factor

between E1 and I1.

11) Close the switch S. Adjust the dynamometer control knob for no load (utmost counterclockwise position). Set the DC excitation to zero. Turn ON the PS. Measure and record in a

new Data table the values of stator voltage E1, stator current I1, rotor current I2 (it must

be approximately zero this time), apparent and real powers, and the power factor.

Repeat the same measurements for the values of rotor current from 0.1 to 0.9 A with a step of

0.1 A. Note: due to line voltage, power supply and motor winding tolerances, some students

could not be able to increase the DC excitation to 0.9 A.

12) Increase the motor load to 1.0 Nm and repeat the same measurements as in Part 11 for the

same range of values of the DC excitation current. Record these full-load values in your Data

table.

In your report:

1) Using Matlab and the data recorded in Part 6, plot the dependence of stator current on the

motor load for the loads from 0 to 1.4 Nm. Is this dependence linear? Calculate the

developed motor horsepower under the normal load of 1.0 Nm. Does the speed of the

synchronous motor depend on the load?

2) Describe and explain what you have observed in Part 7. For the data you have collected, plot

the stator current I2 as a function of rotor excitation Er.

3) For the data recorded in Part 8, calculate and report the apparent power of the motor at the

starting torque. Calculate and report the full load torque that corresponds to hp at 1800

rpm. Calculate and report the ratio of starting torque to the full load torque.

4) Using Matlab and the data recorded in Parts 8 and 9, plot the dependence of the voltage

induced on the rotor winding E2 on the load for all values of torque you used in the

experiments. Explain why a large AC voltage was induced in the rotor winding and why it

decreased as the rotor speed increased.

5) Using Matlab and the data recorded in Part 11, plot the stator current as a function of the

rotor current. On separate axes, plot the dependence of power factor on the rotor current.

Comment on the appearance of both no-load curves.

6) Using Matlab and the data recorded in Part 12, plot the stator current as a function of the

rotor current. On separate axes, plot the dependence of power factor on the rotor current.

Page|7

ELEN3441FundamentalsofPowerEngineering

Lab#9

Spring2008

Comment on the appearance of both full-load curves. Estimate and report the motor

efficiency for the full-load condition.

7) Plot the difference between two power factor curves obtained for no-load and full-load

conditions.

Page|8

You might also like

- PHYS 369 Formula Sheet CombinedDocument4 pagesPHYS 369 Formula Sheet Combineddarro d92No ratings yet

- Champion CL7-11D Parts ManualDocument60 pagesChampion CL7-11D Parts ManualRich KoolNo ratings yet

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- NABC Footing StructuresDocument3 pagesNABC Footing StructuresHanafiahHamzahNo ratings yet

- Lab 07 - DC MotorsDocument9 pagesLab 07 - DC MotorsChamila SumathiratnaNo ratings yet

- Answers 4,5,6Document8 pagesAnswers 4,5,6Mohsin TariqNo ratings yet

- Lab 13 - Wound Rotor Induction MotorDocument6 pagesLab 13 - Wound Rotor Induction MotorJeth MadriagaNo ratings yet

- Experiment No:-09 Dt-09.02.2019 Aim of The ExperimentDocument23 pagesExperiment No:-09 Dt-09.02.2019 Aim of The ExperimentPrasant Kumar sahooNo ratings yet

- Principle Operation of Synchronous MotorDocument9 pagesPrinciple Operation of Synchronous MotorGideon MoyoNo ratings yet

- Ecte 323 Labexperiment 3Document13 pagesEcte 323 Labexperiment 3Malik ZaidNo ratings yet

- Dr. Ali Abdul Razzaq ALTAHIR: Lecture 6: Third ClassDocument20 pagesDr. Ali Abdul Razzaq ALTAHIR: Lecture 6: Third ClassAli Altahir100% (1)

- Synchronous Motor & Its Applications & Power Factor ImprovementDocument4 pagesSynchronous Motor & Its Applications & Power Factor ImprovementYash BansalNo ratings yet

- Three-Phase Induction MotorDocument10 pagesThree-Phase Induction MotorMadarwi SarwaNo ratings yet

- Lab 11 - Capacitor Start and Capasitor Run MotorsDocument4 pagesLab 11 - Capacitor Start and Capasitor Run MotorscostpopNo ratings yet

- Pilot ExciterDocument6 pagesPilot ExciterRudy HerreraNo ratings yet

- Chapter-2: Dynamic Behavior of Electric DrivesDocument43 pagesChapter-2: Dynamic Behavior of Electric DrivesMuket AgmasNo ratings yet

- Rohini 71612278397Document3 pagesRohini 71612278397Manu K PNo ratings yet

- Blocked Rotor TestDocument11 pagesBlocked Rotor TestIjabi100% (1)

- Syncronous MotorDocument22 pagesSyncronous MotorSambhav JainNo ratings yet

- Electrical Machine - 2 Lab ManualDocument50 pagesElectrical Machine - 2 Lab ManualMohit ChetiwalNo ratings yet

- Induction and Synchronous Motor FundamentalsDocument9 pagesInduction and Synchronous Motor FundamentalsfitxvNo ratings yet

- Lab 14 - 3-Phase AlternatorDocument7 pagesLab 14 - 3-Phase AlternatorjalilemadiNo ratings yet

- Braking Schemes of TractionDocument7 pagesBraking Schemes of TractionSuraj BhushanNo ratings yet

- Unit-4-Electrical Machines: Lecture-3 Starting methods of 3-Φ Induction MotorDocument13 pagesUnit-4-Electrical Machines: Lecture-3 Starting methods of 3-Φ Induction MotorPratik SarkarNo ratings yet

- Lab 12 - Universal MotorDocument8 pagesLab 12 - Universal MotorSanjeev Kumar Jha50% (2)

- Induction Synchronous MotorsDocument35 pagesInduction Synchronous MotorsDeandre LaingNo ratings yet

- ColchaI Starting MethodsDocument8 pagesColchaI Starting Methodsivancho04mNo ratings yet

- Induction1 PDFDocument2 pagesInduction1 PDFAkhilrajscribdNo ratings yet

- Plant Efficiencies Benefit by Selection of Synchronous MotorDocument9 pagesPlant Efficiencies Benefit by Selection of Synchronous Motorpichet_krongyart2859No ratings yet

- Unit 2 Co2Document12 pagesUnit 2 Co2Gokul anandNo ratings yet

- Induction MatlabDocument12 pagesInduction Matlabgrido002No ratings yet

- Single Phase MotorDocument32 pagesSingle Phase MotorsnzaimahNo ratings yet

- What Are The Speed Control Method of Induction MotorsDocument12 pagesWhat Are The Speed Control Method of Induction MotorsRajeev ValunjkarNo ratings yet

- EM 2 - Unit 4Document62 pagesEM 2 - Unit 4Black DiamoondNo ratings yet

- Synchronous Machines and SCDocument6 pagesSynchronous Machines and SCivancho04mNo ratings yet

- Part II - AC MotorsDocument30 pagesPart II - AC MotorsYan Liang HaoNo ratings yet

- DC MACH - Chapter 5Document53 pagesDC MACH - Chapter 5marryjohnopalla05No ratings yet

- Electrical Machines Final AssignmentDocument13 pagesElectrical Machines Final Assignmentaamir.faiazNo ratings yet

- DC Brush Motor TheoryDocument7 pagesDC Brush Motor Theoryjfsmenezes4534No ratings yet

- Induction MotorDocument43 pagesInduction MotorJanine Jade SetiasNo ratings yet

- EM-II Lab 4Document4 pagesEM-II Lab 4Subhash KumarNo ratings yet

- EES (Lec20)Document16 pagesEES (Lec20)Muhammad SagheerNo ratings yet

- Synchronous Motor Control PDFDocument20 pagesSynchronous Motor Control PDFPradeep_VashistNo ratings yet

- 6 EE441 3 Phase Synchronous MotorsDocument11 pages6 EE441 3 Phase Synchronous MotorsFos AlharbiNo ratings yet

- Induction GeneratorDocument5 pagesInduction GeneratorAmarjeetRanjanNo ratings yet

- EEE363 (Exp 7) Study of The Starting Characteristics and Torque Speed Relationship of Three Phase Synchronous MotorDocument6 pagesEEE363 (Exp 7) Study of The Starting Characteristics and Torque Speed Relationship of Three Phase Synchronous Motorsalad.ass420420No ratings yet

- Synchronous MotorsDocument11 pagesSynchronous MotorsSanjay GhoshNo ratings yet

- Emlab 2Document21 pagesEmlab 2hafizrahimmitNo ratings yet

- Speed Control Methods of Induction MotorDocument6 pagesSpeed Control Methods of Induction MotorsahebraoNo ratings yet

- Induction Motor 1Document34 pagesInduction Motor 1hitesh89No ratings yet

- Torque Speed CurveDocument4 pagesTorque Speed CurveEfosa ImafidonNo ratings yet

- Unit 5 FinalDocument10 pagesUnit 5 FinaljayababNo ratings yet

- Course Notes - AC MOTORDocument21 pagesCourse Notes - AC MOTORHarold DuranoNo ratings yet

- Electrical Machines II AnswerDocument24 pagesElectrical Machines II AnswerGurulathan SoosairajNo ratings yet

- Starting Methods of Three Phase Induction MotorsDocument15 pagesStarting Methods of Three Phase Induction MotorsMohitSharmaNo ratings yet

- EE 448 Laboratory Experiment 4 Introduction To DC MotorsDocument10 pagesEE 448 Laboratory Experiment 4 Introduction To DC MotorsjegjegtNo ratings yet

- Electrical Machines: Lecture Notes for Electrical Machines CourseFrom EverandElectrical Machines: Lecture Notes for Electrical Machines CourseNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- A New System of Alternating Current Motors and Transformers and Other EssaysFrom EverandA New System of Alternating Current Motors and Transformers and Other EssaysRating: 5 out of 5 stars5/5 (1)

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetFrom EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Theory of ElasticityDocument719 pagesTheory of ElasticityAlberto Gaxiola HernándezNo ratings yet

- Hss Watami - AriconDocument1 pageHss Watami - AriconJovani G. BallonNo ratings yet

- Machine Design Data BookDocument19 pagesMachine Design Data BookSunnyChoudharyNo ratings yet

- Timber Design ProblemDocument2 pagesTimber Design ProblemRod Anthony Oraño Paña0% (1)

- r7310306 Heat TransferDocument4 pagesr7310306 Heat TransfersivabharathamurthyNo ratings yet

- Maintenance Products 1. Wear Abrasion Resistant Products: Salient FeaturesDocument12 pagesMaintenance Products 1. Wear Abrasion Resistant Products: Salient FeaturesjohnNo ratings yet

- Specification: Unit Description Specification ABS ESP HecuDocument21 pagesSpecification: Unit Description Specification ABS ESP HecuEfrén SantínNo ratings yet

- DocxDocument9 pagesDocxjamsheed sajidNo ratings yet

- Aprilia Leonardo 125 KészDocument146 pagesAprilia Leonardo 125 Készpisti79No ratings yet

- Inst Headers Install TitianDocument3 pagesInst Headers Install TitianhuntersgreenNo ratings yet

- Daikin Refrigeration Malaysia Sdn. Bhd participates in EUROVENT certificationDocument6 pagesDaikin Refrigeration Malaysia Sdn. Bhd participates in EUROVENT certificationSicologo CimeNo ratings yet

- Airconditioning - HTML: Solar "Commercial Air-Conditioning" Systems Our Achievements and Our GoalsDocument9 pagesAirconditioning - HTML: Solar "Commercial Air-Conditioning" Systems Our Achievements and Our GoalsWeyuma ToleraNo ratings yet

- Non Circular Pipe FrictionDocument3 pagesNon Circular Pipe Frictionravi_radanNo ratings yet

- Heat and Moisture TransferDocument14 pagesHeat and Moisture TransferTooba GhouriNo ratings yet

- Schapery RA 1962 (PHD Dissertation)Document182 pagesSchapery RA 1962 (PHD Dissertation)Marcelo MedeirosNo ratings yet

- (WM) L200 (Ka#,kb#)Document1 page(WM) L200 (Ka#,kb#)Gabriel HreczyńskiNo ratings yet

- Numerical Methods HW2Document6 pagesNumerical Methods HW2Shaisone Shoop100% (2)

- SANY SR250 Rotary Drilling RigDocument8 pagesSANY SR250 Rotary Drilling RigАлександр СупрягаNo ratings yet

- Washer - ISO 7093-1-2000Document9 pagesWasher - ISO 7093-1-2000Corneliu VilcuNo ratings yet

- FAQ Lecture 1Document5 pagesFAQ Lecture 1Richard De Medeiros Castro100% (1)

- Solution Manual Gas Dynamics 3rd Edition James Ea John Theo GDocument10 pagesSolution Manual Gas Dynamics 3rd Edition James Ea John Theo Gsuthur27No ratings yet

- ÍTEM 2. - MINEFLEX Hose - ESPECIFICACIONES TÉCNICAS - FLUIDOSDocument3 pagesÍTEM 2. - MINEFLEX Hose - ESPECIFICACIONES TÉCNICAS - FLUIDOSGiancarloNo ratings yet

- Griffiths Diesel EngineDocument30 pagesGriffiths Diesel Enginesunahsuggs50% (2)

- Lean NOx Trap StudyDocument38 pagesLean NOx Trap Studydhruv royNo ratings yet

- Ab-522 Standard Pneumatic Test Procedure Requirements PDFDocument17 pagesAb-522 Standard Pneumatic Test Procedure Requirements PDFMarizta Perdani PutriNo ratings yet

- Global PositioningDocument6 pagesGlobal PositioningAkash BansalNo ratings yet

- Technical Data TAD734GE Technical Data TAD734GE: GeneralDocument8 pagesTechnical Data TAD734GE Technical Data TAD734GE: GeneralAndres SorinNo ratings yet