Professional Documents

Culture Documents

Impact of Refractory Lining Design On Its

Uploaded by

gjanklesariaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Impact of Refractory Lining Design On Its

Uploaded by

gjanklesariaCopyright:

Available Formats

National Seminar on Thermal Power Plant Performance Management - NSTPPPM

131

Impact of Refractory Lining Design on its

Performance

D.K. Singh, Ashok Kumar and Prem Lata Singh

Abstract--- Reliable and Predictable performance of

refractory lining system of a boiler is an indispensable

condition for smooth functioning of a thermal power plant.

This is much more applicable for a power plant boiler

working on CFBC technology. In India the availability of coal

of prime quality is limited and interior quality coal is

available in abundance. Under this situation the CFBC based

power plants are gaining popularity due to its flexibility of

using coal of interior quality and many other combustibles as

fuel. This was unthinkable in case of P.C. fired boilers.

However, there is one drawback, specific to CFBC boiler,

being faced by the power plant operators. The process

technology of a CFBC boiler generates conditions of severe

erosion and corrosion on the path of flue gases. Application of

refractory lining becomes essential for protection of the boiler

structure and its pressure parts. The present design of

refractory lining system has proved inadequate to withstand

the destructive forces working on the lining. These results in

failure of the lining in highly stressed areas forcing power

plant operators to take unplanned shut downs for repairs at

the cost of uninterrupted functioning of the power plant.

Fig. 1

The ultimate aim of a designer is to provide a lining

system which remain Stable during its entire campaign life,

i.e. at the beginning of the campaign period when the lining is

new and also at the end of the campaign when the gets worn

out. Stability is an important property of any lining

construction. The statement that No lining fails because of

wear itself but because of instability is no exaggeration

(Fig2).

This paper deals with the causes of refractory lining

failures due to design deficiencies and some possible

improvement for a trouble free operation of the thermal power

plant.

I.

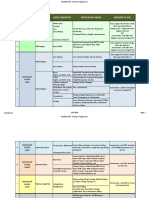

PERFORMANCE OF A REFRACTORY LINING SYSTEM

DEPENDS LARGELY ON THE FOLLOWING THREE

FACTORS

Lining Design

Quality of Installation and initial Heat-up

Consistent Operation

For a reliable, predictable, and consistent performance all

the above factors must be given due importance. (Fig.1).This

paper deals with the issue of Lining design work and its

impact on the overall performance of a Refractory lining

system. The causes of lining failure due to design

deficiencies and possible remedial measures have also been

discussed in detail.

D.K. Singh, Refractories Dynamics, Pune.

Ashok

Kumar,

Refractories

Dynamics,

Pune.

ak@refractoriesdynamics.com

Prem Lata Singh, Refractories Dynamics, Pune.

pjyoti@refractoriesdynamics.com

Fig. 2

Any lining work has a campaign life. Depending upon the

duty conditions to which the lining is exposed, the designed

campaign life may vary from few weeks to many years. At the

end of the campaign the lining needs overhauling, partially or

completely, to begin the new campaign. The lining wear

which takes place during the campaign must be uniform or

balanced so that the lining stability is maintained throughout.

To achieve a balanced lining wear the lining design in

different parts of any refractory lined unit has to be different

based on the prevailing service condition in that part. (Fig. 3)

E-mail:

E-mail:

ISBN 978-93-83459-12-4 2014 Bonfring

Fig. 3

National Seminar on Thermal Power Plant Performance Management - NSTPPPM

132

To design a lining system which wears out uniformly and

maintain its Stability it is important to understand the factors

which cause the lining wear. Such factors are the Stresses of

different nature and dimensions working individually or in

various combinations on the lining and cause their destruction.

Fig. 4

In Fig.4 the different types of stresses working on the

lining in service are given. Such stresses or the Destructive

forces cause wear and tear of the lining. The lining must be

designed in a way so that it can withstand such stresses and

allow a balanced or uniform wear pattern. Non uniform wear

will always give an unstable lining configuration resulting in

premature failures. Fig. 5-8 gives in detail the causes of such

stresses and the properties required in the refractory material

which can resist them.

The first step in the design work is to obtain complete

information and knowledge about the service conditions which

will be encountered by the refractory lining during service.

Refractory materials are then chosen which will be compatible

with the thermal, thermo mechanical and thermo chemical

requirements of the process. Once this is done the engineering

part of the design work follows. This is the most crucial step

in the entire process of design activity. Due to multiple

choices available, such as shaped, unshaped, or precast form

of refractory material, the designer is confronted with the

dilemma of selecting the best option. The choice between a

shaped refractory material and an unshaped one is one such

ISBN 978-93-83459-12-4 2014 Bonfring

National Seminar on Thermal Power Plant Performance Management - NSTPPPM

dilemma. Both have got their advantages and disadvantages.

Fig 9-12 gives the advantages and disadvantages of using a

shaped or an unshaped refractory material for any application.

While selecting any of them it remains uppermost in the mind

of the designer that any selection must result in a stable lining

construction.

At this point of time it is worthwhile to discuss briefly

about the lining geometries which are followed in refractory

lining construction work in any refractory lined unit. There is

close relationship between lining stability and the lining

geometry. All lining designs can be classified into five major

geometries:

Flat Walls

Arches

Cones

Spherical Domes

Cylinders

Out of the five geometrical forms the Flat wall

construction is the weakest from stability point of view

whereas, the cylindrical constructions provide maximum

stability. Therefore, a flat construction, either shaped or

unshaped, require external support system to attain stability.

These supports, which, in majority of the cases are metallic

parts, are non-refractory materials. Unless they are designed

and installed with great precision, can do more harm than help

the lining integrity and stability. A lining which does not

require external support for its stability will perform better

compared to a lining requiring a support system such as

metallic anchors, holders, shelf plates etc.

In any lining system which is exposed to high temperature,

the working face and the cold face behave differently. The hot

face will remain in compression while the cold face will be

under tension. For stability and rigidity of refractory structure

it is important that the lining is maintained under compression

during service. This is especially important where liquid metal

is to be contained or hot gases flow past the lining under

positive pressure. It is also necessary that the thermal gradient

through the lining is maintained in a way that the outside shell

temperature does not exceed its safe limit. If the shell expands

too much at service temperature, the linings will become

loose. In other words compression of the lining will be lost

which may give rise to problems such as liquid metal

penetration, gas leakages, loss of lining stability, and in worst

case collapse of the lining itself. Therefore, a lining which is

under compression, that is fully contained (or restrained) will

result in a successful lining and will give a reliable,

predictable and consistent performance. Example of a fully

contained lining is a cylindrical lining. At the design stage one

133

must take care to provide correct expansion allowances so that

at the operating temperature the lining does not get crushed

due to lack of space for expansion or does not become loose

due to more than required expansion allowance.

The above issues must be addressed adequately at the

design stage. The following few points, if kept in mind, will

go a long way in designing a stable lining system.

Can a lining geometry be followed which gives the

maximum stability?

Can a lining be designed which is self-sustaining and

does not require any or minimal external support

system for its stability?

Can a refractory be used, such as a brick or a precast

shape, which does not require any treatment at site to

achieve the desired properties unlike a monolithic

whose performance entirely depends upon the manner

in which it has been prepared at site and installed?

If a monolithic lining is to be installed, can all the

requirements of a technically correct lining installation

be met at site?

Is proper storage facility available at site especially for

materials which are hydroscopic in nature and has a

limited shelf life?

If we critically analyze the above requirements it may be

concluded that a lining made preferably of a shaped refractory

material is likely to perform better under specified conditions.

However, one must not forget its limitations and take adequate

measures and safeguards at the design stage to nullify or at

least minimize the risks involved. Provision of expansion

allowances and design of joints needs special attention.

In the light of what have been mentioned above we would

examine the refractory lining system generally adopted in a

CFBC boiler. The working lining consists of both shaped and

unshaped refractory materials. Unshaped product (mostly

castable) contributes almost 80% of the total working lining.

The service condition for refractory of the boiler during

operation is shown in Fig.3. The entire boiler is an assemblage

of many sub units having complicated geometry joined

together. The service conditions vary widely and hence the

lining is subjected to varying degree of stresses during

operation. Under such stresses the refractory lining failure

mostly takes place in the areas mentioned in Fig. 13. These

areas have been further shown in Figs. 14-17.

Bull-Nose of cyclone (Fig.14)

Seal Pot/Loop Seal (Fig.15)

Cyclone Inlet and Target area (Fig.16)

Return Legs (Fig.17)

ISBN 978-93-83459-12-4 2014 Bonfring

National Seminar on Thermal Power Plant Performance Management - NSTPPPM

134

Fig. 17

The failures do take place in other areas also but they are

less frequent. Examination and failure analysis of the above

areas reveal few critical observations and possible causes of

failure, which are listed below:

The profile/geometry of failure prone areas is very

complex and the lining is subjected to extreme

thermo-chemical stresses.

Due to complicated geometry the refractory lining is

done with unshaped refractories, mostly castables,

which entirely depend on the reliability of anchorage

system for their stability. It has been found that most

of the failure takes place due to the failure of

anchorage system. The metallic anchors fail either due

to quality reasons anchor design and its orientation or

the anchor weld fails under the prevailing stress.

The other cause of failure may be attributed to poor

quality of lining installation. Quality suffers due to the

fact that the job of monolithic installation in such

complicated geometrical contour requires supervision

and skill of highest order. Invariably, the laid down

procedures are not followed which result is poor

installation work and ultimately result in its failure.

We have been able to find out few reliable solutions to

arrest such failures. Our approach to solve the problem is by:

Design modification, without altering the original

lining profile, with use of shaped refractory

refractories (Bricks or Precast) in place of castables.

In case of lining with shaped refractories, suitable selflocking arrangements have been provided and the use

of non-refractory supports has been minimized.

The above design philosophy was followed for modifying

the refractory lining system for one our clients having a

captive power plant with CFBC boiler (Fig.18-21). After

modifications the refractory lining failure and breakdowns

have become nonexistent.

ISBN 978-93-83459-12-4 2014 Bonfring

National Seminar on Thermal Power Plant Performance Management - NSTPPPM

Refractories Dynamics

It is further working on development of integrated lining

design for the refractory ling of failure prone areas of CFBC

135

boiler mostly with shaped materials (bricks/pre casts) and

hope that the modified design will eliminate most of the

problems associated with lining failures (Fig.-22).

Fig. 22

II.

ABOUT THE AUTHOR

CONCLUSION

Proponents of maximizing the use of monolithic for

refractory lining work may not agree to some of the points

mentioned in this paper. This is due the fact that today much

sophisticated high performance monolithic is available which

can perform better than shaped refractories. We appreciate

their feelings any may agree to the fact that such materials are

available. But, the moot point is, can a technically correct

installation be guaranteed with these materials all the time?

The answer is No. Therefore, when the performance of a

lining system ultimately depends upon technically correct

installation, one has to move cautiously. Refractories

Dynamics, in its lining design work keeps a balance between

the use of shaped and unshaped refractory materials to develop

a most stable lining which gives a reliable, consistent, and

predictable performance.

REFERENCES

[1] Refractories Lining Design and Installation Charles A. Schacht,

Pittsburgh, U.S.A.Michael Maupin, Michigan, U.S.A.

[2] Refractories for Copper North American Refractories- TUCSON-1997

[3] Refractories Engineering: Material-Design-Construction, VULKANVERLAG-ESSEN

Mr.D.K. Singh is Graduated in Ceramic Engineering

from BHU, Varanasi,in the year 1970. Joined Tata

Steel, Jamshedpur, India in the year 1970 as Graduate

Trainee and worked till 1992, during which he occupied

various senior positions in the company. Lead the

refractories team in PhaseI & II expansion &

modernization projects of TATA STEEL as Chief of

Refractories and received special recognition from

Bharat Ratna late J. R. D. Tata for excellent performance with respect to

timely execution of refractories work in the largest and most modern blast

furnace of the company. He worked as Divisional Manager of Refractories

Development and Control Department of Tata Steel till 1992.

Joined Tata Refractories Limited, India in 1993 and worked till 2005.

Occupied senior management positions in the company like General Manager

(Scientific Services), General Manager (Operations), Director (Operations),

Vice President (Operations) & Head of Camp, Executive Vice President

(Marketing & Technology), Executive Vice President (Strategy Management).

Joined Global Steel Holding Company in 2005 and worked for one year

as their Advisor (Refractories) for overseas operations. Appointed as Chief

Executive Officer of Magnohrome Refractories, Serbia, a company acquired

by Global Steel Holding Company Limited and served there for a brief period.

Started own Company, Refractories Dynamics in the year, 2007. This

company was later incorporated as partnership firm with its Head Office at

Pune and Branch Office at Jamshedpur. At present working as Managing

Director & Chief Executive Officer of the company.

The Indian Ceramic Society honored him with Refractory

Technologistof the year award in 2008. Indian Refractory Makers

Association awarded him as Refractory Technologistof the year in 2009 for

contribution in the field of refractories technology

ISBN 978-93-83459-12-4 2014 Bonfring

National Seminar on Thermal Power Plant Performance Management - NSTPPPM

Mr. Ashok Kumar is a refractories and industrial

engineer served TATA STEEL for nearly 38 years in

area of refractories lining design, application and

maintenance activities. Attended 1.5 months training

programs on steel plant refractories practices in British

Steel- U.K. and Thyssel Germany in connection with

the modernization program of TATA STEEL Phase I

& phase II. Developed refractories lining design for

various refractory lined units of TATA STEEL its

modernization programs.

He visited many countries of Europe, Australia, Africa and Asia in

connection with refractories, design and application of Refractory lining

systems for ferrous and nonferrous industries. He presented technical papers

on refractories lining design development and application in national and

international seminars.

He served TATA REFRACTORIES LTD., INDIA for 4 years (19992003). Established and headed Refractories Solutions Department, a new

business unit to meet the emerging demand of customers. Presently he is Jt.

MD & COO of Refractories Dynamics

Mrs. Prem Lata Singh did her diploma in Ceramic

engineering from Government Polytechnic, Gulzarbag,

Patna in the year 2000 securing a Gold Medal for her

academic excellence. She joined Refractories Dynamics

as an officer in the year 2008. Presently she is working

as Asst. General Manager (Tech. & Adm.) in the same

organization.

She obtained training from the Govt. recognized

professional institute in the area of CAD, Administration and company

finance.

During her instinct with RD, she had developed refractory lining design

for various units such as steel ladles, Incinerators, CFBC Boilers etc. Designs

developed by her are successfully performing.

ISBN 978-93-83459-12-4 2014 Bonfring

136

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Fuel Audit Full ReportDocument198 pagesFuel Audit Full ReportgjanklesariaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Significant Supreme Court RulingsDocument5 pagesSignificant Supreme Court Rulingsapi-307941674No ratings yet

- Toshiba Power PlantDocument24 pagesToshiba Power PlantMac Gerald Alindong100% (2)

- Shut Down Inspection of A Chinese Make CFBC BoilerDocument15 pagesShut Down Inspection of A Chinese Make CFBC Boilerparthi20065768No ratings yet

- Hematology SOPsDocument99 pagesHematology SOPssalamon2t100% (1)

- BMDocument12 pagesBMAbhishek KumarNo ratings yet

- Performance Guarantee Tests On Khaperkheda Thermal Power ProjectDocument60 pagesPerformance Guarantee Tests On Khaperkheda Thermal Power Projectgjanklesaria100% (4)

- Best Practice For Thermal Power PlantsDocument186 pagesBest Practice For Thermal Power Plantsnao100% (27)

- Make Swiss RollDocument16 pagesMake Swiss RollFelicia LiNo ratings yet

- 2A2. Circulating Fluidized-Bed Combustion Technology (CFBC)Document1 page2A2. Circulating Fluidized-Bed Combustion Technology (CFBC)Deepak JhaNo ratings yet

- CFBC Boiler - A SurveyDocument11 pagesCFBC Boiler - A SurveygjanklesariaNo ratings yet

- Financial Risk Management (Zain Ullah)Document12 pagesFinancial Risk Management (Zain Ullah)Afaq AhmadNo ratings yet

- Sheetplate SteeldataDocument1 pageSheetplate SteeldatahfenangadNo ratings yet

- Implrepo2 PDFDocument93 pagesImplrepo2 PDFgjanklesariaNo ratings yet

- Is 276 2000Document12 pagesIs 276 2000gotosudNo ratings yet

- Option Strategies Payoff Calculator v2Document9 pagesOption Strategies Payoff Calculator v2samcool87No ratings yet

- E-Book On Coal DehydrationDocument88 pagesE-Book On Coal DehydrationArun Parikshat100% (1)

- Writing Cover Letters BusinessDocument9 pagesWriting Cover Letters BusinessHappy ChauhanNo ratings yet

- Crack Detection PDFDocument14 pagesCrack Detection PDFgjanklesariaNo ratings yet

- Snowbird JR MDocument53 pagesSnowbird JR MgjanklesariaNo ratings yet

- Condenser Enhanced Condenser Venting, For Condensate Oxygen ControlDocument11 pagesCondenser Enhanced Condenser Venting, For Condensate Oxygen ControlgjanklesariaNo ratings yet

- Post Election StrategyDocument31 pagesPost Election StrategygjanklesariaNo ratings yet

- Improvement To Rankine CycleDocument11 pagesImprovement To Rankine Cyclegjanklesaria100% (1)

- Application of KKSDocument18 pagesApplication of KKSrawatbs2020No ratings yet

- 2 2a3Document2 pages2 2a3gjanklesariaNo ratings yet

- Report 85 Pul Coal PDFDocument59 pagesReport 85 Pul Coal PDFelrajilNo ratings yet

- Technical Guidelines For DesignDocument130 pagesTechnical Guidelines For DesignafargerhfgjdtNo ratings yet

- Energy Efficiency BoilersDocument71 pagesEnergy Efficiency Boilerskarthik1646100% (1)

- Innovative Smart Mini-Grid Based Off-Grid Power Solutions For Enhancing Energy Security in Rural and Urban ScenarioDocument35 pagesInnovative Smart Mini-Grid Based Off-Grid Power Solutions For Enhancing Energy Security in Rural and Urban Scenariogjanklesaria100% (1)

- Fly Ash UtilizationDocument10 pagesFly Ash UtilizationgjanklesariaNo ratings yet

- Metal Recovery From Bottom AshDocument18 pagesMetal Recovery From Bottom Ashgjanklesaria100% (1)

- Isomembrane Write Up & Reference ListDocument7 pagesIsomembrane Write Up & Reference ListgjanklesariaNo ratings yet

- Impulse Cleaning SystemDocument18 pagesImpulse Cleaning SystemgjanklesariaNo ratings yet

- Genomics and Crop ImprovementDocument56 pagesGenomics and Crop Improvementsenguvelan100% (6)

- LabExercise2 PoriferaDocument13 pagesLabExercise2 PoriferaMarvin I. Delos SantosNo ratings yet

- Bandura Social Cognitive TheoryDocument93 pagesBandura Social Cognitive TheoryВикторияNo ratings yet

- Bad Effects of Festivals On The EnvironmentDocument10 pagesBad Effects of Festivals On The EnvironmentSahil Bohra85% (52)

- Manual GISDocument36 pagesManual GISDanil Pangestu ChandraNo ratings yet

- Astm c126 Jtvo9242Document5 pagesAstm c126 Jtvo9242Nayth Andres GalazNo ratings yet

- High Voltage - WikipediaDocument7 pagesHigh Voltage - WikipediaMasudRanaNo ratings yet

- Rubric On Baking CakesDocument3 pagesRubric On Baking CakesshraddhaNo ratings yet

- Laboratory Diagnosis of Parasitic DiseasesDocument57 pagesLaboratory Diagnosis of Parasitic DiseasesAmanuel MaruNo ratings yet

- From Crème Fraîche To Sour Cream: What's The Difference?Document14 pagesFrom Crème Fraîche To Sour Cream: What's The Difference?Maricel BautistaNo ratings yet

- B 700 FDocument25 pagesB 700 FMohammed HdyliNo ratings yet

- Breastfeeding PlanDocument7 pagesBreastfeeding Planapi-223713414No ratings yet

- Separating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationDocument4 pagesSeparating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationAndrea SobredillaNo ratings yet

- UAW-FCA Hourly Contract SummaryDocument20 pagesUAW-FCA Hourly Contract SummaryClickon DetroitNo ratings yet

- State/ District-Dehradun, Uttarakhand Year 2016-17Document20 pagesState/ District-Dehradun, Uttarakhand Year 2016-17jitendra rauthanNo ratings yet

- Location: Map of Naga CityDocument2 pagesLocation: Map of Naga Citycatherine boragayNo ratings yet

- NANOGUARD - Products and ApplicationsDocument2 pagesNANOGUARD - Products and ApplicationsSunrise VenturesNo ratings yet

- Ir33+ Range: ... Continuity, Innovation and DesignDocument4 pagesIr33+ Range: ... Continuity, Innovation and DesignbenNo ratings yet

- International Trade Law: AssignmentDocument2 pagesInternational Trade Law: AssignmentQuỳnh PhạmmNo ratings yet

- H1.001858 Strongpack Nigeria-Electrical Loads List For Layout Utilities-Rev-02Document1 pageH1.001858 Strongpack Nigeria-Electrical Loads List For Layout Utilities-Rev-02yseffoNo ratings yet

- High Resolution Computed Tomography of The Lungs - UpToDateDocument83 pagesHigh Resolution Computed Tomography of The Lungs - UpToDatejjjkkNo ratings yet

- MS Fresher HR DocumentDocument4 pagesMS Fresher HR DocumentJahanvi KambojNo ratings yet

- SM Electrical Guidelines: General Notes:: Site HereDocument1 pageSM Electrical Guidelines: General Notes:: Site HereNathaniel DreuNo ratings yet

- ms1471pt5-99 - Vocabulary Smoke ControlDocument8 pagesms1471pt5-99 - Vocabulary Smoke ControlBryan Ng Horng HengNo ratings yet

- Intelligent: - 60 AMP - 80 AMPDocument8 pagesIntelligent: - 60 AMP - 80 AMPHayson NuñezNo ratings yet

- 50-Article Text-116-1-10-20191113Document6 pages50-Article Text-116-1-10-20191113Annisa FauziahNo ratings yet