Professional Documents

Culture Documents

Compact Block & Bleed Valve

Uploaded by

rawrr90Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compact Block & Bleed Valve

Uploaded by

rawrr90Copyright:

Available Formats

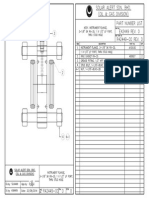

BLOCK & BLEED VALVE

Contents

Introduction

Application

Maintenance & Installation

Specification..

Ball Valve Type.

OS & Y Needle Type..

Globe Needle Valve Type..

Block & Bleed Valve

Monoflange Valve..

Introduction

HZ VALVEs response to the demand for reducing in leakage path has been the combination of primary and secondary

valve into one compact unit. The combination of piping and instrument valve into a single unit has benefitted various

markets. HZ VALVEs will offer the special combination of Double Block & Bleed Valve systems together with fittings,

both being designed and manufactured by GARWAORK. Choice of this combination results in the elimination of taper

thread connections and the need for thread sealant.

(M) SDN BHD

BLOCK & BLEED VALVE

Application

Solutions

HZ VALVE instrumentation products provided the ultimate suitable solution for a integral block & bleed valve, which is

consist of one forged body it provide many marits, featuring a choice of end connections, body style and

Product Detail

A block and bleed valve is a hydraulic manifold that combines one or more block/isolate valve, usually ball valve, and

one or more bleed/vent valves, usually ball or needle valve into one component, for interface with other components

(pressure measurement transmitters, gauge, switch) of a fluid system

Application

Double Block & Bleed Valve used to isolate or block the flow of fluid in the system, so the fluid from upstream of the

manifold does not reach other components of the system that are downstream, then bleed off or vent the remaining

fluid from the system on the downstream side of the manifold. Double Block and Bleed Valves replace existing

traditional techniques employed by pipeline engineers to generate a double block and bleed configuration in the

pipeline. DBBs also used in combustionable gas trains in many industrial applications. Most commonly this product

used for:

i. Gauge isolation

ii. Instrument drain

iii. Chemical injection connection

iv. Sampling connection

v. Piping & instrument interface

vi. Chemical seal instrument isolation

vii. Pressure measurement

(M) SDN BHD

BLOCK & BLEED VALVE

Maintenance & Installation

(1) Conventional Installation:

i. A welded flange, connected to a primary ANSI class isolating valve. The primary valve will be connected to a

secondary instrument valve. A pressure gauge or transmitter will then be installed downstream of the instrument

valve.

(2) Block & Bleed Valve:

i. A one-piece integral forging incorporating up 3 ball valve or mixture of ball and needle design.

ii. Improved safety : leak paths reduced by up to 60%

iii. Reduced costs : installation and component costs reduced by up to 70%

iv. Reduced weight : by up to 80%

v. Reduced susceptibility to problems caused by vibration

(3) Monoflange:

i. More compact then SUPERLOK DBB valve, adding further space and weight saving possibilities.

ii. Improved safety : leak paths reduced by up to 60%, less susceptibility to vibration

iii. Reduced costs : installation and component costs saving up to 80%

iv. Reduced weight : up to 85%

(M) SDN BHD

BLOCK & BLEED VALVE

Specification

Design Codes according to:

ANSI / ASME B 16.34 Designed to meet the pressure and temperature requirements

ANSI / ASME B 16.5 Flange dimensions

ANSI / ASME B 1.20.1 National pipe threads

API 607 / BS 6755 Fire safe designed

Ball Valve

Description

Material

Duplex

Stainless

Steel

A182 F316

A350 LF2

A182 F51

A182 F316

A350 LF2

A182 F51

A479 TP316

S31803

PTFE / RPTFE / PEEK

A479 TP316

S31803

A479 TP316

S31803

PTFE

Graphite

A479 TP316

S31803

SS 316

S31803

SS316

SS316

A194 8M

Stainless

Steel

1

2

3

4

5

6

7

8

9

10

11

12

13

Body

Outlet Connector

Ball

Ball Seal

Seat Capsule

Steam

Lower Stem Seal

Upper Stem Seal

Packing Gland

Stop Pin

Handle

Stem Washer

Stem Nut

Carbon

Steel

316 Stainless steel construction.

Maximum cold working pressure rating 6,000 psig (414 bar) with PTFE

seats.

Temperature rating PTFE seats -54C to 204C (-65F to 400F)

Maximum cold working pressure rating 10,000 psig (689 bar) with PEEK

seats.

Temperature rating PEEK seats -54C to 232C (-65F to 450F)

Features

Two piece body design - minimize leakage paths.

Designed to comply with requirements of ANSI/ASME B16.34.

Bi-directional.

Ball seats choice of seat materials is PTFE(virgin or filled)PVDF , NYLON or PEEK.

Bubble tight shutoff.

Floating ball principal with dynamic response seats featuring inherent self relief.

Anti blowout stem.

Integral compression ends available eliminating taper threads and thread sealants.

Low torque operation.

Connector thread environmentally sealed.

Anti static design as standard.

Firesafe designed to meet BS 6755 Part2 / API 607(optional)

(M) SDN BHD

BLOCK & BLEED VALVE

Outside screw and yoke (OS&Y) needle valve

Material

Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Stainless

Steel

Body

OS & Y Bonnet

Gland Flange

Insert

Packing

Bushing

Vee Tip

Stem

Flange Bolt

Flange Nut

Bonnet Bolt

Bonnet Seal

Dust Cap

Bar Handle

A182 F316

A351 CF8M

A351 CF8M

Carbon Steel

A105 / N

A350 LF2

A105 / N

A352 LCC

A105 / N

A352 LCC

A105 / N

Graphite

A479 TP316

A479 TP316 / PH17-4

A479 TP316

A193 B8M

A320 L7M

A194 8M

A194 Gr.7

A193 B8M

A320 L7M

Graphite

Nylon

A276 TP316

Duplex

Stainless

Steel

A182 F51

A182 F51

A182 F51

S31803

S31803

S31803

S31803

A453

Gr.660

S31803

316 Stainless steel construction.

Maximum cold working pressure rating 10,000 psig (690

bar)

Temperature rating PTFE seats -54C to 204C

(-65F to 400F)

Features

Externally adjustable gland.

PTFE or Graphite packing for bubble tight sealing.

Self centering crimped needle tip for bubble tight shut off and repeatability.

All componets stainless steel .

Firesafe certified to BS6755 part 2/API 607.

Flange gasket seal ensures a bubble-tight between body and yoke.

Back seat design provides secondary stem sealing and prevents stem blow out.

Rolled stem operating threads.

Independent stem thread bush with maximum female thread interface.

Colour coded close contact dust cap and function label for easy indentification.

(M) SDN BHD

BLOCK & BLEED VALVE

Globe style needle valve

BODY MATERIAL

DESCRITION

1

2

3

4

5

6

7

8

9

10

11

BODY

BONNET

PACKING

PACKING GLAND

PACKING BOLT

STEM

VEE TIP

LOCK NUT

BONNET SEAL

DUST CAP

BAR HANDLE

STAINLESS

STEEL

SS 316

SS 316

CARBON

STEEL

DUPLEX

STAINLESS

STEEL

A182 F51

A182 F51

A350 LF2

A350 LF2

GRAPHITE

A479 TP316

SS 316

A350 LF2

A479 TP316

SS630 + Hard Cr

SS 316

A350 LF2

GRAPHITE

NYLON

A276 TP316

S31803

S31803

S31803

S31803

S31803

316 Stainless steel construction.

Maximum cold working pressure rating 10,000 psig (690

bar)

Temperature rating PTFE seats -54C to 204C

(-65F to 400F)

Features

Rolled stem operating theads for low torque operation.

Gland packing in PTFE or Graphite for bubble tight sealing.

Colour coded close contact dust cap and function label for easy identification.

Self centering crimped needle tip for bubble tight seat sealing.

Close contact dust cap for operating thread protection.

Packing bolt with easy access.

Lock nut for vibration protection.

(M) SDN BHD

BLOCK & BLEED VALVE

Block & Bleed Valve

Features

Standard sizes for inlet connection are according to ANSI B16.5 and API 6A, - 6.

Designed flanges for pressure and temperature requirement of ASME B16.34/B16.5 and API 6A.

Standard outlet range to 1 NPT (Female). The flow outlet was depending on bore size.

Standard material of connection is ASTM A182 F316/F316L, ASTM A350 LF2/A105, and ASTM A182 F51.

Designing face types styles are Raised-Face (RF) and Ring-Type-Joint (RTJ).

One-piece forged construction flange as standard.

Fire safe designed and tested according BS 6755 Part 2 / API 607.

Pressure boundary design calculated according ASME VIII Div 1 and verified by testing.

Bubble tight shut-off and positive lever stop.

Locking and anti-tamper devices for all valve types available (option).

Positive lever stop and Bubble tight shut off.

Heat code traceable material to EN10204.3.1.

ANSI Class 150 to 2500 rated.

Integral compression ends available eliminating taper threads and thread sealants.

Low torque operation

Permanent affixed reference label

Positive level stop

User preferred handles

(M) SDN BHD

BLOCK & BLEED VALVE

DB-S1/S2 Series

Dimension

(10mm BORE)

SIZE

(inch)

1/2

(DN15)

3/4

DN(20)

1

(DN25)

1-1/2

(DN40)

2

(DN50)

RATING

(lb)

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

DIMENSION (mm)

DB - S1

L (RF)

89

60.3

96

66.7

121

134

99

82.5

88.9

69.8

118

82.5

130

140

108

88.9

95.2

79.4

124

88.9

170

150

159

127

101.6

108.0

98.4

179

156

114.3

186

200

178

203

152

124.0

146.1

120.6

165

127.0

216

235

165.1

171.5

11.2

14.2

20.6

28.8

36.6

12.7

15.7

22.1

31.8

38.2

14.2

17.5

23.9

34.8

41.5

17.5

20.6

27.0

38.2

50.9

22.4

24.0

30.4

44.5

57.2

170

179

186

175

179

186

170

179

186

179

186

200

208

*Dimension are for reference only and are subjected to change

(M) SDN BHD

BLOCK & BLEED VALVE

Dimension

(14mm BORE)

SIZE

(inch)

3/4

DN(20)

1

(DN25)

1-1/2

(DN40)

2

(DN50)

RATING

(lb)

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

DIMENSION (mm)

DB - S1

L (RF)

99

69.8

118

82.5

130

140

108

88.9

95.2

79.4

124

88.9

150

159

127

101.6

108.0

98.4

218

156

114.3

224

238

178

203

152

124.0

146.1

120.6

165

127.0

216

235

165.1

171.5

12.7

15.7

22.1

31.8

38.2

14.2

17.5

23.9

34.8

41.5

17.5

20.6

27.0

38.2

50.9

22.4

24.0

30.4

44.5

57.2

208

218

224

208

218

224

227

208

218

224

238

246

*Dimension are for reference only and are subjected to change

Dimension

(20mm BORE)

SIZE

(inch)

3/4

DN(20)

1

(DN25)

1-1/2

(DN40)

2

(DN50)

RATING

(lb)

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

DIMENSION (mm)

DB - S1

L (RF)

99

69.8

118

82.5

130

140

108

88.9

95.2

79.4

124

88.9

150

159

127

101.6

108.0

98.4

218

156

114.3

224

238

178

203

152

124.0

146.1

120.6

165

127.0

216

235

165.1

171.5

12.7

15.7

22.1

31.8

38.2

14.2

17.5

23.9

34.8

41.5

17.5

20.6

27.0

38.2

50.9

22.4

24.0

30.4

44.5

57.2

208

218

224

208

218

224

227

208

218

224

238

246

*Dimension are for reference only and are subjected to change

(M) SDN BHD

BLOCK & BLEED VALVE

DB-D1/D2 Series

Dimension

(10mm BORE)

SIZE

(inch)

1/2

(DN15)

3/4

DN(20)

1

(DN25)

1-1/2

(DN40)

2

(DN50)

RATING

(lb)

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

DIMENSION (mm)

DB - S1

L (RF)

89

60.3

96

66.7

121

134

99

82.5

88.9

69.8

118

82.5

130

140

108

88.9

95.2

79.4

124

88.9

235

150

159

127

101.6

108.0

98.4

254

156

114.3

267

314

178

203

152

124.0

146.1

120.6

165

127.0

216

235

165.1

171.5

11.2

14.2

20.6

28.8

36.6

12.7

15.7

22.1

31.8

38.2

14.2

17.5

23.9

34.8

41.5

17.5

20.6

27.0

38.2

50.9

22.4

24.0

30.4

44.5

57.2

235

254

267

235

254

267

235

254

267

254

267

314

334

*Dimension are for reference only and are subjected to change

(M) SDN BHD

BLOCK & BLEED VALVE

Dimension

(14mm BORE)

SIZE

(inch)

3/4

DN(20)

1

(DN25)

1-1/2

(DN40)

2

(DN50)

RATING

(lb)

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

DIMENSION (mm)

DB - S1

L (RF)

99

69.8

118

82.5

130

140

108

88.9

95.2

79.4

124

88.9

150

159

127

101.6

108.0

98.4

254

156

114.3

267

334

178

203

152

124.0

146.1

120.6

165

127.0

216

235

165.1

171.5

12.7

15.7

22.1

31.8

38.2

14.2

17.5

23.9

34.8

41.5

17.5

20.6

27.0

38.2

50.9

22.4

24.0

30.4

44.5

57.2

235

254

267

235

254

267

273

235

254

267

334

*Dimension are for reference only and are subjected to change

Dimension

(20mm BORE)

SIZE

(inch)

1

(DN25)

1-1/2

(DN40)

2

(DN50)

RATING

(lb)

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

DIMENSION (mm)

DB - S1

L (RF)

108

79.4

124

88.9

150

159

127

101.6

108.0

98.4

254

156

114.3

268

334

178

203

152

124.0

146.1

120.6

165

127.0

216

235

165.1

171.5

14.2

17.5

23.9

34.8

41.5

17.5

20.6

27.0

38.2

50.9

22.4

24.0

30.4

44.5

57.2

235

254

267

273

235

254

173

334

*Dimension are for reference only and are subjected to change

(M) SDN BHD

BLOCK & BLEED VALVE

Dimension

(REDUCER BORE)

SIZE

(inch)

BORE

(mm)

1-1/2

(DN40)

25.4

2

(DN50)

38.1

3

(DN75)

50.8

RATING

(lb)

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

RF FLANGE

L

T

279

19.5

285

22.6

301

30.8

370

40.2

396

52.9

150

21.1

372

27.9

390

33.8

415

46.5

475

59.2

150

25.9

410

30.9

428

40.2

441

46.2

500

56.2

DIMENSION (mm)

RTJ FLANGE

L

T

292

25.9

301

30.8

370

40.2

399

54.4

377

27.5

393

35.3

418

48.0

478

60.7

413

32.3

431

41.7

444

48.0

503

57.7

298

132

325

147

452

170

298

132

325

147

452

170

*Dimension are for reference only and are subjected to change

(FULL BORE)

SIZE

(inch)

BORE

(mm)

1

(DN25)

25.4

1-1/2

(DN40)

38.1

2

(DN50)

50.8

RATING

(lb)

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

RF FLANGE

L

T

272

16.2

279

19.5

292

25.9

364

36.8

377

43.5

361

19.5

367

22.6

384

30.8

402

40.2

463

52.9

390

21.1

398

24.9

416

33.8

481

46.5

DIMENSION (mm)

RTJ FLANGE

L

T

285

22.6

292

25.9

364

36.8

377

43.5

374

25.9

384

30.8

402

40.2

466

54.4

403

27.5

419

35.3

484

48.0

*Dimension are for reference only and are subjected to change

(M) SDN BHD

BLOCK & BLEED VALVE

Chemical Injection Valve

This Chemical Injection Valve range is designed to replace conventional multiple-valve installation where injection into

the process stream is required. This design has been developed to inject directly into the process stream at full system

pressure. The injection probe length must be specified from the raised face to the end of the probe in mm. Probe

length shall be decided in consideration of injection insert length in the pipeline and customers request. This type is

using Non-Return Check Valve and the part of spring return valve has a viton soft seal.

FLOW

CHECK VALVE

Injection Quill

The probe length must be specified from the raised face to the end of the probe in mm

Probe length shall be decided in consideration of injection insert length in the pipeline and customers request.

Non return check valve

This poppet type spring return valve has a viton soft seal (HZ VALVES Standard)

Sampling Valve

This Sampling Valve range is designed to replace conventional multiple-valve installation where sampling of the

process stream is required. This design has been developed to remove a sample directly from the process steam at full

system pressure. The sampling probe length must be specified from the raised face to the end of the probe in mm, to

the nearest mm. Probe are supplied to suit the insertion length required by the pipeline and thus must be specified by

the customer.

FLOW

Sampling Probe

The probe length must be specified from the raised face to the end of the probe in mm to the nearest mm.

Probe are supplied to suit the insertion length required by the pipeline and thus must be specified by the customer.

(M) SDN BHD

BLOCK & BLEED VALVE

Fugitive Emission

ISO 15848 parts 1&2 (defining a classification system and qualification procedures, and production acceptance test of

industrial valves, respectively) specify new ultra low standards for emissions. This standard is becoming the

requirement for oil and gas and petrochemical organizations worldwide. The standard was originally created for

process valves and control valves but is now being applied to Instrument valves which include primary isolation valves,

especially on environmentally sensitive projects. Meeting these low levels is a challenge, which BMT Instrument has

solved with the new ball and needle valve designs used in these DBB valves and mono flanges. These designs meet

the highest class A level over the temperature range -29C to +180C, alongside the standard instrumentation

manifold pressure ranges. Production testing and certification is available upon request. Please specify sample

quantity required for production testing with your order.

Valve Specification

Tightness class A >1 x 10-6 mg.s-1.m-1.

Maximum cold working pressure rating 6,000 psig.

Temperature rating -29C to 180C (-20F to 356F)

ISO15848-1 prototype tested using global helium vacuum method.

Performance class -ISO FE AH-CO1-SSA1-t(RT,180C)-ANSI2500-ISO 15848-1

The ISO 15848 standard effectively sets a requirement for zero emissions for processes involving volatile air pollutants

and hazardous fluids. This design has been developed to minimize fugitive emissions.

(M) SDN BHD

BLOCK & BLEED VALVE

Ordering Information

1. Valve Series

SERIES

IDENTIFY

SB

SINGLE BLOCK

&

BLEED VALVES

1st

ISOLATE

S1 / D1

S2 / D2

S1 / D1

DB

DOUBLE BLOCK

&

BLEED VALVES

S2 / D2

2. Bore size (mm)

(NIL) - 10mm (STANDARD)

14 - 14mm

20 - 20mm

RB - Reducing Bore

FB - Full Bore

3. Connection type

F - RAISED FACE FLANGE

J - RING JOINT FLANGE

N - FEMALE NPT

M - MALE NPT

FF - FLAT FACE FLANGE

BW - BUTT WELD

SW - SOCKET WELD

4. Connection size (inch)

4 - 1/4

16 - 1

6 - 3/8

24 - 1-1/2

8 - 1/2

32 - 2

12 - 3/4

48 - 3

1

2

3

1

2

3

1

2

3

4

5

6

1

2

3

4

2st

ISOLATE

BALL

OS & Y

BALL

OS & Y

NEEDLE

5. Flange rating (class)

R1 - 150

R4 - 900

R2 - 300

R5 - 1500

R3 - 600

R6 - 2500

7. Option

SP - SAMPLING PROBE

IQ - INJECTION QUILL

FE - FUGITIVE EMISSION

LD - LOCKING DEVICE

AT - ANTI TAMPER KEY

FS - FIRE SAFETY

6. Ball seat material

(NIL) - R.PTFE (STANDARD)

PV - PVDF

PE - PEEK

PC - PCTFE

DE - DEVLON-V

(M) SDN BHD

NEEDLE

OS & Y

BALL

OS & Y

NEEDLE

NEEDLE

BALL

VENT

NEEDLE

BALL

NEEDLE

OS & Y

NEEDLE

NEEDLE

OS & Y

BALL

NEEDLE

OS & Y

NEEDLE

8. Body material

SS(NIL) - ASTM A182 F316

105 - ASTM A105

LF2 - ASTM A350 LF2

F51 - ASTM A182 F51

M - MONEL ALLOY 400

BLOCK & BLEED VALVE

Monoflange Valve

Features

ANSI B16.5 flanged inlet connections 1/2" to 2" sizes.

Class 150 rated to class 2500 rated.

1/2"-14 NPT(female) standard outlet.

1/4"-18 NPT(female) standard vent

Standard materials of connection: Stainless steel

Optional materials on request.

- ASTM A182 F316/F316L

- ASTM A350 LF2/A105

- ASTM A182 F51,

- Super Duplex

- Monel, Hastelloy, 6Mo, Incoloy.

Combined needle and OS & Y valves available.

Raised face and ring type joint flange face styles.

One-piece forged construction flange as standard.

Fire safe designed to meet BS 6755 Part 2 / API 607. (As option)

Pressure boundary designs calculated to ASME

VIII Div 1 and verified by testing.

Heat code traceable material to EN 10204.3.1.

Bubble tight shut off valve seats 17-4 PH tips standard.

Optional PEEK tips available.

Colour coded functional valves.

Locking and anti tamper devices for all valve types available. (As option)

Permanent marked body with full order and specification details.

(M) SDN BHD

BLOCK & BLEED VALVE

MF-V1 Series

MF-V2 Series

MF-V3 Series

(M) SDN BHD

BLOCK & BLEED VALVE

MF-V4 Series

Dimensions

SIZE

(inch)

1/2

(DN15)

3/4

DN(20)

1

(DN25)

1-1/2

(DN40)

2

(DN50)

RATING

(lb)

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

2500

150

300

600

900/1500

L(RF)

64

68

64

68

73

64

DIMENSION (mm)

L(RTJ)

A

89

B

60.3

96

66.7

121

134

99

82.5

88.9

69.8

118

82.5

130

140

108

88.9

95.2

79.4

124

88.9

150

159

127

101.6

108.0

98.4

156

114.3

123.8

146.1

120.6

64

68

73

68

68

73

73

64

69

68

69

73

73

82

84

73

178

203

152

75

165

127.0

84

216

165.1

69

73

82

*Dimension are for reference only and are subjected to change

(M) SDN BHD

BLOCK & BLEED VALVE

Ordering Information

1. Valve Series

SERIES

IDENTIFY

V1

V2

MF

V3

V4

2. Connection type

F - RAISED FACE FLANGE

J - RING TYPE JOINT FLANGE

N - NPT

BW - BUTT WELD

SW - SOCKET WELD

4. Flange rating (class)

R1 - 150

R4 - 900

R2 - 300

R5 - 1500

R3 - 600

R6 - 2500

1

2

1

2

1

2

1

2

3

4

1st

ISOLATE

NEEDLE

OS & Y

NEEDLE

OS & Y

NEEDLE

OS & Y

NEEDLE

OS & Y

2st

ISOLATE

VENT

NEEDLE

NEEDLE

NEEDLE

OS & Y

NEEDLE

OS & Y

NEEDLE

5. Body Material

SS (NIL) - ASTM A 182 F316

105 - ASTM A105

LF2 - ASTM A350 LF2

F51 - ASTM A182 F51

M - MONEL ALLOY 400

6. Option

BB - BOLTED BONNET

FE - FUGITIVE EMISSION

LD - LOCKING DEVICE

AT - ANTI TAMPER KEY

FS - FIRE SAFETY

3. Connection size (inch)

4 - 1/4

16 - 1

6 - 3/8

24 - 1-1/2

8 - 1/2

32 - 2

12 - 3/4

(M) SDN BHD

BLOCK & BLEED VALVE

(M) SDN BHD

You might also like

- SSNDocument1,377 pagesSSNBrymo Suarez100% (9)

- Technical Data Book For Industrial Trace Heating 2006Document152 pagesTechnical Data Book For Industrial Trace Heating 2006AdelCh100% (1)

- EN-FAB Custody Transfer (LACT) & Meter ProversDocument28 pagesEN-FAB Custody Transfer (LACT) & Meter Proverscarmel BarrettNo ratings yet

- Inspection Test Plan - Piping FabricationDocument5 pagesInspection Test Plan - Piping Fabricationhassan_ndt80% (5)

- API 682 BasicsDocument8 pagesAPI 682 BasicsIslam FawzyNo ratings yet

- FS 3210 - FS-Gas Flow ComputerDocument6 pagesFS 3210 - FS-Gas Flow ComputerBinu ManiNo ratings yet

- Design Your Loyalty Program in 2 WeeksDocument53 pagesDesign Your Loyalty Program in 2 WeeksLorena TacuryNo ratings yet

- Spiral Granny Square PatternDocument1 pageSpiral Granny Square PatternghionulNo ratings yet

- PSV SizingDocument18 pagesPSV SizingGo IELTSNo ratings yet

- Operation and Control Philosophy: PROJ Kurdistan Pumping Station (KPS2)Document21 pagesOperation and Control Philosophy: PROJ Kurdistan Pumping Station (KPS2)Nobar GulajanNo ratings yet

- Norsok Standard I-106Document6 pagesNorsok Standard I-106Boureghda FayçalNo ratings yet

- Catalogue PlantpAxDocument16 pagesCatalogue PlantpAxaharnishaNo ratings yet

- PV Elite WebinarDocument24 pagesPV Elite WebinarAndrea Hank LattanzioNo ratings yet

- Plantpax Process Automation Solution For Oil and GasDocument24 pagesPlantpax Process Automation Solution For Oil and GaszkaticNo ratings yet

- Perkins 2806a E18tag1 2806a E18tag2 Briz MotorDocument20 pagesPerkins 2806a E18tag1 2806a E18tag2 Briz MotorTechno Diesel DieselNo ratings yet

- Rectangular Tank CalculationDocument28 pagesRectangular Tank CalculationHiếu Nguyên78% (32)

- Process Skid TrainingDocument5 pagesProcess Skid TrainingrutujaNo ratings yet

- Hydraulic ServicesDocument4 pagesHydraulic ServicesZulhilmi ZalizanNo ratings yet

- A. What Is Balanced/objective Review or Criticism?Document11 pagesA. What Is Balanced/objective Review or Criticism?Risha Ann CortesNo ratings yet

- (SB0A012) Smith Meter® Integrated Biofuels Blending SkidsDocument8 pages(SB0A012) Smith Meter® Integrated Biofuels Blending SkidsRoberto Carlos TeixeiraNo ratings yet

- Pressure Drop of Full Bore Vs Reduced Bore Ball ValvesDocument1 pagePressure Drop of Full Bore Vs Reduced Bore Ball ValvesArt G. EnziNo ratings yet

- (SF0A029) Oil Field Skid SolutionsDocument2 pages(SF0A029) Oil Field Skid SolutionsRoberto Carlos TeixeiraNo ratings yet

- PFS WedgeDocument26 pagesPFS WedgeMontheardNo ratings yet

- Bently Nevada Orbit 60 Series System DatasheetDocument34 pagesBently Nevada Orbit 60 Series System Datasheetabhishek malhotraNo ratings yet

- Paper ID-44201631Document13 pagesPaper ID-44201631lataNo ratings yet

- Access Control ITPDocument2 pagesAccess Control ITPehteshamNo ratings yet

- 7 React Redux React Router Es6 m7 SlidesDocument19 pages7 React Redux React Router Es6 m7 Slidesaishas11No ratings yet

- SVM Understanding the Smart Valve MonitorDocument24 pagesSVM Understanding the Smart Valve MonitorpcherukaraNo ratings yet

- Fabm2 q2 Module 4 TaxationDocument17 pagesFabm2 q2 Module 4 TaxationLady HaraNo ratings yet

- ITP - 031 (Earthing)Document2 pagesITP - 031 (Earthing)mohamed wahebNo ratings yet

- Leakage Acceptance Rates Comparison Metal & Soft Seated Valves Api 598/api 6D/Mss Sp-61/Fci 70-2Document5 pagesLeakage Acceptance Rates Comparison Metal & Soft Seated Valves Api 598/api 6D/Mss Sp-61/Fci 70-2Ashfaq AnwerNo ratings yet

- Code and Standard in OGDocument8 pagesCode and Standard in OGTatit P. PrapancaNo ratings yet

- P&id SeminarDocument30 pagesP&id SeminaryasirvazhikkadavuNo ratings yet

- Capacity Design of Gas Distribution SystemsDocument32 pagesCapacity Design of Gas Distribution SystemsErickNo ratings yet

- CSIKSDocument52 pagesCSIKSGustavoSilvinoSilvinoNo ratings yet

- P-sr-005r1 Methanol Injection Skid SpecDocument6 pagesP-sr-005r1 Methanol Injection Skid SpecHedi Ben MohamedNo ratings yet

- Odorising SystemDocument36 pagesOdorising SystemSarah DeanNo ratings yet

- ACI, ANSI, API standards for construction, safety, petroleum measurementDocument32 pagesACI, ANSI, API standards for construction, safety, petroleum measurementDesmond Chang100% (1)

- Siegfried Kracauer - Photography (1927)Document17 pagesSiegfried Kracauer - Photography (1927)Paul NadeauNo ratings yet

- Process Basis of DesigneDocument14 pagesProcess Basis of Designeamini_mohiNo ratings yet

- Hydraulic Wellhead 10K ControlDocument2 pagesHydraulic Wellhead 10K ControlDidik PramujiNo ratings yet

- Subsea Production Control Systems: 1 ForewordDocument25 pagesSubsea Production Control Systems: 1 ForewordBSFNo ratings yet

- 3.0 Systems Division-FiltersDocument8 pages3.0 Systems Division-Filtersmatteo2009No ratings yet

- Elster-Instromet M2000 FCDocument0 pagesElster-Instromet M2000 FCsaid_rahmansyah4750No ratings yet

- Pac 8000Document191 pagesPac 8000matteo.magriniNo ratings yet

- SF 06015Document4 pagesSF 06015ricky100% (1)

- Double Block and Bleed With Ultra-Low Emission Options: Catalog 4190-FPDocument17 pagesDouble Block and Bleed With Ultra-Low Emission Options: Catalog 4190-FPAnandNo ratings yet

- 60.30-069 - 1994specification For Differential PressureDocument5 pages60.30-069 - 1994specification For Differential PressurepradeepNo ratings yet

- Catalogue 2019Document450 pagesCatalogue 2019AntonNo ratings yet

- Ringleman Chart FlareDocument12 pagesRingleman Chart FlareguhadebasisNo ratings yet

- Flowstation Debottlenecking and Optimization ProjectDocument1 pageFlowstation Debottlenecking and Optimization ProjectogunsholadanielNo ratings yet

- Seprasol Plus: Liquid/Gas CoalescersDocument4 pagesSeprasol Plus: Liquid/Gas CoalescersSiavash YarahmadiNo ratings yet

- Turndown Ratio ExplainedDocument3 pagesTurndown Ratio ExplainedklashincoviskyNo ratings yet

- Surface Preparation & Painting Procedure: List of ContentDocument14 pagesSurface Preparation & Painting Procedure: List of ContentZafr O'ConnellNo ratings yet

- Technical Recommendations For Choke Valve SpecificationsDocument7 pagesTechnical Recommendations For Choke Valve SpecificationsajaysapruNo ratings yet

- Flow-X Flow ComputerDocument12 pagesFlow-X Flow ComputerKuan Yue ChanNo ratings yet

- Welker 2Document2 pagesWelker 2faradbNo ratings yet

- M2000 Technical Manual V6 300Document271 pagesM2000 Technical Manual V6 300Martijn Groot100% (1)

- I&c Profile Scope.Document6 pagesI&c Profile Scope.anon_238993516No ratings yet

- Det-Tronics - 92-1037-06Document4 pagesDet-Tronics - 92-1037-06Javierfox98No ratings yet

- Oil & Gas Processing Plants Design and Operation Training CourseDocument58 pagesOil & Gas Processing Plants Design and Operation Training CoursefacebookshopNo ratings yet

- Norsok H-003Document22 pagesNorsok H-003ElmoNo ratings yet

- X ViberDocument4 pagesX ViberNivedh VijayakrishnanNo ratings yet

- Closed Drain System - CompressDocument166 pagesClosed Drain System - CompressMiguel FNo ratings yet

- Vertical Coalescer Separators For API-1581 Category C Type SDocument2 pagesVertical Coalescer Separators For API-1581 Category C Type SGaluh AjengNo ratings yet

- Technical Data Sheet Magnetic Flow Meter Material Selection Guide en 74360Document40 pagesTechnical Data Sheet Magnetic Flow Meter Material Selection Guide en 74360gustirizkiawanNo ratings yet

- AC-32 Rev 2015Dec-CURRENTDocument2 pagesAC-32 Rev 2015Dec-CURRENT李俊No ratings yet

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979From EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonNo ratings yet

- MRE - Course Manual 2017 - 2018 PDFDocument30 pagesMRE - Course Manual 2017 - 2018 PDFrawrr90No ratings yet

- Material Specification ChartDocument1 pageMaterial Specification ChartIdu Baz AzharNo ratings yet

- MRE - Course Manual 2017 - 2018 PDFDocument30 pagesMRE - Course Manual 2017 - 2018 PDFrawrr90No ratings yet

- 01C Future Two-Wheeler TransportDocument1 page01C Future Two-Wheeler Transportrawrr90No ratings yet

- Access Fitting ManualDocument18 pagesAccess Fitting Manualsteffy182No ratings yet

- Ejemplos Norma Asme PDFDocument55 pagesEjemplos Norma Asme PDFCarlos Ramos MorenoNo ratings yet

- Expansion TankDocument102 pagesExpansion Tankrawrr90No ratings yet

- Threaded Half CouplingDocument1 pageThreaded Half CouplingwhngomjNo ratings yet

- Design CalculationDocument13 pagesDesign Calculationrawrr90No ratings yet

- Utility PumpsDocument4 pagesUtility Pumpsrawrr90No ratings yet

- Friction Stir WeldingDocument20 pagesFriction Stir Weldingrawrr90No ratings yet

- GWS 1-08-Att.1-R1Document7 pagesGWS 1-08-Att.1-R1solrac4371No ratings yet

- Org ChartDocument1 pageOrg Chartrawrr90No ratings yet

- Instrument Flange Side ViewDocument1 pageInstrument Flange Side Viewgk_corinaNo ratings yet

- Non Retractable InjectorDocument1 pageNon Retractable Injectorrawrr90No ratings yet

- Gambar 1Document10 pagesGambar 1Mario HanamiciNo ratings yet

- Design of Steel Structures Handout 2012-2013Document3 pagesDesign of Steel Structures Handout 2012-2013Tushar Gupta100% (1)

- DJDocument907 pagesDJDeepak BhawsarNo ratings yet

- Conceptual Framework For Group Processing of Lyric Analysis Interventions in Music Therapy Mental Health PracticeDocument9 pagesConceptual Framework For Group Processing of Lyric Analysis Interventions in Music Therapy Mental Health Practiceantonella nastasiaNo ratings yet

- Hilton 5-29 Case SolutionDocument4 pagesHilton 5-29 Case SolutionPebbles RobblesNo ratings yet

- Manuais - 727312 - manuais-Raios-X AXR - 77000001249Document72 pagesManuais - 727312 - manuais-Raios-X AXR - 77000001249Hosam Ahmed HashimNo ratings yet

- Plumbing Arithmetic RefresherDocument80 pagesPlumbing Arithmetic RefresherGigi AguasNo ratings yet

- Data Sheet FC SIDocument2 pagesData Sheet FC SIAndrea AtzeniNo ratings yet

- Minimum Fees To Be Taken by CADocument8 pagesMinimum Fees To Be Taken by CACA Sanjay BhatiaNo ratings yet

- CM Template For Flora and FaunaDocument3 pagesCM Template For Flora and FaunaJonathan Renier Verzosa0% (1)

- An RNA Vaccine Drives Expansion and Efficacy of claudin-CAR-T Cells Against Solid TumorsDocument9 pagesAn RNA Vaccine Drives Expansion and Efficacy of claudin-CAR-T Cells Against Solid TumorsYusuf DemirNo ratings yet

- Theatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THDocument18 pagesTheatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THAppleSamsonNo ratings yet

- Country Profile - NigerDocument1 pageCountry Profile - Nigernana kayNo ratings yet

- Badminton Lesson 1 4 - 5 Grade: TH THDocument31 pagesBadminton Lesson 1 4 - 5 Grade: TH THLoxcey LopezNo ratings yet

- Evolution BrochureDocument4 pagesEvolution Brochurelucas28031978No ratings yet

- Lec 5Document22 pagesLec 5Abcdefgh EfghabcdNo ratings yet

- Sheet (1) : An Iron Ring Has A Cross-Sectional Area of 3 CMDocument2 pagesSheet (1) : An Iron Ring Has A Cross-Sectional Area of 3 CMKhalifa MohamedNo ratings yet

- CAM TOOL Solidworks PDFDocument6 pagesCAM TOOL Solidworks PDFHussein ZeinNo ratings yet

- Homer Christensen ResumeDocument4 pagesHomer Christensen ResumeR. N. Homer Christensen - Inish Icaro KiNo ratings yet

- Control Systems Engineering by S C Goyal U A Bakshi PDFDocument3 pagesControl Systems Engineering by S C Goyal U A Bakshi PDFShubham SinghNo ratings yet

- Cypress Enable Basic Rer Erence ManualDocument2 pagesCypress Enable Basic Rer Erence ManualCarlos RodasNo ratings yet

- ACM JournalDocument5 pagesACM JournalThesisNo ratings yet

- VFD ManualDocument187 pagesVFD ManualgpradiptaNo ratings yet

- List of DEA SoftwareDocument12 pagesList of DEA SoftwareRohit MishraNo ratings yet