Professional Documents

Culture Documents

Diagram and Apparatus: 1. Membrane Test Unit (Model TR14) 2. Digital Weighing Balance 3. Stopwatch 4. Beaker

Uploaded by

ameyakemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diagram and Apparatus: 1. Membrane Test Unit (Model TR14) 2. Digital Weighing Balance 3. Stopwatch 4. Beaker

Uploaded by

ameyakemCopyright:

Available Formats

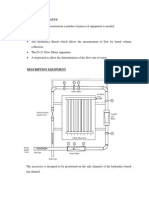

DIAGRAM AND APPARATUS

APPARATUS

1. Membrane Test Unit (Model TR14)

2. Digital Weighing Balance

3. Stopwatch

4. Beaker

MATERIAL

1. Sodium chloride.

2. Water.

3. Polyamide Film (AFC90)

4. Polyamide Film (AFC40)

5. Cellulose Acetate (CA202)

6. PVDF (PVDF)

MATHODOLOGY/PROCEDURE

General start-up procedure

1.

All the valves were making sure initially closed.

2.

A sodium chloride solution was prepared by adding 100g of sodium chloride into 20L of

water.

3.

The tank was filled up with the salt solution that was prepared in step 2. The feed was

maintained at room temperature.

4.

The power for control panel was turned on. All sensors and indicators were checked to

functioning properly.

5.

Thermostat was switched on and the thermo oil level was checked to make sure it is

above the coil inside thermostat. The thermostat was checked if connections were

properly fitted.

The temperature was adjusted at the thermostat to maintain feed temperature.

6.

The unit is now ready for experiments.

Experiment procedure

1.

The experiment was started with membrane 1. Valves V2, V5, V7, V11 and V15 were

opened.

2.

To set the maximum working pressure at 20 bars, the plunger pump (P1) was switched on

and valve V5 was slowly closed. The pressure value at pressure gauge was observed and

the pressure regulator was adjusted to 20 bars.

3.

Valve V5 was opened. Then, membrane maximum inlet pressure was set to 18 bars for

Membrane 1 by adjusting the retentive control valve (V15).

4.

The system was allowed to run for 5 minutes. Sample from permeate sampling port was

collected and the sample was weighed using digital weighing balance. The weight of

permeates was recorded every 1 minute for 10 minutes.

5.

The step 1 to 5 was repeated for Membrane 2, 3 and 4. The respective sets of valves were

opened and closed and the membrane maximum inlet pressure was adjusted for every

membrane.

Membrane

Open Valves

Sampling Valves

Retentive control

Membrane

valve

maximum inlet

pressure(bar)

V2, V5, V7, V11 Open V19 and

and V15

6.

12

V17

10

V18

8.5

close valve V13

V2, V5, V10, V14 Open V22 and

and V18

V16

close valve V12

V2, V5, V9, V13 Open V21 and

and V17

18

close V11

V2, V5, V8, V12 Open V20 and

and V16

V15

close V14

The graph of permeate weight versus time was plotted.

General shut-down operation

1.

The plunger pump was switched off.

2.

Valve 2 was then closed.

3.

All liquid in the feed tank and product tank were drained by opening valves V3 and V4.

4.

The entire pipes were flushed with clean water. V3 and V4 were closed; the clean water

was filled to the feed tank until 90% full.

5.

The system was run with the clean water until the feed tank is nearly empty.

REFERENCES

http://en.wikipedia.org/wiki/Membrane_technology

http://vedyadhara.ignou.ac.in/wiki/images/6/63/Unit_11_Membrane.DOC_1.pdf

http://www.epa.gov/ogwdw/disinfection/lt2/pdfs/guide_lt2_membranefiltration_final.pdf

APPENDIX

You might also like

- Soal Bahasa InggrisDocument7 pagesSoal Bahasa InggrisPelkeh Prianda25% (16)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Boiler House Procedures GuideDocument18 pagesBoiler House Procedures GuidePrakash WarrierNo ratings yet

- SOP For Milestone Microwave DigestionDocument11 pagesSOP For Milestone Microwave Digestionapi-26966403No ratings yet

- Climbing Film EvaporatorDocument8 pagesClimbing Film Evaporatorsaz140% (1)

- Dehydrogenation of Isopropyl Alcohol To AcetoneDocument1 pageDehydrogenation of Isopropyl Alcohol To Acetoneameyakem100% (1)

- Experiment 1 CSTR DynamicsDocument24 pagesExperiment 1 CSTR DynamicsFarhan Hazeeq50% (2)

- Alovebali: SOP HTST MachineDocument7 pagesAlovebali: SOP HTST MachinePt Putra W SNo ratings yet

- ZSFM Deluge Valve PDFDocument7 pagesZSFM Deluge Valve PDFkhalidwy6342No ratings yet

- Radar PlottingDocument23 pagesRadar Plottingthugsdei100% (2)

- Atlas TechNotes - Complete Set Rev Nov 2011Document50 pagesAtlas TechNotes - Complete Set Rev Nov 2011caod1712No ratings yet

- System Modelling and SimulationDocument260 pagesSystem Modelling and SimulationArvind Kumar100% (13)

- Judo Bio MechanicsDocument11 pagesJudo Bio MechanicsAttilio Sacripanti100% (6)

- AbstractDocument4 pagesAbstractRadhi AbdullahNo ratings yet

- AbstractDocument15 pagesAbstractRadhi AbdullahNo ratings yet

- CHE504 Membrane Test UnitDocument2 pagesCHE504 Membrane Test UnitSyazwina AziziNo ratings yet

- RecommendationDocument6 pagesRecommendationIskandar IslahudinNo ratings yet

- Procedure Heat ExchangerDocument3 pagesProcedure Heat ExchangerxxooNo ratings yet

- Membrane Filtration UpdatedDocument12 pagesMembrane Filtration UpdatedFazlie IslamNo ratings yet

- Group 2 (Lab 3)Document25 pagesGroup 2 (Lab 3)Riethanelia UsunNo ratings yet

- Level 0 - CGE617 - Gas Meter CalibrationDocument8 pagesLevel 0 - CGE617 - Gas Meter CalibrationMuhammad Nazrin Mohd AzmiNo ratings yet

- Experiment No: 3: ObjectivesDocument14 pagesExperiment No: 3: ObjectivesAlimah Azeli100% (1)

- Apparatus and Procedure Lab 1 Boy's CalorimeterDocument2 pagesApparatus and Procedure Lab 1 Boy's CalorimeterNaufal Syafiq Mohd IsaNo ratings yet

- Over Speed TestDocument8 pagesOver Speed TestsaitamaopmofficialNo ratings yet

- Shop Inspection & Test procedure-GVK-1Document7 pagesShop Inspection & Test procedure-GVK-1Sungil ChoiNo ratings yet

- BSEE Test ProcedureDocument35 pagesBSEE Test ProcedureNatraji100% (2)

- SOP 75v4 Specific-Gravity FinalDocument22 pagesSOP 75v4 Specific-Gravity FinalAldwiNo ratings yet

- ESSAR-HAZIRA FURNACE LEAK TESTDocument13 pagesESSAR-HAZIRA FURNACE LEAK TESTTheleapInoblivionNo ratings yet

- Jun Liu, Yuchen Wang, Baoshuang Shi, Daoming Wang, Liquan Wang, Xiangjuan XuDocument10 pagesJun Liu, Yuchen Wang, Baoshuang Shi, Daoming Wang, Liquan Wang, Xiangjuan Xunarendar.1No ratings yet

- Neopuff Tech ManDocument6 pagesNeopuff Tech ManoechimNo ratings yet

- Test Bench For Safety ValveDocument8 pagesTest Bench For Safety ValvekhairurNo ratings yet

- Performance Qualification of Autoclave Cum Bung ProcessorDocument17 pagesPerformance Qualification of Autoclave Cum Bung ProcessorĐức LinhNo ratings yet

- Williams GeismarDocument5 pagesWilliams GeismarGuru PrasadNo ratings yet

- Performance Qualification of Isolator Systems - Pharmaceutical GuidelinesDocument7 pagesPerformance Qualification of Isolator Systems - Pharmaceutical Guidelinessaeed216No ratings yet

- Running Pumps in Series and ParallelDocument2 pagesRunning Pumps in Series and ParallelKogulan SubramaniamNo ratings yet

- SOP For Well Test REV 1.01 - ENIDocument4 pagesSOP For Well Test REV 1.01 - ENIibraheem alsarrajNo ratings yet

- NurAfifah Water Cooling Unit 30.04.17Document11 pagesNurAfifah Water Cooling Unit 30.04.17Anonymous iic8AcNo ratings yet

- W08g09an Mha 1.1. A Pan OperationsDocument4 pagesW08g09an Mha 1.1. A Pan Operationswaziri maulidiNo ratings yet

- Fugitive Emission Testing Procedures for 1Document15 pagesFugitive Emission Testing Procedures for 1Nitin AggarwalNo ratings yet

- Membrane Test UnitDocument14 pagesMembrane Test UnitAzzian AriffinNo ratings yet

- Hydrogen Storage Vessel Hydro Test Procedure.Document6 pagesHydrogen Storage Vessel Hydro Test Procedure.Ahsun HabibNo ratings yet

- Ijaret: ©iaemeDocument10 pagesIjaret: ©iaemeIAEME PublicationNo ratings yet

- Lab ReportDocument26 pagesLab ReportMuhaimen RahmanNo ratings yet

- Hydrotesting Procedure Requirement at SiteDocument8 pagesHydrotesting Procedure Requirement at Siteramundt100% (1)

- AS6 Commissioning Run ProtocolDocument7 pagesAS6 Commissioning Run ProtocolMaximino OlveraNo ratings yet

- Calibration Procedures Virginia PDFDocument81 pagesCalibration Procedures Virginia PDFraja qammarNo ratings yet

- SRV - Accumulation TestDocument1 pageSRV - Accumulation TestcadaxeshpatelNo ratings yet

- Group 1A - Lab Report Combine PDFDocument87 pagesGroup 1A - Lab Report Combine PDFHanifatur AffiqNo ratings yet

- S T K SQ1: Set Up and User GuideDocument16 pagesS T K SQ1: Set Up and User GuideDella DellaNo ratings yet

- Marine Engineering 2 Lab #1 Operations, Control and Performance Analysis of A Marine EvaporatorDocument4 pagesMarine Engineering 2 Lab #1 Operations, Control and Performance Analysis of A Marine EvaporatorgdgraphNo ratings yet

- 11.2.9 OWS Operating ProcedureDocument1 page11.2.9 OWS Operating ProcedureRISHI CHANDRANo ratings yet

- Setup and User Guide for Steam Quality Test Kit SQ1Document16 pagesSetup and User Guide for Steam Quality Test Kit SQ1schumonNo ratings yet

- Valve) - 2. End Fittings For ClosureDocument10 pagesValve) - 2. End Fittings For ClosureNaveen Vel100% (1)

- Midterm - Unit OpsDocument19 pagesMidterm - Unit OpsKrizzia Anne ShengNo ratings yet

- Total Coliform Multiple Tube Fermentation Technique - EPADocument18 pagesTotal Coliform Multiple Tube Fermentation Technique - EPARaihana NabilaNo ratings yet

- Lab Manual PDFDocument191 pagesLab Manual PDFAbdul QayyumNo ratings yet

- MFE LabDocument12 pagesMFE Lab076bch031.ritishaNo ratings yet

- Experiment C5: Phase DiagramDocument6 pagesExperiment C5: Phase DiagramChengyan YapNo ratings yet

- BIOLOGY PLANNING AND DESIGNING LAB SAMPLEDocument3 pagesBIOLOGY PLANNING AND DESIGNING LAB SAMPLESonia OmapersaudNo ratings yet

- Method 27 - Determination of Vapour TightnessDocument11 pagesMethod 27 - Determination of Vapour TightnessGeorge NicolaidesNo ratings yet

- Sole Pit Clipper WashDocument11 pagesSole Pit Clipper WashStiflar SparksNo ratings yet

- Lonkar Well Testing Ltd. Procedures: PurposeDocument2 pagesLonkar Well Testing Ltd. Procedures: Purposeweldsv1No ratings yet

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManFrom EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManNo ratings yet

- Cryogenics Safety Manual: A Guide to Good PracticeFrom EverandCryogenics Safety Manual: A Guide to Good PracticeNo ratings yet

- Chapter 3Document14 pagesChapter 3ameyakemNo ratings yet

- Chapter 4Document4 pagesChapter 4ameyakemNo ratings yet

- Chapter 1Document9 pagesChapter 1ameyakemNo ratings yet

- Chapter 5Document2 pagesChapter 5ameyakemNo ratings yet

- Large-Scale Pyrolysis Oil ProductionDocument93 pagesLarge-Scale Pyrolysis Oil ProductionKarez Marto100% (1)

- Rubrics For CHE692 AssigmentDocument6 pagesRubrics For CHE692 AssigmentameyakemNo ratings yet

- Controller Design (Based On Transient Response Criteria: To Determine Controller Settings For P, PI or PID ControllersDocument66 pagesController Design (Based On Transient Response Criteria: To Determine Controller Settings For P, PI or PID Controllerssatya sagarNo ratings yet

- ControlDocument1 pageControlameyakemNo ratings yet

- (Aq) + (Aq) - (Aq)Document2 pages(Aq) + (Aq) - (Aq)ameyakemNo ratings yet

- Preliminary Report Part 1Document21 pagesPreliminary Report Part 1ameyakemNo ratings yet

- EXPERIMENTERDocument7 pagesEXPERIMENTERameyakemNo ratings yet

- Mass BalanceDocument55 pagesMass BalanceJoshua Johnson100% (1)

- Determinatin Weak Acid-SENIORDocument13 pagesDeterminatin Weak Acid-SENIORameyakemNo ratings yet

- Consultation-Determination of The Ka of A Weak AcidDocument5 pagesConsultation-Determination of The Ka of A Weak AcidameyakemNo ratings yet

- LAB 6 Soaps and DetergentDocument10 pagesLAB 6 Soaps and DetergentMuhd AkmalNo ratings yet

- Experiment 4Document1 pageExperiment 4ameyakemNo ratings yet

- Introduction A As LABDocument2 pagesIntroduction A As LABameyakemNo ratings yet

- Experiment 1Document13 pagesExperiment 1ameyakemNo ratings yet

- Determination Acetic AcidDocument21 pagesDetermination Acetic Acidameyakem100% (1)

- Determination Acetic AcidDocument21 pagesDetermination Acetic Acidameyakem100% (1)

- Determination Acetic AcidDocument21 pagesDetermination Acetic Acidameyakem100% (1)

- Introduction A As LABDocument2 pagesIntroduction A As LABameyakemNo ratings yet

- Introduction A As LABDocument2 pagesIntroduction A As LABameyakemNo ratings yet

- Anti Derivative Chain RuleDocument4 pagesAnti Derivative Chain Ruletutorciecle123No ratings yet

- DARK ENERGY TECHNOLOGY - Theory and Science of The Rainbow BridgeDocument78 pagesDARK ENERGY TECHNOLOGY - Theory and Science of The Rainbow BridgeBoris Petrovic100% (4)

- STAAD Service Stage and Seismic Analysis ResultsDocument14 pagesSTAAD Service Stage and Seismic Analysis ResultsVikasNo ratings yet

- Maxwell Stress Tensor ExplainedDocument6 pagesMaxwell Stress Tensor ExplainedSyeda Tehreem IqbalNo ratings yet

- CH 3 Concept of ViscosityDocument11 pagesCH 3 Concept of ViscosityJenny ChenNo ratings yet

- Bearings ShaftsDocument74 pagesBearings ShaftsCik MinnNo ratings yet

- Jar TestDocument1 pageJar TestEduardo Tonino Chavez GaytanNo ratings yet

- Development of Biomass-Based Plastic Resins From Natural Algal PolysaccharidesDocument72 pagesDevelopment of Biomass-Based Plastic Resins From Natural Algal Polysaccharidesjustin_domingo_2100% (2)

- ZDocument265 pagesZAdal ContrerasNo ratings yet

- Cati Pakistan Training Course - MechanicalDocument13 pagesCati Pakistan Training Course - MechanicalImam Haryadi WibowoNo ratings yet

- Beryllium and Beryllium Compounds: 2005 Wiley-Vch Verlag GMBH & Co. Kgaa, WeinheimDocument28 pagesBeryllium and Beryllium Compounds: 2005 Wiley-Vch Verlag GMBH & Co. Kgaa, WeinheimjaimeNo ratings yet

- Thesis MainDocument144 pagesThesis MainIvan GrkajacNo ratings yet

- Slide Micro Teaching 5.3Document18 pagesSlide Micro Teaching 5.3Mastura MohamadNo ratings yet

- Parameter Estimation of Single Diode PV Module Based On GWO AlgorithmDocument12 pagesParameter Estimation of Single Diode PV Module Based On GWO AlgorithmFelicia Itusaca CcariNo ratings yet

- FLUIDME Quiz 02 AnswersDocument5 pagesFLUIDME Quiz 02 AnswersSam Denielle TugaoenNo ratings yet

- Technical Notes On Duplex SSDocument22 pagesTechnical Notes On Duplex SSBhyrappaNo ratings yet

- Stp417-Eb 5820 PDFDocument219 pagesStp417-Eb 5820 PDFS R Kumar KonathalaNo ratings yet

- Adjoint Rans With Filtered Shape Derivatives For Hydrodynamic OptimisationDocument11 pagesAdjoint Rans With Filtered Shape Derivatives For Hydrodynamic Optimisationvolo87No ratings yet

- Interactions and Incompatibilities of Pharmaceutical ExcipientsDocument24 pagesInteractions and Incompatibilities of Pharmaceutical ExcipientsEmmanuel Vachon LachanceNo ratings yet

- Flight Equations of Motion for 6 DOF Aircraft ModelDocument24 pagesFlight Equations of Motion for 6 DOF Aircraft ModelNeetu SharmaNo ratings yet

- Heat Exchangers Types & Applications, LMTD Derivation & ProblemsDocument11 pagesHeat Exchangers Types & Applications, LMTD Derivation & Problemsananth2012No ratings yet

- Cluster ExpansionDocument4 pagesCluster ExpansionflytrapsolNo ratings yet

- Numerical Programming I (For CSE) : Final ExamDocument7 pagesNumerical Programming I (For CSE) : Final ExamhisuinNo ratings yet

- Thermodynamic Study On Density and Viscosity of Binary Mixtures of Ethyl Acetoacetate With (C4-C9) Aliphatic Ketones at (303.15 and 308.15) KDocument17 pagesThermodynamic Study On Density and Viscosity of Binary Mixtures of Ethyl Acetoacetate With (C4-C9) Aliphatic Ketones at (303.15 and 308.15) KInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cementing EquipDocument12 pagesCementing Equipzbhdzp100% (1)