Professional Documents

Culture Documents

000007

Uploaded by

Rama Krishna Reddy DonthireddyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

000007

Uploaded by

Rama Krishna Reddy DonthireddyCopyright:

Available Formats

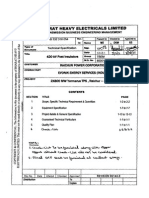

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

THIS DOCUMENT/DRAWING IS THE PROPERTY OF ABB LUMMUS GLOBAL B.V. INCLUDING ALL PATENTED AND PATENTABLE FEATURES AND/OR CONFIDENTIAL INFORMATION AND ITS USE IS CONDITIONED UPON THE USERS AGREEMENT NOT TO REPRODUCE

THE DOCUMENT/DRAWING, IN WHOLE OR IN PART, NOR THE MATERIAL DESCRIBED THEREON, NOR TO USE THE DOCUMENT/DRAWING FOR ANY PURPOSE OTHER THAN AS SPECIFICALLY PERMITTED IN WRITING BY ABB LUMMUS GLOBAL B.V.

Doc. No.

04184-120311-000007

Rev. 0

Specification For:

GENERAL ELECTRICAL SPECIFICATION

N-601

0

A

REV.

2005-03-11

FOR FEED PACKAGE

PCP

POV

HHI

2005-02-14

ISSUED FOR COMMENTS / APPROVAL

PCP

POV

HHI

DATE

LGV SSPE 04-3911-01.020 (1999-02-18)

DESCRIPTION

PREPARED

CHECKED

04184-120311-000007

APPROVED

Page 1 of 30

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev 0

INDEX

SECTION

PAGE

1. SCOPE

2. DEFINITIONS

3. RESPONSIBILITIES

4. REGULATIONS

4.1

NATIONAL CODES AND STANDARDS

4.2

IEC STANDARDS, OTHER INTERNATIONAL STANDARDS AND PUBLICATIONS

4.3

ELECTRICAL PROJECT ENGINEERING SPECIFICATIONS

5. DESIGN

5.1

5.1.1

5.1.2

5.1.3

5.1.4

5.1.5

5.1.6

GENERAL

Engineering criteria

Overview of the power distribution system.

System Voltages and Frequency

Voltage and Frequency Variations

Electrical Loads and Electricity Consumption

Shortcircuit Ratings

9

9

9

9

10

11

11

5.2

SERVICE CONDITIONS

12

5.3

ENCLOSURE DEGREE OF PROTECTION

12

5.4

ELECTRICAL AREA CLASSIFICATION

12

5.5

5.5.1

5.5.2

5.5.3

SUBSTATION

Location

Construction Requirements

Safety

13

13

13

14

5.6

ELECTRICAL INSTALLATIONS OF BUILDINGS

14

5.7

AC SWITCHGEAR AND CONTROL GEAR ASSEMBLIES.

15

5.8

TRANSFORMERS

16

5.9

EARTHING RESISTORS

16

LGV SSPE 04-3911-01.020 (1999-02-18)

04184-120311-000007

Page 2 of 31

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev 0

INDEX

SECTION

PAGE

5.10

BUS DUCT

16

5.11

ELECTRIC MOTORS

17

5.12

PROTECTION AND CONTROL REQUIREMENTS

17

5.13

EMERGENCY SUPPLY SYSTEMS

17

5.14

ANNUNCIATORS

18

5.15

POWER INSTALLATION

18

5.16

EARTHING INSTALLATION

19

5.17

LIGHTING INSTALLATION

20

5.18

MAINTENANCE SOCKET OUTLETS

22

5.19

ELECTRIC TRACING

22

5.20

COMMUNICATION AND SECURITY SYSTEMS

22

5.21

CATHODIC PROTECTION

22

6. MATERIALS

23

7. TESTING AND COMMISSIONING

23

8. CORROSION PROTECTION

23

9. DOCUMENTATION

24

10. MARKING

24

11. REFERENCE DOCUMENTS

25

12. ATTACHMENTS

25

LGV SSPE 04-3911-01.020 (1999-02-18)

04184-120311-000007

Page 3 of 31

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

1.

04184-120311-000007

Rev. 0

SCOPE

This specification gives directives for design, selection criteria, methods, instructions and

examples for the electrical scope of work for a petrochemical plant.

This specification, together with the applicable project specifications, shall govern the

engineering of the electrical facilities.

The scope of this specification applies to the complete electrical installation which includes

following:

2.

Detailed engineering and design.

A complete package of installation drawings.

Supply and installation of equipment and materials.

Testing and commissioning.

DEFINITIONS

For this specification following definitions are applicable:

Client:

Indian Oil Corporation Limited (IOCL)

Contractor:

Contractor is the party which carries out all or part of the design, engineering,

procurement, construction applicable to this specification.

Supplier:

Any manufacturer or supplier or seller who is appointed by the contractor and

responsible for the supply of materials or equipment or services.

3.

RESPONSIBILITIES

3.1

All contact in connection with this specification shall be between Client and Contractor.

3.2

Any conflict between the requirements of this specification and the related codes, standards

and/or project engineering specifications shall be referred to Client for clarification.

In case of any conflict or deviations amongst the various referenced regulations and documents

general the order of precedence shall be as follows:

Country laws and regulations (statutory requirements)

Project specifications and drawings

IEC and internationally recognized standards

Country standards

3.3

Assumptions to cover lack of information are not allowed. Contractor is obliged to obtain reliable

information from Client or other sources.

3.4

Contractor shall fully describe all proposed deviations from this specification for review and

approval by Client.

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

3.5

04184-120311-000007

Rev. 0

Contractor shall verify all (existing) dimensions and conditions shown on Client's documents.

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

4.

04184-120311-000007

Rev. 0

REGULATIONS

The installation shall be designed, constructed, inspected and tested in accordance with the

requirements of this specification and the edition of the statutory requirements, national

standards and international standards as valid on the contract award date.

The IEC International standards shall be used to the maximum extent and usage of Indian

standards shall be limited to authority related designs (statutory requirements).

Electrical equipment and materials manufacturing standards shall be in accordance with IEC

standards, with the option for Indian manufacturers to offer equipment and materials

manufactured to offer equipment and materials manufactured to equivalent Indian Standards

(IS).

Certification of equipment and materials for duty, rating, environmental suitability, hazardous

area use shall be obtained from recognised National or International testing authorities.

Evidence of the appropriate certification shall be obtained prior to commitment to purchase.

Equipment of Indian origin selected for installation in hazardous areas shall have a test

certificate from the Central Mining Research Station (CMRS) and approval certificates from the

Chief Controller of Explosives (CCE).

Contractor shall be responsible for obtaining necessary approvals from the statutory authorities

e.g. Electrical inspectorate, CCE as applicable before commissioning of electrical facilities.

The main codes and standards, which shall be considered as minimum requirements, are given

below.

4.1

NATIONAL CODES AND STANDARDS

Indian Electricity Act 1910.

Indian Electricity Rules 1956.

The Factory Act 1948.

The Petroleum Act 1934

The Petroleum Rules 1976 (Ministry of Industry, Government of India)

Indian Standards (IS) as listed below

IS 732

Code of practice for electrical wiring installations system voltages not

exceeding 650V

IS 1255

Code of Practice for installation and maintenance of power cables up to

and including 33 kV rating

IS 1646

Code of practice for fire safety of buildings and electrical installations

IS 2309

Code of practice for the protection of buildings and allied structures

against lightning

IS 3034

Code of practice for fire safety of industrial buildings - Electrical generating

& distributing stations

IS 3043

Code of practice for earthing

IS 3646

Code of practice for interior illumination: Part I & Part II

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

IS 3716

Application guide for insulation co ordination

IS 5571

Guide for selection of electrical equipment for hazardous areas

IS 5572

Classification of hazardous areas for electrical installations

IS 6665

Code of practice for Industrial lighting

IS 7098

Cross-linked polyethylene insulated PVC sheathed cables

IS 7689

Guide for control of undesirable static electricity.

IS 9676

Reference ambient temperature for electrical equipment

IS 10028

Code of practice for selection, installation and maintenance of

transformers

IS 12360

Voltage bands for electrical installations including preferred voltages and

frequency

IS 12459

Code of practice for fire protection of cable runs.

IS 13234

Guide for short circuit calculations

IS 13346

General requirements for electrical

atmosphere

IS 13408

Code of practice for the selection, installation and maintenance of

electrical apparatus for use in potentially explosive atmospheres.

apparatus

for explosive

gas

Publications issued by the Oil Industry Safety Directorate (OISD) as listed below :

OISD 113

Classification of areas for electrical installation at hydrocarbon processing

and handling facilities

OISD RP 147 Inspection and safe practices during electrical installations

OISD RP 149 Design aspects for safety in electrical system

4.2

OISD 173

Fire prevention and protection system for electrical installation

OISD GDN

180

Lightning protection

IEC STANDARDS, OTHER INTERNATIONAL STANDARDS AND PUBLICATIONS

This subsection only lists the most relevant IEC standards. The detailed project engineering

specifications shall define the specific IEC standards to be used.

Standards issued by the International Electrotechnical Standards Committee(IEC) as

listed below :

IEC 60034

Rotating Electrical Machines

IEC 60038

IEC Standard Voltages.

IEC 60050

International Electrotechnical Vocabulary

IEC 60076

Power Transformers

IEC 60079

Electrical Apparatus for Explosive Gas Atmospheres.

IEC 60099

Surge Arrestors

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

IEC 60146

Semiconductor Converters

IEC 60183

Guide to the Selection of High Voltage Cables

IEC 60204

Safety of Machinery. Electrical Equipment of Machines

IEC 60255

Electrical Relays.

IEC 60269

Low Voltage Fuses

IEC 60287

Electric Cables - Calculation of the Continuous Current Rating

IEC 60289

Reactors

IEC 60331

Test for Electrical Cables under Fire Conditions Circuit Integrity

IEC 60332

Test on Electric Cables under Fire Conditions

IEC 60364

Electrical Installations of Buildings.

IEC 60439

Low Voltage Switchgear and Control Gear Assemblies

IEC 60470

High Voltage Alternating Current Contactors and Contactor-based Motor

Starters

IEC 60478

Stabilised Power Supplies, DC Output

IEC 60502

Power Cables with Extruded Insulation and their Accessories for Rated

Voltages from 1 kV (Um = 1.2 kV) up to 30 kV (Um = 36 kV)

IEC 60529

Degrees of Protection Provided by Enclosures (IP Code).

IEC 60621

Electrical Installations for Outdoor Sites under Heavy Conditions

(including Open-cast Mines and Quarries

IEC 60694

Common Specifications for High Voltage Switchgear and Control Gear

Standards

IEC 60896

Stationary Lead-Acid Batteries. General Requirements and Methods of

Test.

IEC 60909

Short Circuit Current Calculations in Three Phase AC Systems.

IEC 60947

Low Voltage Switchgear and Control Gear

IEC 61000

Electromagnetic Compatibility.

IEC 61024

Protection of Structures against Lightning.

IEC 61082

Preparation of Documents used in Electrotechnology.

IEC 61140

Protection Against Electric Shock. Common Aspects for Installation and

Equipment

IEC 61200

Electrical Installation Guide

IEC 61241

Electrical Apparatus for Use in the Presence of Dust

IEC 61312

Protection Against Lightning Electromagnetic Impulse

IEC 61800

Adjustable Speed Electrical Power Drive Systems

IEC 61936

Power Installations Exceeding 1 kV AC

IEC 62040

Uninterruptible Power Systems (UPS)

IEC 62271

High Voltage Switchgear and Control Gear

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

Note:

04184-120311-000007

Rev. 0

Parts of multipart IEC standards issued from 1997 will carry the 60000 series reference, while existing parts

and related amendments will continue to carry old references.

Standards issued by the American Petroleum Institute (API) as listed below :

API RP 505

4.3

Recommended Practice for Classification of Locations for Electrical

Installations at Petroleum Facilities, Classified as Class 1, Zone 0, Zone 1

and Zone 2.

ELECTRICAL PROJECT ENGINEERING SPECIFICATIONS

All electrical project engineering specifications shall be developed by Client.

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

5.

DESIGN

5.1

GENERAL

5.1.1

Engineering criteria

The engineering of the electrical installation shall be based upon the following factors:

Rev. 0

Safety to personnel and equipment during operation and maintenance.

Reliability of service.

Ease of maintenance.

Facility for limited addition of future loads.

Convenience of operation.

Maximum standardization of equipment and materials.

Maximum interchangeability of equipment.

Elimination of fire risk.

Suitability for applicable environmental factors

Safe conditions shall be ensured under all operating conditions including those associated with

start up and shut down of plant as well as those arising out of failure of electrical equipment. The

isolation of part of system of electrical equipment due to either maintenance or shut down shall

not compromise safety.

5.1.2

Overview of the power distribution system.

The Overall Single Line Diagram (04084-120311-000013) gives a general overview of the power

distribution system and the related electrical installations.

The power supply shall consist of a double grid connection at 33 kV. The connection shall be

made by underground power feeders coming from the overall plant substation.

The battery limit for the facilities shall be at the primary side of the 33 / 6.6 kV transformers at

the Naphta Cracker Unit substation.

The main power distribution inside the Naphta Cracker Unit shall be at 6.6 kV.

Emergency loads shall be supplied by a dedicated LV emergency generator.

UPS power, either AC or DC, shall as a minimum be provided for ESD, fire & gas, switchgear

control, DCS, security systems, critical control systems and telecommunication systems.

AC and DC UPS systems will be single type execution (100 % rectifier, 100 % battery for DC

UPS systems; 100 % rectifier, 100 % battery, 100 % inverter and 100 % static bypass for AC

UPS systems).

Inside the instrument building a dedicated AC UPS for instrument systems shall be installed.

5.1.3

System Voltages and Frequency

Voltage selection is based upon economic considerations, taking the following factors into

account:

a. Size and location of loads.

b. Provision of future extension.

c. Short-circuit level.

d. Availability of switchgear with suitable current rating and rupturing capacity.

e. Possibility of keeping the number of different voltage levels to a minimum.

f. Voltage levels available in the overall plant

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

The voltages listed in Table 1 below are available:

DESCRIPTION

VOLTAG

E

33 kV

6.6 kV

6.6 kV

415 V

PHASES

WIRES

3/3

3/3

3/3

3/3

AC/DC

FREQ.

50 Hz

50 Hz

50 Hz

50 Hz

EARTHING

METHOD

Resistance

Resistance

Resistance

Solid

240 V

1/2

50 Hz

Solid

Normal lighting, small power, etc.

415 V

240 V

3/4

1/2

50 Hz

50 Hz

Critical lighting (*2)

220 V

-/2

DC

Solid

Solid

-

AC UPS system (*1)

Control circuits (general)

For MCC starter units to be derived

from individual feeder in MCC

Control circuits switchgear:

240 V

240 V

1/2

1/2

50 Hz

50 Hz

Solid

Solid

Closing / metering

Trip / protection (*2)

Instruments (general)

DCS, F&G, SGS systems.

To be derived from AC UPS

Fire alarm system (*2)

Solenoids (*2)

240 V

110 V

240 V

110 V

1/2

-/2

1/2

1/2

50 Hz

DC

50 Hz

50 Hz

Solid

Solid

Solid

24 V

110 V

-/2

-/2

DC

DC

Plant intake voltage

Plant distribution

Electric motors Pn > 160 kW

0.37 Pn 160 kW

Pn < 0.37 kW

Table 1

Notes

1. Pending on UPS output a three phase four wire system (415/240 V AC UPS) can be selected.

2. Floating supply systems shall be provided with an earth-fault detection system.

5.1.4

Voltage and Frequency Variations

Voltage and frequency static variations in the AC supply system shall remain within the following

limits:

Voltage

Unom

Frequency

50 Hz

Combined voltage and frequency

10%.

3%.

10%.

The voltage variations static variations in DC supply systems shall remain within + 10 % and 20

% of the nominal voltage at the equipment terminals. This voltage window accounts for

variations during charging and discharging of the battery systems.

The system design shall be such that the system stability is maintained when the supply voltage

and frequency remain within the limits given above.

The system design shall ensure that the voltage drop at the affected bus does not exceed 10 %

in case of start-up if the largest motor or reacceleration of a group of motors.

The voltage available at the motor terminals during start-up must be sufficient to ensure positive

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

starting or reacceleration of the motor (even with the motor fully loaded, if required), without

causing any damage to the motor.

Fore low voltage motors, the voltage available at the motor terminals must not be less than 80 %

of the rated value during start-up or reacceleration.

For high voltage motors, the voltage available at the motor terminals must not be less than 80 %

of the rated value during start-up or reacceleration.

5.1.5

Electrical Loads and Electricity Consumption

All the components of the electrical systems must be sized for 120% of the maximum load,

under the worst operating conditions.

The worst operating condition is specified as that condition that can occur under normal

operating conditions with limited maintenance in the electrical system, e.g. one transformer out

of service in a double ended distribution system.

Generally, the worst condition for a distribution system can be calculated as follows:

100% of the normal continuous running load +

30% of the intermittent and spare load +

10% of the stand-by load (or the largest loads, whichever is the largest).

5.1.6

Shortcircuit Ratings

All equipment shall be designed to have a making, withstand and breaking capacity higher

than the maximum value of short-circuit current calculated at the fault location.

Equipment shall withstand the maximum available fault current for one (1) second or three (3)

seconds as applicable in relation to the protection.

The sizing of medium-voltage cables shall be based on the short-circuit withstand capacity for

a minimum time period as dictated by the protection system.

Short-circuit duties shall include motor contribution.

All equipment shall be capable of withstanding the effects of short circuit currents and

consequential voltages arising in the event of equipment or circuit faults. Damage occurring at

the fault location is excluded from the above.

For installations above 1000 Volts, the short circuit current contributions from all supplies

which can be operated in parallel shall include contributions via bus section switches or

interconnectors which are capable of being operated simultaneously in the closed position.

This includes bus section switches or interconnectors, etc., which are intended for normally

open operation and on which no interlocking has been provided to prevent simultaneous

closure.

For LV switchboards equipped with multiple transformer incomers and/or generator incomers,

the shortcircuit rating of LV switchboards may be based on the number of permanently

connected incoming feeders, provided that the remainder of the LV incoming feeders shall be

equipped with automatic disconnecting logic circuitry ensuring that parallel operation of all LV

infeeds over max 5 seconds is not possible.

For installations above 1000 Volts, automatic break-before-make changeover arrangements of

supply capacity shall not be introduced with the specific aim of justifying the use of equipment

having a lower short circuit rating than would otherwise be required when based on the

parallel operation of all available supplies.

When determining equipment short circuit ratings, the effects of contributions from

asynchronous and synchronous machines on the switching duties of switchgear and on the

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

dynamic and thermal loading of the electrical installations in general shall be taken into

account.

Note:

Attention shall be paid to the short-circuit strength of the switchgear and all its components and the

relationship between peak and rms values of the short circuit currents that may occur, particularly when

the switchboard is directly connected to generators.

5.2

SERVICE CONDITIONS

5.2.1

The site conditions as described in the Process Design Basis Memorandum (LTD Job No

12605) and as per Site & Utility Data Sheet shall be applicable as design basis for all outdoor

installed electrical equipment and apparatus. (Refer Attachment 1)

Inside air-conditioned buildings the standard operating temperatures and humidities apply as per

applicable IEC standards. However all electrical equipment shall meet the requirements for

tropicalization.

5.3

ENCLOSURE DEGREE OF PROTECTION

5.3.1

The minimum equipment enclosure degree of protection according to IEC 60529 shall be as

follows:

IP 31

IP 20

IP 55

Indoor.

Panels with open doors (life parts shielded).

Outdoor.

Note that explosion protection requirements may require a higher degree of protection.

5.4

ELECTRICAL AREA CLASSIFICATION

5.4.1

All the areas within the battery limits shall be classified for the degree and the extent of hazard

from flammable material. The basis for hazardous area classification recognizes the differing

degrees of probability, with which flammable atmosphere may arise in installation, in terms of

frequency of occurrence and the probable duration of existence on each occasion.

The area classification layout shall show the sources of gas explosion hazards.

5.4.2

The area classification shall be in accordance with IS:5572.

For undefined cases IEC 60079-10 and/or API RP 505 shall be applied.

5.4.3

The electrical equipment and installations shall be selected for suitability of use in the classified

areas in accordance with IS 5571.

The selected electrical apparatus shall be adequately protected against corrosive and solvent

agencies, water ingress, thermal and mechanical stresses as determined by the environmental

conditions. General guidelines for type of protection for electrical equipment in hazardous areas

are listed below in table 2.

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

AREA

CLASSIFICATION

Zone 0

Zone 1

Zone 2

04184-120311-000007

DESCRIPTION

Intrinsic safe category "ia"

Other electrical apparatus, specifically designed for zone 0

Any type of protection adequate for zone 0 (not preferred)

Flameproof enclosure

Intrinsic safe category "ib"

Pressurization (see table 2)

Sand filling

Other electrical apparatus specifically designed for zone 1

Any type of protection adequate for zone 0 or zone 1 (not

preferred)

Oil immersion (see note 2)

Increased safety (see note 1)

Nonsparking apparatus (see note 1)

Rev. 0

SYMBOL

Ex

ia

s

d

ib

p

q

s

o

e

n

Table 2. Adequate types of protection

Notes:

1.

2.

For all outdoor installations, including the apparatus with type of protection "e" and type of protection

"n", the degree of protection shall be in accordance with section 5.3.

Oil-immersed apparatus may be used only in case its security will not be impaired by tilting or

vibration of the apparatus.

5.4.4

All materials installed in a hazardous area shall have a certificate of conformity or a declaration

of compliance issued by the appropriate authority.

5.5

SUBSTATION

5.5.1

Location

5.5.1.1

Substation buildings shall be located in an unclassified area, at least 15 meters away from any

source of gas explosion hazard. Ingress of sand and hazardous gases into the building shall be

prevented.

5.5.1.2

The buildings and the outdoor facilities shall be easily accessible from the road.

5.5.2

Construction Requirements

5.5.2.1

An outdoor transformer yard shall be provided. Transformers shall be separated by fire walls.

Bays shall be enclosed with wire mesh fences. A minimum free space of 1 meter shall be

provided around transformers and neutral earthing resistors.

5.5.2.2

The switch room shall be designed taking into consideration a future equipment expansion of

20%.

5.5.2.3

Equipment arrangement shall allow easy installation, operation and maintenance of the

equipment and future equipment extensions. The minimum equipment clearances are given in

table 3 below. The free distance between HV and LV equipment shall be minimum 2.5 meters.

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

Positioning of the transformer bays shall be related to the switchgear orientation, such to

minimize the bus duct or cable length.

DESCRIPTION

HV switchgear front

LV MCC front

LV switchgear ends

Common aisle space

Equipment door width

Equipment door height

MINIMUM

CLEARANCE

2500 mm

1500 mm

1000 mm

Largest equipment

depth + 200 mm

200 mm wider than

equipment width

200 mm higher than

highest equipment

REMARKS

Table 3

5.5.2.4

The battery room shall be completely separated from the switch room and shall only have

access from the outside of the building. The floor shall be acid resistant. Possible spilled liquid

shall be collected in a suitable basin. The ventilation system of the battery room shall extract air

from the higher part of the room and shall provide sufficient air changes as to keep the hydrogen

concentration below 10% LEL during boost charging. Air shall be supplied from the HVAC

system to keep the room temperature low thus increasing the battery lifetime.

5.5.2.5

A cable vault shall be provided under the switch room. Cables shall enter the switch room via

this vault and shall be installed on cable trays.

All cut-outs / openings in the substation requiring fireproofing as per statutory equirements, shall

have a fire withstand capacity of minimum 3 hous.

5.5.3

Safety

5.5.3.1

The switch room shall have two (2) doors located opposite of each other which can be used in

case of emergency. Doors shall be provided with panic bars. Same requirements apply to the

door to the battery room. Emergency doors shall be permanently closed and shall be sealed with

gaskets.

5.5.3.2

Manual fire alarm stations shall be provided outside the substation and shall be located near the

doors.

5.5.3.3

A fire detection system shall be provided covering at least the switch room, cable cellar and

battery room. Detectors shall be ceiling mounted preferably above potential fire hazards. The

battery room shall be provided with a hydrogen gas detector.

5.5.3.4

An eyewash bottle shall be provided inside the battery room.

5.6

ELECTRICAL INSTALLATIONS OF BUILDINGS

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

5.6.1

The electrical installation shall as a minimum comply with the IEC 60364 requirements and the

requirement of this section.

5.6.2

The lighting installation inside the building shall consist of normal and emergency lighting

5.6.3

Normal lighting shall be fluorescent type. Lighting inside buildings shall be controlled by

switches. Switch room lighting control shall be by change-over switches located near each door.

Lighting on the outside of the building (in transformer bays, etc.) shall be photocell controlled

together with the general outdoor lighting.

5.6.4

Normal emergency lighting shall be of the fluorescent type with built-in nickel-cadmium batteries

with a minimum back-up time of one (1) hour. Exit lights with pictograms shall be provided as

part of the emergency lighting installation.

5.6.5

A portable lighting fixture complete with battery and battery charger shall be provided for the

substation building.

5.6.5

Battery room lighting shall be suitable for zone 1, gas group IIC, T3.

5.6.6

Metal structures, reinforcing steel, doors and fences shall be earthed.

5.7

AC SWITCHGEAR AND CONTROL GEAR ASSEMBLIES.

5.7.1

High voltage switchgear and controlgear assemblies shall be designed to minimise the risk of

short circuit and to ensure personnel and operational safety during all operating conditions,

inspection, maintenance, the connection of main, control and auxiliary cables, and the equipping

and commissioning of spare panels whilst alive in operation.

High voltage switchgear and controlgear assemblies shall be of the metal clad withdrawable

type, dead front structure, having a single busbar system and consist of a number of separate

panels assembled into one or more sections. Sections shall be electrically interconnected by a

sectionalising switching device.

HV switchgear and controlgear assemblies shall be freestanding, floor mounted, consisting of

switchgear panels forming a single assembly with a common bus-bar system.

HV switchgear and controlgear assemblies shall be installed indoors in an airconditioned

environment.

Switchgear insulation medium shall be atmospheric air. The switching medium shall be either

vacuum or gas (SF6).

The design shall be arc-proof in accordance with IEC 62271.

5.7.2

All LV switchgear and control gear (also covering Motor Control Centres) shall be of indoor type,

metal enclosed execution. LV switchgear and control gear shall be draw-out design, air-break

equipment and shall as a minimum have form 3 protection in accordance with IEC 60439.

The low-voltage AC switchgear and controlgear assembly shall be designed to minimise the

risk of short circuit and to ensure personnel and operational safety during all operating

conditions, inspection, maintenance, the connection of main, control and auxiliary cables, and

the equipping and commissioning of spare panels whilst alive in operation.

Low voltage AC switchgear and controlgear assemblies shall be freestanding, floor mounted.

The assembly shall consist of standard switchgear and control gear panels forming a single

assembly with a common bus-bar system and shall have front access only for operation, cable

connection and maintenance activities.

The low-voltage AC switchgear and controlgear assembly shall be installed indoors in an

airconditioned environment.

Starter and outgoing feeder units shall be executed with fuse / switch combinations.

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

5.7.3

Switchgear shall be designed in accordance with the relevant project engineering specifications.

Switchgear sizing shall be accordance with the system calculations taking into consideration the

future expansions.

5.7.3

Low-voltage local distribution panels and/or switchboards shall be provided for following:

Lighting.

Socket outlets.

Electric tracing.

HVAC.

Electrical installations in buildings.

Package units.

Remote areas where motors are grouped and it is impractical to group starters into a

centralized Motor Control Center.

These distribution panels shall as a minimum comply with the project engineering specification

and shall be installed locally as close as possible to the loads to be connected.

5.7.4

All cabinets, panels or apparatus in which dangerous touch voltage occurs, and which are not

fully insulated shall be equipped with facilities for safety earthing.

5.8

TRANSFORMERS

5.8.1

Transformers shall be supplied in accordance with the requirements of project engineering

specification. Transformers shall be of the oil-immersed type (ONAN) and shall be suitable for

outdoor installation. Rating of transformers shall include a minimum spare capacity of 20%.

For the secondary voltage adjustment transformers shall be equipped with a 5-step (2.5% per

step) manual off-circuit tap changer.

Transformers shall have provisions for the addition of automatic cooling fans. The space for

components such as starters, switches, contacts, etc., as required to fulfill this requirement shall

be provided in the marshalling box

5.9

EARTHING RESISTORS

5.9.1

Earthing resistors shall be rated for ten (10) seconds and a maximum of three (3) interventions

per hour. The specified minimum duration of each intervention shall be five (5) times the clearing

time of the slowest earth fault relay in response to 80% of the initial maximum earth-fault current.

5.10

BUS DUCTS

The bus bars (MV and LV) shall be made of electrolytic copper or aluminum. It must be suitably

supported at regular intervals and both bus bars and supports shall be adequately sized and

damped to withstand the estimated short-circuit current without permanent deformation.

Medium-voltage bus duct shall be of phase segregated type. The bus insulators shall be of

nonhygroscopic noninflammable material.

Earth bus bars shall run along the full length of the bus duct without any break. The bus bars

shall be color coded. The bus duct housing the bus bars shall be of totally enclosed, sheet steel

construction, dust and vermin proof with removable covers. The bus duct shall also be supplied

with flexible links for connection at both the ends (for power buses, neutral and earth as

applicable) and bus duct support material. The flexible links shall be made up of metal to match

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

with mating surface to avoid bimetallic corrosion.

All hardware shall be corrosion resistant.

5.11

ELECTRIC MOTORS

5.11.1

Electric motors shall be in accordance with project engineering specifications. Motors shall be

supplied together with the driven equipment in which the supplier of the complete unit will be

responsible for compliance with the project requirements.

5.11.2

Motors shall be standardized on make, type and execution to the maximum extent.

5.11.3

In case speed control is required this shall be done with frequency controlled asynchronous

3-phase cage induction motors. The system shall comply with the applicable project engineering

specification.

5.12

PROTECTION AND CONTROL REQUIREMENTS

5.12.1

The minimum required protection functions for MV feeder types and for LV incoming and

buscoupler circuits are indicated in Attachment II.

5.12.2

LV motor feeder units (starter units) shall furthermore as a minimum be equipped with the

following control and protection functions:

Overload.

Shortcircuit

Earth fault.

Auto restart provisions.

5.12.3

Electric motor drives shall in principle receive start and stop commands from a control station in

the field, local to the motor. In the off position this switch shall function as safety switch, by short

circuiting the main contactor coil.

As per statutory requirement, each electric motor drive shall also be provided with an emergency

stop switch local to the motor.

Operational start/stop commands may also come via the DCS.

Motor control circuits shall be hard-wired from MCC via interposing relays to the plant

safeguarding system.

Emergency shutdown of equipment shall, if required, be possible irrespective of any PLC /

microprocessor failure.

In the case of A-B set-up motor drives, emergency change over shall be possible via the

safeguarding system.

5.12.4

Motor control circuits shall include provisions for including a safety switch and an emergency

switch (see above).

5.12.5

When connected to a subfeeder circuit, small motors driving non process equipment may be

controlled by manual starters at the motor.

5.12.6

Contactor or circuitbreaker controlled switchgear and MCC feeder units shall include provisions

for external opening and closing commands.

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

5.13

EMERGENCY SUPPLY SYSTEMS

5.13.1

The basic arrangement of the emergency supply systems shall be as indicated on the key single

line diagram.

5.13.2

An emergency distribution network shall be provided as an integrated part of the normal power

distribution system.

5.13.3

The emergency generator set shall form a complete self-sustained package, not requiring any

other power source for start-up and control. The set shall be complete with the necessary

starting equipment, associated control panel and shall be suitable for remote starting.

The emergency generator set shall be designed to start automatically on power failure and feed

the emergency loads. It shall be capable of dealing with load variations such as the starting of

large motors on a loaded system.

The emergency generator shall be diesel engine driven.

5.13.4

The AC UPS shall be in accordance with the project engineering specification and have a backup time of minimum 30 minutes. A maintenance bypass switch shall be included. The UPS

bypass shall include a low-capacity type transformer with the possibility for voltage adjustment.

5.13.5

The DC UPS system (rectifiers and batteries) shall be in accordance with the project

engineering specification. A single rectifier with a battery with a back-up time of minimum 30

minutes is required.

Fire alarm systems shall have a dedicated 24 V DC UPS system, with a battery backup time in

accordance with IS 2189.

Telephone systems shall have an independent battery back-up system

5.14

ANNUNCIATORS

5.14.1

An annunciator panel shall be provided in the substation close to the entrance collecting the

common system alarms. Status indications shall be maintained even when a power failure

occurs. Alarms shall have a manual reset. A general electrical alarm shall be brought to the

DCS.

5.15

POWER INSTALLATION

5.15.1

Cable sizing shall be based on the following:

1.

2.

3.

4.

5.

Current carrying capacity conform to IEC 60287.

Rating factors appropriate for the method of installation.

Load factors as specified in paragraph 5.15.3.

Allowable circuit voltage drop as specified in table 4.

Limitation of conductor temperature rise during short circuit to 160C for PVC and 250C

for XLPE insulated cables (for sizing see IEC 60364-4-43).

5.15.2

Cables shall be sized in accordance with the applicable IEC standards. In office buildings

deviations to these requirements are allowed provided that the requirements of IEC 60364, part

4 are fulfilled.

5.15.3

Main feeder cables as well as the bus-bar systems shall be sized to allow for 20% future load

(i.e. main feeders to the plant shall be sized for 120% of the maximum working load).

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Transformer cables shall, when applicable, be sized for the forced cooled rating of the

transformer.

Feeder cables to subdistribution systems shall be sized for 120% apparent power or the

nameplate power, whichever is the highest.

Rev. 0

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

DESCRIPTION

MV distribution system cables

LV distribution system cables

Motors

Cables to lighting and small power

panels

Cables to lighting fixtures

Cables to tracing panels

Cables to tracing circuits

04184-120311-000007

NOMINAL

VOLTAGE

DROP

1%

1%

5%

1%

VOLTAGE

DROP @

START

N.A.

N.A.

15%

N.A.

4%

2%

3%

N.A.

N.A.

N.A.

Rev. 0

Table 4

5.15.4

Minimum conductor sizes shall be as follows:

Cable Rated Voltage

Power

Power

Lighting circuits

Control circuits

6.6 kV

0.415 kV

70 mm2

2.5 mm2

2.5 mm2

1.5 mm2

6/10 kV

0.6/1 kV

0.6/1 kV

0.6/1 kV

Um

12 kV

1 kV

1 kV

1 kV

5.15.5

Power and control cables shall be installed conform the requirements of the project design

specification and the project construction specification.

5.15.6

MV cables shall comply with IEC 60502. Cables shall be single or multi core and have stranded

copper conductors with extruded XLPE insulation. MV cable terminations shall be executed with

dedicated termination kits.

5.15.7

Low-voltage power cable shall have XLPE insulated plain or metal-coated circular copper wires,

solid circular up to 4 mm, stranded circular or shaped 6 mm and above, in accordance with IEC

60228, class 1 and class 2, respectively. Cables shall have a non-flame propagating PVC outer

sheath in accordance with IEC 60332-3 category C.

5.15.8

All cables in process / paved areas shall be installed underground in concrete trenches filled

with clean sand.

In other areas cables may be directly buried and shall be covered with a warning tape

throughout the length of the trench.

For consumers at grade cables shall run completely underground. For consumers above-grade

cables shall run in trenches up to the nearest structure and shall then continue in cable trays

with covers to protect them from sun radiation. Single cables shall be installed in open conduit.

Cables shall be identified with a unique number conform the project cable numbering system.

Tags shall be installed on each end of the cable, at one end of the pipe sleeves and at

substation entry points.

5.16

EARTHING INSTALLATION

5.16.1

A reliable earthing installation shall be provided for safety earthing, static earthing, lightning

protection and instrument earthing systems that considers the basic requirement and principles

of IEC 61000 supplemented by statutory requirements (IS 3043). The earthing system shall

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

ensure safety to personnel in relation to touch and step voltages and protect equipment against

damage associated with rise of potential.

5.16.2

The earthing system for new units shall be interconnected with the earthing system of the overall

plant and (if applicable) the existing earthing grid in order to create one (1) overall earthing

system.

5.16.3

The type of earthing grid shall be determined on basis of the soil conductivity. The resistance of

the grid shall be 1 ohm maximum.

5.16.4

The grid shall consist of 70 mm yellow/green insulated PVC stranded copper wire. Branches to

equipment shall be minimum 16 mm.

5.16.5

All exposed conductive parts of equipment shall be connected to an earth loop. For power

transformers equipped with a tank protective device, the active part shall be led through the

protection current transformer.

5.16.6

Inside hazardous areas all in-line instruments and valves that are clamped between

nonconductive packings shall be interconnected with a conductor of 16 mm. For this purpose

adequate lugs shall be provided on both the instrument (valve) and the pipeline.

5.16.7

The earthing installation shall meet the requirements of IEC 60364-5-54. Special attention shall

be given to touch voltages.

5.16.8

The lightning protection system shall (if required) be designed in accordance with IEC 61024-1.

Where appropriate, surge protection shall be installed to limit secondary effects of lightning

strokes. Self conducting structures shall not be provided with lightning rods and down

conductors, but shall be connected to the earthing grid at two points of the base.

5.16.9

Metal structures, reinforcing steel, doors and fences shall be connected to the earth loop of each

unit. Large structures shall be earthed every 25 meter.

5.16.10

For multiple connections an earth collector bus bar shall be used. This busbar shall be mounted

above grade and shall be mechanically protected.

5.16.11

The earth connection of the 415/240 V system shall be made in the switchgear between the

neutral and the earth bus bar by means of a removable link.

5.17

LIGHTING INSTALLATION

5.17.1

The plant lighting design shall be such that an economic optimization is obtained by applying a

combination of both area and local lighting with a mixture of floodlights and fluorescent fixtures.

For street and security lighting high pressure sodium fixtures shall be used.

5.17.2

The lighting installation shall be designed using local distribution panels suitable for the area

classification and environmental conditions in the unit.

5.17.3

The lighting system shall be designed to provide a sustained and uniform illumination level of not

less than the levels given in table 5 taking into consideration a fouling factor of .8 for outdoor

installed fixtures. The table has been derived from table 4 of API RP 540 and uses currently

recommended values for chemical and petrochemical plants. OISD RP-149 has been

accounted for as well.

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

Area description

04184-120311-000007

Horizontal

illumination

level

Average

Equipment areas, pumps, valves, manifolds,

operating platforms, instruments*, gauges*

Furnaces, heat exchangers

Compressor area

Pump houses, sheds

General areas, ladders (inactively used)

Main operation platforms & access stairs

Ordinary platforms

Stairs (other than main)

Outdoor control panels *

Central control room, instrument panels*,

Consoles*

Satellite control, instrument panels*,

Consoles*

Laboratories & test rooms

Locker rooms, lavatory

General loading area

Tank/truck loading points

Tank farm

Outdoor switchyards operating area

Outdoor switchyards other areas

Substation general (indoor),

switchracks

Under substation (cellar)

Substation operating aisles

Battery room

Transformer bays

Maintenance workshop

Warehouses and stores

Administration building general offices

Drafting office

Reception areas, hallways

Street lighting (main roads)

Street lighting (secondary roads)

Parking lots

Rev. 0

Elevation

(mm)

Lux

60

Ground

60

200

100

10

60

20

50

200 (Vert)

500

Ground

Ground

Ground

Ground

Floor

Floor

Floor

Floor

Floor

500 (Vert)

+750

800

100

30

100

10

100

50

150

+750

Floor

+ 750

Point

Ground

Ground

Ground

Floor

70

150

150

100

200

100

800

1000

200

10

5

1

Ground

Ground

Floor

Ground

Workbench

Workbench

+750

+750

Floor

Ground

Ground

Ground

Table 5

Note:

5.17.4

Denotes vertical illumination level.

Emergency lighting shall be provided inside buildings, on escape routes inside the process units

and in vital operator areas. The lighting level on the escape routes shall under emergency

conditions be at least 10 lux.

Emergency lighting fixtures shall form part of the normal lighting installation and shall have builtin nickel-cadmium batteries with a back-up time of minimum 30 minutes.

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

5.17.5

Fixtures for general room or area lighting shall be fluorescent fixtures with symmetrical lens. For

control rooms, a ceiling metallic grid parabolic system shall be provided. Lighting for control

rooms instrument boards and other similar installation shall be designed to illuminate vertical

panel mounted equipment and details without glare.

5.17.6

Long life high pressure sodium vapor fixtures shall, when used, have constant wattage highpower factor ballasts and color-corrected lamps.

Sodium vapor lighting fixtures shall only be used for non-hazardous areas.

Floodlights for use in hazardous area shall be high pressure mercury vapor type execution

5.17.7

General process unit lighting shall be automatically controlled by a photocell. Hand-Off-Auto

selector switches and contactors for automatic lighting control shall be installed in the lighting

panels.

5.17.8

The load of each lighting circuit shall be balanced over the 3 phases, as much as possible. In

general, circuits shall be switched from lighting panels.

5.18

MAINTENANCE SOCKET OUTLETS

5.18.1

Receptacle assemblies for maintenance power shall be installed on such locations that the

maximum length of extension cords will be limited to 30 m. The centerline elevation of

receptacles shall be approximately 1.20 m. Receptacles shall have earth-fault protection

(sensitivity 30 mA).

5.18.2

For maximum voltage drop table 4 shall be applied with values as for lighting.

5.19

ELECTRIC TRACING

5.19.1

Only where indicated on the piping and instrument diagrams electric tracing shall be installed.

Calculations shall be based on the minimum design ambient temperature.

5.19.2

The requirements for design, supply, installation and testing are given in project engineering

specification.

5.20

COMMUNICATION AND SECURITY SYSTEMS

5.20.1

Communication and security system requirements are defined in the project specifications of the

Instrumentation and Control Systems group (section 120.331)

5.21

CATHODIC PROTECTION

5.21.1

Cathodic protection shall be provided on underground metallic piping, storage tanks etc. In case

of extensions to existing systems the existing cathodic protection system shall be modified for

the extensions.

The system shall be designed and installed by an experienced cathodic protection firm in

accordance with the requirements of the project engineering specification

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

6.

MATERIALS

6.1

All materials shall be new and of proven design. All equipment and material shall be suitable for

the at the installation site applicable circumstances.

6.2

Materials applied inside buildings shall be flame retardant, low smoke generation execution.

6.3

The bidders list issued by the Client, who may specify certain makes and types, shall be

followed. When a supplier cannot fully comply with the requirements, the deviations shall be

listed and alternatives shall be specified in detail.

6.3

Application of deviating materials can, if of similar quality, or when they are built to equivalent US

standards, be approved by Client.

7.

TESTING AND COMMISSIONING

7.1

All equipment and material shall tested and/or inspected in accordance with the applicable

project engineering specification prior to shipment to site.

7.2

The contractor shall prepare commissioning procedures, including test records. Subject

procedures shall be approved by Client prior to commissioning.

7.3

After installation completion field tests shall be performed in accordance with the approved

commissioning procedures. For complex equipment vendor representatives shall be present

during commissioning.

8.

CORROSION PROTECTION

8.1

All metal parts belonging to the electrical installation shall be protected against corrosion in

accordance with manufacturer's standard corrosion protection system suitable for the

environmental conditions specified.

8.2

Supporting steelwork shall be treated in accordance with the system specified for structural

steel.

8.3

Underground coated metallic systems shall, if damaged parts are subject to electrolytic

corrosion, be cathodically protected (see subsection 5.21)

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

9.

DOCUMENTATION

9.1

Documentation and information shall be supplied as specified by Client.

9.2

During the detailed design phase those documents that give a clear impression of the

functioning and the configuration of the systems, apparatus and installation shall be submitted to

Client for approval.

As a minimum following document shall be sent for approval:

Specifications.

Area classification layouts, sections and list of hazardous sources.

Substation lay-out drawings.

Single-line diagrams.

Electrical consumer list.

Equipment and material requisitions.

System calculations.

Relay coordination diagrams.

Main cable lay-out drawings.

Cable sizing calculation and criteria.

Cable lists.

Installation drawings and functional block diagrams for control and protection systems.

Other documents shall be issued to Client for information.

9.3

Approval of documents does not release Contractor or Supplier of his responsibilities with regard

to the quality and reliability of his installation.

9.4

Drawings and schematics shall be prepared in accordance with the relevant IEC standards. If

the applied symbology deviates from the IEC symbols a legend shall be supplied with

explanatory notes.

9.5

Basically all documents shall be prepared on electronic format. CAD tools shall be selected in

coordination with the Client. Listings, calculations and reports shall be generated with standard

available commercial software (subject to approval by Client).

9.6

All documents shall bear a unique identification (document) number.

9.7

Drawings, schematics, operating and maintenance manuals shall be in the English language.

10.

MARKING

10.1

Equipment and material shall be marked in compliance with the project requirements.

10.2

Wiring shall be marked on both ends with the terminal numbers of the terminals to which the

wires are connected.

10.3

Requirements for rating plates, nameplates and equipment number plates shall be conform IEC

standards and shall be specified in detail in the individual equipment and material specifications.

10.3

Equipment certified for use in hazardous areas shall be marked in accordance with the

requirements of IEC 60079.

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

11.

REFERENCE DOCUMENTS

12.

04184-120311-000007

04184-120311-000008

04184-120311-000009

04184-120311-000010

04184-120311-000013

04184-120331-000018

Electrical Consumer List

Electrical Load Calculation

Electrical Load Summary Report

Overall Single-line Diagram.

Main Instrument and Electrical Cable Trench

Routing

ATTACHMENTS

I

II

Site & Utility Data (extract of Process Design Basis Memorandum)

Minimum Protection Requirements (tabulation)

Rev. 0

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

ATTACHMENT I Site and Utility Data

04184-120311-000007

Rev. 0

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

ATTACHMENT II Minimum Protection Requirements

PROTECTION PER FEEDER TYPE

DESCRIPTION OF BASIC FUNCTIONS

04184-120311-000007

Rev. 0

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

ANSI

Device Short Protection Description

Number

2

Timer

25

Synchronism Check

26

High Winding Temperature

27

Under Voltage

30

Annunciator Relay

32

Directional Power

37

Under Power / Loss of Load

38

Bearing Protective Device

46

Phase Unbalance

47

Phase Sequence Check

48

Stall Protection

49

Thermal Over Current

50

(Time delayed) Instantaneous

Over Current

ANSI

Device Short Protection Description

Number

51

AC Time Over Current

04184-120311-000007

Rev. 0

Long Protection Description

Timer relay is a device that functions to give a desired amount

of time delay before or after any point of operation in a

switching sequence or protective relay system, except as

specifically provided by device functions 48, 62 and 79.

Synchronism check device is a device that operates when two

AC circuits are within the desired limits of frequency, phase

angle and voltage, to permit or to cause the paralleling of these

two circuits.

High winding temperature device is device that functions when

the temperature of the winding of a machine exceeds a

predetermined value.

Under voltage relay is a relay that functions on a given value of

undervoltage.

Annunciator relay is a non-automatically reset device that gives

a number of separate visual indications upon the functioning of

protective devices and which may also be arranged to perform

a lock-out function.

Directional power relay is a device that functions on a desired

value of power flow in a given direction.

(32N/64N = Watt metric Earth Fault)

Under power relay is a relay that functions when the power

flow decreases below a predetermined value.

Bearing protective device is a device that functions on

excessive bearing temperature, or on other abnormal

mechanical conditions associated with bearings, such as

undue wear, which may eventually result in excessive bearing

temperature or failure.

Phase unbalance relay is a relay that functions when the

polyphase currents are unbalance or contain negative phasesequence components above a given value.

Phase sequence check relay is a relay that functions upon a

predetermined value of polyphase voltage in the desired phase

sequence.

Stall protection relay is a relay that generally returns the

equipment to the normal or off position and locks it out if the

normal starting or operating sequence is not properly

completed within a predetermined time.

Thermal over current relay is a relay that functions when the

temperature of a load-carrying winding or element of a

machine exceeds a predetermined value.

Instantaneous over current relay is a relay that functions

instantaneously on an excessive value of current or on an

excessive rate of current rise. The operation can be time

delayed for selectivity.

(50N = Earth Fault Core Balance Type)

Long Protection Description

AC time over current relay is a relay with either a definite or

inverse time characteristic that functions when the current in an

AC circuit exceeds a predetermined value.

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

55

Out-of-Step

59

Over Voltage

63

Pressure Switch (Buchholz)

64

Earthfault Protective Relay.

67

AC Directional Over Current

74

Trip Circuit Supervision

81

Frequency Relay

86

Lock-out Relay

87

Differential Current

97

Fuse Failure

04184-120311-000007

Rev. 0

(51LR = AC Time Over Current Locked Rotor)

Out-of-Step relay is a relay that operates when the power

factor in an AC circuit falls below a predetermined value for a

definite time.

Over voltage relay is a relay that functions on a given value of

over voltage.

(59N = Residual Over Voltage Earth Fault)

A device that operates at a given pressure value or at a given

rate of change of pressure.

Earthfault protective relay is a relay that functions on failure of

the insulation of a machine, transformer or of other apparatus

to earth.

(32N/64N = Watt metric Earth Fault)

AC directional over current relay is a relay that functions on a

desired value of AC over current flowing in a predetermined

direction.

Trip circuit supervision relay is a relay, other than an

annunciator as covered under device function 30, that is used

to operate, or to operate in connection with a visual or audible

alarm.

Frequency relay is a relay that functions on a predetermined

value of frequency.

Lock-out relay is an electrically operated, hand or electrically

reset, relay or device that functions to shut down or hold an

equipment out of service or both, upon the occurrence of

abnormal conditions.

Differential current relay is a protective relay that functions on a

percentage or phase angle or other quantitative difference of

two currents.

Used only for specific applications.

ABB Lummus Global B.V.

SPECIFICATION

Client

Indian Oil Corporation Limited (IOCL)

Plant

Naphta Cracker Unit

Location

Panipat, Haryana, India

Always refer to this number

120.311

04184

N-601

Dept./Sect.

Project

Specification

Doc. No.

04184-120311-000007

Rev. 0

TABLE FOR PROTECTION PER FEEDER TYPE (MV distribution)

6.6 kV Distribution

ANSI

Device

Number

2

25

26

27

30

32N

37

38

47

48

49

50

51

50N

46

51LR

49O

50

50N

51 2)

51N

51NB

55

59

59N

63

64N

64R

67N

74 3)

81U

86

87

97

1)

2)

3)

4)

5)

6)

7)

Protection Description

Timer

Synchronism Check

High Winding Temperature

Under Voltage

System Analysis and Measurement Unit for

Remote Monitoring

Reverse power (earth fault)

Under Power / Loss of Load

Bearing Protective Device

Phase Sequence Check

Stall Protection

Motor Protection Relay with:

Thermal Over Current

Instantaneous Over Current

AC Time Over Current

Earth Fault (Core Balance Type)

Phase Unbalance

Locked Rotor

Transformer High Oil Temperature

(Time delayed) Instantaneous Over

Current

Earth Fault (Core Balance Type)

AC Time Over Current

AC Time Over Current (Earth Fault)

Backup Earthfault Relay (secondary side

neutral)

Out-of-Step

Over Voltage

Residual Over Voltage

Transformer Buchholz

Earth Fault Protection (neutral

displacement)

Restricted Earth Fault

AC Directional Earth Fault

Trip / Close Circuit Supervision

Under Frequency

Lock Out Relay

Differential Current

Fuse failure

Incoming

Transf.

Feeder

X

4)

Bus-Tie &

Metering

X

X

Distrib

Transf.

Feeder

4)

4)

X

X

X

4)

4)

X

X

Outgoing

Line

Feeder

4)

4)

Incoming

Line

Feeder

X

4)

X

X

4)

4)

4)

4)

4)

Motor

Feeder

X 4) 5)

X

4)

X

4)

Capacitor

Bank

Feeder

4)

S 1) 4)

S 1) 4)

S 1)4)5)

S 1) 4)

S 1) 4)

X

4)

X

X

4)

4)

4)

4)

X

X

4)

4)

X

X

X

X

4)

4)

4)

4

4)

X

X

X

4)

4)

4)

X

X

4)

4)

4)

1) 4)

S

S

S

1) 4)

1) 4)

1) 4)

1) 4)

4) 6)

X

X

4)

4)

X

X

4)

4)

4)

4)

4)

4)

X X 4)

X X 4)

4)

4)

4)

4)

4)

X 4)

X 4).7)

4)

X X 4)

4)

4)

4)