Professional Documents

Culture Documents

RCPT of Light WT Concrete

Uploaded by

kishor150688Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCPT of Light WT Concrete

Uploaded by

kishor150688Copyright:

Available Formats

Bashar S. Mohammed, Khandaker M. Anwar Hossain, W. L. Foo, M.

Abdullahi/ International

Journal of Engineering Research and Applications (IJERA)

ISSN: 2248-9622

www.ijera.com

Vol. 1, Issue 4, pp.1863-1870

Rapid Chloride Permeability Test on Lightweight Concrete Made

with Oil Palm Clinker

Bashar S. Mohammed1, Khandaker M. Anwar Hossain1, W. L. Foo2and M.

Abdullahi3

1

Department of Civil Engineering, Ryerson University, 350 Victoria Street, Toronto, Ontario, M5B 2K3

Civil Engineering Department, College of Engineering, University Tenaga Nasional, Km-7, Jalan KajangPuchong, 43009 Kajang, Selangor, Malaysia.

3

Department of Civil Engineering, Federal University of Technology, Minna, Nigeria.

Abstract

This paper presents an experimental program

on rapid chloride permeability test on

lightweight concrete produced from oil palm

clinker aggregates. Oil palm clinker is obtained

from by-product of palm oil milling. Utilising oil

palm clinker in concrete production not only

solves the problem of disposing this solid waste

but also help to converse natural resources. The

parameter of investigation included rapid

chloride permeability test for a period of 7 days,

28 days and 90 days. 3 oil palm clinker concrete

specimens of 10050 mm cylinders were cast

and tested. The chloride permeability values of

oil palm clinker concrete were compared to

ASTM C1202 criteria.

Keywords- Oil palm clinker,

permeability, Lightweight concrete

Chloride

1. Introduction

Increase of population has made large demand on

construction material and it leads to a chronic

shortage of building materials and thereby

increasing the construction cost due to the shortage.

To solve this problem, engineers are not only

challenged for the future homebuilding in term of

construction cost control but also need to convert

the industrial wastes to useful construction and

building materials. Once of the way was introduced

industrial waste material in concrete to reduce the

use of aggregate. Such wastes material like fly ash,

wood chipping, paper mill, crumb rubber, silica

fume and palm oil clinker etc [1-7].

Extensive research work has been carried

out by Mohammed and Mohammed et al. to

produce lightweight concrete utilizing oil palm

clinker as full replacement to fine and coarse

aggregate [8,9]. The physical and mechanical

properties of the oil palm clinker concrete have

been established. The developed oil palm clinker

concrete easily attains strength of more than 17

MPa, which is a requirement for structural

lightweight concrete as per ASTM C330 [10].

Lightweight concrete using oil palm clinker as

replacement aggregate is still a relatively new

Construction material and the structural

performance of the concrete has not yet been

investigated. Therefore, the ability of chloride ions

to penetrate the concrete must then be known for

design as well as quality control purposes.

Reinforced concrete structures are

exposed to harsh environments yet is often

expected to last with little or no repair or

maintenance for long periods of time (often 100

years or more). To do this, a durable structure

needs to be produced. For reinforced concrete

bridges, one of the major forms of environmental

attack is chloride ingress, which leads to corrosion

of the reinforcing steel and a subsequent reduction

in the strength, serviceability, and aesthetics of the

structure. This may lead to early repair or

premature replacement of the structure. A common

method of preventing such deterioration is to

prevent chlorides from penetrating the structure to

the level of the reinforcing steel bar by using

relatively impenetrable concrete. The ability of

chloride ions to penetrate the concrete must then be

known for design as well as quality control

purposes. The resistance of concrete to penetration

by chlorides is an important factor in protecting

reinforced concrete structures from premature

deterioration.

The penetration of the concrete by chloride ions,

however, is a slow process. It cannot be determined

directly in a time frame that would be useful as a

quality control measure. Therefore, in order to

assess chloride penetration, a test method that

accelerates the process is needed, to allow the

determination of diffusion values in a reasonable

time. The Rapid Chloride Permeability Test

(RCPT), as it is commonly called, has been in

existence for over 20 years and was standardized

1863 | P a g e

Bashar S. Mohammed, Khandaker M. Anwar Hossain, W. L. Foo, M. Abdullahi/ International

Journal of Engineering Research and Applications (IJERA)

ISSN: 2248-9622

www.ijera.com

Vol. 1, Issue 4, pp.1863-1870

by ASTM over 16 years ago. The test is used

extensively in the concrete industry for assessing

concrete quality.

2. Oil Palm Clinker Aggregate Properties

The oil palm clinker was sieved to 2 categories

which is fine aggregate (< 5mm) and coarse

aggregate (5mm-14mm). Table 1 below shows the

aggregate properties for both fine and coarse

aggregate.

Table 1: Properties of oil palm clinker

Properties

Fine

Aggregate size (mm)

<5

Bulk Density (kg/m3)

1118.86

Specific gravity (SSD)

2.01

Moisture content

0.11

26.45

Water absorption (24 hours)

Fineness modulus

3.31

Los Angeles abrasion value, %

Aggregate impact value (AIV), %

Aggregate crushing value (ACV),%

Aggregates having dry unit weights (of

less than) 1200 kg/m3 are classified as lightweight

[11]. Due to the porous nature of oil palm clinker

aggregate, low bulk density and high water

absorption were expected. Oil palm clinker fine and

coarse aggregate has a unit weight of 1119 kg/m3

and 781 kg/m3. This is approximately 25% lighter

compared to the conventional river fine sand [12]

and 48% lighter compared to the crashed granite

stone [13]. Consequently, the resulting concrete

will be lightweight. This reduces the overall dead

load in a structure, which comes with a significant

amount of saving in the total construction cost.

In general, most lightweight aggregate

have higher water absorption values compared to

conventional aggregate. Although oil palm clinker

has high water absorption, even higher water

absorption were reported for pumice aggregate

which have a value of about 37% [14]. However

the high water absorption of oil palm clinker

aggregate can be beneficial to the resulting

hardened concrete. It has been reported that

lightweight concretes with porous aggregate (high

water absorption) are less sensitive to poor curing

as compared to normal weight concrete especially

in the early ages due to the internal water supply

stored in the porous lightweight aggregate. [15]

From Table 1, it can be observed that the

aggregate impact value (AIV) and aggregate

crushing value (ACV) of oil palm clinker

aggregates were higher compared to the

conventional crushed stone aggregates [12]. More

specifically the AIV and ACV were approximately

34% and 30% higher respectively compared to the

granite aggregate. The higher ACV value for the oil

palm clinker aggregate might be caused by the

Coarse

5-14

781.08

1.82

0.07

4.35

6.75

27.09

25.36

18.08

particle shape of oil palm clinker used in this study

which is porous and angular. The aggregate with

such shape and condition have the possibility to be

crushed when load is applied on them.

3. Experimental Program

3.1. Material

The materials used in this work are water, Ordinary

Portland Cement and oil palm clinker aggregate.

The water used is a potable drinking water from tap

which suitable for concrete work [16]. Commercial

cement meeting the ASTM C150 [17] for Type I

Portland cement was employed in this study. The

aggregate used is oil palm clinker obtained from

locally palm oil manufacturer in Malaysia. The

clinkers are crushed and were separated into

desired size; fine aggregate (particles less than5mm)

and coarse aggregate (particle between 5-14mm).

3.2. Mix Proportions

The mix proportioning was done in according to

the requirements of ACI Committee 211.2-98 [18].

A central composite design (CCD) was employed

for the factor setting after an extensive trail mixes

were done in the laboratory. The factors used in

this work are water-cement ration (x1) and cement

content (x2). Each factor has fixed the limit in

accordance to the requirements of ACI Committee

211.2-98 [18] which water-cement ratio and

cement content have range 0.40-0.46 and 480-520

kg/m3 respectively. The factors value is shown in

Table 2.

Table 2: Factor setting using central composite design

1864 | P a g e

Bashar S. Mohammed, Khandaker M. Anwar Hossain, W. L. Foo, M. Abdullahi/ International

Journal of Engineering Research and Applications (IJERA)

ISSN: 2248-9622

www.ijera.com

Vol. 1, Issue 4, pp.1863-1870

Factor

Axial

point

minimum

x1

x2

0.38

460.00

0.40

480.00

Figure 1 has shown the water-cement ratio

verses cement content in the range water-cement

ratio (0.4-0.46) and cement content (480-520

530

Cement content (kg)

520

centre

Maximum

Axial

point

0.44

0.46

0.50

500.00

520.00

540.00

3

kg/m ). 5 mixes proportions design were chosen to

obtain the concrete properties and the five mixes

proportion were denoted as A1, A2, A3, A4 and A5

respectively.

0.4, 520

0.46, 520

510

500

0.43, 500

490

480

0.4, 480

0.46, 480

470

0.38

0.4

0.42

0.44

0.46

0.48

Water-Cement Ratio (W/C)

Figure 1: Mix proportion water-cement ration over cement content

The aggregate is considered in dry

condition since oil palm clinker is easily loses its

water. The natural moisture content of oil palm

clinker is almost zero when the aggregate is kept

for some day. Since material results have shown

that oil palm clinker have high value of water

absorption so pre-soaking oil palm clinker for 24

hours with water was employed before mixing.

This is expected to prevent further absorption

during mixing. The saturated surface dry (SSD)

state oil palm clinker was obtained. Two stage

mixing approach was employed to allow the

cement paste to coat the aggregate permitting the

absorbed water to be retained and preventing any

water absorption or penetration of cement paste

into the aggregate. For each of the mix proportions

the air dry density was measured in accordance to

the requirement of [19]. Nine cylindrical and three

100mm x 100mm x 500mm concrete specimens

were cast and cured under water according to the

requirement of [20] for each mixes and the

specimens tested for compressive strength, splitting

tensile strength, flexural strength and modulus of

elasticity at 28 days in accordance to the

requirement of [21-24].

3.3 Compressive Strength Test

Compressive strength test usually gives an overall

picture of the quality of concrete because strength

is directly related to the structure of the hydrated

cement paste. The compression test is an important

concrete test to determine the strength development

of the concrete specimens. Compressive strength

tests were performed on the cube specimens at the

ages of 28 days.

3.4 Splitting Tensile Strength

The indirect method of applying tension in the form

of splitting was conducted to evaluate tensile

properties of POC concrete. The split tensile

strength is a more reliable technique to evaluate

tensile strength of concrete (lower coefficient of

variation) compared to other methods. The split

tensile strength of 150 mm diameter and 300 mm

high concrete cylindrical specimens was

determined to assess the tensile properties of the

POC concrete.

3.5. Air Dry Density

The measured or calculated equilibrium density of

structural lightweight concrete determines whether

specified density requirements have been met. Test

Method ASTM C567 - 05a will be use to

determine the density of 100 mm x100mm POC

concrete cube specimens at the ages of 28 days.

3.6 Modulus of Rupture

Modulus of Rupture (MOR) for concrete is the

tensile strength of the concrete determined using a

flexural specimen. ASTM C78 Flexural Strength of

Concrete (Using Simple Beam with Third-Point

Loading) will be used to determine the MOR of

100mm x 100mm x 500mm Moist-cured POC

concrete beams at the ages of 28 days.

3.7 Elastic modulus

Modulus of elasticity is the ratio of the stress

applied to a body to the strain that results in the

body in response to it. The modulus of elasticity of

a material is a measure of its stiffness and for most

materials remains constant over a range of stress.

The modulus of elasticity of 150 mm diameter and

1865 | P a g e

Bashar S. Mohammed, Khandaker M. Anwar Hossain, W. L. Foo, M. Abdullahi/ International

Journal of Engineering Research and Applications (IJERA)

ISSN: 2248-9622

www.ijera.com

Vol. 1, Issue 4, pp.1863-1870

300 mm high concrete cylindrical specimens was

determined to assess the mechanical properties of

the POC concrete at age of 28 days.

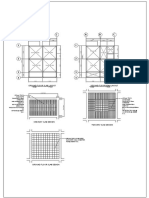

3.8 Rapid Chloride Permeability Test

The Rapid Chloride Permeability Test method

(RCPT) was carried out in accordance to ASTM C

1202 [25]. The concrete specimen used for this test

was 100 mm diameter x 50 mm thick slices cut

from middle portion of the 100 mm diameter x 200

mm height cylindrical specimen. Figure 2 shows

the top view of RCPT set up. A direct current

voltage of 60.0 0.1 V was applied across the two

faces and the current passing through the concrete

specimen was monitored at 30 min intervals over a

period of 6 h. The total charge passed in Coulombs

was determined and the rating of the concrete was

determined according to Table 3. The tests were

performed at the age of 7, 28 and 90 days and the

results obtained at each age were reported as an

average of three tested specimens. The following

formula, based on the trapezoidal rule can be used

to calculate the average current flowing through

one cell.

Q

=

900(I0+2I30+2I60+2I90+2I120++2I300+2I330+I360)

Where,

Q = current flowing through one cell (coulombs)

I0 = Current reading in amperes immediately after

voltage is applied, and

It = Current reading in amperes at t minutes after

voltage is applied

Table 3: RCPT ratings as per ASTM C 1202

Charge passing in Coulombs

Chloride permeability rating

Greater than 4000

2001 to 4000 Moderate

1001 to 2000

100 to 1000

Less than 100 Negligible

High

Moderate

low

Very low

Negligible

Figure 2: Schematic diagram of RCPT (ASTM C 1202-94)

The properties of the hardened oil palm clinker

concrete for the 5 mix proportions tested at an age

of 28 days are presented in Table 4.

4. Results and Discussions

4.1 Properties of POC Concrete

Table 4: Properties of oil palm clinker concrete for 5 chosen mix proportion

Air dry

Compressive Splitting tensile

Modulus of

Elastic

Mixture

density

strength,

strength,

rupture,

modulus,

(kg/m3)

MPa

MPa

MPa

Gpa

A1

1845.62

42.56

2.72

4.64

26.94

A2

1835.79

32.08

2.51

4.38

19.35

A3

1832.95

27.15

2.26

4.01

16.87

A4

1820.53

26.52

1.90

3.64

12.61

A5

1818.24

25.50

1.85

3.46

9.73

1866 | P a g e

Bashar S. Mohammed, Khandaker M. Anwar Hossain, W. L. Foo, M. Abdullahi/ International

Journal of Engineering Research and Applications (IJERA)

ISSN: 2248-9622

www.ijera.com

Vol. 1, Issue 4, pp.1863-1870

Figure 3 show the test result for

compressive strength ranges between 25.5 to 42.56

N/mm2. It is approximately 60% higher than the

minimum required strength of 17 N/mm2 for

structural lightweight concrete recommended by

ASTM C330 [10].

Compressive Strength

(MPa)

Compressive Strength for POC Concrete

60

40

20

0

A1

A2

A3

A4

A5

POC Comcrete

Figure 3: The Compressive strength of POC concrete

Lightweight concrete normally have

density of less than 2000 kg/m3 and the air dry

density for oil palm clinker concrete ranges

between 1818.24 to 1845.62 kg/m3 are fall within

this limit and it is approximately 16% lighter than

normal concrete (2200 kg/m3). The result was show

in Figure 4. [13].

Air Dry Density (Kg/m3)

Air Dry Density for POC

2400

2200

2000

1800

1600

1400

1200

1000

800

600

400

200

0

Normal Concrete Density (2200

A1

A2

A3

A4

A5

POC Concrete

Figure 4: The Density of POC concrete

The test results shown that the oil palm

clinker concrete modulus of elasticity ranges 9.73

to 26.94 GPa. The splitting tensile strength and

modulus of rupture result ranges 1.85 to 2.72

N/mm2 and 3.46 to 4.64 N/mm2 respectively. The

results show that splitting tensile strength and

modulus of rupture have an increasing value by

increase the cement content and a decreasing value

by increase the water-cement ratio.

4.2 Rapid Chloride Permeability Test

The centralize mix proportion (A3) which

compressive strength ranged within 25-30 N/mm2

was chosen to be use in the further study of RCPT

with oil palm clinker concrete. The acceptable mix

comprised 500 kg/m3 cement, 473 kg/m3 fine oil

palm clinker aggregate, 155 kg/m3 coarse oil palm

clinker aggregate and with a free water/cement

ratio of 0.44. The concrete properties are presented

in Table 5.

1867 | P a g e

Bashar S. Mohammed, Khandaker M. Anwar Hossain, W. L. Foo, M. Abdullahi/ International

Journal of Engineering Research and Applications (IJERA)

ISSN: 2248-9622

www.ijera.com

Vol. 1, Issue 4, pp.1863-1870

Table 5: Properties of oil palm clinker concrete

Average of 3

Concrete Properties

sample

3

Air dry density (kg/m )

1832.95

Compressive strength, 28days (MPa)

27.15

Splitting tensile strength (MPa)

2.26

Modulus of rupture (MPa)

4.01

Elastic modulus (GPa)

16.87

The object of the test was to evaluate the

performance of POC concrete and compared the

chloride permeability value with ASTM rating as

Table 3. Chloride ion penetrability test were

conducted on cylinder specimens for each concrete

mixture at 7, 28 and 90 days for POC concrete. The

results of chloride permeability in coulombs for

different age are given in Table 6.

Table 6: Chloride permeability for POC concrete with age

Sample

7 days Chloride

Permeability

28 days Chloride

Permeability

90 days Chloride

Permeability

Coulombs

Remark

Coulombs

Remark

Coulombs

Remark

C1

5126

4387

3945

C2

5389

4294

3972

C3

5174

4573

3871

Average

5230

4418

3929

The seven-day total charged passed for

POC concrete are ranged from 5126 to 5389

coulombs and the average charge passed was 5230

coulombs. The twenty-eight day total charged

passed for POC concrete are ranged from 4294 to

4573 coulombs and the average charge passed was

4418 coulombs. The ninety day total charged

passed for POC concrete are ranged from 3871 to

3972 coulombs and the average charge passed was

3929 coulombs.

According to ASTM rating standard, POC

concrete show high chloride-ion penetrability at

age 7 days and 28 days. This high value of

chloride-ion penetrability of POC concrete was

expected because of the porous nature of POC. The

chloride resistance of concrete is thus highly

dependent on the porosity of concrete in terms of

pore size, pore distribution and interconnectivity of

the pore system [26]. At age 90 days, POC concrete

show moderate chloride-ion penetrability. From

previous researches [27-30], concrete will exhibit a

general downward trend in the amount of electrical

charge passed with an increase in time. The result

is show in Figure 5. With the age increasing, the

cement paste hydrates the pores become less well

connected and therefore more resistant to the

passage of electrical current are recorded.

In preview research [28], moderate

chloride-ion penetrability value was recorded for

ordinary concrete which form by river sand. The

RCPT result for POC concrete at age 90 days are

comparable to ordinary concrete.

1868 | P a g e

Bashar S. Mohammed, Khandaker M. Anwar Hossain, W. L. Foo, M. Abdullahi/ International

Journal of Engineering Research and Applications (IJERA)

ISSN: 2248-9622

www.ijera.com

Vol. 1, Issue 4, pp.1863-1870

RCPT for POC Concrete

Charge Passed (coulombs)

6000

5000

4000

3000

2000

1000

0

7

28

90

Testing date (days)

Figure 5: RCPT value for different testing date

5. Conclusions

The result from this study shown that the chloride

permeability value of oil palm clinker concrete is

comparable to ordinary concrete and give

encouragement for oil palm clinker to be used as

aggregate in production of durable structural

lightweight concrete. The following conclusions

can be made on the basis of the current

experimental results.

1. The compressive strength of POC concrete at

age of 28 days ranges between 25.5 N/mm2to 42.56

N/mm2. It is approximately 60% higher than the

minimum required strength of 17 N/mm2 for

structural lightweight concrete recommended by

ASTM C330.

2. The density of POC concrete ranges between

1818.24 kg/m3 to 1845.62 kg/m3 are fall within the

limit of lightweight and it is approximately 16%

lighter than normal concrete (2200 kg/m3)

3. The oil palm clinker concrete modulus of

elasticity ranges 9.73 GPa to 26.94 GPa. The

splitting tensile strength and modulus of rupture

result ranges 1.85 N/mm2 to 2.72 N/mm2 and 3.46

N/mm2 to 4.64 N/mm2 respectively. The splitting

tensile strength and modulus of rupture have an

increasing value by increase the cement content

and a decreasing value by increase the watercement ratio.

4. POC concrete show high value of chloride-ion

penetrability at age of 7 days and 28 days due to

the porous nature of POC.

5. Moderate value of chloride-ion penetrability was

recorded for POC concrete in age 90 days resulted

by the cement paste hydrates the pores become less

well connected.

6. The results show that POC concrete are

comparable to ordinary concrete. Therefore POC

concrete are suitable to be use as durable structural

lightweight concrete.

Reference

[1] B.S. Mohammed, M.K.A. Hossain., Jacksonn,

Grace and A Abdullahi. Properties of crumb rubber

hollow concrete block, Cleaner Production Journal, V.

23, 2012, pp. 57-67.

[2] B.S. Mohammed and C. F.Ong. Mechanical and

durability properties of concretes containing paper-mill

residuals and fly ash, Construction and Building

Materials Journal. V.25, 2011, pp. 717-725.

[3] B.S. Mohammed., N. A. Juwaini and Abdullahi,

Evaluation of rubbercrete based on ultrasonic pulse

velocity and rebound hammer tests, Construction and

Building Materials Journal. V. 25, 2011, pp. 1388-1397.

[4] B. S. Mohammed. Structural Behavior and m-k

value of composite slab utilizing concrete containing

crumb rubber, Construction and Building Materials

Journal. V. 24, 2010, pp 1214-1224.

[5] B.S. Mohammed and C. F.Ong. Assessing the

properties of freshly mixed concrete containing papermill residuals and class F fly ash, Journal of Civil

Engineering and Construction Technology V.2,2011, pp.

17-26

[6] B. S. Mohammed and N. A. Juwaini. Failure Mode

and Modulus Elasticity of Concrete Containing Recycled

Tire Rubber, The Journal of Solid Waste Technology

and Management. V.37. 2011, pp16-24.

1869 | P a g e

Bashar S. Mohammed, Khandaker M. Anwar Hossain, W. L. Foo, M. Abdullahi/ International

Journal of Engineering Research and Applications (IJERA)

ISSN: 2248-9622

www.ijera.com

Vol. 1, Issue 4, pp.1863-1870

[7] B. S. Mohammed. Papercrete as Infill Materials for

Composite Wall System, Europian Journal for Scientific

Research.V.34. 2009, pp 455-462.

[8]. Mohammed A. (2009). Development of an Expert

System for Lightweight Concrete Mix Design. PhD

Thesis. Universiti Tenaga Nasional.

[9]. Mohammed B.S., Mohammed A. Al-Ganad, M.

Abdullahi (2011). Analytical and experimental studies on

composite slabs utilising palm oil clinker concrete.

Construction and Building Materials Journal. Volume 25,

Issue 8, Pages 3550-3560.

[10] ASTM C 330 03a. Standard Specification for

Lightweight Aggregates for Structural Concrete Annual

Book of ASTM Standards. American Society for Testing

and Material

[11] Owens P.L., Lightweight Aggregates for Structural

Concrete, Structural Lightweight Aggregate Concrete.

Edited by J.L. Clarke, Blackie Academic & Professional,

London, 1993.

[12]. Delsye, C.L., Manna, M.A. and Kurian, J.V.

Flexural behaviour of reinforced lightweight concrete

beams made with oil palm shell (OPS). Journal of

advanced concrete technology. 2006. 4(3): 1 -10.

[13] D. C. L. Teo, M. A. Mannan, V. J. Kurian.

Structural Concrete Using Oil Palm Shell (OPS) as

Lightweight aggregate Turkish J. Eng. Env. Sci. 30

(2006), 1 -7.

[14] Hossain, K. M. A. (2004). Properties of volcanic

pumice based cement and lightweight concrete Cement

and Concrete Research, 34(2), 283-291

[15] Al-Khaiat, H. and Haque, M. N. (1998). Effect of

initial curing in early strength and physical properties of

a lightweight concrete. Cement and Concrete Research,

28(6), 859-866.

[16] BS 3148:1980. Test for water for making concrete.

British Standards Institution, Her Majesty Stationery

Office, London.

[21] ASTM C39/C 39M-04A. Standard test method for

compressive strength of cylindrical concrete specimens. .

Annual Book of ASTM Standards. American Society for

Testing and Material

[22] ASTM C 496/C 496M 04. Standard Test Method

for Splitting Tensile Strength of Cylindrical Concrete

Specimens. Annual Book of ASTM Standards.

American Society for Testing and Material

[23] ASTM C293-02. Standard Test Method for

Flexural Strength of Concrete (Using Simple Beam With

Center-Point Loading) Annual Book of ASTM

Standards. American Society for Testing and Material

[24] ASTM C 469 02. Standard Test Method for

Static Modulus of Elasticity and Poisson's Ratio of

Concrete in Compression Annual Book of ASTM

Standards: Concrete and Aggregate. 04.02. Philadelphia:

American Society for Testing and Material

[25] ASTM C 1202 Standard test method for electrical

indication of concretes ability to resist chloride ion

penetration. Annual Book of ASTM Standards

[26] Cement Concrete & Aggregates Australia. Chloride

Resistance of Concrete. June 2009

[27] D. C. L. Teo, M. A. Mannan, V. J. Kurian,

Durability of lightweight OPS concrete under different

curing conditions. Materials and Structures (2010)

43:113 DOI 10.1617/s11527-008-9466-7

[28] M. Shahul Hameed , V.Saraswathi ,A.S.S. Sekar.

Rapid Chloride Permeability Test on Self-Compacting

High Performance Green Concrete.

[29] Whiting, D. 1981. Rapid determination of the

chloride permeability of concrete. Final Report No.

FHWA/RD-81/119. Federal Highway Administration,

Washington, DC.

[30] Jiang Lin Hua, Chloride Permeability Test On

Concrete Dept. of Material Science and Engineering,

Hehai University, Nanjing 210098. Vol.22 No. 6. Dec.

2002

[17] ASTM C150 / C150M 09. Standard Specification

for Portland Cement. Annual Book of ASTM Standards.

American Society for Testing and Material

[18] ACI Committee 211.2-98. Standard Practice for

Selecting Proportion for structural Lightweight Concrete.

Detroit, American Concrete Institute.

[19] ASTM C567 - 05a. Standard Test Method for

Determining Density of Structural Lightweight Concrete.

Annual Book of ASTM Standards. American Society for

Testing and Material

[20] ASTM C192 / C192M -07. Standard Practices for

Making and Curing Concrete Test Specimens in the

Laboratory. Annual Book of ASTM Standards.

American Society for Testing and Material

1870 | P a g e

You might also like

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Al-Fahdawi 2020 IOP Conf. Ser. Mater. Sci. Eng. 881 012179Document10 pagesAl-Fahdawi 2020 IOP Conf. Ser. Mater. Sci. Eng. 881 012179Saif LlNo ratings yet

- Achieving Sustainable Concrete Through Use of Mineral Admixtures ConfirmationDocument3 pagesAchieving Sustainable Concrete Through Use of Mineral Admixtures ConfirmationLalitha Krishna MoorthyNo ratings yet

- The Use of Blast Furnace Slag As A Supplementary CDocument13 pagesThe Use of Blast Furnace Slag As A Supplementary CCivil manNo ratings yet

- Evaluation of Environmental Requirements For Sustainable Ready-Mix Concrete Production in Abu Dhabi EmirateDocument7 pagesEvaluation of Environmental Requirements For Sustainable Ready-Mix Concrete Production in Abu Dhabi EmirateeorenusNo ratings yet

- 4N5 Ijeset0202520 PDFDocument8 pages4N5 Ijeset0202520 PDFBia MughalNo ratings yet

- 4096-Article Text-20292-1-10-20210531Document11 pages4096-Article Text-20292-1-10-20210531janhvi muleNo ratings yet

- Matecconf Imeti2017 01010Document15 pagesMatecconf Imeti2017 01010SOMNo ratings yet

- Devi PDFDocument12 pagesDevi PDFDharmaraaj RajalinggamNo ratings yet

- Replacing Cement with Fly Ash for Sustainable ConcreteDocument22 pagesReplacing Cement with Fly Ash for Sustainable Concretekaushal yadavNo ratings yet

- Properties of Palm Ash Concrete: P.Premalatha, K.R.Vinodh, L.Chris Anto, R.NithiyaDocument4 pagesProperties of Palm Ash Concrete: P.Premalatha, K.R.Vinodh, L.Chris Anto, R.NithiyainventionjournalsNo ratings yet

- Concrete with Crushed Tiles and Oil Palm FibreDocument5 pagesConcrete with Crushed Tiles and Oil Palm FibreEloisa FabroaNo ratings yet

- Influence of Silica Fume On Concrete: Prof. Vishal S. Ghutke, Prof. Pranita S.BhandariDocument4 pagesInfluence of Silica Fume On Concrete: Prof. Vishal S. Ghutke, Prof. Pranita S.BhandariBia MughalNo ratings yet

- Framework For Durable ConcreteDocument8 pagesFramework For Durable ConcreteDai ThanhNo ratings yet

- SCC 2Document4 pagesSCC 2Arunkumar BnNo ratings yet

- Quality Control of Reinforced Concrete Structures For DurabilityDocument9 pagesQuality Control of Reinforced Concrete Structures For Durabilitychirag dumaniyaNo ratings yet

- Using copper slag in concrete improves strengthDocument10 pagesUsing copper slag in concrete improves strengthemraan KhanNo ratings yet

- An Overview of the Properties of Self Compacting ConcreteDocument9 pagesAn Overview of the Properties of Self Compacting ConcreteMohamedRaahimNo ratings yet

- 3) Ijret20170608008Document4 pages3) Ijret20170608008SOMNo ratings yet

- Jurnal Beton Busa PDFDocument8 pagesJurnal Beton Busa PDFIqbalArifkyNo ratings yet

- Corcon Full Paper Dhanya in FormatDocument9 pagesCorcon Full Paper Dhanya in FormathuntNo ratings yet

- Concrete Durability Presented by Acceptable Chloride Level and Chloride Diffusion Coefficient in Concrete: 10-Year Results in Marine SiteDocument11 pagesConcrete Durability Presented by Acceptable Chloride Level and Chloride Diffusion Coefficient in Concrete: 10-Year Results in Marine SiteTarek ChikerNo ratings yet

- Effect of Aggregate Size on Self-Compacting Concrete StrengthDocument6 pagesEffect of Aggregate Size on Self-Compacting Concrete StrengthvinothiniNo ratings yet

- HJKKKDocument27 pagesHJKKKTafaraNo ratings yet

- BuildingsDocument22 pagesBuildingsSai PavanNo ratings yet

- Report On Summer RainingDocument16 pagesReport On Summer RainingAr G S YadavNo ratings yet

- Construction and Building MaterialsDocument8 pagesConstruction and Building MaterialsVeronika PrymNo ratings yet

- Effects of Used Engine Oil As Chemical Admixtures On The Properties of High Strength ConcreteDocument6 pagesEffects of Used Engine Oil As Chemical Admixtures On The Properties of High Strength Concretedear_toraNo ratings yet

- Studies On Relationship Between Water/Binder Ratio and Compressive Strength of High Volume Fly Ash ConcreteDocument8 pagesStudies On Relationship Between Water/Binder Ratio and Compressive Strength of High Volume Fly Ash ConcreteAJER JOURNALNo ratings yet

- Investigation of Abrasion Test and Mechanical Properties of Concrete Using Fly Ash As A Partial Replacement of CementDocument11 pagesInvestigation of Abrasion Test and Mechanical Properties of Concrete Using Fly Ash As A Partial Replacement of CementIJRASETPublicationsNo ratings yet

- 45 - Foundry Sand Utilisation As A Partial Replacement of Fine Aggregate For Establishing Sustainable Concrete PDFDocument4 pages45 - Foundry Sand Utilisation As A Partial Replacement of Fine Aggregate For Establishing Sustainable Concrete PDFArunkumar AKNo ratings yet

- Concrete Specification and Methods of Quality TestingDocument18 pagesConcrete Specification and Methods of Quality TestingKhalid Abdel Naser Abdel RahimNo ratings yet

- Translucent Concrete Mechanical Properties EvaluationDocument8 pagesTranslucent Concrete Mechanical Properties EvaluationsehunNo ratings yet

- Irjet V3i720Document6 pagesIrjet V3i720SHARAN PATILNo ratings yet

- Water Absorption and Compressive Strengt PDFDocument8 pagesWater Absorption and Compressive Strengt PDFMohamed HamdyNo ratings yet

- Coconut Shells As Coarse AggregateDocument7 pagesCoconut Shells As Coarse AggregateAnkitSinghNo ratings yet

- Proportioning of Fly Ash Concrete MixesDocument6 pagesProportioning of Fly Ash Concrete Mixesjignesh shahNo ratings yet

- STRENGTH PROPERTIES OF HIGH VOLUME FLY ASH ROLLER COMPACTED CONCRETEDocument7 pagesSTRENGTH PROPERTIES OF HIGH VOLUME FLY ASH ROLLER COMPACTED CONCRETEMohamad AzharNo ratings yet

- Use of Water Reducers To Impove Grindability and Performance of PC Clinker PDFDocument10 pagesUse of Water Reducers To Impove Grindability and Performance of PC Clinker PDFTran Huynh NamNo ratings yet

- I JR Et 20150405058hjggDocument4 pagesI JR Et 20150405058hjgggtarun22guptaNo ratings yet

- Experimental Studies of Coconut Shell Ash Composites in ConcreteDocument4 pagesExperimental Studies of Coconut Shell Ash Composites in ConcreteaswathyNo ratings yet

- Properties of Pervious Concrete With Various Types and Sizes of AggregateDocument14 pagesProperties of Pervious Concrete With Various Types and Sizes of Aggregatetrisutomo10No ratings yet

- Mix Design Procedure for Self Compacting ConcreteDocument9 pagesMix Design Procedure for Self Compacting ConcretesaxraviNo ratings yet

- Literature Review: Nova John (2013) Examined The Strength Properties of Metakaolin Admixed Concrete. HeDocument9 pagesLiterature Review: Nova John (2013) Examined The Strength Properties of Metakaolin Admixed Concrete. Henutan acharyaNo ratings yet

- Construction and Building Materials: Li-Jeng Hunag, Her-Yung Wang, Yu-Wu WuDocument5 pagesConstruction and Building Materials: Li-Jeng Hunag, Her-Yung Wang, Yu-Wu Wuhans_conanNo ratings yet

- Feasibility of Producing Nano Cement in A TraditioDocument31 pagesFeasibility of Producing Nano Cement in A TraditioReda Shewit GebretsadikNo ratings yet

- Oscar Power PointDocument36 pagesOscar Power PointAbdullahi MuhammadNo ratings yet

- Use of Aluminium Powder in The Production of Lightweight ConcreteDocument12 pagesUse of Aluminium Powder in The Production of Lightweight ConcreteTan Khern Wee17% (6)

- Comparative Study of Rapid Chloride Penetration Test (RPCT) On Self Compacting Concrete (SCC)Document8 pagesComparative Study of Rapid Chloride Penetration Test (RPCT) On Self Compacting Concrete (SCC)IJRASETPublicationsNo ratings yet

- Comparative Analysis of The Compressive Strength of Concrete UnderDocument11 pagesComparative Analysis of The Compressive Strength of Concrete UnderIsnaldo Barros OviedoNo ratings yet

- Bamboo As A Building MaterialDocument56 pagesBamboo As A Building MaterialMahesh KoppakaNo ratings yet

- Inhibitive Effect of Organic Inhibitors in Concrete Containing Quarry Dust As Fine AggregateDocument7 pagesInhibitive Effect of Organic Inhibitors in Concrete Containing Quarry Dust As Fine AggregateReeja MathewNo ratings yet

- Study of Structural Performance and Durability of Concrete by Partial Replacement of Cement With Hypo Sludge (Paper Waste)Document5 pagesStudy of Structural Performance and Durability of Concrete by Partial Replacement of Cement With Hypo Sludge (Paper Waste)Innovative Research PublicationsNo ratings yet

- Use of Rice Husk Ash As Strength-Enhancing Additive in Lightweight Cementitious Composite MortarsDocument12 pagesUse of Rice Husk Ash As Strength-Enhancing Additive in Lightweight Cementitious Composite MortarsFolorunsho AyomideNo ratings yet

- Parative Study of Strength and Corrosion Resistant Properties of Plain and Blended Cement Concrete TypesDocument14 pagesParative Study of Strength and Corrosion Resistant Properties of Plain and Blended Cement Concrete TypeszeeNo ratings yet

- Aboobacker 2019Document4 pagesAboobacker 2019joelNo ratings yet

- Evaluation of The Impact of Short-Term Aging On Volumetric and Marshall Properties of Palm Oil Clinker Fine Modified Asphalt Concrete (Pocf-Mac)Document12 pagesEvaluation of The Impact of Short-Term Aging On Volumetric and Marshall Properties of Palm Oil Clinker Fine Modified Asphalt Concrete (Pocf-Mac)Cesar Idrogo MontalvoNo ratings yet

- Laboratory Study On Mechanical Strength and Mix Proportions of RCC Pavements in Cold RegionsDocument11 pagesLaboratory Study On Mechanical Strength and Mix Proportions of RCC Pavements in Cold RegionsFoolad GharbNo ratings yet

- The Fabrication of Materials: Materials TechnologyFrom EverandThe Fabrication of Materials: Materials TechnologyRating: 5 out of 5 stars5/5 (1)

- A Simulation Framework For Cluster-Based Web Services: Emiliano CasalicchioDocument13 pagesA Simulation Framework For Cluster-Based Web Services: Emiliano CasalicchioIan NazarethNo ratings yet

- ) IS: 101 (Part L/set 2) - 1987: First Reprint AUGUST 1991Document2 pages) IS: 101 (Part L/set 2) - 1987: First Reprint AUGUST 1991kishor150688No ratings yet

- Is 302 2 204 1994Document13 pagesIs 302 2 204 1994kishor150688No ratings yet

- CONQUASDocument50 pagesCONQUASFrankie Chan100% (2)

- Hardened Concrete Methods of Test: Indian StandardDocument14 pagesHardened Concrete Methods of Test: Indian Standardjitendra86% (7)

- Declaration of Performance: The Undersigned, Representing Lava Mining and Quarrying S.A. Declares ThatDocument2 pagesDeclaration of Performance: The Undersigned, Representing Lava Mining and Quarrying S.A. Declares Thatkishor150688No ratings yet

- Guidelines On Water ProofingDocument88 pagesGuidelines On Water Proofingkishor150688No ratings yet

- Is 516 5 1 2018Document18 pagesIs 516 5 1 2018kishor150688No ratings yet

- Procurement Specification GuideDocument11 pagesProcurement Specification GuideDexter Gerald Lorzano GingoNo ratings yet

- The Compelling Relevance of Chanakya: For Challenging TimesDocument24 pagesThe Compelling Relevance of Chanakya: For Challenging Timeskishor150688No ratings yet

- TDS Grade NCS 3Document1 pageTDS Grade NCS 3kishor150688No ratings yet

- Types and Causes of Concrete Deterioration Is536 PDFDocument16 pagesTypes and Causes of Concrete Deterioration Is536 PDFDEVINo ratings yet

- Technical Bulletin Tile InstallationDocument2 pagesTechnical Bulletin Tile Installationkishor150688No ratings yet

- Ride Details Bill Details: Thanks For Travelling With Us, Kishor KDocument3 pagesRide Details Bill Details: Thanks For Travelling With Us, Kishor Kkishor150688No ratings yet

- Masterglenium Sky 909 MsdsDocument10 pagesMasterglenium Sky 909 Msdskishor150688No ratings yet

- Masterglenium Sky 8522 v1Document3 pagesMasterglenium Sky 8522 v1kishor150688No ratings yet

- World Glass Standard SummaryDocument2 pagesWorld Glass Standard Summarykishor150688No ratings yet

- Power of Attorney Form PDFDocument3 pagesPower of Attorney Form PDFKunal BaruaNo ratings yet

- Handy Calculations - Volume Solids and Spreading RateDocument4 pagesHandy Calculations - Volume Solids and Spreading Ratevengadesh100% (1)

- Disclosure To Promote The Right To InformationDocument17 pagesDisclosure To Promote The Right To InformationSimbu ArasanNo ratings yet

- D7031 1093127-1Document8 pagesD7031 1093127-1Diego_Benalc_z_7438100% (1)

- Spec Aama 611-14Document13 pagesSpec Aama 611-14杜文欽100% (1)

- Kirlosker PM BallValveDocument8 pagesKirlosker PM BallValveSavalia HardikNo ratings yet

- Chopped Carbon Fibers Innovative MateriaDocument7 pagesChopped Carbon Fibers Innovative Materiakishor150688No ratings yet

- ASTM E1003 13 Hydrostatic Leak Testing 1 PDFDocument3 pagesASTM E1003 13 Hydrostatic Leak Testing 1 PDFAndrea Fabiana BlaschiNo ratings yet

- Handy Calculations - Volume Solids and Spreading RateDocument4 pagesHandy Calculations - Volume Solids and Spreading Ratevengadesh100% (1)

- The Compelling Relevance of Chanakya: For Challenging TimesDocument24 pagesThe Compelling Relevance of Chanakya: For Challenging Timeskishor150688No ratings yet

- Nikolaides Manthos Sarafidou SEMBpaperDocument12 pagesNikolaides Manthos Sarafidou SEMBpaperkishor150688No ratings yet

- En Reaction To Fire ClassificationDocument1 pageEn Reaction To Fire ClassificationIoana UtiuNo ratings yet

- ASTM B 499 09 Yr 14 Coating MeasurementDocument5 pagesASTM B 499 09 Yr 14 Coating MeasurementPrabath Nilan GunasekaraNo ratings yet

- Retrofit X Brace 2018 PDFDocument18 pagesRetrofit X Brace 2018 PDFMuhammad Sami SyamlanNo ratings yet

- Site Class B Response Spectrum GraphDocument8 pagesSite Class B Response Spectrum Graphsudhir12345100% (1)

- Advance Staad by SarojDocument90 pagesAdvance Staad by SarojSAROJ BISWAS100% (3)

- Concrete Technology Assignment QuestionsDocument4 pagesConcrete Technology Assignment QuestionsAyush BhardwajNo ratings yet

- Preparation of Bar Bending Schedule (B.B.S) - Daily CivilDocument6 pagesPreparation of Bar Bending Schedule (B.B.S) - Daily CivilfelixNo ratings yet

- Services Integration With Concrete Buildings Guidance For A Defect Free Interface (Sample)Document7 pagesServices Integration With Concrete Buildings Guidance For A Defect Free Interface (Sample)AndRew YNo ratings yet

- Tec 301 HCS (KSA) : Non Shrink Very High Strength GroutDocument2 pagesTec 301 HCS (KSA) : Non Shrink Very High Strength Groutmanikandan4strlNo ratings yet

- Bondek Design & Construct Manual COMPLETEDocument48 pagesBondek Design & Construct Manual COMPLETEMuhd Hamizan Mohd SallehNo ratings yet

- Design of Laterally Restrained BeamsDocument15 pagesDesign of Laterally Restrained Beamsdixn__No ratings yet

- Regulator TypesDocument58 pagesRegulator Typesramkumar121No ratings yet

- Design Moments for Hume Pipe CulvertDocument4 pagesDesign Moments for Hume Pipe CulvertYatendra TyagiNo ratings yet

- Proposed three-storey commercial/residential building bid proposalDocument11 pagesProposed three-storey commercial/residential building bid proposalKurama BasketNo ratings yet

- Recent Advances in Pile Foundation - BCM SeminarDocument15 pagesRecent Advances in Pile Foundation - BCM Seminarapi-19915731No ratings yet

- 2012 Wood Frame 2012 Wood Frame Construction Manual: Construction Manual: Construction Manual: Construction ManualDocument23 pages2012 Wood Frame 2012 Wood Frame Construction Manual: Construction Manual: Construction Manual: Construction ManualLourdes PaivaNo ratings yet

- Pushover Analysis of An Existing R.C.CDocument5 pagesPushover Analysis of An Existing R.C.CYuliusRiefAlkhalyNo ratings yet

- Two-way slab design layoutDocument1 pageTwo-way slab design layoutMark Anthony TajonNo ratings yet

- GEC No 3 LRFD Seismic Design and AnalysisDocument588 pagesGEC No 3 LRFD Seismic Design and Analysisrshaghayan100% (1)

- CAUSES AND PREVENTION OF BUILDING CRACKSDocument7 pagesCAUSES AND PREVENTION OF BUILDING CRACKSbhanu jammuNo ratings yet

- Short RCC Notes by Devesh Sir.Document93 pagesShort RCC Notes by Devesh Sir.sandeepknit3428No ratings yet

- Fabric Formwork Systems Used in Marine Construction: Martin G. Hawkswood Proserve LTDDocument13 pagesFabric Formwork Systems Used in Marine Construction: Martin G. Hawkswood Proserve LTDVishwas BhatNo ratings yet

- As 3600Document10 pagesAs 3600ToniHospitaler0% (4)

- Curriculum Vitae: Indrasan GondDocument4 pagesCurriculum Vitae: Indrasan GondindrasabNo ratings yet

- EC2 Bending With or Without Axial ForceDocument11 pagesEC2 Bending With or Without Axial ForceselinaNo ratings yet

- BEMO RAIL BV Rail Technology SystemsDocument19 pagesBEMO RAIL BV Rail Technology SystemsAulia OkkyNo ratings yet

- Project Cost Estimate and Breakdown for Commercial Building RenovationDocument2 pagesProject Cost Estimate and Breakdown for Commercial Building RenovationlhyteNo ratings yet

- Seminar Report at RachithaDocument18 pagesSeminar Report at RachithaMegha KallihalNo ratings yet

- HB Ground Improvement Solutions MatrixDocument3 pagesHB Ground Improvement Solutions MatrixSheik Mohamed LiakathNo ratings yet

- Verification Manual Indian CodesDocument44 pagesVerification Manual Indian CodesArunkumar AKNo ratings yet

- Sarkisian, Mark P. - Designing Tall Buildings - Structure As Architecture (2016)Document7 pagesSarkisian, Mark P. - Designing Tall Buildings - Structure As Architecture (2016)dhea nadyaNo ratings yet

- Assignment Estimation and SpecificationDocument26 pagesAssignment Estimation and SpecificationElsa kNo ratings yet