Professional Documents

Culture Documents

Risk Assessment Form

Uploaded by

ThomasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment Form

Uploaded by

ThomasCopyright:

Available Formats

HSE Project Risk Assessment

work

Office of Facility Management

Construction

Minor Work

Contractor

Name: ______________________________________________________________Date__________

For use by project co-ordinators to conduct preliminary risk identification and assessment, prior to allocating jobs or projects to contractors or employees

Refer also to Guide Construction Project Hazard Controls

STEP 1:

Define the projects/job or tasks

Location(s) of Work (Campus/Building/Level/Room

Project title

Project /Task Number:

Define the projects/tasks. Consider the whole project. List the main stages in the job and then break them down into key sections.

Date

Risk assessment done by:

STEP 2:

a.

Identify major hazards

Critical equipment, tasks, environmental, substances that may be present or produced

Will contractors or employees be using or working with (Check all applicable boxes)

portable electrical equipment for construction work 2

pressurized equipment sand, water or other blasting equipment 2

compressed gases in cylinders [ tick below] 2

hazardous substances 1,2, 4

lasers 3

explosives or powder actuated hand held fastening tools 2, 4

b.

c.

formwork 2

fixed scaffolding 3,2

mobile scaffolding 2

material hoists/cranes/dogging/rigging/load shifting vehicles 3

earth moving machinery 3

using plant or equipment that produce excessive vibration 2

Does the project / job involve (Check boxes)

lifting or moving awkward or heavy objects by mechanical means eg: cranes 2,

potential contact with electrical or construction wiring underground or

overhead 2,

welding or grinding or other heat /spark producing activities 2,

producing hazardous waste [ rubbish] 1

excavation / entering all trenches ( >1.5m depth) 2,, 4

demolition work [ not dismantling in building alteration] 4 ,3 2

possible contact or disturbance of asbestos material 2, 4

asbestos removal 4, 3, 2

working in close proximity to occupied or high pedestrian traffic areas

offices or meeting areas 2,

interruption or isolation of emergency services, fire or alarm systems 2,

working off ladders 2,

working at a height (>2.0 m) 2,4

working on sloping roof (> 26 0 pitch ) 2,4

tilt up and precast construction work 2,4

working in area with potentially contaminated or flammable atmosphere 2,4

work involving major structural alterations and use of temporary

supports 2,4

working on or near pressurised gas distribution mains or consumer

piping 2,4

working on or near high voltage electrical installations 2,4

working near exposed energised electrical installation 2,4

working live with electricity, testing or faultfinding 2

working on or near roads with vehicle traffic or mobile plant 2,4

working on or near a chemical , fuel or refrigerant line 2,4

working on telecommunications towers 2,4

working in isolation time or place

working in or accessing a confined space 1, 2, 4

working in laboratories or on laboratory equipment 2

working near x-ray or other ionising radiation sources 2

working around installed electro magnetic objects 3

working on, over, or adjacent to water where risk of drowning 2,4

working in area with artificial extremes of temperature 2,4

Is there likely to be added risks of

excessive dust/fumes/vapours/gases produced 2,

building air quality affected or contaminated 2

objects falling from heights onto students or staff 2,

objects striking others - students or staff 2,

slippery surfaces/ trip hazards created

risk of fire/explosion2,

poor ventilation /air flow into work area 2

a poorly designed or restricted work area for the project/job 2

access issues with general public or others 2

soil or local ecology erosion 2

stormwater drains or natural waterway damage 2

other_________________________________________

1

2

3

Specific detailed risk assessments must be completed for these hazards see Step 4(b)

Special controls or methods prescribed under WHS Regulations must be put in place for these hazards see Step 4 (c) & Check Legislation

These hazards may require specific individual or company licences or approvals - identify this requirement in the control section, in step 4 ( c)

4 These jobs are

automatically High Risk Construction Activity and require a Safe Work Method Statement [SWMS] for that job.

F6577 Project job risk assessment 06.doc Rev 1:06

Update web version if changes made to original version

1 of 3

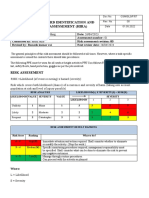

Step 3:

Assess the risks

Consider each identified hazard/risk

Rate the level of risk for each hazard, based on the LIKELIHOOD of harm occurring , without controls in place and the most likely SEVERITY of that harm or

loss.

Potential severity

Likelihood

Insignificant

Minor

Moderate

Major

Catastrophic

Almost certain

High

High

Extreme

Extreme

Extreme

Likely

Medium

High

High

Extreme

Extreme

Possible

Low

Medium

High

Extreme

Extreme

Unlikely

Low

Low

Medium

High

Extreme

Rare

Low

Low

Medium

High

High

* For unspecified projects/jobs that present a high or extreme risk, a Safe Work Method Statement should be completed.

Step 4:

Control the risks

Consider how each of the hazards & risks you have identified and

assessed, should be controlled using the prioritised options model at

right.

Remember, the higher the risk level, the higher the level of

safety control needed.

1. Eliminate the hazard

2. Keep the hazard and people apart

3. Change work methods

4. Use personal protection

1 EXTRA RISK ASSESSMENT required for these high-risk hazards.

A.

Any hazards noted as

requires further assessment or action [if current risk assessment not applicable or available]

hazardous substance risk assessment

confined spaces risk assessment [ if not already done]

atmospheric gas or explosivity testing / monitoring prior to confined

space entry

- Check any hazards noted as 2 requiring specific

control or action . These may be University specific controls eg: isolations/notification and /or as required by WH & S or other legislation.

Refer also to OFM Guide Construction Project Hazard Risk Controls

Construction hazard control options A combination or more than one may be required to control risk levels

B.

2 LEGALLY REQUIRED RISK CONTROLS to be in place for this hazard /risks

Re-design or special set up of work environment

Reschedule timing of job /work activity

Check Asbestos register for presence of asbestos material

Notification to occupants of affected space about impact of

works

Safety signage to be put in place

Temporary relocation of occupants to alternative space

Substitution of substances or use less hazardous methods

Arrange disconnection of plant components , pipe work, ducting

or other services with appropriate persons

Use of suitable safety barriers, fences or other isolation /

enclosure methods to restrict unauthorised access and

prevent flying /falling objects

Notify Security of Emergency system isolations

Issue of Prescribed Work Permit Hot work, Height/roof work, Tree

Provide site specific information local hazards &/or safe methods

Check plant, tools, equipment or vehicles in safe working order

Site Induction training for new persons /contractors * Mandatory

Tag out, lockout procedure to be applied fume cupboards etc

Ensure air flow , building ventilation & quality is maintained

Provide information from MSDS or chemical registers to/ from contractor

Ensure use of Personal Protective Equipment & clothing, safety harnesses

etc is suitable for work

Follow University work instructions or procedures or other plans

felling, Confined space entry ,Working in excavations

Note additional emergency systems required to support this job

first aid kit

extended first aid kit

chemical spill kit

emergency stop buttons on plant

special emergency or rescue procedures or plans

C.

safety shower/ eye wash station

evacuation/ fire control - extinguishers

remote communication mechanism

others

3 Prescribed Activity or Occupation Check any hazards noted as 3 requiring organisational licenses /registration

Demolition work

Asbestos removal

Certificates of competency/licenses - Check any hazards noted as 3 for individual operators.

Scaffolding

Class B Asbestos Removal

Rigging or Dogging

Earth & other load shifting machinery operation

F6577 Project job risk assessment 06.doc Rev 1:06

Update web version if changes made to original version

Pesticide application

Operators of cranes, hoists materials or personnel

Elevating work platforms

Boiler or pressure equipment operations

2 of 3

D.

4 Are Safe Work Method Statement(s) required?

Yes

No Check any hazards noted as 4

Safe Work Method Statements are required for any job involving High Risk Construction Activities identified in step 2 or other high or extreme

risk projects/tasks assessed in step 3. If unsure, contact the Office of Facilities Management Health Safety & Environment co-ordinator for

further assistance.

Step 5:

Agreed actions required to control the risks for this job or project

Summarise any controls and further specific risk assessments required for this job.

Copy to be given to contractor.

Details of action required

Responsibility

Signed

List any Safe Work Method Statements required from contractor (for high and extreme risk activities)

From which contractor

1.

2.

3.

4.

To be signed by project co-ordinator and contractor when risks controls are agreed & understood as noted in step 4, and Safe

Work Method Statements are submitted [if required. ]

Project co-ordinators signature

Print name

Date

Contractors signature

To evaluate Safe Work Method Statements received from contractors , use SWMS Check sheet F 6581or PSP Check sheet F # 6580

F6577 Project job risk assessment 06.doc Rev 1:06

Update web version if changes made to original version

3 of 3

You might also like

- Risk Assessment Procedures - Step To Prepare Risk AssessmentDocument5 pagesRisk Assessment Procedures - Step To Prepare Risk AssessmentaneethavilsNo ratings yet

- Environmental Health and Safety Policy - Gcu 2017Document9 pagesEnvironmental Health and Safety Policy - Gcu 2017Michael KaziNo ratings yet

- Health Safety Risk Assessment Template 1Document4 pagesHealth Safety Risk Assessment Template 1alokcNo ratings yet

- Installation & Safety Guide for Waste Compactors & Recycling SystemsDocument21 pagesInstallation & Safety Guide for Waste Compactors & Recycling SystemsVuong BuiNo ratings yet

- SOP - Motor Bike SafetyDocument4 pagesSOP - Motor Bike SafetyTafadzwaNo ratings yet

- Procedure For Reporting HazardsDocument3 pagesProcedure For Reporting HazardsPaige Jones100% (1)

- Risk Assessment Checklist For New and Expectant MothersDocument2 pagesRisk Assessment Checklist For New and Expectant MothersDave NalugonNo ratings yet

- Bloodborn Pathogen ProgramDocument22 pagesBloodborn Pathogen Programsitimaezyaroh100% (1)

- Mock DrillDocument2 pagesMock DrillTarun MajumdarNo ratings yet

- Procedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresDocument10 pagesProcedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresradhouaneNo ratings yet

- General Information For Hazardous MaterialsDocument8 pagesGeneral Information For Hazardous MaterialsAshraf shaikhNo ratings yet

- Department of Health.: Occupational Health & Safety PolicyDocument10 pagesDepartment of Health.: Occupational Health & Safety PolicyMuhammad SaeedNo ratings yet

- Premobilisation Wheel Loader InspectionDocument1 pagePremobilisation Wheel Loader InspectionArjun Satheesan100% (1)

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerNo ratings yet

- Health and Safety Policy Manual Issue 14Document34 pagesHealth and Safety Policy Manual Issue 14caskevNo ratings yet

- Eskom IncidentDocument93 pagesEskom IncidentEd ChikuniNo ratings yet

- Chapter 1-Introduction To OshaDocument32 pagesChapter 1-Introduction To OshafettaneNo ratings yet

- HSE guidance on safety devices for rapid roller doorsDocument11 pagesHSE guidance on safety devices for rapid roller doorsmsc920138No ratings yet

- Accident Reporting PolicyDocument3 pagesAccident Reporting Policysalehi123No ratings yet

- Health and Safety Risk AssessmentDocument2 pagesHealth and Safety Risk AssessmentShahil IslamNo ratings yet

- Cps 0460 Incident Notification ReportDocument2 pagesCps 0460 Incident Notification ReporttabaquiNo ratings yet

- Site Induction PresentationDocument16 pagesSite Induction PresentationMewan Naveenda Perera100% (1)

- HSE Safety AuditsDocument3 pagesHSE Safety Auditsvlad100% (1)

- Fit For Duty Work Policy Short FormDocument3 pagesFit For Duty Work Policy Short FormSunish RathaurNo ratings yet

- Appointment of Health and Safety RepresentativeDocument3 pagesAppointment of Health and Safety RepresentativeReham Bagundang LauNo ratings yet

- Risk Assessment: General Business Activity N/ADocument5 pagesRisk Assessment: General Business Activity N/AMOHAMEDNo ratings yet

- FOELH Covid PolicyDocument3 pagesFOELH Covid PolicyLewisNo ratings yet

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDocument1 pageScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilNo ratings yet

- Hira - 01Document3 pagesHira - 01Angw BasumataryNo ratings yet

- Role of Safety OfficerDocument12 pagesRole of Safety OfficerChristian MeanaNo ratings yet

- Heat Stress ProcedureDocument13 pagesHeat Stress ProcedureKneekEy CastleNo ratings yet

- Guidelines For Personal Protective Equipment (Ppe) : JUNE 2020Document40 pagesGuidelines For Personal Protective Equipment (Ppe) : JUNE 2020Tanri Andita Wicaksono100% (1)

- Australia Anti-Bullying Policy - 1oct12Document7 pagesAustralia Anti-Bullying Policy - 1oct12Maheshwaran IrulappanNo ratings yet

- Standard Operating Procedure - COVID 19 Transport Infrastructure - May 4 - DraftDocument27 pagesStandard Operating Procedure - COVID 19 Transport Infrastructure - May 4 - DraftChandra Kumar100% (1)

- Personal Protective Equipment Hazard Assessment: Location: Conducted By: Date: Tasks Performed at This LocationDocument4 pagesPersonal Protective Equipment Hazard Assessment: Location: Conducted By: Date: Tasks Performed at This LocationAnge JuanNo ratings yet

- Ladder Safety Tips <40Document2 pagesLadder Safety Tips <40Ange JuanNo ratings yet

- Hazard IdentificationDocument11 pagesHazard IdentificationMahmoud T' KantonaNo ratings yet

- SAFETY PLAN AND EMERGENCY PROCEDURESDocument4 pagesSAFETY PLAN AND EMERGENCY PROCEDURESBilal QureshiNo ratings yet

- Risk AssessmentDocument3 pagesRisk Assessmentss04946197No ratings yet

- Accident and Incident Report ProcedureDocument23 pagesAccident and Incident Report ProcedureWakarusa Co100% (1)

- QPSC Confined Space Entry ProcedureDocument54 pagesQPSC Confined Space Entry ProcedureUnais RahmanNo ratings yet

- UAE Law No. - 21 - of 2005 Concerning Waste Management in Abu Dhabi Emirate EngDocument9 pagesUAE Law No. - 21 - of 2005 Concerning Waste Management in Abu Dhabi Emirate EngwholenumberNo ratings yet

- ISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFDocument5 pagesISBN Sample OHS Action Plan For Community Services Sector 2007 01 PDFpurva02No ratings yet

- Model Infection Control Plan For Veterinary Practices 2008Document6 pagesModel Infection Control Plan For Veterinary Practices 2008ernie pNo ratings yet

- Health, Safety, Security, Environment, and Quality PolicyDocument1 pageHealth, Safety, Security, Environment, and Quality PolicyVăn PhúcNo ratings yet

- Role and Responsibility of HSE ProfessionalDocument5 pagesRole and Responsibility of HSE Professionalrnp2007123No ratings yet

- Tun Razak Exchange, Retail Plot 1: Appendix 4 - Emergency Response PlanDocument32 pagesTun Razak Exchange, Retail Plot 1: Appendix 4 - Emergency Response PlanMatthew Mohan PerumalNo ratings yet

- Accident Incident Investigation and ControlDocument6 pagesAccident Incident Investigation and ControlEdmil PabellanoNo ratings yet

- Identifying and Controlling Workplace HazardsDocument45 pagesIdentifying and Controlling Workplace HazardsAijaz Ahmed ShaikhNo ratings yet

- Inherent V Residual RiskDocument2 pagesInherent V Residual RiskAlephNo ratings yet

- 06-F02 Training Needs AnalysisDocument36 pages06-F02 Training Needs AnalysisSn AhsanNo ratings yet

- Young Persons Risk Assessment V2.0 October 2021Document2 pagesYoung Persons Risk Assessment V2.0 October 2021Lucas SantosNo ratings yet

- Integr Ted Business Re S: at SourceDocument14 pagesIntegr Ted Business Re S: at SourcecyclopsoctopusNo ratings yet

- Electrical Safety PlanDocument53 pagesElectrical Safety PlanLawrence adeleke OmisakinNo ratings yet

- 4 August 2021 ExamDocument5 pages4 August 2021 ExamRafa'eel BickooNo ratings yet

- First Aid PolicyDocument63 pagesFirst Aid PolicyMohamed GerezaNo ratings yet

- Guide Lines For NSC HSE PlanDocument52 pagesGuide Lines For NSC HSE Planജിനാദ് അബ്ദുസ്സലാംNo ratings yet

- Hazardous Substances & Dangerous Goods WHSPRO-007 CMDocument7 pagesHazardous Substances & Dangerous Goods WHSPRO-007 CMJason McIntoshNo ratings yet

- Method Statement For Insulation Works and JacketingDocument8 pagesMethod Statement For Insulation Works and JacketingThomas100% (8)

- Method Statement For Hot Tapping Rev 0Document9 pagesMethod Statement For Hot Tapping Rev 0Thomas100% (4)

- Atmosphere Management: O Consumption (CFM) CO Production (CFM) Activity SourceDocument16 pagesAtmosphere Management: O Consumption (CFM) CO Production (CFM) Activity SourceThomasNo ratings yet

- Risk Assessment - ScaffoldingDocument4 pagesRisk Assessment - ScaffoldingThomasNo ratings yet

- List of Tools and Equipment for Welding and Erection WorkDocument3 pagesList of Tools and Equipment for Welding and Erection WorkThomas80% (5)

- Atmosphere Management: O Consumption (CFM) CO Production (CFM) Activity SourceDocument16 pagesAtmosphere Management: O Consumption (CFM) CO Production (CFM) Activity SourceThomasNo ratings yet

- Guidelineforgasturbineinletairfiltrationsystems 1Document116 pagesGuidelineforgasturbineinletairfiltrationsystems 1ThomasNo ratings yet

- Carmagen 6 10Document3 pagesCarmagen 6 10ikhleifNo ratings yet

- Baseline For Setting Out TheodoliteDocument70 pagesBaseline For Setting Out Theodolitemitualves100% (5)

- Air Conditioners That Works On Solar EnergyDocument2 pagesAir Conditioners That Works On Solar EnergyThomasNo ratings yet

- MCQ ExamDocument9 pagesMCQ ExamAnup Lal RajbahakNo ratings yet

- How To Conduct Performance Risk AnalysisDocument2 pagesHow To Conduct Performance Risk AnalysisThomasNo ratings yet

- For Overseas DentistsDocument11 pagesFor Overseas DentistsThomasNo ratings yet

- Endo Problems SolvedDocument5 pagesEndo Problems SolvedThomas100% (1)

- 1000 MCQ Bank QuestionsDocument157 pages1000 MCQ Bank Questionsapi-2629165193% (59)

- Webbing Sling Load ChartDocument2 pagesWebbing Sling Load ChartThomasNo ratings yet

- HCG LevelsDocument1 pageHCG LevelsThomasNo ratings yet

- For Overseas DentistsDocument11 pagesFor Overseas DentistsThomasNo ratings yet

- ECE5530 HW1 Bosela Power DistributionDocument4 pagesECE5530 HW1 Bosela Power Distributionjosephbailey10No ratings yet

- PCH VLT AutomationDrive Design 0 75 KW PDFDocument200 pagesPCH VLT AutomationDrive Design 0 75 KW PDFAnkitdarkoptiNo ratings yet

- SRG Major Test Paper 12-12-2023Document28 pagesSRG Major Test Paper 12-12-2023pal018488No ratings yet

- 3 Term Worksheet (2018 - 19) : Subject - Science Class - V Name: Sec.Document10 pages3 Term Worksheet (2018 - 19) : Subject - Science Class - V Name: Sec.Paulo C. CruzNo ratings yet

- Alan Electronics' Story of Quality, Consistency and ReliabilityDocument6 pagesAlan Electronics' Story of Quality, Consistency and Reliabilitysathishsutharsan87No ratings yet

- 5 1 00 Tables1Document29 pages5 1 00 Tables1shunmugathason100% (1)

- ReadingSkill 4 - Insert Sentences, p.35-48Document14 pagesReadingSkill 4 - Insert Sentences, p.35-48Pfeliciaro FeliciaroNo ratings yet

- PedgkDocument32 pagesPedgkGokulakrishnanNo ratings yet

- 巴拉圭DIGITAL ENG H2 Propuesta de InnovacionDocument57 pages巴拉圭DIGITAL ENG H2 Propuesta de InnovacionXA ShrexerNo ratings yet

- ELT-01-ER-RPT-0018 - SIMOPS Report - R0Document131 pagesELT-01-ER-RPT-0018 - SIMOPS Report - R0Vladimir DovalNo ratings yet

- 1 12 020 Is A105n - DatasheetDocument3 pages1 12 020 Is A105n - DatasheetRico Eka ArfiansyahNo ratings yet

- t2 G 2567167 All About Global Warming Powerpoint LT Powerpoint GT Ver 1Document13 pagest2 G 2567167 All About Global Warming Powerpoint LT Powerpoint GT Ver 1Balaguru DevanNo ratings yet

- Preparation of A Feasibility Study For NPPDocument143 pagesPreparation of A Feasibility Study For NPPIrfan YogaNo ratings yet

- Sheet 5Document5 pagesSheet 5Mohamed AbdulazimNo ratings yet

- Physics: Pearson Edexcel GCEDocument24 pagesPhysics: Pearson Edexcel GCERabia HasanNo ratings yet

- Series 150 Overshot Make Up Torques PDFDocument8 pagesSeries 150 Overshot Make Up Torques PDFRazvan RaduNo ratings yet

- Question Bank SMDocument10 pagesQuestion Bank SMamurugan_22No ratings yet

- Sample Thesis Defense Powerpoint PresentationDocument8 pagesSample Thesis Defense Powerpoint Presentationafjrtopab100% (2)

- Garnituri DIN 2697Document12 pagesGarnituri DIN 2697Dumitru SorinaNo ratings yet

- Centrifugal Compressor Settle Out Conditions TutorialDocument5 pagesCentrifugal Compressor Settle Out Conditions TutorialJHOEARGNo ratings yet

- EET summary notes: Thevenin's theorem, superposition, ethical responsibilitiesDocument4 pagesEET summary notes: Thevenin's theorem, superposition, ethical responsibilitiesshondelB 5No ratings yet

- Solar Thermo-Mechanical PowerDocument2 pagesSolar Thermo-Mechanical PowerROBINSON PRADO VILLEGASNo ratings yet

- Steam BlowingDocument11 pagesSteam BlowingSamNo ratings yet

- Final Expcurves SiDocument37 pagesFinal Expcurves Siمصطفى أحمد عبد الرزاق هاديNo ratings yet

- Swartland SDFDocument68 pagesSwartland SDFAerial ChenNo ratings yet

- Part-Turn Worm Gearboxes Gs 160 - Gs 250Document2 pagesPart-Turn Worm Gearboxes Gs 160 - Gs 250SUNIL SINGHNo ratings yet

- LR HAZID Study For LNG Fuel SupplyDocument116 pagesLR HAZID Study For LNG Fuel SupplyMatteo ConciNo ratings yet

- Basic Sight Words Individual CardDocument12 pagesBasic Sight Words Individual CardSheryl David PanganNo ratings yet

- Energetics QuestionsDocument2 pagesEnergetics QuestionsBrandeice BarrettNo ratings yet

- Portable welding load banks for testing AC/DC welding powerDocument2 pagesPortable welding load banks for testing AC/DC welding powerlauguicoNo ratings yet