Professional Documents

Culture Documents

Cfmeu Health and Safety Audit

Uploaded by

suhanisingh0 ratings0% found this document useful (0 votes)

28 views12 pagesreport

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentreport

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views12 pagesCfmeu Health and Safety Audit

Uploaded by

suhanisinghreport

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 12

Environmental & Occupational

Health and Safety Unit

HEALTH SAFETY &

ENVIRONMENTAL

WORKSITE AUDIT

This health and safety audit report is advisory only. This information is not

intended to be relied upon to meet any legal standards of care. This safety audit is

for the recipient only and is not a substitute for professional advice in relation to all

matters of occupational health and safety. The CFMEU disclaims all liability for

any loss or damage whether foreseeable or not suffered by any person acting

upon any information, representation or statement in this document.

1

CFMEU HEALTH AND SAFETY AUDIT

CONTENTS:

1. Management responsibilities

2. Amenities

3. First aid

4. Traffic Management

5. Training and consultation

6. Electrical

7. Scaffolding

8. Hazardous Materials

9. Cranes and Rigging

10. Plant and Equipment

11. Excavation and trenching

12. Oxy-acetylene cutting and welding

13. Confined space

14. Work at heights

15. Environmental

2

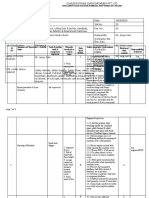

CFMEU HEALTH AND SAFETY AUDIT

1. MANAGEMENT RESPONSIBILITIES

YES NO COMMENT

1.1 Is there an Environmental, Health and Safety

Management Plan developed for this project?

1.2 Is the Health and Safety Policy displayed and

signed by management?

1.3 Are emergency response procedures developed

and displayed at appropriate locations?

1.4 Is there safe access in and out of the site?

1.5 Is there suitable public protection where building

works are next to, or over public access ways?

ie gantries, hoardings

1.6 Does site management consult with OH&S

representatives?

1.7 Are site personnel kept informed on

incident/accident data?

1.8 Are personnel records, certificates of competency

and induction records kept on site?

1.9 Are contractor/sub contractor method statements

& J SAs provided before commencing each major

task?

1.10 Is the management involved in regular, formal

site inspections?

1.11 Are appropriate signs posted at entrance ie hard

hats, report to site office?

1.12 Are necessary permits developed and retained

on site?

2. AMMENITIES

2.1 Is there covered access from inclement weather?

2.2 Is crib hut seating adequate for the numbers on

site?

2.3 Are crib huts hygienic, tidy bins with bin liners?

2.4 Are there adequate numbers of toilet cubicles

with clean tidy washing facilities?

3

2.5 Are there notice boards in crib huts?

2.6 Cool clean drinking water available at appropriate

locations?

2.7 Are there toilets for women?

3. EMERGENCY RESPONSE/FIRST AID

3.1 Are site personnel aware of the first aid location

and is it clearly identified?

3.2 Is the first aid box adequately stocked?

3.3 Are there adequate first aid personnel clearly

identified for contact.

3.4 Are first aid treatment records kept on site?

3.5 Are emergency response personnel trained in site

emergency procedures? Last test date of emergency

procedure ___/___/_________

3.6 Emergency siren and equipment ie stretcher,

trauma kit, oxy viva.

4. TRAFFIC MANAGEMENT

4.1 Has a traffic management plan been selected or

provided?

4.2 Are all roadwork signs and devices installed

according to the plan?

4.3 Have safety barriers been installed correctly?

4.4 Have the needs of other road users, pedestrians

and pedestrian support vehicles been provided for?

5. TRAINING AND CONSULTATION

5.1 Is there a site induction for new starters to

project?

5.2 Are induction records maintained on site?

5.3 Do all site personnel hold a current industry

induction card?

5.4 Is emergency response and evacuation training

conducted?

4

5.5 Are personnel trained in fire precautions and use

of fire extinguishers?

5.6 Is training for identified hazardous work

processes conducted? i.e. confined spaces.

5.7 Are visitors inducted as to site hazards and

procedures?

5.8 Have managers and supervisors attended a

health and safety course?

5.9 Are hazards, incidents, and accidents reported to

site personnel at toolbox meetings?

5.10 Do supervisors conduct regular toolbox

meetings?

5.11 Do supervisors carry out risk assessments, and

incident reports?

5.12 Are health and safety committees established

on site?

5.13 Are health and safety committee meetings held

regularly?

5.14 Are health and safety committee meeting

minutes discussed at toolbox meetings and displayed

in the crib hut?

5.15 Where subcontractors collaborate, interface, co-

operate or work together, is everybody involved

inducted together by the builder?

6. ELECTRICAL

6.1 Does a licensed electrician test portable electrical

equipment every quarter?

6.2 Are all electrical leads supported above the

ground with insulated hooks or stands?

6.3 Are extension leads correctly connected to

temporary power boards?

6.4 Are temporary power boards weatherproof?

6.5 Is the electrical testing register maintained on

site?

6.6 Are temporary power boards installed 30 meters

from all work areas?

6.7 Is all electrical equipment in good condition?

5

7. SCAFFOLDING

7.1 Scaffold types in use

7.2 Are standards on solid foundations with adequate

soul boards?

7.3 Is there adequate bracing in all directions?

7.4 Are the ties correctly positioned and fixed? (Every

3 bays, 2 lifts)

7.5 Are there working platforms at required locations?

7.6 Are handrails and kickboards installed on

scaffolds over 2mts?

7.7 Are mesh guards installed where a risk of

material falling may occur? i.e. bricks.

7.8 Is there access to and from all working platforms?

7.9 Are working platforms the correct distance from

the working face?

7.10 Are ladders of an industrial grade?

7.11 Are ladders secured top and bottom and

exceeding platform 1 meter at a 4:1 pitch?

7.12 Are scaffold boards secured to prevent uplift

from winds?

7.14 When completed, are scaffolds tagged with

scaftag system or similar?

7.15 Are signs or barriers erected for incomplete

scaffolds?

7.16 Are scaffolds regularly inspected and records

kept of details?

8. HAZARDOUS MATERIALS

8.1 Are Material Safety Data Sheets available for all

hazardous substances?

8.2 Is a chemical register kept on site?

8.3 Do site personnel understand MSDSs ?

6

8.4 Are appropriate signs posted at storage areas on

site?

8.5 Are containers appropriately labeled?

8.6 Are chemical storage facilities provided with

appropriate containment area? i.e. bunds and

containment medium

8.7 Is appropriate PPE supplied when using

hazardous materials.

9. CRANES AND RIGGING

9.1 Crane certificates of inspection provided and kept

on record at site.

9.2 Crane drivers certificate of competency and

licenses. Intermediate riggers for concrete panel

erection.

9.3 Is the manufacturers instruction book and cranes

log book in crane and completed daily?

9.4 Cranes set up on firm level ground; engineers

specification details where applicable? ie suspended

floors & near excavations

9.5 Riggers and dogmen certified and recorded and

used for crane operations?

9.6 Is there a safe working zone established for crane

operation?

9.7 Is all rigging equipment in good condition with

inspection records kept on site?

10. PLANT AND EQUIPMENT

10.1 Are excavators used as cranes fitted with

velocity valves and SWL stamped on boom?

10.2 Are manufacturers instructions for lifting

capacities in all directions in excavator cabins?

10.3 Are roll over protection systems on all

earthmoving equipment?

10.4 Where applicable, are reverse and visual alarms

operating and audible?

7

10.5 Are isolation procedures developed for

maintenance and repair work on plant?

10.6 Are Elevated Work Platform logbooks and daily

inspections completed, recorded and kept on the

machine?

10.7 Do only licensed operators operate Elevated

Work Platform?

10.8 Are Elevated Work Platforms used on a firm

level surface?

10.9 Are hoists erected on stable ground and tied into

the structure?

10.10 Is overhead protection provided for operator

with material hoist?

10.11 Are limit switches correctly installed?

10.12 Is the operators manual readily accessible?

10.13 Are all combustion type engines only operated

outdoors or with extra ventilation?

eg portable welders, generators etc.

10.14 Are seatbelts installed in the forklift and used

by the operators?

11. EXCAVATION AND TRENCHING

11.1 Are excavation permits developed and

implemented on site?

11.2 Is a site plan available for existing and new

services?

11.3 Are new and existing services identified on site

and controls implemented to prevent accidental

contact?

11.4 Are procedures in place to avoid isolated

personnel working in excavations?

11.5 Is air quality testing carried out to ensure toxic

gas build up does not occur?

11.6 Is signage and barricading used to reduce

erosion or collapse?

11.7 Are excavations regularly inspected for erosion

or collapse?

8

11.8 Are excavations battered or benched to prevent

collapse?

11.9 Has safe access/egress been provided for deep

excavations?

11.10 Has spoil material and equipment been stored

away from excavation edges?

11.11 Are dust control measures in place?

12. OXY-ACETYLENE CUTTING &

WELDING

12.1 Are hot work permits developed for site?

12.2 Are permits completed and signed by

supervisors and kept on site?

12.3 Are bottles stored upright in a lockable trolley?

12.4 Fire fighting equipment is located with bottles or

at work area?

12.5 Flash back arresters fitted to both the hand

piece and at the bottles?

12.6 Correct personnel protective equipment for

oxy/acetylene works?

12.7 Is lifting box or cradle used for crane lifting of

bottles?

12.8 Are hoses and fittings in good condition?

12.9 Is welding equipment in good working order?

12.10 Are screens and ventilation provided for

welding works?

12.11 Is there any risk of dust exploding?

13. CONFINED SPACE

13.1 Are permits developed for confined space

works?

13.2 Are emergency procedures developed for

confined space works?

13.3 Is emergency rescue equipment available? i.e.

radios, RPD, air monitors.

13.4 Are personnel trained for confined space works

including sentries?

9

14. WORK AT HEIGHTS

14.1 Are procedures developed for working at

heights?

14.2 Are emergency procedures developed for

retrieval of a fallen or injured person?

14.3 Are personnel trained for working at heights?

14.4 Is safe access and egress provided for

personnel?

14.5 Are harnesses inspected and inspection records

kept on site?

14.6 Are anchorage points assessed by a qualified

engineer?

14.7 Are barriers, barricades and signs erected to

delineate restricted areas?

15. ENVIRONMENTAL

15.1 Is water or other means used to prevent dust

generation?

15.2 Are roadways defined and used by site

personnel?

15.3 Is there adequate watering equipment when

cutting and chasing?

15.4 Are noisy work tasks defined, controls used to

reduce noise levels and signage utilised?

15.5 Is sound pressure level testing performed to

ensure compliance?

15.6 Are signs posted to alert personnel?

15.7 Is hearing protection provided and used where

required?

16. PERSONNEL PROTECTIVE

EQUIPMENT (PPE)

16.1 Are signs displayed to identify the required

PPE?

16.2 Is PPE readily available and complying with the

relevant Australian standards?

16.3 Are personnel trained in the use of the specific

PPE?

10

16.4 Are facilities provided for the maintenance and

storage of PPE?

Whats a Site Audit and What Does it Mean?

Many workers have been exposed to hazardous substances in the past because

people didnt know they were there. Employers have an obligation under the

Victorian Occupational Health & Safety (Asbestos) Regulations 2003. (Part 5

Asbestos in workplace and Part 6 demolition including refurbishment to ensure

that a site audit is done before your job starts. Its better for all parties if this is

done properly because it avoids any exposures or other problems and its usually

cheaper to do it when theres not other people wanting to work in the same area).

What to look for When Reading Site Audits:

Check that the audit is up to date.

Make sure its a full hazard audit and not just and asbestos audit. The

audit should identify anything and everything that may be hazardous to the

people working on the site or the general public. This could include

chemicals, PCBs (in light fittings or elsewhere), lead paints, synthetic

mineral fibres or asbestos.

When reading an audit, make sure that it has

a) A register of all hazardous materials that may be present

b) An asbestos register identifying all possible asbestos containing

materials

c) The condition the material is in

d) The friability the material is in

e) The friability of any asbestos

f) Areas where access could not be obtained during the auditing process.

No access should be allowed in those areas until they are opened

and assessed for any hazardous materials.

Ensure that all different coloured floor tiles have been analysed for

asbestos content. Asbestos floor tiles re non-homogenous, that is the

asbestos content is not evenly distributed throughout the tile. The content in

floor tiles is usually about 2% - 3%. It is very common for one consultant to

obtain a clear result and for another to find asbestos.

Asbestos can be presented in the form of: White Chrysotile

Brown Amosite

Blue Crocidolite

11

PCBs can be found in capacitors and electrical equipment. Paper insulated

capacitors manufactured by DUCON between 1960 and 1974, operated on

AC voltages, mainly 250V, 330V, 370V, 400V and 600V, contained PCBs.

Capacitors are usually enclosed in an oval shaped aluminium tin can

approximately 40mm x 25mm (long and short axis) and an overall length of

112mm. There is usually a model number beginning with letters APA, APB,

APC, APD or APF. There is also a 4 digit number which indicates the week

and year manufacturing, eg 2264 means the 22

nd

week in 1964.

Other capacitors manufactured in the same period are rectangular in shape

with a painted or unpainted tin plate can and have model numbers

beginning with the letters GPA, GPB or GPM.

Capacitors are also found in electrical control circuits, usually in a grey

coloured time plated enclosure manufactured in the same period with model

numbers being with GP will also contain PCBs.

Before any work starts make sure that hazardous materials have been

stripped and removed. If any are to remain onsite they must be clearly

labelled and identifiable, to ensure that everyone knows that hazardous

materials are present.

12

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- HIRADocument57 pagesHIRAAnonymous Uc25fP83% (6)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- JSA-Site Survey and Downloading of Relay ConfigurationDocument4 pagesJSA-Site Survey and Downloading of Relay Configurationfrancis_e_tan100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- OHS Policies and Procedures ManualDocument13 pagesOHS Policies and Procedures Manualismailines100% (2)

- Attachment 16. Site HSSE PlanDocument79 pagesAttachment 16. Site HSSE PlanCristianMontoyaMujica100% (1)

- KCC DATASHEET Technical Data Sheet Thinner-024 EngDocument2 pagesKCC DATASHEET Technical Data Sheet Thinner-024 EngIsabelo AbaoNo ratings yet

- Electrical Installation and Maintenance ActivityDocument11 pagesElectrical Installation and Maintenance ActivityAlle Eiram Padillo100% (1)

- Plant Manual IOM S PDFDocument829 pagesPlant Manual IOM S PDFluis olivoNo ratings yet

- Ecm 367 - Project and Construction ManagementDocument84 pagesEcm 367 - Project and Construction ManagementMuhd Muqhrey50% (2)

- 010-MS For Grouting PDFDocument33 pages010-MS For Grouting PDFKöksal PatanNo ratings yet

- Construction HAZID Workshop Report PK Pipeline-FinalDocument18 pagesConstruction HAZID Workshop Report PK Pipeline-FinalsaqibNo ratings yet

- Work OrderDocument9 pagesWork Orderiyappa civil100% (1)

- Accura Operation Manual Version 2.0 20160621Document64 pagesAccura Operation Manual Version 2.0 20160621Duy DangNo ratings yet

- Health, Safety & WellbeingDocument13 pagesHealth, Safety & WellbeingImran ChowdhuryNo ratings yet

- MST For Roof Slab WaterproofingDocument6 pagesMST For Roof Slab Waterproofingdina gunasekeraNo ratings yet

- Hacking Work & Patch BackDocument4 pagesHacking Work & Patch BackJamruz JamilNo ratings yet

- PI - Standard - Feed Mill Standard - Issue 2.1 - 23-May-2017 PDFDocument29 pagesPI - Standard - Feed Mill Standard - Issue 2.1 - 23-May-2017 PDFRomy Bennouli TambunanNo ratings yet

- 6 Common TesdaDocument28 pages6 Common TesdaStevenNo ratings yet

- Qhse Prequalification QuestionnaireDocument3 pagesQhse Prequalification QuestionnaireaymenmoatazNo ratings yet

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- Kristal Violet PDFDocument4 pagesKristal Violet PDFGanjar Tri Gita AzhariNo ratings yet

- Jurnal K3 Terbit EnglishDocument6 pagesJurnal K3 Terbit Englishadhan efendiNo ratings yet

- Elvex Is Committed To Innovative SolutionsDocument48 pagesElvex Is Committed To Innovative SolutionssanpkaruNo ratings yet

- Msds Shell Thermia BDocument7 pagesMsds Shell Thermia BMuhammad Nurul AminNo ratings yet

- TPC-HOMO02 - (No FDA)Document5 pagesTPC-HOMO02 - (No FDA)Nicky AfrilliaNo ratings yet

- COVID Handbook and Outbreak Management Plan (4974)Document32 pagesCOVID Handbook and Outbreak Management Plan (4974)Rachit SharmaNo ratings yet

- Industrial Training Final ReportDocument28 pagesIndustrial Training Final ReportMuhammad Harith Hilmi Zen AzharNo ratings yet

- Safety Data Sheet: Product Name: MOBILGEAR 600 XP 220Document12 pagesSafety Data Sheet: Product Name: MOBILGEAR 600 XP 220muhammad imtiazNo ratings yet

- Group # 28-Introduction To ISO 45001-Mini-ProjectDocument14 pagesGroup # 28-Introduction To ISO 45001-Mini-ProjectA to z type videosNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument20 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingsantiagoNo ratings yet

- Diesel SDS enDocument10 pagesDiesel SDS enfidan muradovaNo ratings yet